Preparation of Black Copper Electrolyte by Acid Oxidation Leaching of Refining Slag

-

摘要:

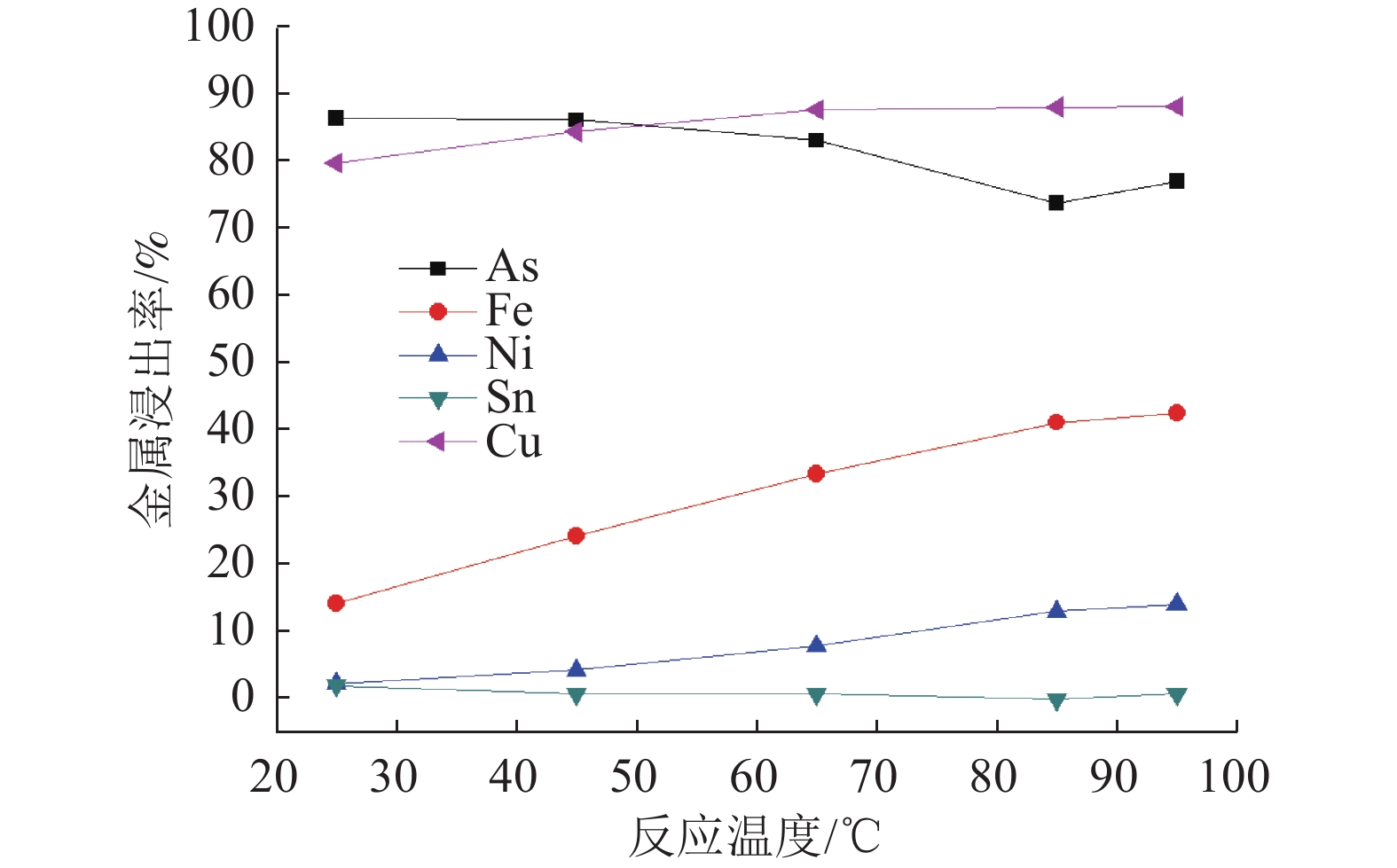

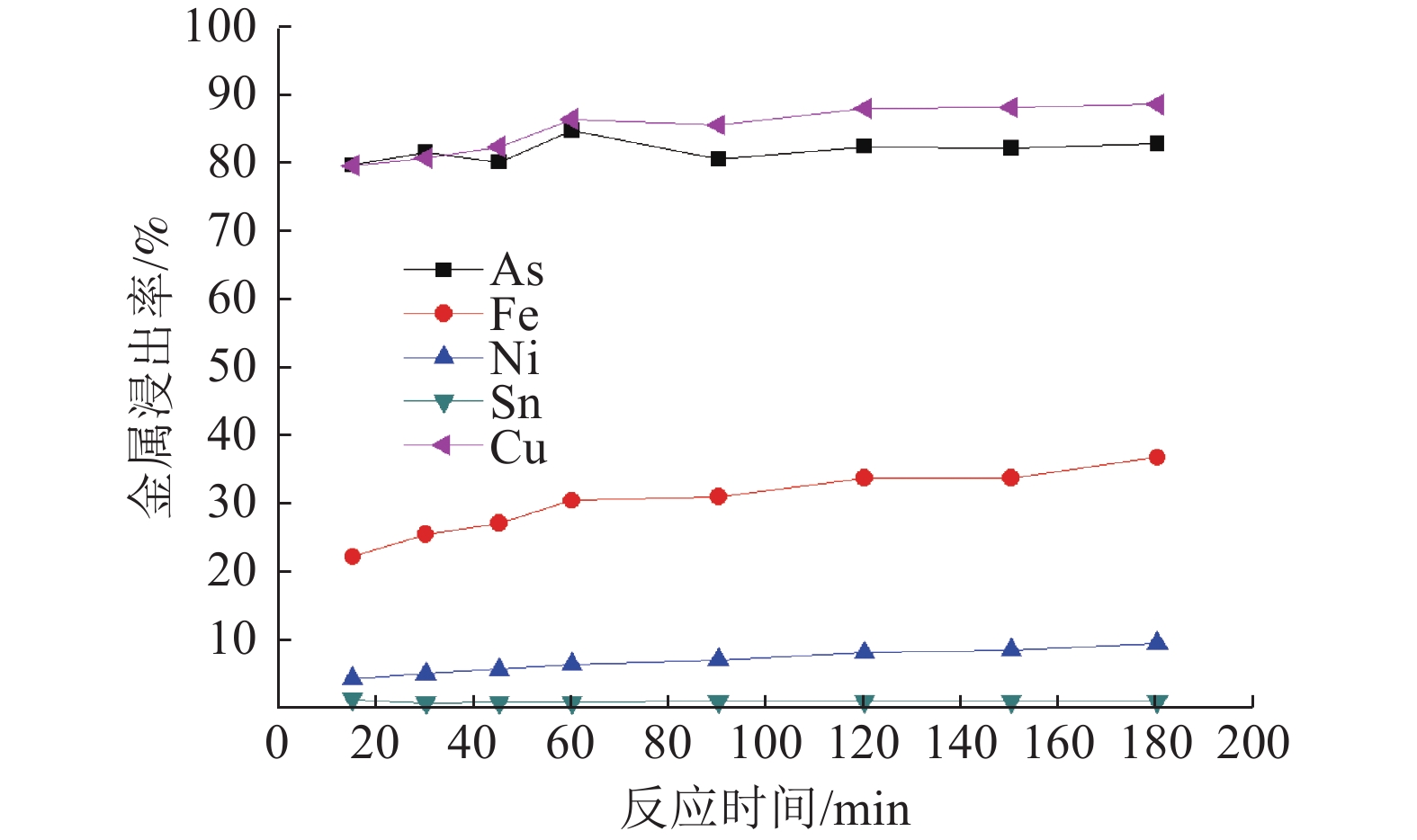

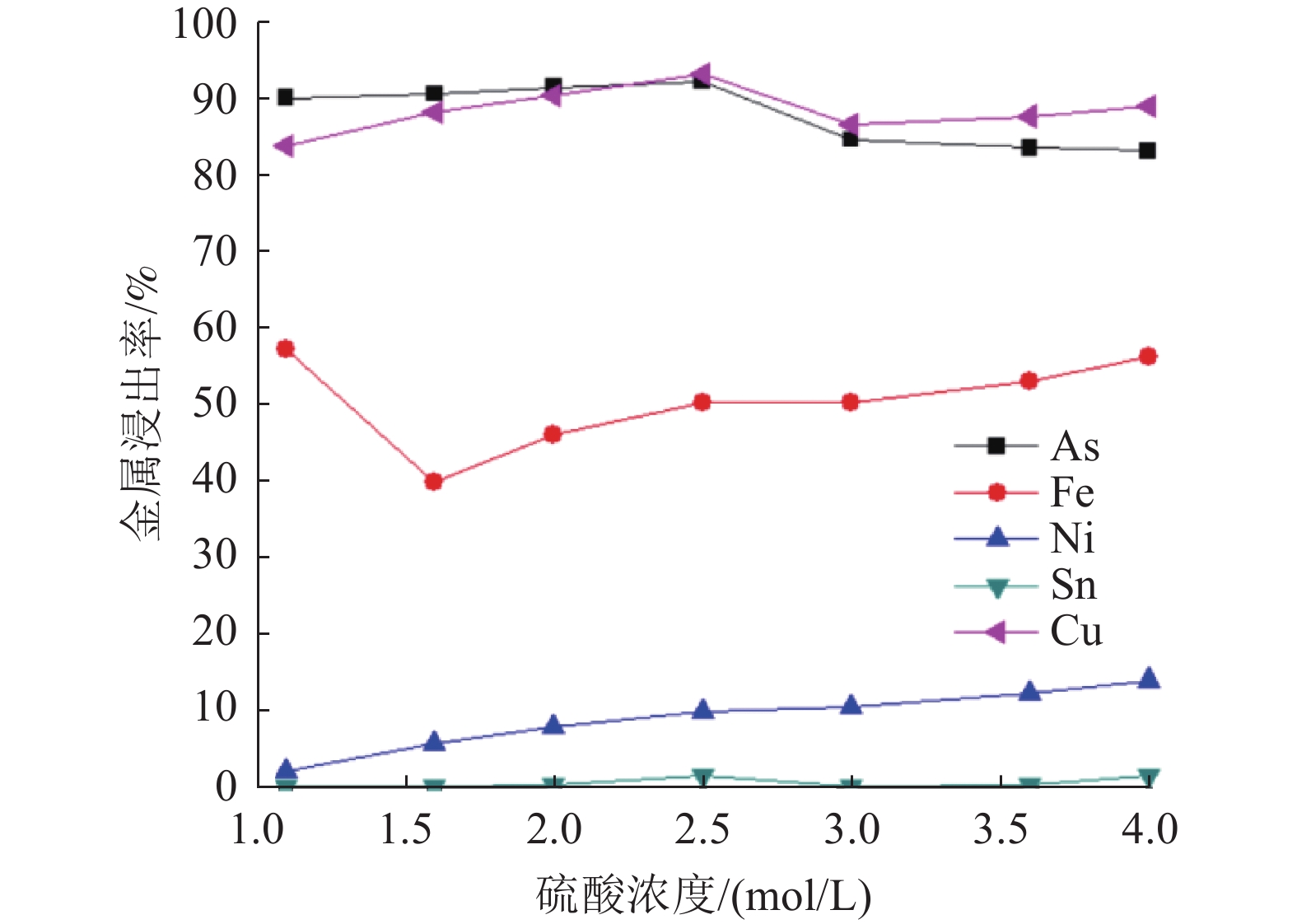

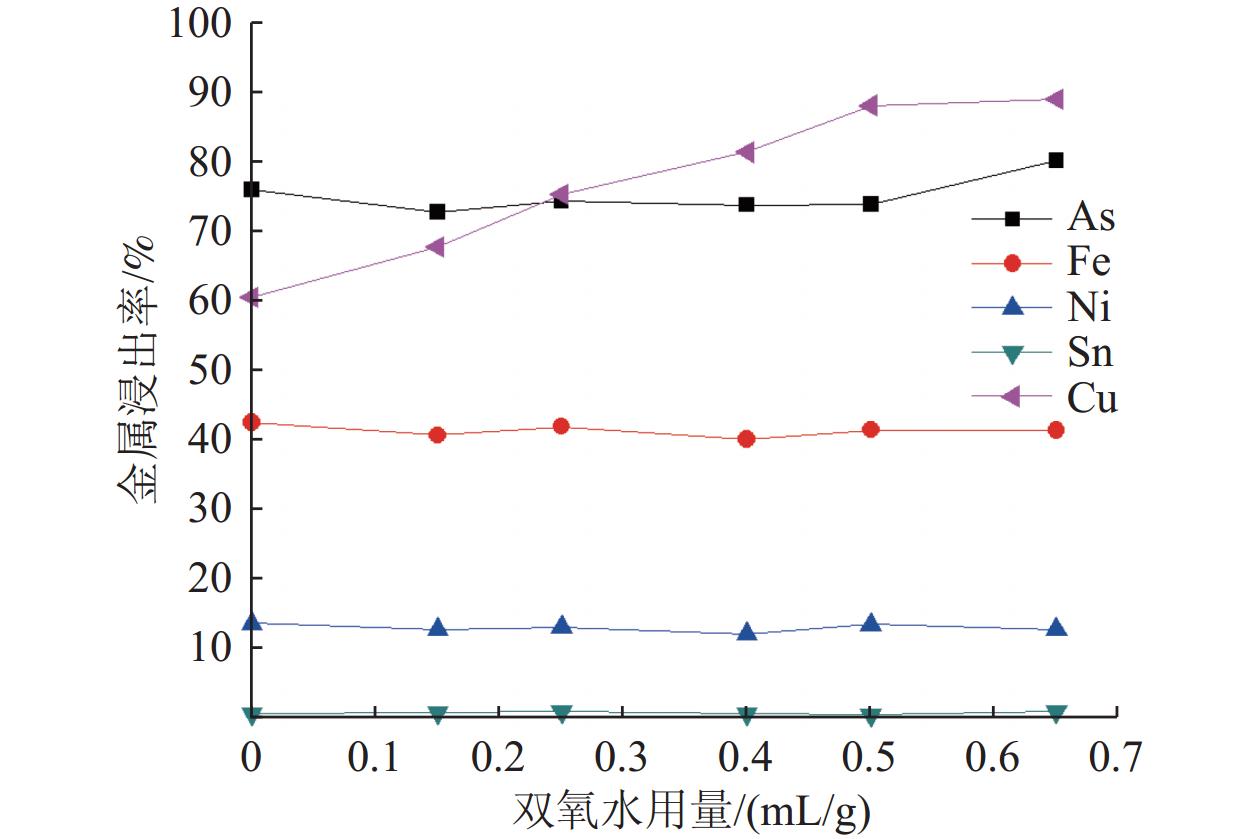

这是一篇冶金工程领域的文章。研究了双氧水氧化酸性浸出法从高铜高锡阳极炉精炼渣中脱除铜制备黑铜电解液。主要考查了双氧水用量、反应温度、硫酸浓度、固液比和反应时间等因素对铜脱除效果的影响。结果表明, 在精炼渣20.0 g,2.0 mol/L硫酸溶液200 mL,S/L=1/10,浸出温度65 ℃,双氧水用量10.0 mL,搅拌速度400 r/min和浸出时间60 min时,Cu、As的平均浸出率分别达到88.98%、87.33%,而Ni和Sn的浸出率仅为7.72%和1.34%,浸出液中铜离子浓度为48.48 g/L,可用于黑铜电解液的补充液。

Abstract:This is an article in the field of metallurgical engineering. The preparation of black copper electrolyte by removing copper from secondary refining slag of high copper and high tin anode furnace by hydrogen peroxide oxidation and acid leaching was studied. The process conditions related to the removal efficiency of the copper and arsenic were researched including the hydrogen peroxide dosage, reaction temperature, sulfuric acid concentration and reaction time. Results show that, under the following optimal conditions, including refining slag of 20.0 g, 2.5 mol/L sulfuric acid of 200 mL, solid-liquid ratio of 1/10, temperature of 65 ℃, dosage of hydrogen peroxide of 10.0 mL, stirring speed of 400 r/min and leaching time of 60 min, the leaching ratios of Cu and As can reach 88.98% and 87.33%, respectively, and the leaching ratios of Ni and Sn were only 7.72% and 1.34%, respectively. The concentration of copper ion in the leaching solution was 48.48 g/L, which can be used as the supplement of black copper electrolyte.

-

Key words:

- Metallurgical engineering /

- Refining slag /

- Removal /

- Oxidation leaching /

- Copper electrolyte

-

-

表 1 精炼渣的主要化学成分/%

Table 1. Main chemical composition of refining slag

Cu Fe Ni As Sn Sb Zn Pb 61.46 3.787 2.941 2.043 2.922 0.551 0.427 0.654 表 2 精炼渣中铜的物相组成

Table 2. Phase composition of copper in refining slag

物相名称 Cu0 硫化物 Cu2O CuO CuO·Fe2O3 分布率/% 15.32 3.03 72.64 3.91 5.10 表 3 精炼渣酸性浸出实验结果

Table 3. Test results of acid leaching of refining slag

氧化剂类型 用量/

(mL/g物料)浸出率/% As Fe Ni Sn Cu 无氧化剂 / 75.79 42.21 13.25 0.15 60.28 空气 / 73.63 39.60 11.69 0.00 69.72 浓硝酸 0.5 75.43 41.59 14.68 0.00 91.22 双氧水 0.5 75.42 41.15 13.05 0.00 87.97 表 4 浸出液组成情况/(g/L)

Table 4. Composition of leaching solution

名称 Cu As Ni Fe Sn Sb Bi 浸出液 48.48 1.64 0.20 1.08 0.03 0.33 / 某黑铜电解液 40~55 < 15 < 20 < 3.0 / < 0.7 < 1 表 5 浸出渣平均化学成分/%

Table 5. Average chemical composition of acid leaching residue

Cu As Ni Fe Sn Sb Bi 20.20 0.80 8.11 7.51 8.49 0.9 0.06 表 6 浸出渣中铜的物相组成

Table 6. Phase composition of copper in leaching residue

物相名称 Cu0 硫化物 Cu2O CuO CuO·Fe2O3 分布率/% 27.28 25.68 3.29 0.96 42.79 -

[1] 谭芳香, 黄以伟. 高品位杂铜NGL炉冶炼工艺及生产实践[J]. 矿冶, 2021, 30(1):52-57.TAN F X, HUANG Y W. Research and production practice of high grade miscellaneous copper in a NGL furnace smelting process[J]. Mining and Metallurgy, 2021, 30(1):52-57. doi: 10.3969/j.issn.1005-7854.2021.01.010

TAN F X, HUANG Y W. Research and production practice of high grade miscellaneous copper in a NGL furnace smelting process[J]. Mining and Metallurgy, 2021, 30(1):52-57. doi: 10.3969/j.issn.1005-7854.2021.01.010

[2] 吴迪, 刘玉坤. 含铜工业污泥危废高温熔池处置技术工艺路线[J]. 中国资源综合利用, 2020, 38(8):180-182.WU D, LIU Y K. Disposal technology route of hazardous waste high temperature molten pool of copper sludge[J]. China Resources Comprehensive Utilization, 2020, 38(8):180-182. doi: 10.3969/j.issn.1008-9500.2020.08.055

WU D, LIU Y K. Disposal technology route of hazardous waste high temperature molten pool of copper sludge[J]. China Resources Comprehensive Utilization, 2020, 38(8):180-182. doi: 10.3969/j.issn.1008-9500.2020.08.055

[3] 郭鹏辉. 含铜污泥与废线路板协同处理及综合利用技术[J]. 中国资源综合利用, 2019, 37(10):71-73.GUO P H. Co-treatment and comprehensive utilization of copper-containing sludge and waste circuit board[J]. China Resources Comprehensive Utilization, 2019, 37(10):71-73. doi: 10.3969/j.issn.1008-9500.2019.10.022

GUO P H. Co-treatment and comprehensive utilization of copper-containing sludge and waste circuit board[J]. China Resources Comprehensive Utilization, 2019, 37(10):71-73. doi: 10.3969/j.issn.1008-9500.2019.10.022

[4] 李冲, 徐小锋, 黎敏, 等. 侧吹熔池熔炼废线路板工艺及装置[J]. 有色金属(冶炼部分), 2019(9):87-91.LI C, XU X F, LI M, et al. Technology and equipment of waste printed circuit board treated by side-blown bath smelting process[J]. Nonferrous Metals(Extractive Metallurgy), 2019(9):87-91.

LI C, XU X F, LI M, et al. Technology and equipment of waste printed circuit board treated by side-blown bath smelting process[J]. Nonferrous Metals(Extractive Metallurgy), 2019(9):87-91.

[5] 任朋, 田应忠, 郭鑫. 河南某冶炼铜渣浮选回收铜的实验研究[J]. 矿产综合利用, 2021(6):155-157.REN P, TIAN Y Z, GUO X. Experimental study of recycling copper by flotation in copper smelting slag in Henan Province[J]. Multipurpose Utilization of Mineral Resources, 2021(6):155-157. doi: 10.3969/j.issn.1000-6532.2021.06.026

REN P, TIAN Y Z, GUO X. Experimental study of recycling copper by flotation in copper smelting slag in Henan Province[J]. Multipurpose Utilization of Mineral Resources, 2021(6):155-157. doi: 10.3969/j.issn.1000-6532.2021.06.026

[6] 吕旭龙, 衷水平, 印万忠, 等. 某铜冶炼企业冶炼炉渣配矿浮选试验研究[J]. 矿产综合利用, 2019(1):114-118.LYU X L, ZHONG S P, YIN W Z, et al. Experimental study on flotation of different proportion smelter slag in a copper smelting enterprise[J]. Multipurpose Utilization of Mineral Resources, 2019(1):114-118. doi: 10.3969/j.issn.1000-6532.2019.01.025

LYU X L, ZHONG S P, YIN W Z, et al. Experimental study on flotation of different proportion smelter slag in a copper smelting enterprise[J]. Multipurpose Utilization of Mineral Resources, 2019(1):114-118. doi: 10.3969/j.issn.1000-6532.2019.01.025

[7] 杨俊奎, 徐斌, 马永鹏, 等. 铜冶炼开路烟尘综合回收研究现状[J]. 矿产综合利用, 2019(5):9-16.YANG J K, XU B, MA Y P, et al. Research status of comprehensive recovery of open-circuit dusts in copper smelter[J]. Multipurpose Utilization of Mineral Resources, 2019(5):9-16. doi: 10.3969/j.issn.1000-6532.2019.05.003

YANG J K, XU B, MA Y P, et al. Research status of comprehensive recovery of open-circuit dusts in copper smelter[J]. Multipurpose Utilization of Mineral Resources, 2019(5):9-16. doi: 10.3969/j.issn.1000-6532.2019.05.003

[8] 王成彦, 王忠. 铜的再生与循环利用[M]长沙: 中南大学出版社, 2010.12: 67-77.WANG C Y, WANG Z. Copper regeneration and recycling[M]. Changsha: Central South University Press, 2010.12: 67-77.

WANG C Y, WANG Z. Copper regeneration and recycling[M]. Changsha: Central South University Press, 2010.12: 67-77.

[9] 付文峰. 使用再生氧化铜制备电解铜箔用电解液[J]. 印制电路信息, 2015, 23(4):66-67.FU W F. Use recycled copper oxide preparation of electrolytic copper foil electrolyte[J]. Printed Circuit Information, 2015, 23(4):66-67. doi: 10.3969/j.issn.1009-0096.2015.04.018

FU W F. Use recycled copper oxide preparation of electrolytic copper foil electrolyte[J]. Printed Circuit Information, 2015, 23(4):66-67. doi: 10.3969/j.issn.1009-0096.2015.04.018

[10] 范翔, 廖星星, 史磊. 废杂铜电解主要作业参数和添加剂使用方法研究及生产实践[J]. 中国资源综合利用, 2020, 38(3):38-40.FAN X, LIAO X X, SHI L. Research on the main operating parameters and additives for waste copper electrolysis and production practice[J]. China Resources Comprehensive Utilization, 2020, 38(3):38-40. doi: 10.3969/j.issn.1008-9500.2020.03.011

FAN X, LIAO X X, SHI L. Research on the main operating parameters and additives for waste copper electrolysis and production practice[J]. China Resources Comprehensive Utilization, 2020, 38(3):38-40. doi: 10.3969/j.issn.1008-9500.2020.03.011

[11] 株洲冶炼厂《冶金读本》编写小组. 铜、铅、锌冶金分析[M]. 长沙: 湖南人民出版社, 1974.10: 416-420.Zhuzhou Smelting Plant "Metallurgy Reader" Writing Group. Metallurgical analysis of copper, lead and zinc[M]. Changsha: Hunan People's Publishing House, 1974.10: 416-420.

Zhuzhou Smelting Plant "Metallurgy Reader" Writing Group. Metallurgical analysis of copper, lead and zinc[M]. Changsha: Hunan People's Publishing House, 1974.10: 416-420.

-

下载:

下载: