Technological Mineralogical Characteristics and Mineral Processing Test of Donganshan Iron Ore

-

摘要:

这是一篇矿物加工工程领域的论文。为准确掌握各类型矿石对现场生产的影响,采用化学分析和矿物自动分析系统(AMICS)测试手段对各类型矿石进行了系统深入的工艺矿物学研究,在工艺矿物学的基础上,进行了配矿方案拟定,并按照较佳的配矿比进行了全流程实验。结果表明:各类型矿石为高硅、贫铁低硫磷贫铁矿石。各类型矿石的嵌部特性较复杂,对矿石可磨度及单体解离具有一定的影响。根据采区各类型矿石可选性实验结果等条件,确定综合配矿比为:(磁性矿∶亚铁矿∶东部红矿∶混合矿∶绿泥矿∶碳酸铁矿)=(25∶25∶25∶10∶10∶5)。综合配矿经过弱磁-强磁-混磁精阴离子反浮选闭路流程,获得了综合精矿品位66.06%,产率34.60%,综合尾矿品位15.20%,产率65.40%的较好指标。

Abstract:This is an article in the field of mineral processing engineering. In order to accurately grasp the influence of various types of ores on field production, the process mineralogy of various types of ores was systematically and deeply studied by means of chemical analysis and automatic mineral analysis system (AMICS). Based on the process mineralogy, the ore blending scheme was drawn up, and the whole process test was carried out according to the optimal ore blending ratio. The results show that all kinds of ores are lean iron ores with high silicon, low iron and low sulfur and phosphorus. The embedding characteristics of various types of ores are complex, which has a certain influence on the grindability of ores and monomer dissociation. According to the washability test results of various types of ores in the mining area, the comprehensive ore blending ratio is determined as follows: (magnetic ore∶ sub-iron ore∶ eastern red ore∶mixed ore∶ chlorite ore∶ iron carbonate ore) =(25∶25∶25∶10∶10∶5). Through the closed-circuit process of weak magnetic field-strong magnetic field-mixed magnetic fine anion reverse flotation, the comprehensive ore blending obtained good indexes of comprehensive concentrate grade of 66.06%, yield of 34.60%, comprehensive tailings grade of 15.20% and yield of 65.40%.

-

-

表 1 各类型矿石化学多元素分析结果/%

Table 1. Results of chemical multi-element analysis of various types of ores

矿石类型 FeO CaO MgO SiO2 Al2O3 S P MnO Ig TiO2 亚铁矿 7.11 1.28 1.21 48.06 0.96 0.092 0.044 0.171 1.21 0.054 磁性矿 15.84 2.00 2.42 47.32 0.82 0.092 0.038 0.129 1.63 0.024 东部红矿 1.37 0.68 0.30 49.08 0.48 0.066 0.028 0.053 1.54 0.017 混合矿 9.99 1.44 1.11 46.54 1.04 0.079 0.038 0.114 3.17 0.025 绿泥矿 10.53 1.07 1.50 51.96 2.96 0.110 0.053 0.071 1.90 0.075 碳酸铁矿 1.88 2.25 1.40 42.67 0.63 0.066 0.032 0.196 5.96 0.019 表 2 各类型矿石物相分析结果

Table 2. Phase analysis results of various types of ores

名称 FeO FeCO3 FeSiO3 Fe3O4 假半 赤、褐 TFe 亚铁矿 含量/% 7.11 3.20 1.30 12.25 2.75 13.00 32.50 分布率/% - 9.85 4.00 37.69 8.46 40.00 100.00 磁性矿 含量/% 15.84 1.25 1.10 25.90 0.00 4.24 32.49 分布率/% - 3.85 3.39 79.72 0.00 13.05 100.00 东部红矿 含量/% 1.37 1.10 0.25 3.60 0.00 29.68 34.63 分布率/% - 3.18 0.72 10.40 0.00 85.71 100.00 混合矿 含量/% 9.99 3.40 1.15 12.30 3.70 12.43 32.98 分布率/% - 10.31 3.49 37.30 11.22 37.69 100.00 绿泥矿 含量/% 10.53 1.70 2.10 15.00 2.45 6.98 28.23 分布率/% - 6.02 7.44 53.13 8.68 24.73 100.00 碳酸铁矿 含量/% 1.88 5.00 1.40 6.70 0.30 20.20 33.60 分布率/% - 14.88 4.17 19.94 0.89 60.12 100.00 表 3 各类型矿石弱磁-强磁选别指标对比

Table 3. Comparison of low-intensity and high-intensity magnetic separation indexes of various types of ores

矿石

类型原矿

品位/%场强/

T混磁精 强尾 品位/

%产率/

%收率/

%品位/

%产率/

%收率/

%亚铁矿 32.50 0.90 43.80 66.22 89.24 10.35 33.78 10.76 磁性矿 32.49 0.90 43.00 70.00 92.65 7.96 30.00 7.35 东部红矿 34.63 0.90 47.00 62.10 84.29 14.36 37.90 15.71 混合矿 32.98 0.90 44.30 68.00 91.34 8.93 32.00 8.66 绿泥矿 28.23 0.90 39.90 65.86 93.08 5.72 34.14 6.92 碳酸铁矿 33.60 0.90 39.40 78.00 91.46 13.04 22.00 8.54 表 4 各类型矿石开路浮选条件实验指标对比

Table 4. Comparison of test indexes of open-circuit flotation conditions of various types of ores

矿石类型 药剂制度/(g/t) 浮精 浮尾 NaOH 淀粉+K6 CaO TD-II 品位/% 产率/% 品位/% 产率/% 粗选 精选 亚铁矿 1 250 1 350 500 1 800 750 66.79 25.83 15.67 17.71 磁性矿 1 250 1 500 500 1 200 600 66.65 25.86 15.24 18.24 东部红矿 1 250 1 650 500 1 800 900 66.54 23.61 19.62 17.00 混合矿 1 250 1 350 500 1 200 600 65.80 24.15 16.80 18.37 绿泥矿 1 250 1350 500 1 350 675 65.05 23.28 10.40 17.88 碳酸铁矿 1 250 1 650 500 750 375 59.65 24.95 18.64 19.55 表 5 综合配矿混磁精粒度分析及解离度测定结果

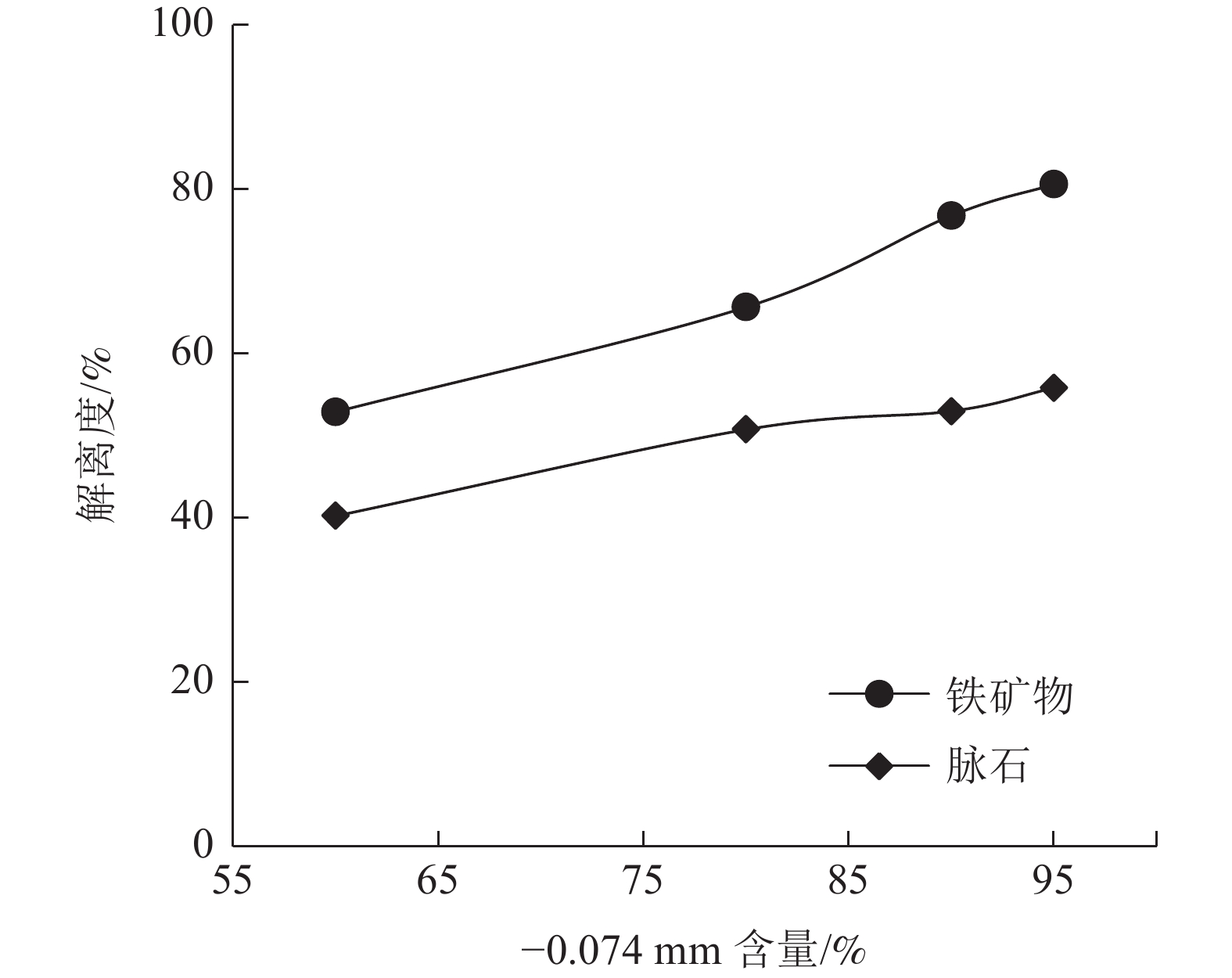

Table 5. Particle size analysis and dissociation degree determination results of comprehensive ore blending magnetic concentrate

粒级

/μm品位

/%产率/% 收率/% 解离度/% 个别 累计 个别 累计 铁矿物 脉石 +100 30.24 2.62 100.00 1.81 100.00 38.90 24.30 -100+76 40.28 6.08 97.38 5.59 98.19 54.13 31.12 -76+45 47.08 10.36 91.30 11.14 92.60 73.71 36.94 -45+37 45.27 12.32 80.94 12.74 81.45 82.66 43.50 -37+25 47.77 10.25 68.62 11.19 68.71 85.95 48.46 -25 43.14 58.37 58.37 57.52 57.52 85.95 48.46 合计 43.77 100.00 100.00 81.11 44.97 表 6 综合配矿混磁精再磨粒度分析及解离度测定结果

Table 6. Particle size analysis and dissociation degree determination results of comprehensive ore blending and magnetic fine regrinding

粒级

/μm品位

/%产率/% 收率/% 解离度/% 个别 累计 个别 累计 铁矿物 脉石 +100 26.53 1.10 100.00 0.65 100.00 38.93 24.72 -100+76 40.28 3.64 98.90 3.28 99.35 56.06 34.49 -76+45 43.28 8.44 95.26 8.16 96.07 70.98 42.77 -45+37 47.11 13.49 86.82 14.19 87.91 80.84 52.68 -37+25 49.41 10.73 73.33 11.84 73.72 88.42 59.79 - 25 44.25 62.60 62.60 61.88 61.88 88.42 59.79 合计 44.77 100.00 100.00 84.20 56.09 -

[1] 李博琦, 谢贤, 纪翠翠, 等. 鞍山地区贫磁铁矿选矿工艺实验[J]. 矿产综合利用, 2020(4):93-99.LI B Q, XIE X, JI C C, et al. Experimental study on ore dressing of lean magnetite in Anshan area[J]. Multipurpose Utilization of Mineral Resources, 2020(4):93-99. doi: 10.3969/j.issn.1000-6532.2020.04.015

LI B Q, XIE X, JI C C, et al. Experimental study on ore dressing of lean magnetite in Anshan area[J]. Multipurpose Utilization of Mineral Resources, 2020(4):93-99. doi: 10.3969/j.issn.1000-6532.2020.04.015

[2] 王长艳, 徐冬林, 史达, 等. 鞍千磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2022(4):193-199.WANG C Y, XU D L, SHI D, et al. Research on process mineralogy of Anqian magnetite ore[J]. Multipurpose Utilization of Mineral Resources, 2022(4):193-199. doi: 10.3969/j.issn.1000-6532.2022.04.033

WANG C Y, XU D L, SHI D, et al. Research on process mineralogy of Anqian magnetite ore[J]. Multipurpose Utilization of Mineral Resources, 2022(4):193-199. doi: 10.3969/j.issn.1000-6532.2022.04.033

[3] 杨光, 苏兴国, 马自飞, 等. 东鞍山贫杂铁矿石选矿技术研究进展[J]. 矿产保护与利用, 2021, 41(5):140-148.YANG G, SU X G, MA Z F, et al. Research status and development trend of beneficiation technology for Donganshan iron ore with low grade and complex composition[J]. Conservation and Utilization of Mineral Resources, 2021, 41(5):140-148.

YANG G, SU X G, MA Z F, et al. Research status and development trend of beneficiation technology for Donganshan iron ore with low grade and complex composition[J]. Conservation and Utilization of Mineral Resources, 2021, 41(5):140-148.

[4] 杨光, 任慧, 杨春, 等. 磁选-浮选联合工艺从东鞍山铁矿浮选尾矿中回收铁的实验研究[J]. 矿产保护与利用, 2022, 42(6):66-72.YANG G, REN H, YANG C, et al. Experimental study on iron recovery from flotation tailings of donganshan iron ore by combined magnetic separation and flotation process[J]. Conservation and Utilization of Mineral Resources, 2022, 42(6):66-72.

YANG G, REN H, YANG C, et al. Experimental study on iron recovery from flotation tailings of donganshan iron ore by combined magnetic separation and flotation process[J]. Conservation and Utilization of Mineral Resources, 2022, 42(6):66-72.

[5] 柳林, 王威, 刘红召, 等. 磁化焙烧-磁选回收某褐铁矿中铁的实验研究[J]. 矿产综合利用, 2019(4):33-37.LIU L, WANG W, LIU H Z, et al. Research on recovery of iron from limonite by magnetization roasting and magnetic separation[J]. Multipurpose Utilization of Mineral Resources, 2019(4):33-37. doi: 10.3969/j.issn.1000-6532.2019.04.006

LIU L, WANG W, LIU H Z, et al. Research on recovery of iron from limonite by magnetization roasting and magnetic separation[J]. Multipurpose Utilization of Mineral Resources, 2019(4):33-37. doi: 10.3969/j.issn.1000-6532.2019.04.006

[6] 黄贵臣, 谢冬冬, 韩呈, 等. 基于正交实验的赤铁矿浮选实验研究[J]. 矿产综合利用, 2019(4):63-67.HUANG G C, XIE D D, HAN C, et al. Experimental study on flotation of hematite based on orthogonal test[J]. Multipurpose Utilization of Mineral Resources, 2019(4):63-67. doi: 10.3969/j.issn.1000-6532.2019.04.013

HUANG G C, XIE D D, HAN C, et al. Experimental study on flotation of hematite based on orthogonal test[J]. Multipurpose Utilization of Mineral Resources, 2019(4):63-67. doi: 10.3969/j.issn.1000-6532.2019.04.013

[7] 宋保莹, 袁立宾, 韦思明. 含碳酸盐赤铁矿分步浮选工艺研究及生产实践[J]. 矿冶工程, 2015, 35(5):63-67.SONG B Y, YUAN L B, WEI S M. Investigation on stepped flotation process for carbonate-containing hematite and its production practice[J]. Mining and Metallurgical Engineering, 2015, 35(5):63-67. doi: 10.3969/j.issn.0253-6099.2015.05.018

SONG B Y, YUAN L B, WEI S M. Investigation on stepped flotation process for carbonate-containing hematite and its production practice[J]. Mining and Metallurgical Engineering, 2015, 35(5):63-67. doi: 10.3969/j.issn.0253-6099.2015.05.018

[8] 余建文, 韩跃新, 李艳军, 等. 东鞍山贫铁矿石磁选预富集行为[J]. 东北大学学报(自然科学版), 2019, 40(1):94-98.YU J W, HAN Y X, LI Y J, et al. Pre-enrichment behaviors of low-grade donganshan iron ore using magnetic separation[J]. Journal of Northeastern University(Natural Science), 2019, 40(1):94-98. doi: 10.12068/j.issn.1005-3026.2019.01.018

YU J W, HAN Y X, LI Y J, et al. Pre-enrichment behaviors of low-grade donganshan iron ore using magnetic separation[J]. Journal of Northeastern University(Natural Science), 2019, 40(1):94-98. doi: 10.12068/j.issn.1005-3026.2019.01.018

[9] 杨光, 周立波, 李文博, 等. 东鞍山铁矿强化细粒铁矿物回收新技术研究[J]. 金属矿山, 2021(541):102-109.YANG G, ZHOU L B, LI W B, et al. Research on new technology of enhanced separation recovery of fine-grained iron minerals in Donganshan iron mine[J]. Mental Mine, 2021(541):102-109.

YANG G, ZHOU L B, LI W B, et al. Research on new technology of enhanced separation recovery of fine-grained iron minerals in Donganshan iron mine[J]. Mental Mine, 2021(541):102-109.

[10] 朱一民, 郭文达, 杨艳平, 等. 新型阳离子捕收剂对东鞍山铁矿的浮选实验研究[J]. 中国矿业, 2016, 25(3):97-101.ZHU Y M, GUO W D, YANG Y P, et al. Flotation experiment of a new cationic collectior for Donganshan's iron ore[J]. China Mining Magazine, 2016, 25(3):97-101. doi: 10.3969/j.issn.1004-4051.2016.03.022

ZHU Y M, GUO W D, YANG Y P, et al. Flotation experiment of a new cationic collectior for Donganshan's iron ore[J]. China Mining Magazine, 2016, 25(3):97-101. doi: 10.3969/j.issn.1004-4051.2016.03.022

[11] 张忠辉. 滇西某低品位菱铁矿选冶工艺实验与理论研究[D]. 上海: 上海大学, 2015.ZHANG Z H. Experimental and theoretical research on comprehensive utilization of low grade siderite ore[D]. Shanghai: Shanghai University, 2015.

ZHANG Z H. Experimental and theoretical research on comprehensive utilization of low grade siderite ore[D]. Shanghai: Shanghai University, 2015.

-

下载:

下载: