Preparation and Properties of Fly Ash and Sintering Red Mud-based Geopolymers

-

摘要:

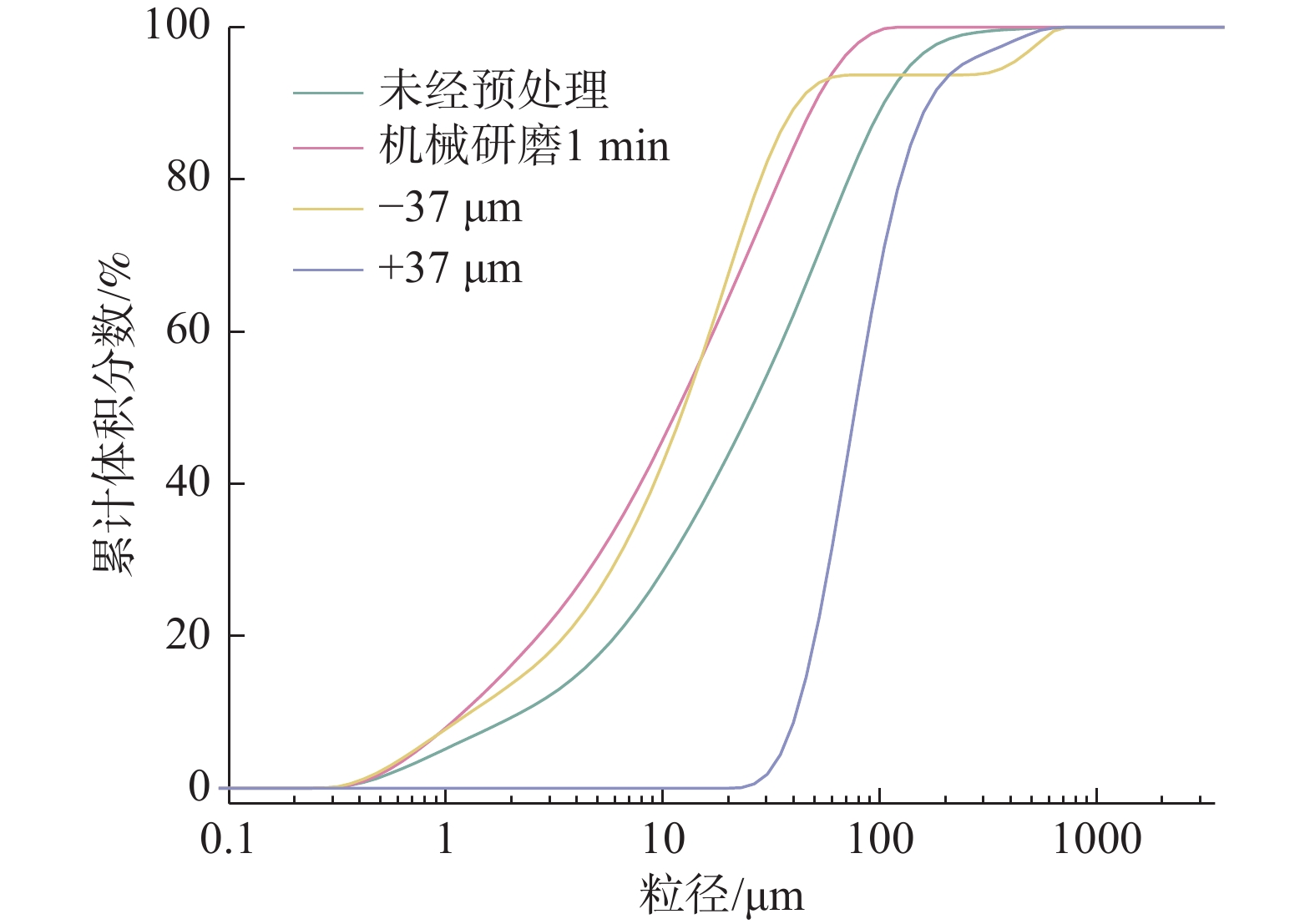

这是一篇陶瓷及复合材料领域的论文。为实现粉煤灰和烧结法赤泥的综合利用,本研究以粉煤灰为主要原料,烧结法赤泥作为辅料,氢氧化钠为碱激发剂协同制备地聚合物。结果表明,地聚合物较佳制备条件为:粉煤灰采取分级(细粒提取)的预处理方式,分级粒径为37 μm,细颗粒粉煤灰与烧结法赤泥质量比为7∶3 (g∶g),氢氧化钠的用量为前驱粉体的15%,此时地聚合物室温养护28 d的抗压强度可达35.52 MPa,满足中国《通用硅酸盐水泥》32.5R矿渣硅酸盐水泥的强度标准。通过XRF、XRD、ICP-OES和SEM-EDS对不同预处理方式下的原料及其所制备的地聚合物进行分析测试表明:相比于机械研磨,分级预处理更能有效改善粉煤灰的反应性,使更多活性硅铝组分参与地聚合反应;烧结法赤泥的加入可以促进富钙铝硅酸盐凝胶的形成,使地聚合物的微观结构致密化。本研究为粉煤灰和烧结法赤泥的综合利用提供了新的思路。

Abstract:This is an article in the field of inorganic non-metallic materials.To achieve comprehensive utilization of fly ash and sintering red mud, this study uses fly ash as the main raw material, sintering red mud as an auxiliary material, and sodium hydroxide as an alkaline activator to synergistically prepare geopolymer. The results showed that the optimal preparation conditions for geopolymer were as follows: fly ash was pretreated with a classification pretreatment (extraction of fine fraction), with a graded particle size of 37 μm. The mass ratio of fine-grained fly ash to sintering red mud is 7∶3 (g∶g), and the dosage of NaOH accounts for 15% of the mass of the precursor powder. The compressive strength of the geopolymer prepared at these conditions reached 35.52 MPa after curing at room temperature for 28 d, meeting the strength standard of 32.5R slag portland cement in the Common Portland Cement of China. The raw materials and geopolymers prepared at different pretreatment methods were analyzed and tested using XRF, XRD, ICP-OES, and SEM-EDS. The test results showed that compared to mechanical grinding, classification pretreatment can effectively improve the reactivity of fly ash, allowing more active silicon and aluminum components to participate in geopolymerization reactions. The addition of sintering red mud can promote the formation of calcium-rich aluminosilicate gel and densify the microstructure of geopolymers. This study provides new insights into the comprehensive utilization of fly ash and sintering red mud.

-

Key words:

- Ceramics and composites /

- Fly ash /

- Sintering red mud /

- Comprehensive utilization /

- Geopolymer

-

-

表 1 原料主要化学成分/%

Table 1. Main chemical composition of raw materials

名称 SiO2 Al2O3 Fe2O3 CaO K2O TiO2 SO3 Na2O 其他 烧失量 粉煤灰 50.84 25.93 5.50 4.03 2.63 1.15 0.54 0.59 1.63 7.16 烧结法赤泥 18.43 7.36 7.04 36.46 1.22 2.77 2.05 2.56 1.68 20.43 表 2 粉煤灰和烧结法赤泥的粒度分布/μm

Table 2. Particle size distribution of fly ash and sintered red mud

名称 D10 D50 D90 粉煤灰 2.237 25.582 104.069 烧结法赤泥 1.269 13.567 170.847 表 3 粉煤灰在不同预处理方式下的化学成分/%

Table 3. Chemical composition of fly ash at different pretreatment methods

预处理方式 SiO2 Al2O3 Fe2O3 CaO K2O TiO2 MgO Na2O 其他 烧失量 未经预处理 50.84 25.93 5.50 4.03 2.63 1.15 0.88 0.59 7.16 1.29 研磨1 min 52.85 24.98 4.56 3.76 2.26 1.09 0.94 0.63 7.85 1.08 -37 μm 52.00 28.04 5.32 3.39 2.36 1.25 0.97 0.64 5.06 0.97 +37 μm 51.67 22.92 5.32 4.67 2.38 1.16 0.87 0.61 9.16 1.24 -

[1] 聂轶苗, 夏淼, 刘攀攀, 等. 粉煤灰基矿物聚合材料研究进展[J]. 矿产综合利用, 2022(4):123-128.NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128.

NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128.

[2] XU X Q, BAO S X, ZHANG Y M, et al. Role of particle fineness and reactive silicon-aluminum ratio in mechanical properties and microstructure of geopolymers[J]. Construction and Building Materials, 313 (2021) 125483.

[3] 秦磊, 包申旭, 张一敏, 等. 页岩提钒尾渣-赤泥混合煅烧制备地聚物研究[J]. 有色金属(冶炼部分), 2020(4):51-56.QIN L, BAO S X, ZHANG Y M, et al. Preparation of geopolymer from vanadium tailings and red mud by mixed calcination[J]. Nonferrous Metals(Extractive Metallurgy), 2020(4):51-56.

QIN L, BAO S X, ZHANG Y M, et al. Preparation of geopolymer from vanadium tailings and red mud by mixed calcination[J]. Nonferrous Metals(Extractive Metallurgy), 2020(4):51-56.

[4] WANG S H, JIN H X, DENG Y, et al. Comprehensive utilization status of red mud in China: a critical review[J]. Journal of Cleaner Production, 2021, 289: 125136.

[5] LAHOTI M, WIJAYA S F, TAN K H, et al. Tailoring sodium-based fly ash geopolymers with variegated thermal performance[J]. Cement and Concrete Composites, 2020, 107:103507.

[6] 郑戈弋, 周海林, 黄青叶, 等. 燃煤渣花岗岩粉基地质聚合物的制备[J]. 有色金属(冶炼部分), 2022(9):133-139.ZHENG G Y, ZHOU H L, HUANG Q Y, et al. Preparation and performance characterization of granite powder-burnt cinder-based geopolymer[J]. Nonferrous Metals(Extractive Metallurgy), 2022(9):133-139.

ZHENG G Y, ZHOU H L, HUANG Q Y, et al. Preparation and performance characterization of granite powder-burnt cinder-based geopolymer[J]. Nonferrous Metals(Extractive Metallurgy), 2022(9):133-139.

[7] NATH S K, KUMAR S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer[J]. Construction and Building Materials, 2020, 233: 117294.

[8] HUANG L X, LI C L, WANG H B, et al. Research progress on comprehensive utilization of red mud[J]. Journal of Physics: Conference Series, 2021(1):12-21. doi: 10.1088/1742-6596/2009/1/012021

[9] 梁晓杰, 常钧, 吴昊泽. 钢渣粉粒度对复合胶凝材料水化性能的影响[J]. 矿产综合利用, 2021(3):180-186.LIANG X J, CHANG J, WU H Z. Effect of particle size of steel slag powder on hydration performance of composite cementitious material[J]. Multipurpose Utilization of Mineral Resources, 2021(3):180-186.

LIANG X J, CHANG J, WU H Z. Effect of particle size of steel slag powder on hydration performance of composite cementitious material[J]. Multipurpose Utilization of Mineral Resources, 2021(3):180-186.

[10] 聂轶苗, 陈阳, 翟培鑫, 等. 粉煤灰中非晶相含量定量分析研究进展[J]. 矿产综合利用, 2023(1):121-126+132.NIE Y M, CHEN Y, ZHAI P X, et al. Research progress of quantitative determination of the amorphous phase in fly ash[J]. Multipurpose Utilization of Mineral Resources, 2023(1):121-126+132.

NIE Y M, CHEN Y, ZHAI P X, et al. Research progress of quantitative determination of the amorphous phase in fly ash[J]. Multipurpose Utilization of Mineral Resources, 2023(1):121-126+132.

[11] RICKARD W D A, WILLIAMS R, TEMUUJIN J, et al. Assessing the suitability of three Australian fly ashes as an aluminosilicate source for geopolymers in high temperature applications[J]. Materials Science and Engineering, 2011, 528: 3390-3397.

[12] RIESSEN A V, CHEN-TAN. Beneficiation of Collie fly ash for synthesis of geopolymer: Part 1 - Beneficiation[J]. Fuel, 106 (2013) 569-575.

[13] 李建伟, 杨久俊, 王晓, 等. 烧结法赤泥资源特性分析[J]. 无机盐工业, 2013, 45(3):42-44.LI J W, YANG J J, WANG X, et al. Research on resource characteristics of red mud from sintering process[J]. Inorganic Chemicals Industry, 2013, 45(3):42-44.

LI J W, YANG J J, WANG X, et al. Research on resource characteristics of red mud from sintering process[J]. Inorganic Chemicals Industry, 2013, 45(3):42-44.

[14] LEE W, DEVENTER J V. The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements[J]. Cement and Concrete Research, 2002, 32: 577-584.

[15] DEVENTER J S, PROVIS J L, DUXSON P, et al. Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products[J]. Journal of Hazardous Materials, 2007, 139: 506-513.

[16] 徐贤庆, 包申旭, 张一敏, 等. 页岩提钒尾渣基地聚合物的制备及其性能[J]. 硅酸盐通报, 2021, 40(11):3668-3676.XU X Q, BAO S X, ZHANG Y M, et al. Preparation and performance of polymer based on shale vanadium extraction tailings[J]. Bulletin of The Chinese Ceramic Society, 2021, 40(11):3668-3676.

XU X Q, BAO S X, ZHANG Y M, et al. Preparation and performance of polymer based on shale vanadium extraction tailings[J]. Bulletin of The Chinese Ceramic Society, 2021, 40(11):3668-3676.

-

下载:

下载: