Mechanical Property Modification of Alkali-activated Slag Fly Ash-based Geopolymer and its Concrete Property

-

摘要:

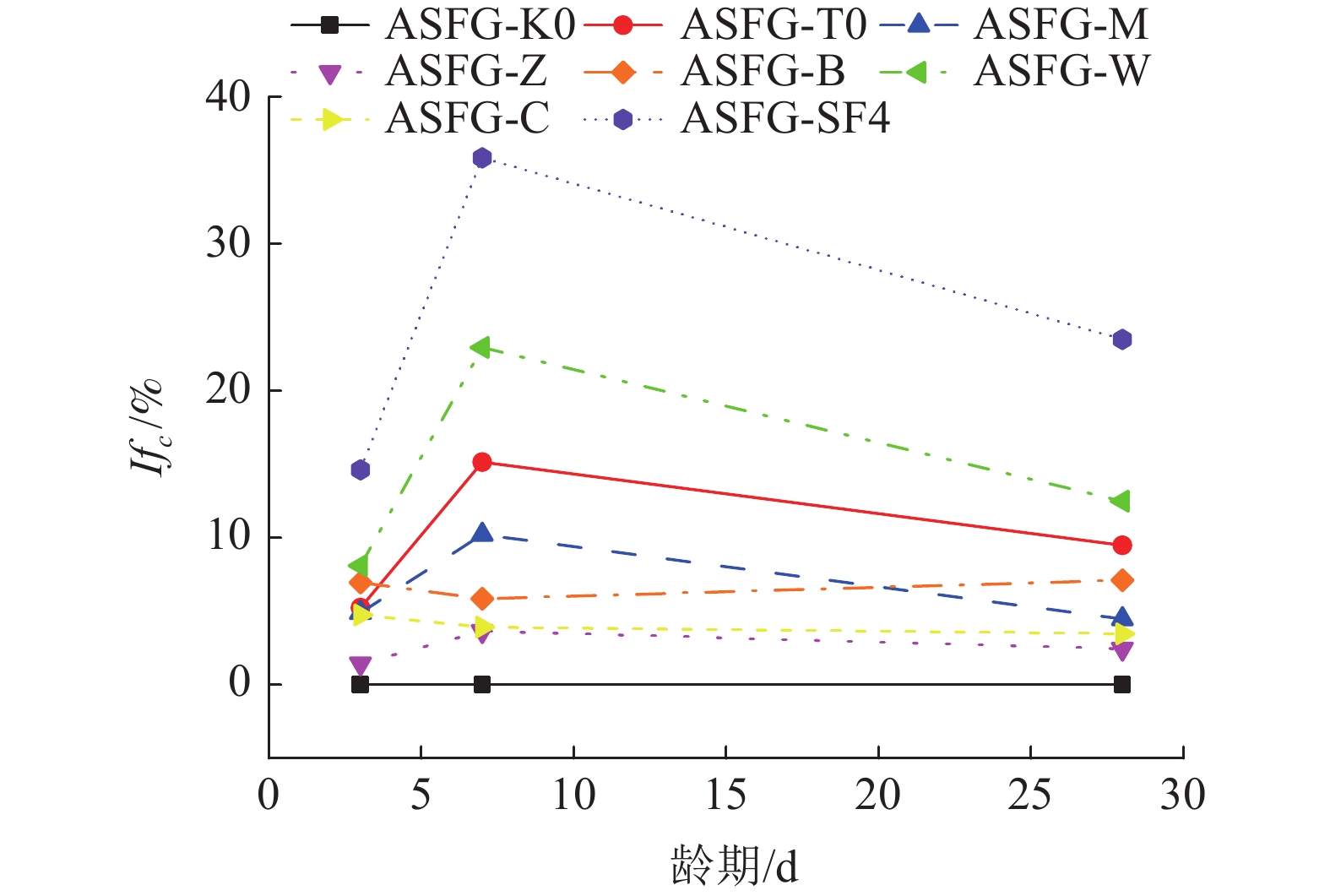

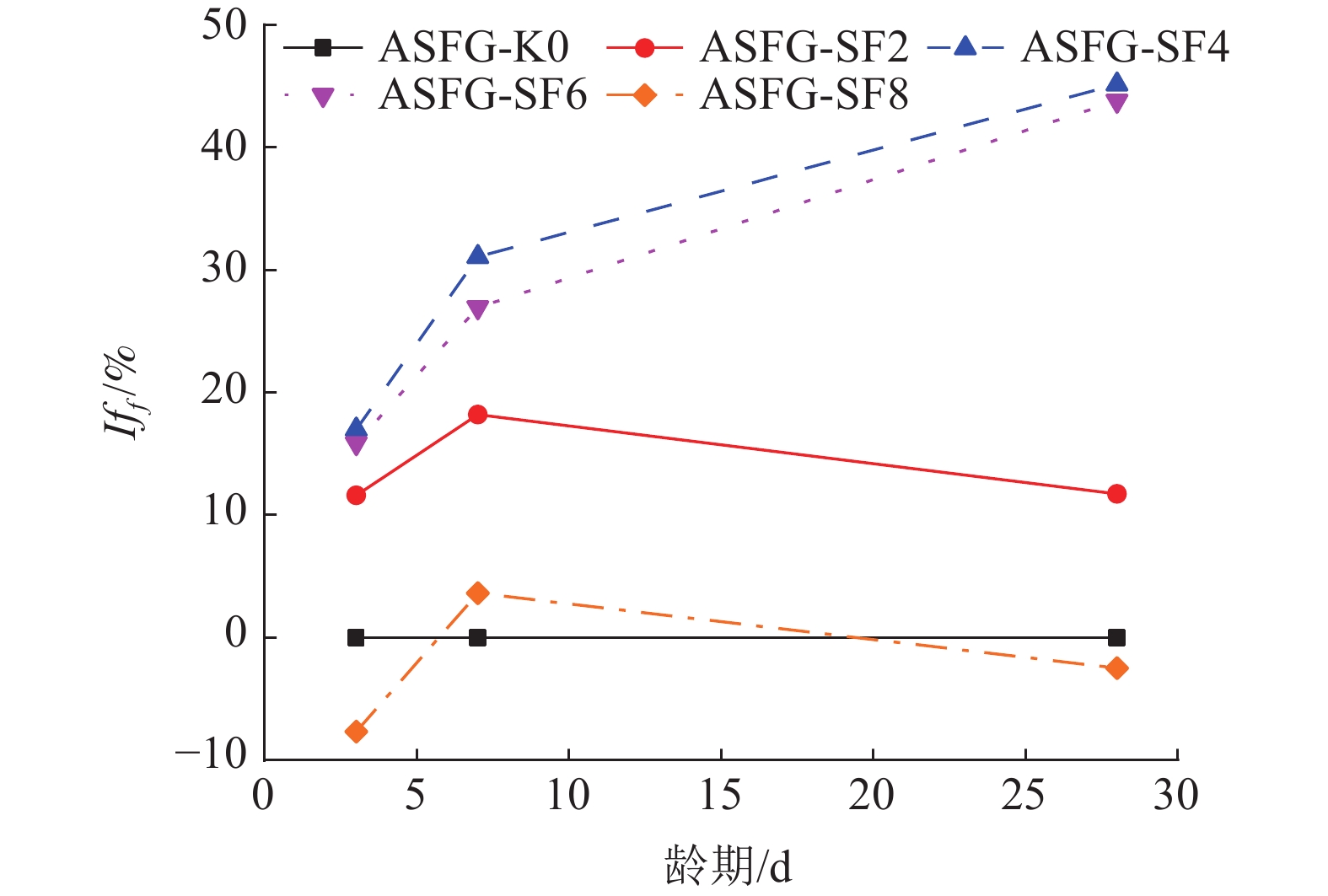

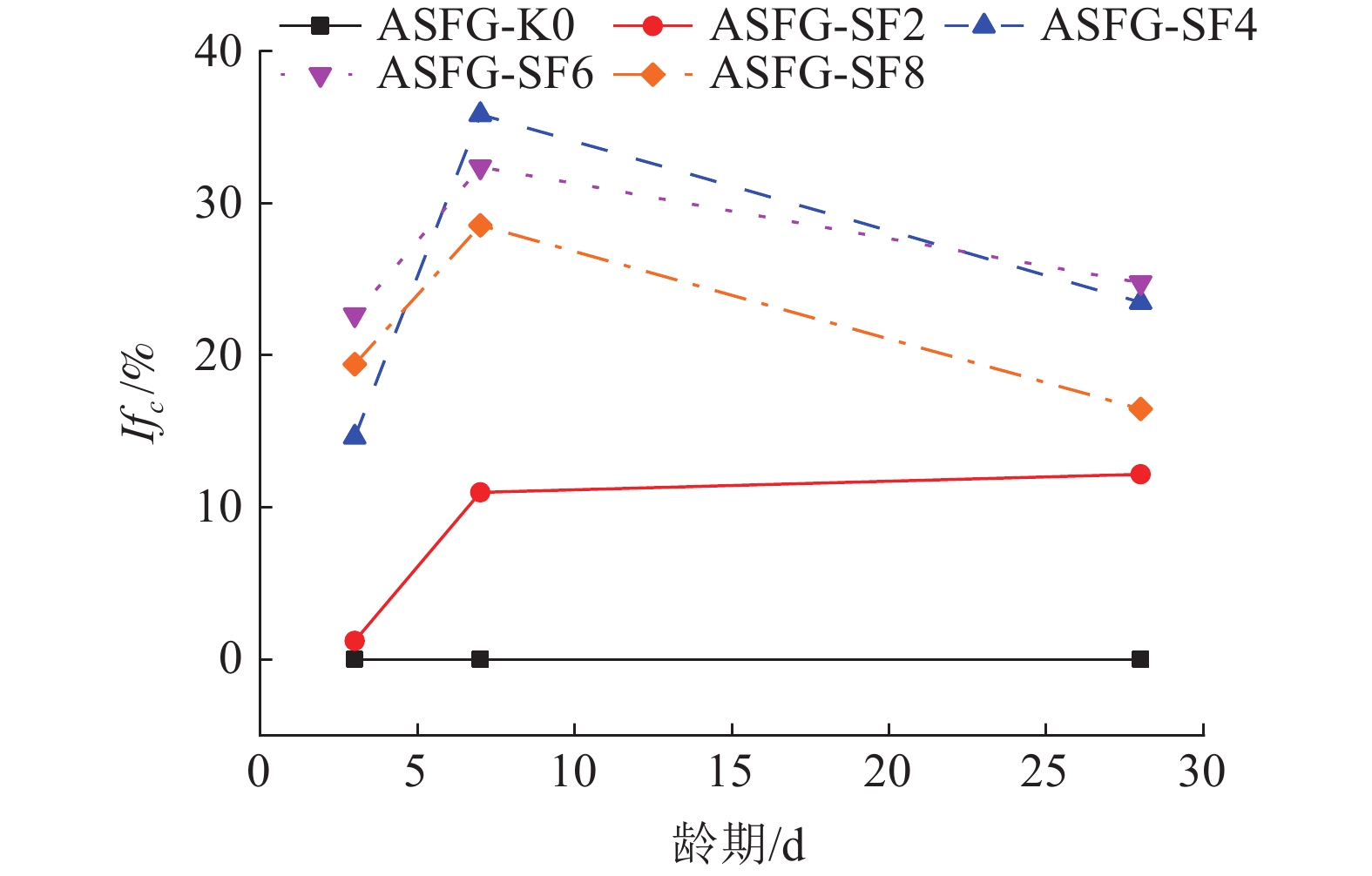

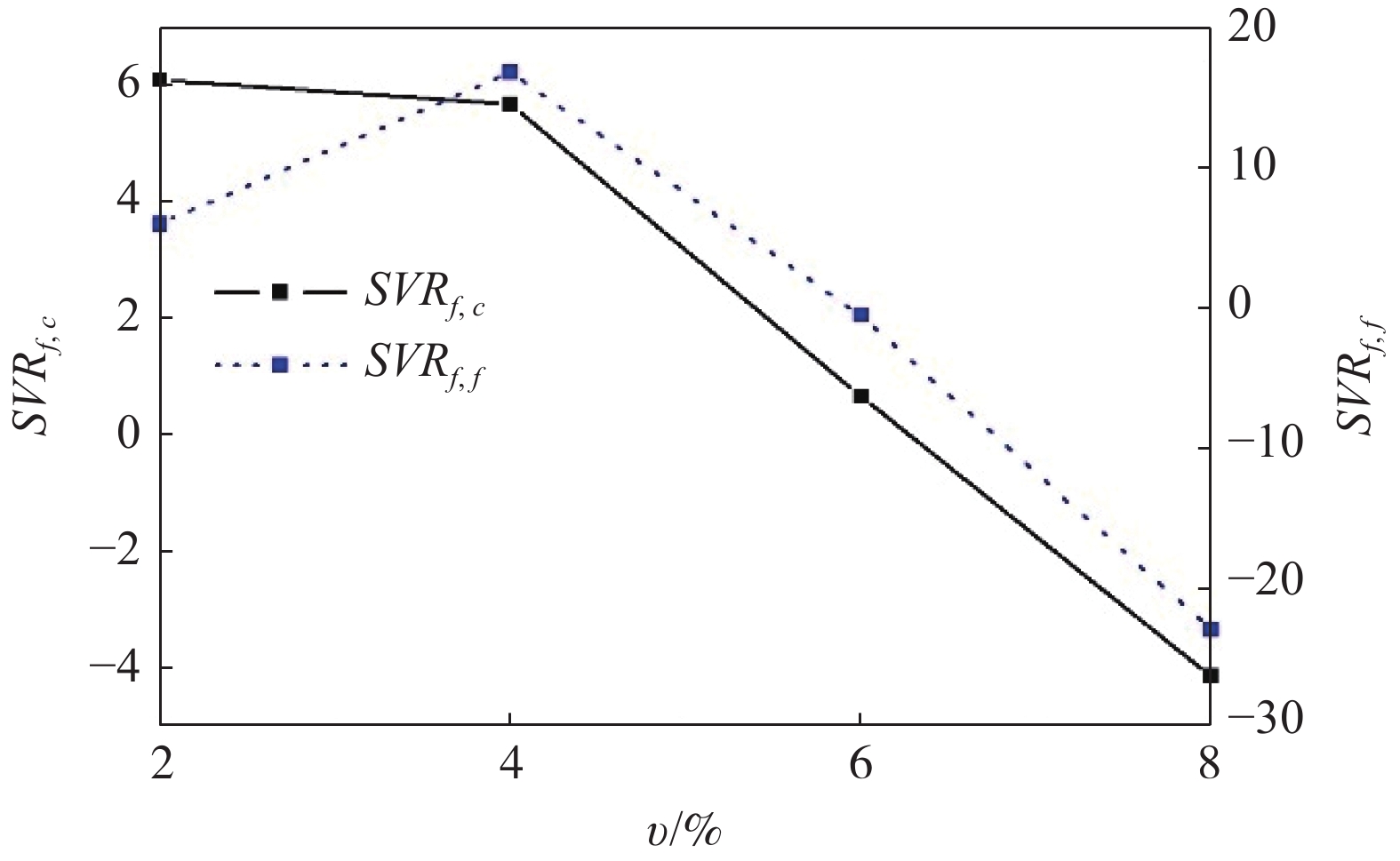

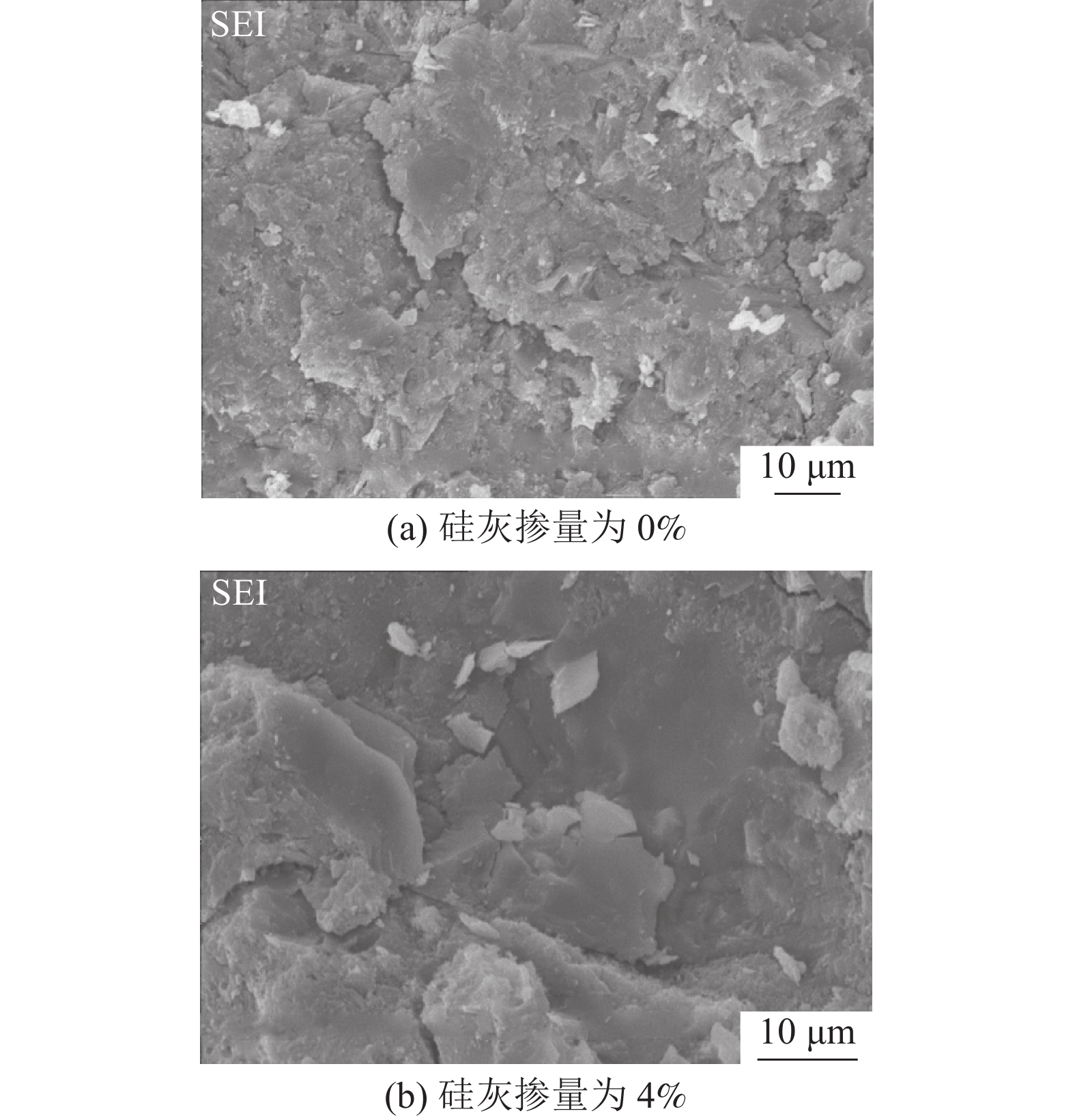

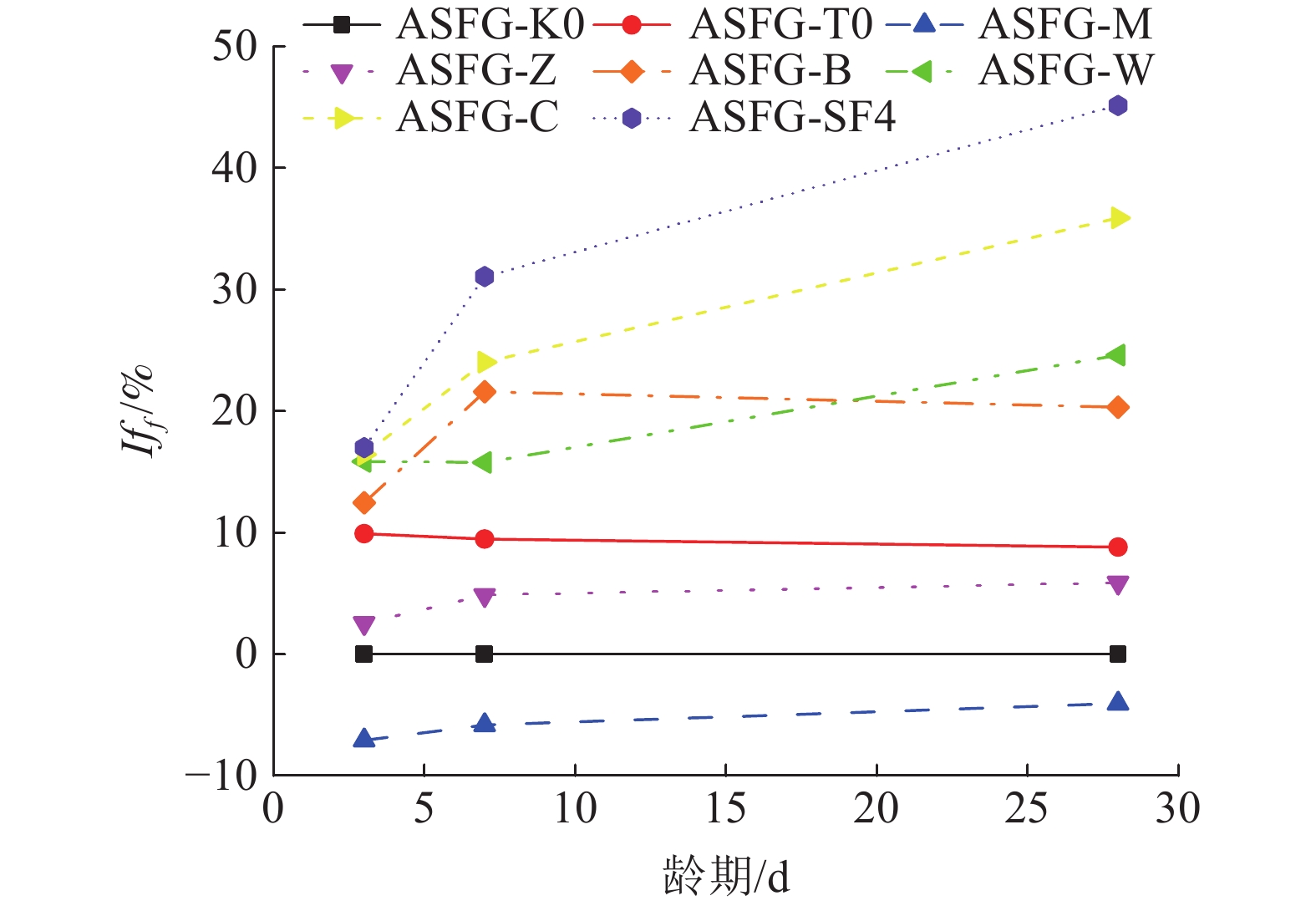

这是一篇陶瓷及复合材料领域的论文。碱激发矿渣粉煤灰地质聚合物(ASFG)具有早期强度高、耐酸碱等优异性能,但脆性大、韧性差等缺陷影响其推广应用。为改善ASFG的性能且拓宽可应用于ASFG改性的矿物掺合料种类,以偏高岭土、沸石粉、膨润土、硅灰石粉、轻质碳酸钙和硅灰六种矿物掺合料作为改性材料,研究了其对ASFG力学性能的改性效果,并确定了硅灰为较佳改性材料。为深入探索硅灰对ASFG力学性能的改善作用,研究了硅灰掺量对ASFG力学性能的影响,并确定了硅灰的较佳掺量。最后,制备了碱激发矿渣-粉煤灰-硅灰地质聚合物混凝土(ASFSGC),并研究了其工作性、准静态力学性能和抗渗性。结果表明:膨润土、硅灰石粉、轻质碳酸钙、硅灰四种矿物掺合料对ASFG的抗折强度具有明显增强效果。硅灰石粉、硅灰两种矿物掺合料对ASFG的抗压强度具有明显增强效果。对ASFG而言,硅灰是一种优质矿物掺合料。随着硅灰掺量的增大,ASFG的力学性能先增大后减小,硅灰的较佳掺量为4%。ASFSGC具有良好的工作性、优异的抗渗性能,且ASFSGC的延性较普通硅酸盐水泥混凝土提高了14.1%。

Abstract:This is an article in the field of ceramics and composites. Alkali-activated Slag-fly Ash-based Geopolymer (ASFG) has excellent properties such as high early strength, acid and alkali resistance, but its large brittleness and poor toughness affect its popularization and application. In order to improve the properties of ASFG and broaden the types of mineral admixtures that can be used for ASFG modification, six kinds of mineral admixtures, including metakaolin, zeolite powder, bentonite, wollastonite powder, light calcium carbonate and silica fume, are used as modified materials, and their modification effects on ASFG are studied. The optimum modified material is silica fume. In order to further explore the improvement effect of silica fume on the mechanical properties of ASFG, the effect of the content of silica fume on the mechanical properties of ASFG is studied, and the optimal content of silica fume is determined. Finally, Alkali-activated Slag-fly Ash-silica Fume-based Geopolymer Concrete (ASFSGC) is prepared, and its workability, quasi-static mechanical properties and impermeability are studied. The results show that bentonite, wollastonite powder, light calcium carbonate and silica fume can significantly improve the flexural strength of ASFG. Wollastonite powder and silica fume can significantly improve the compressive strength of ASFG. For ASFG, silica fume is a premium mineral admixture. With the increase of silica fume content, the mechanical properties of ASFG first increase and then decrease, and the optimal content of silica fume is 4%. ASFSGC has good workability and excellent impermeability, and the ductility of ASFSGC is 14.1% larger than that of ordinary Portland cement concrete.

-

Key words:

- Ceramics and composites /

- Alkali-activated slag-fly ash /

- Geopolymer /

- Concrete /

- Mineral admixtures /

- Silica fume

-

-

表 1 矿渣和粉煤灰的化学组成/%

Table 1. Chemical composition of slags and fly ash

氧化物 SiO2 Al2O3 Fe2O3 CaO Na2O TiO2 MgO K2O P2O5 SO3 其他 烧失量 矿渣 29.2 19.4 5.8 38.6 0.2 0.6 2.8 0.1 — 2.6 0.4 0.3 粉煤灰 45.8 21.4 12.6 13.7 1.1 0.2 1.3 1.8 0.1 1.9 — 0.1 表 2 矿物掺合料的粒径/μm

Table 2. Particle size of mineral admixtures

硅灰 偏高岭土 沸石粉 膨润土 硅灰石粉 轻质碳酸钙 0.1 10 10 75 15 10 表 3 ASFG试件的配合比

Table 3. Mix ratio of ASFG specimens

试件编号 矿物掺合

料种类m(碱性激发剂)∶

m(胶凝材料)m(胶凝材料+

碱性激发剂)∶

m(水)m(NaOH)∶

m(Na2CO3)m(粉煤灰)∶

m(矿渣)m(三聚磷酸钠)∶

m(胶凝材料)m(矿物掺合料)∶

m(胶凝材料)ASFG-K0 - 6.0% 2.8 1.3 0.6 0.4% - ASFG-T0 粉煤灰、矿渣 4.0% ASFG-M 偏高岭土 ASFG-Z 沸石粉 ASFG-B 膨润土 ASFG-W 硅灰石粉 ASFG-C 轻质碳酸钙 ASFG-SF2 硅灰 2.0% ASFG-SF4 4.0% ASFG-SF6 6.0% ASFG-SF8 8.0% 表 4 ASFSGC试件的配合比/(kg/m3)

Table 4. Mix ratio of ASFSGC specimens

矿渣 粉煤灰 NaOH Na2CO3 砂 碎石 水 三聚磷酸钠 硅灰 304 183 17 13 583 1 037 184.6 1.95 19.48 表 5 ASFG的强度测试实验结果/MPa

Table 5. Strength test results of ASFG

试件编号 矿物掺合料种类 ff-3d fc-3d ff-7d fc-7d ff-28d fc-28d ASFG-K0 - 3.53 18.13 4.12 27.20 4.43 44.19 ASFG-T0 粉煤灰、矿渣 3.88 19.08 4.51 31.32 4.82 48.38 ASFG-M 偏高岭土 3.28 19.02 3.88 29.98 4.25 46.17 ASFG-Z 沸石粉 3.62 18.39 4.32 28.19 4.69 45.27 ASFG-B 膨润土 3.97 19.39 5.01 28.79 5.33 47.33 ASFG-W 硅灰石粉 4.09 19.60 4.77 33.44 5.52 49.71 ASFG-C 轻质碳酸钙 4.11 18.99 5.11 28.27 6.02 45.72 ASFG-SF2 硅灰 3.94 18.35 4.87 30.19 4.95 49.57 ASFG-SF4 4.13 20.78 5.40 36.95 6.43 54.57 ASFG-SF6 4.09 22.24 5.23 36.01 6.37 55.14 ASFG-SF8 3.26 21.65 4.27 34.97 4.32 51.47 表 6 ASFSGC抗折、抗压及劈拉实验测试结果

Table 6. Flexural, compressive and splitting test results of ASFSGC

龄期/d 抗折强度/MPa 抗压强度/MPa 劈拉强度/MPa 3 3.27 19.59 3.87 7 3.66 29.37 4.12 28 4.83 42.89 5.13 表 7 ASFSGC的渗水高度

Table 7. Water penetration height of ASFSGC

试件编号 测点 渗水高度/mm 1 2 3 4 5 6 7 8 9 10 ASFSGC-1 14 12 9 10 8 11 14 11 12 13 11.4 ASFSGC-2 7 7 6 5 6 6 4 6 4 4 5.5 ASFSGC-3 10 11 9 9 8 4 7 8 10 12 8.8 ASFSGC-4 12 13 11 7 5 8 6 7 7 6 8.2 ASFSGC-5 19 17 14 13 12 13 15 17 19 20 15.9 ASFSGC-6 8 6 6 5 7 5 3 2 4 7 5.3 结果 ASFSGC试件的平均渗水高度/mm 9.2 -

[1] 王伟杰, 金会心, 张延玲, 等. 含铬固废的资源化处理及循环利用研究进展[J]. 矿产综合利用, 2022, 2(5):64-70.WANG W J, JIN H X, ZHANG Y L, et al. Research progress on resource treatment and recycling of solid waste containing chromium[J]. Multipurpose Utilization of Mineral Resources, 2022, 2(5):64-70.

WANG W J, JIN H X, ZHANG Y L, et al. Research progress on resource treatment and recycling of solid waste containing chromium[J]. Multipurpose Utilization of Mineral Resources, 2022, 2(5):64-70.

[2] 田崇霏, 王亚洲, 刘晓海, 等. 混掺纤维对粉煤灰-矿渣基地质聚合物工作性及力学性能的影响研究[J]. 混凝土, 2023(4):115-119.TIAN C F, WANG Y Z, LIU X H, et al. Study on the effect of mixed fiber on the workability and mechanical properties of flyash-slag base polymer[J]. Concrete, 2023(4):115-119. doi: 10.3969/j.issn.1002-3550.2023.04.024

TIAN C F, WANG Y Z, LIU X H, et al. Study on the effect of mixed fiber on the workability and mechanical properties of flyash-slag base polymer[J]. Concrete, 2023(4):115-119. doi: 10.3969/j.issn.1002-3550.2023.04.024

[3] 李涛, 罗仙平, 钱有军. 加水一体化合成钨尾矿基地聚合物[J]. 矿产综合利用, 2019(1):83-87.LI T, LUO X P, QIAN Y J. Investigation on synthesis of tungsten tailings base geopolymer by water integration[J]. Multipurpose Utilization of Mineral Resources, 2019(1):83-87. doi: 10.3969/j.issn.1000-6532.2019.01.018

LI T, LUO X P, QIAN Y J. Investigation on synthesis of tungsten tailings base geopolymer by water integration[J]. Multipurpose Utilization of Mineral Resources, 2019(1):83-87. doi: 10.3969/j.issn.1000-6532.2019.01.018

[4] 章玉容, 徐雅琴, 姚泽阳, 等. 配合比设计方法对再生混凝土生命周期评价的影响[J]. 浙江工业大学学报, 2020, 48(6):648-653.ZHANG Y R, XU Y Q, YAO Z Y, et al. Influence of mix ratio design method on life cycle evaluation of recycled concrete[J]. Journal of Zhejiang University of Technology, 2020, 48(6):648-653. doi: 10.3969/j.issn.1006-4303.2020.06.009

ZHANG Y R, XU Y Q, YAO Z Y, et al. Influence of mix ratio design method on life cycle evaluation of recycled concrete[J]. Journal of Zhejiang University of Technology, 2020, 48(6):648-653. doi: 10.3969/j.issn.1006-4303.2020.06.009

[5] 孙英娟, 周旋, 岳丽娜, 等. 工业固废制备聚合氯化铝铁及其在煤泥废水处理中的应用[J]. 矿产综合利用, 2021(1):144-150.SUN Y J, ZHOU X, YUE L N, et al. Preparation of polyaluminium ferric chloride from industrial solid waste and its application in coal slurry wastewater treat ment[J]. Multipurpose Utilization of Mineral Resources, 2021(1):144-150. doi: 10.3969/j.issn.1000-6532.2021.01.025

SUN Y J, ZHOU X, YUE L N, et al. Preparation of polyaluminium ferric chloride from industrial solid waste and its application in coal slurry wastewater treat ment[J]. Multipurpose Utilization of Mineral Resources, 2021(1):144-150. doi: 10.3969/j.issn.1000-6532.2021.01.025

[6] 潘钦锋, 陈亚辉, 颜桂云, 等. 钢纤维地质聚合物混凝土静态力学性能研究[J]. 武汉大学学报(工学版), 2023, 56(5):575-583.PAN Q F, CHEN Y H, YAN G Y, et al. Study on static mechanical properties of steel fiber geopolymer concrete[J]. Journal of Wuhan University (Engineering Science), 2023, 56(5):575-583.

PAN Q F, CHEN Y H, YAN G Y, et al. Study on static mechanical properties of steel fiber geopolymer concrete[J]. Journal of Wuhan University (Engineering Science), 2023, 56(5):575-583.

[7] 魏铭, 张长森, 王旭, 等. 微纳米材料改性地质聚合物的研究进展[J]. 材料导报, 2023, 37(4):254-263.WEI M, ZHANG C S, WANG X, et al. Research progress of micro-nanomaterials modified geopolymers[J]. Materials Review, 2023, 37(4):254-263. doi: 10.11896/cldb.21020065

WEI M, ZHANG C S, WANG X, et al. Research progress of micro-nanomaterials modified geopolymers[J]. Materials Review, 2023, 37(4):254-263. doi: 10.11896/cldb.21020065

[8] ZHANG D, ZHU H, WU Q, et al. Investigation of the hydrophobicity and microstructure of fly ash-slag geopolymer modified by polydimethylsiloxane[J]. Construction and Building Materials, 2023, 369:130540. doi: 10.1016/j.conbuildmat.2023.130540

[9] 宋学锋, 王骏, 王艳. 纤维/混杂纤维-矿渣地质聚合物复合材料的弯曲强度与弯曲韧性[J]. 材料导报, 2017, 31(22):121-124+145.SONG X F, WANG J, WANG Y. Bending strength and bending toughness of fiber/hybrid fiber-slag geopolymer composites[J]. Materials Review, 2017, 31(22):121-124+145. doi: 10.11896/j.issn.1005-023X.2017.022.024

SONG X F, WANG J, WANG Y. Bending strength and bending toughness of fiber/hybrid fiber-slag geopolymer composites[J]. Materials Review, 2017, 31(22):121-124+145. doi: 10.11896/j.issn.1005-023X.2017.022.024

[10] 汪应玲, 罗绍华, 姜茂发, 等. 铁尾矿制备地质聚合物工艺条件研究[J]. 矿产综合利用, 2019(5):121-126.WANG Y L, LUO S H, JIANG M F, et al. Study on process conditions for geopolymer from iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2019(5):121-126. doi: 10.3969/j.issn.1000-6532.2019.05.026

WANG Y L, LUO S H, JIANG M F, et al. Study on process conditions for geopolymer from iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2019(5):121-126. doi: 10.3969/j.issn.1000-6532.2019.05.026

[11] 肖建庄, 邓琪, 夏冰. 混凝土制备低碳化演进与展望[J]. 建筑科学与工程学报, 2022, 39(5):1-12.XIAO J Z, DENG Q, XIA B. Evolution and prospect of low-carbon concrete preparation[J]. Journal of Building Science and Engineering, 2022, 39(5):1-12.

XIAO J Z, DENG Q, XIA B. Evolution and prospect of low-carbon concrete preparation[J]. Journal of Building Science and Engineering, 2022, 39(5):1-12.

[12] 吴丽萍, 王军. 铁尾矿粉-硅粉矿物掺合料对混凝土性能的影响[J]. 矿产综合利用, 2023(2):184-190.WU L P, WANG J. Effect of iron tailing powder and silica powder mineral admixture on performance of concrete[J]. Multipurpose Utilization of Mineral Resources, 2023(2):184-190. doi: 10.3969/j.issn.1000-6532.2023.02.028

WU L P, WANG J. Effect of iron tailing powder and silica powder mineral admixture on performance of concrete[J]. Multipurpose Utilization of Mineral Resources, 2023(2):184-190. doi: 10.3969/j.issn.1000-6532.2023.02.028

[13] 孙大全, 顾泽宇, 孙硕, 等. 碱激发粉煤灰-硅灰基地质聚合物的性能及表征[J]. 硅酸盐通报, 2020, 39(5):1533-1539.SUN D Q, GU Z Y, SUN S, et al. Properties and characterization of alkali-excited flyash-silica base polymer[J]. Bulletin of Silicate, 2020, 39(5):1533-1539.

SUN D Q, GU Z Y, SUN S, et al. Properties and characterization of alkali-excited flyash-silica base polymer[J]. Bulletin of Silicate, 2020, 39(5):1533-1539.

[14] 高巧玲, 范功端. 硅灰对新型地质聚合物胶凝材料力学性能影响的研究进展[J]. 武汉工程大学学报, 2020, 42(5):540-545.GAO Q L, FAN G D. Research progress of effects of silica fume on mechanical properties of novel geopolymer cementification materials[J]. Journal of Wuhan Institute of Technology, 2020, 42(5):540-545.

GAO Q L, FAN G D. Research progress of effects of silica fume on mechanical properties of novel geopolymer cementification materials[J]. Journal of Wuhan Institute of Technology, 2020, 42(5):540-545.

[15] Sanghamitra Jena, Ramakanta Panigrahi. Study on the durability and microstructure of geopolymer concrete with ferrochrome slag and silica fume[J]. International Journal of Structural Engineering, 2022, 12(3):302-319. doi: 10.1504/IJSTRUCTE.2022.123745

-

下载:

下载: