Preparation of Foamed Ceramic Materials from Fly Ash and Blast Furnace Slags

-

摘要:

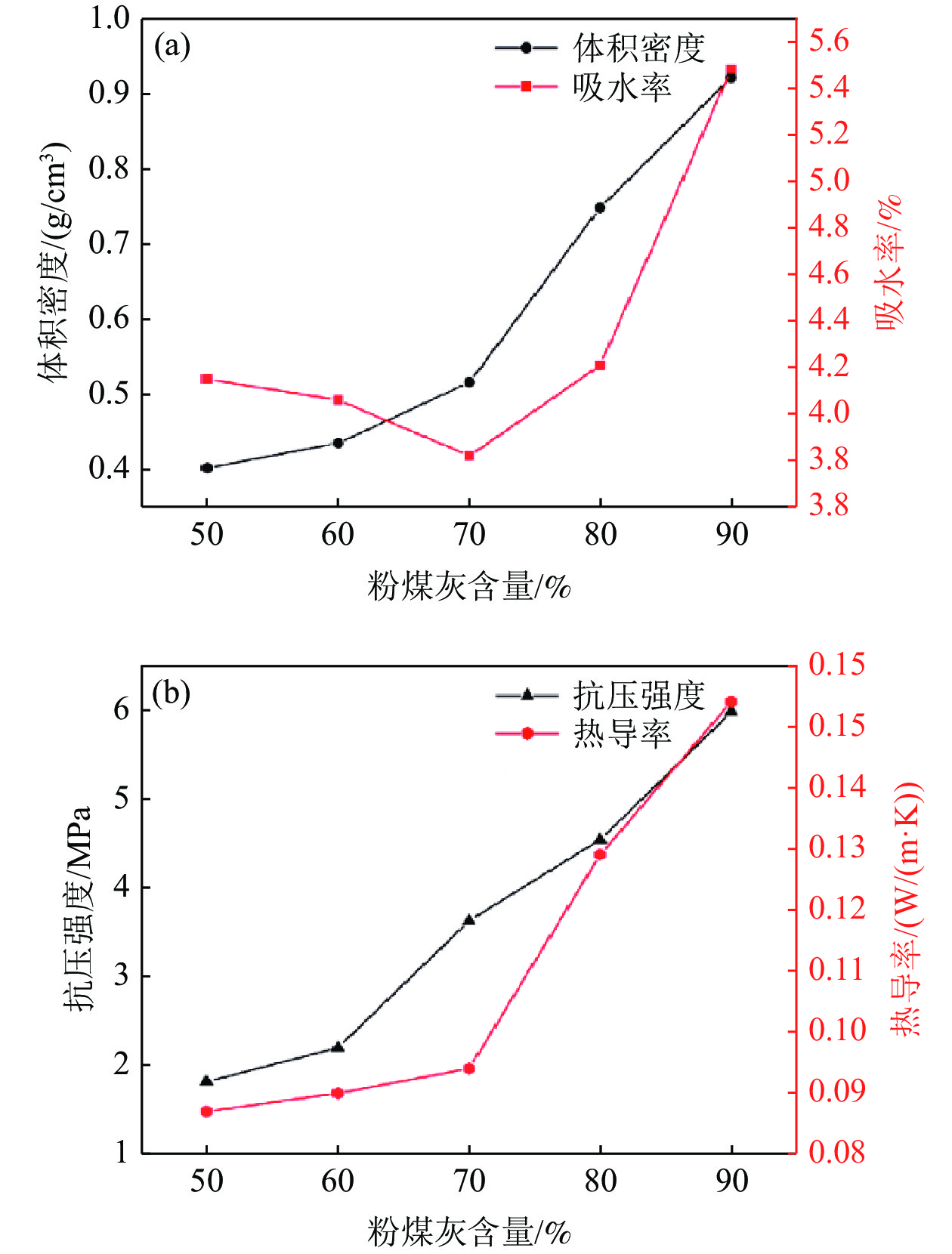

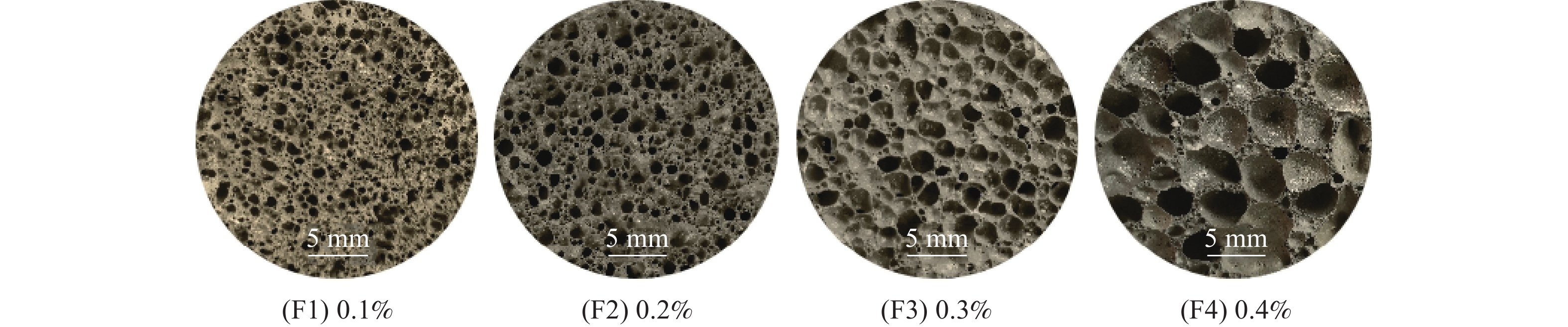

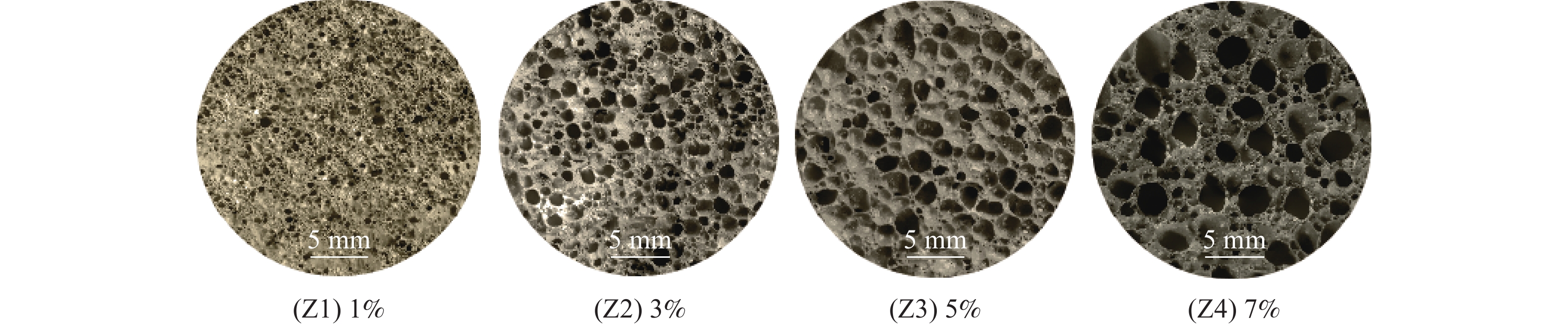

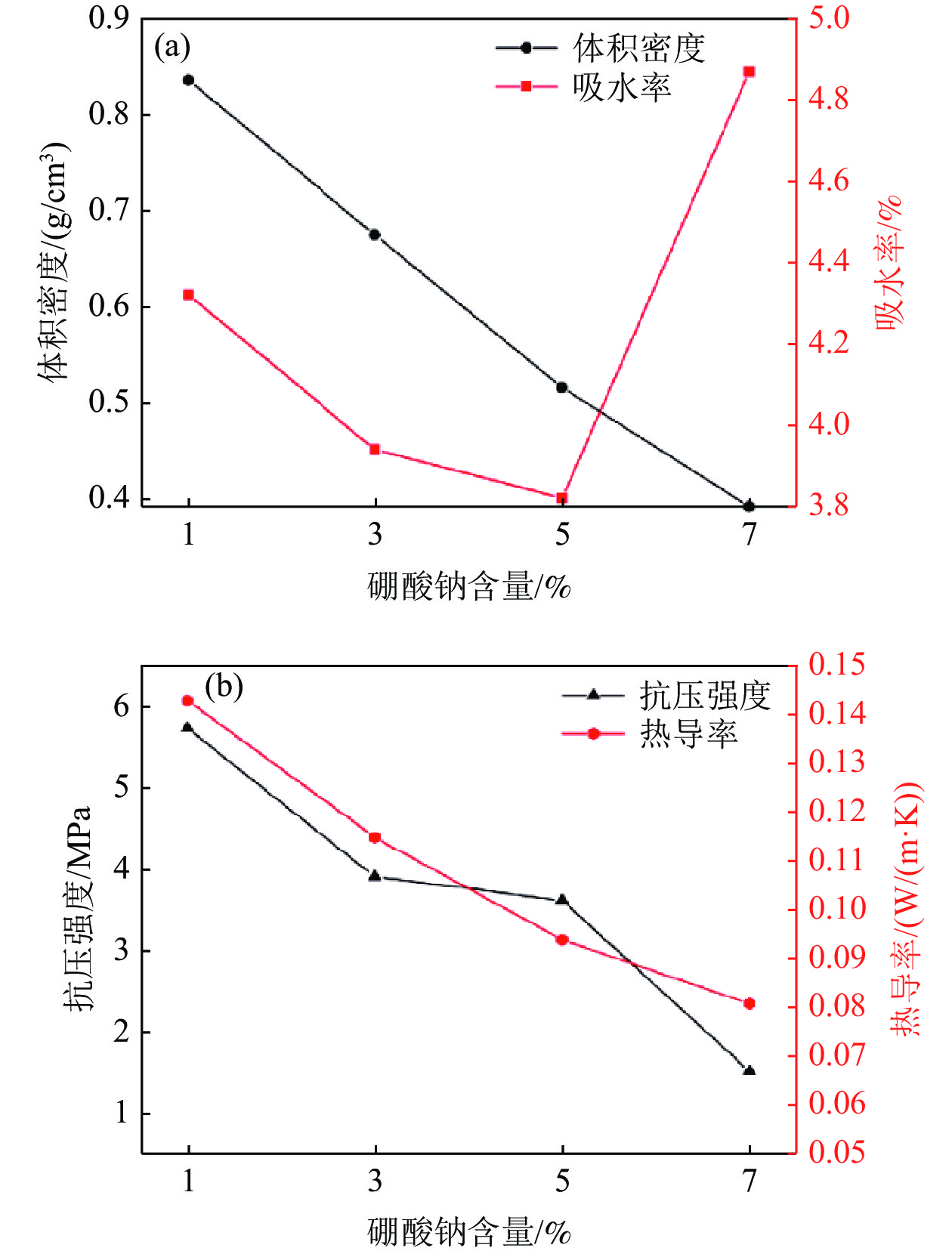

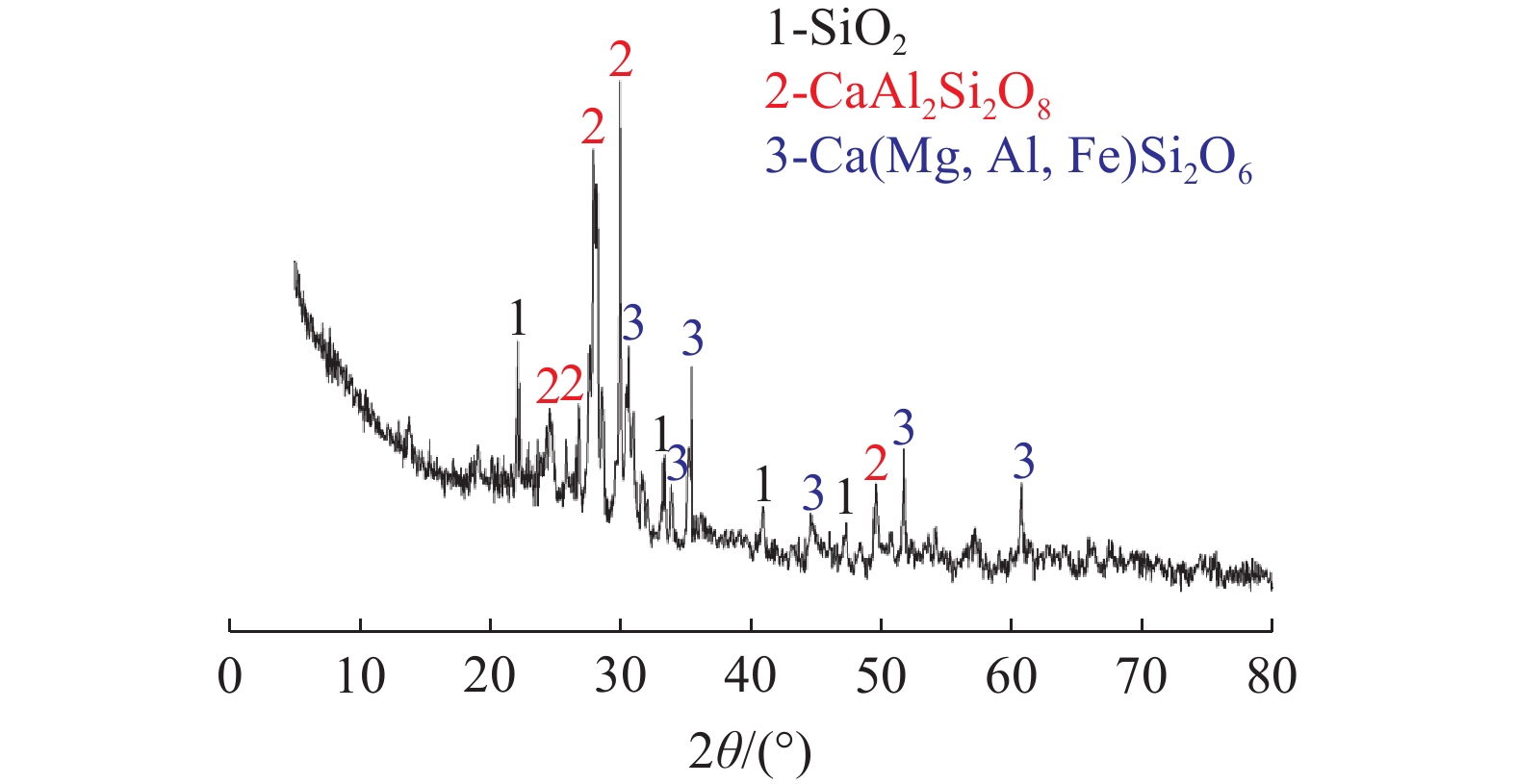

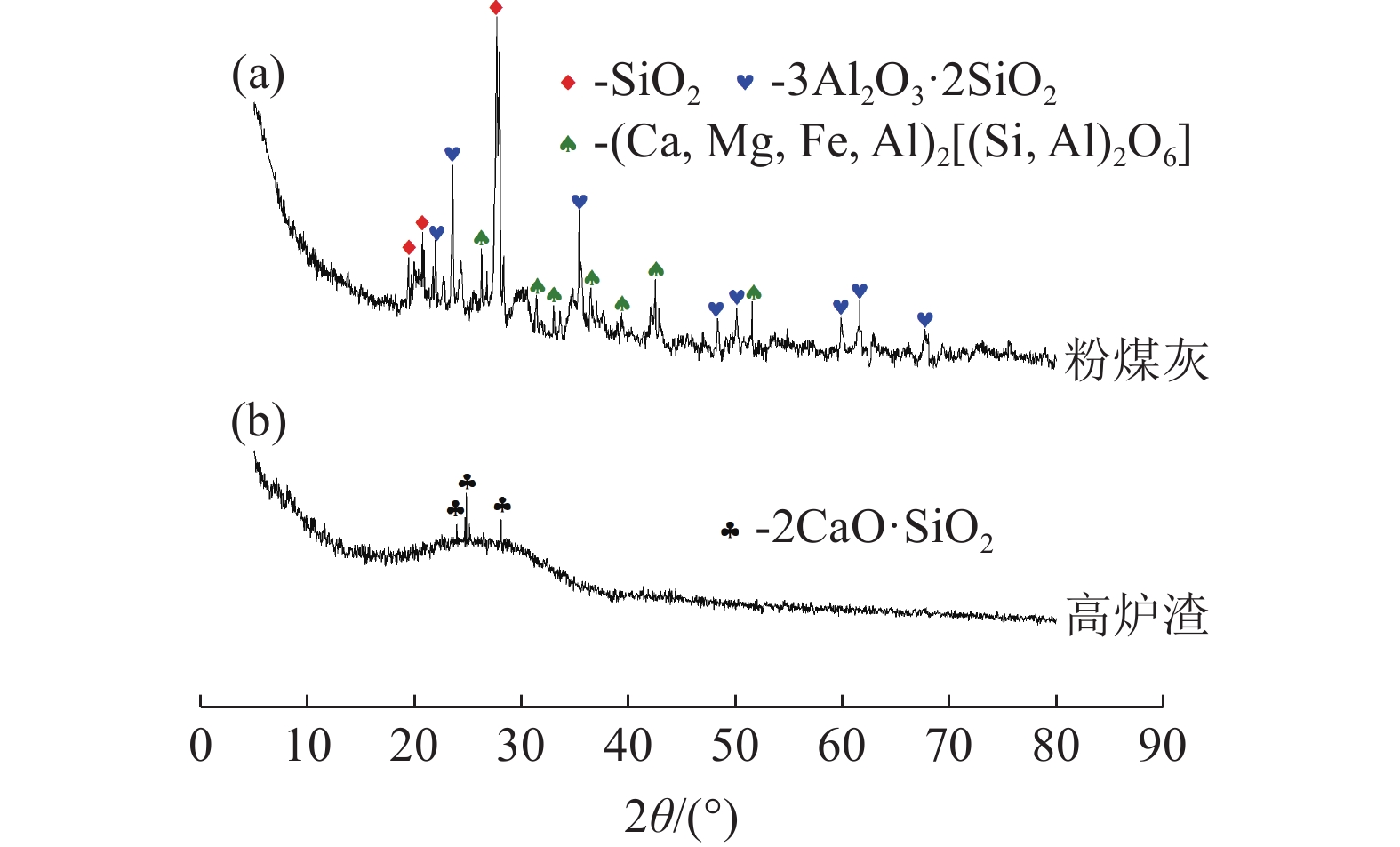

这是一篇陶瓷及复合材料领域的论文。以粉煤灰和高炉渣为主要原料,外加碳化硅(SiC)为高温发泡剂,硼酸钠(Na2B2O7)为助熔剂,采用高温烧结法制备发泡陶瓷材料。主要研究了原料配比、SiC添加量及Na2B2O7添加量对发泡陶瓷的气泡结构、体积密度、吸水率、抗压强度及导热系数的影响。实验结果表明:当粉煤灰含量为70%,高炉渣含量为30%,并额外添加0.3% SiC粉末和5% Na2B2O7,在烧成温度1 100 ℃下保温40 min时,发泡陶瓷具有较佳的综合性能,其体积密度为0.516 g/cm3,吸水率为3.82%,抗压强度为3.62 MPa,导热系数为0.094 W/(m·K)。且该条件下样品的主要物相包括石英相(SiO2)、钙长石(CaAl2Si2O8)和辉石相(Ca(Mg,Al,Fe)Si2O6),大量晶体的析出促进了材料强度的提升。本研究为粉煤灰和高炉渣等工业固体废弃物转成高附加值的建筑保温材料提供一种新方法。

Abstract:This is an article in the field of ceramics and composites.The high-temperature sintering method was used to prepare foamed ceramics by using fly ash and blast furnace slag as the main raw materials, adding silicon carbide (SiC) as a high temperature foaming agent and sodium borate (Na2B2O7) as a flux. The effects of raw material ratio, SiC addition and Na2B2O7 addition on the bubble structure, bulk density, water absorption, compressive strength and thermal conductivity of foamed ceramics were mainly studied. The experimental results showed that when the fly ash was 70%, the blast furnace slag was 30%, 0.3% SiC powder and 5% Na2B2O7 were added additionally, and the sintering temperature was 1 100℃ for 40 min, the foamed ceramic had the best comprehensive properties, and its bulk density was 0.516 g/cm3, with water absorption rate of 3.82%, compressive strength of 3.62 MPa, thermal conductivity of 0.094 W/(m·K). The main phases of the sample under this condition included quartz phase (SiO2), anorthite (CaAl2Si2O8) and pyroxene phase (Ca(Mg,Al,Fe)Si2O6), the massive precipitation of crystals enhanced the strength of the material. This research provided a new method for converting industrial solid wastes such as fly ash and blast furnace slag into high value-added building insulation materials.

-

Key words:

- Ceramics and composites /

- Foamed ceramics /

- Fly ash /

- Blast furnace slag /

- Bubble structure /

- Comprehensive properties

-

-

表 1 粉煤灰和高炉渣的化学成分/%

Table 1. Chemical composition of fly ash and blast furnace slags

名称 SiO2 Al2O3 Fe2O3 TiO2 CaO MgO K2O Na2O L.O.I 粉煤灰 57.14 23.63 4.88 1.13 4.15 1.42 2.24 0.76 4.65 高炉渣 33.81 14.12 0.69 0.57 41.82 6.27 0.33 0.46 1.93 表 2 实验配方/%

Table 2. Test formula

样品编号 粉煤灰 高炉渣 碳化硅 硼酸钠 A1 50 50 0.3 5 A2 60 40 0.3 5 A3 70 30 0.3 5 A4 80 20 0.3 5 A5 90 10 0.3 5 表 3 样品的化学组成/%

Table 3. Chemical composition of samples

样品编号 SiO2 Al2O3 Fe2O3 TiO2 CaO MgO K2O Na2O L.O.I A1 45.48 18.88 2.78 0.85 22.99 3.85 1.28 0.61 3.29 A2 47.81 19.83 3.20 0.90 19.22 3.36 1.47 0.64 3.56 A3 50.14 20.78 3.62 0.96 15.45 2.88 1.67 0.67 3.84 A4 52.47 21.73 4.04 1.02 11.69 2.39 1.86 0.70 4.11 A5 54.81 22.68 4.46 1.07 7.92 1.91 2.05 0.73 4.38 -

[1] 余江, 熊平, 刘建泉, 等. 以污泥、建筑垃圾为基料制备高强轻质发泡环保陶瓷板[J]. 四川大学学报(工程科学版), 2014, 46(5):161-167.YU J, XIONG P, LIU J Q, et al. Preparation of high-strength and light-weight environmental foaming ceramic plate using sludge and construction waste[J]. Journal of Sichuan University (Engineering Science Edition), 2014, 46(5):161-167.

YU J, XIONG P, LIU J Q, et al. Preparation of high-strength and light-weight environmental foaming ceramic plate using sludge and construction waste[J]. Journal of Sichuan University (Engineering Science Edition), 2014, 46(5):161-167.

[2] 李林, 姜涛, 陈超, 等. 攀西钒钛磁铁矿尾矿制备储水泡沫陶瓷的研究[J]. 矿产综合利用, 2020(6):7-13+6.LI L, JIANG T, CHEN C, et al. Study on preparation of water-retaining foam ceramics from vanadium-titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(6):7-13+6. doi: 10.3969/j.issn.1000-6532.2020.06.002

LI L, JIANG T, CHEN C, et al. Study on preparation of water-retaining foam ceramics from vanadium-titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(6):7-13+6. doi: 10.3969/j.issn.1000-6532.2020.06.002

[3] 赵威,韩硕,陈明堃. 钼尾矿基发泡陶瓷墙材的制备及其性能研究[J]. 商洛学院学报, 2021, 35(6):1-5+12.ZHAO W, HAN S, CHEN M K. Preparation of molybdenum tailings-based foamed ceramic wall material and its performance research[J]. Journal of Shangluo College, 2021, 35(6):1-5+12.

ZHAO W, HAN S, CHEN M K. Preparation of molybdenum tailings-based foamed ceramic wall material and its performance research[J]. Journal of Shangluo College, 2021, 35(6):1-5+12.

[4] 聂轶苗, 夏淼, 刘攀攀, 等. 粉煤灰基矿物聚合材料研究进展[J]. 矿产综合利用, 2022(4):123-128.NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128. doi: 10.3969/j.issn.1000-6532.2022.04.022

NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128. doi: 10.3969/j.issn.1000-6532.2022.04.022

[5] 康栋, 杨志杰, 张德. 粉煤灰中提取非晶态硅及硅产物的高值化利用[J]. 矿产综合利用, 2022(4):162-168.KANG D, YANG Z J, ZHANG D. Extraction of amorphous silicon from fly ash and high value utilization of silicon products[J]. Multipurpose Utilization of Mineral Resources, 2022(4):162-168. doi: 10.3969/j.issn.1000-6532.2022.04.028

KANG D, YANG Z J, ZHANG D. Extraction of amorphous silicon from fly ash and high value utilization of silicon products[J]. Multipurpose Utilization of Mineral Resources, 2022(4):162-168. doi: 10.3969/j.issn.1000-6532.2022.04.028

[6] 刘梦茹, 杨亚东, 杨素洁, 等. 粉煤灰资源综合利用现状研究[J]. 化工矿物与加工, 2021, 50(4):45-48.LIU M R, YANG Y D, YANG S J, et al. Study on statues of comprehensive utilization of fly ash[J]. Industrial Minerals & Processing, 2021, 50(4):45-48.

LIU M R, YANG Y D, YANG S J, et al. Study on statues of comprehensive utilization of fly ash[J]. Industrial Minerals & Processing, 2021, 50(4):45-48.

[7] 许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021(1):23-31.XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

[8] 王海风, 张春霞, 齐渊洪, 等. 高炉渣处理技术的现状和新的发展趋势[J]. 钢铁, 2007(6):83-87.WANG H F, ZHANG C X, QI Y H, et al. Present situation and development trend of blast furnace slag treatment[J]. Iron and Steel, 2007(6):83-87. doi: 10.3321/j.issn:0449-749X.2007.06.019

WANG H F, ZHANG C X, QI Y H, et al. Present situation and development trend of blast furnace slag treatment[J]. Iron and Steel, 2007(6):83-87. doi: 10.3321/j.issn:0449-749X.2007.06.019

[9] 刘洋, 张春霞. 钢铁渣的综合利用现状及发展趋势[J]. 矿产综合利用, 2019(2):26-30.LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):26-30. doi: 10.3969/j.issn.1000-6532.2019.02.005

LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):26-30. doi: 10.3969/j.issn.1000-6532.2019.02.005

[10] 曾珍, 张雄. 建筑保温材料的发展[J]. 上海建材, 2005(4):28-30.ZENG Z, ZHANG X. Development of building insulation materials[J]. Shanghai Building Materials, 2005(4):28-30. doi: 10.3969/j.issn.1006-1177.2005.04.014

ZENG Z, ZHANG X. Development of building insulation materials[J]. Shanghai Building Materials, 2005(4):28-30. doi: 10.3969/j.issn.1006-1177.2005.04.014

[11] LIU T Y, LI X Y, GUAN L M, et al. Low-cost and environment-friendly ceramic foams made from ead-zinc mine tailings and red mud: Foaming mechanism, physical, mechanical and chemical properties[J]. Ceramics International, 2016, 42(1):1733-1739. doi: 10.1016/j.ceramint.2015.09.131

[12] 马子钧. 利用硅酸盐工业废(尾)矿制备发泡陶瓷的研究[D]. 北京: 北京工业大学, 2019.MA Z J. Preparation of foamed ceramics from silicate industrial waste (tailing) ore[D]. Beijing: Beijing University of Industry, 2019.

MA Z J. Preparation of foamed ceramics from silicate industrial waste (tailing) ore[D]. Beijing: Beijing University of Industry, 2019.

[13] XI C P, ZHENG F, XU J H, et al. Preparation of glass-ceramic foams using extracted titanium tailing and glass waste as raw materials[J]. Construction and Building Materials, 2018, 190:896-909. doi: 10.1016/j.conbuildmat.2018.09.170

[14] CHEN X J, LU A X, QU G. Preparation and characterization of foam ceramics from red mud and fly ash using sodium silicate as foaming agent[J]. Ceramics International, 2013, 39(2):1923-1929. doi: 10.1016/j.ceramint.2012.08.042

-

下载:

下载: