Study on Comprehensive Properties of Cement-based Backfill based on Phosphogypsum Modification

-

摘要:

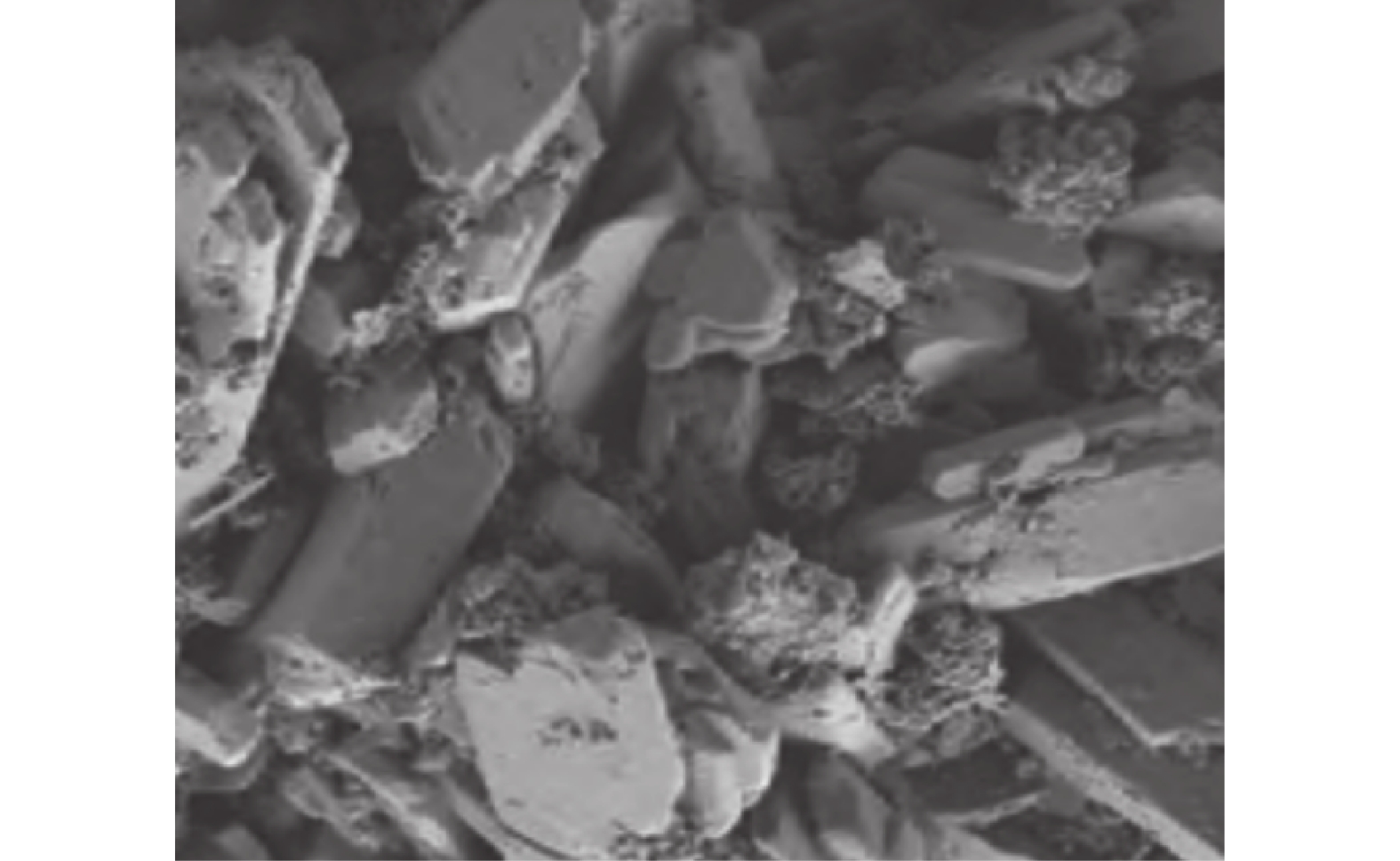

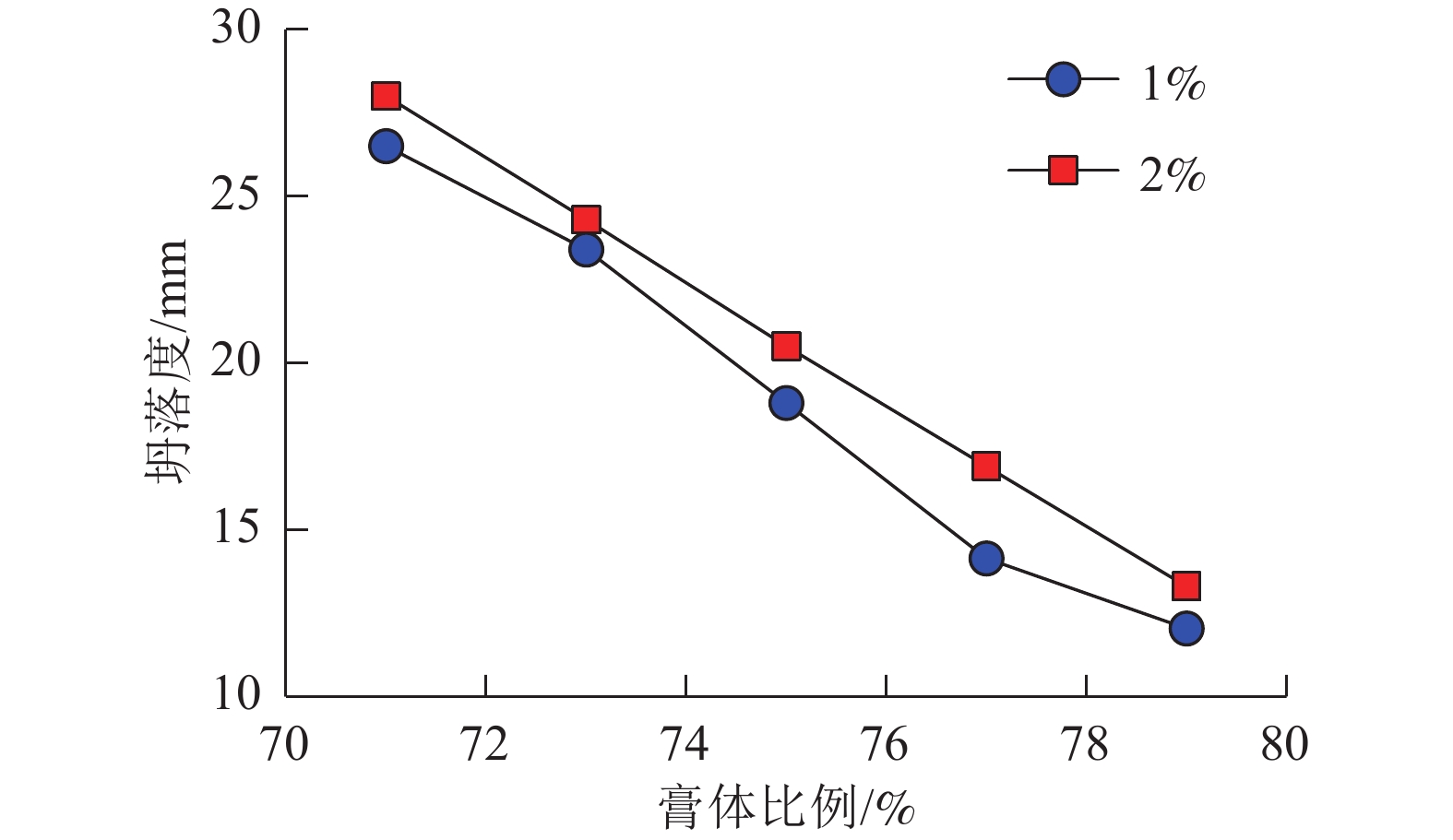

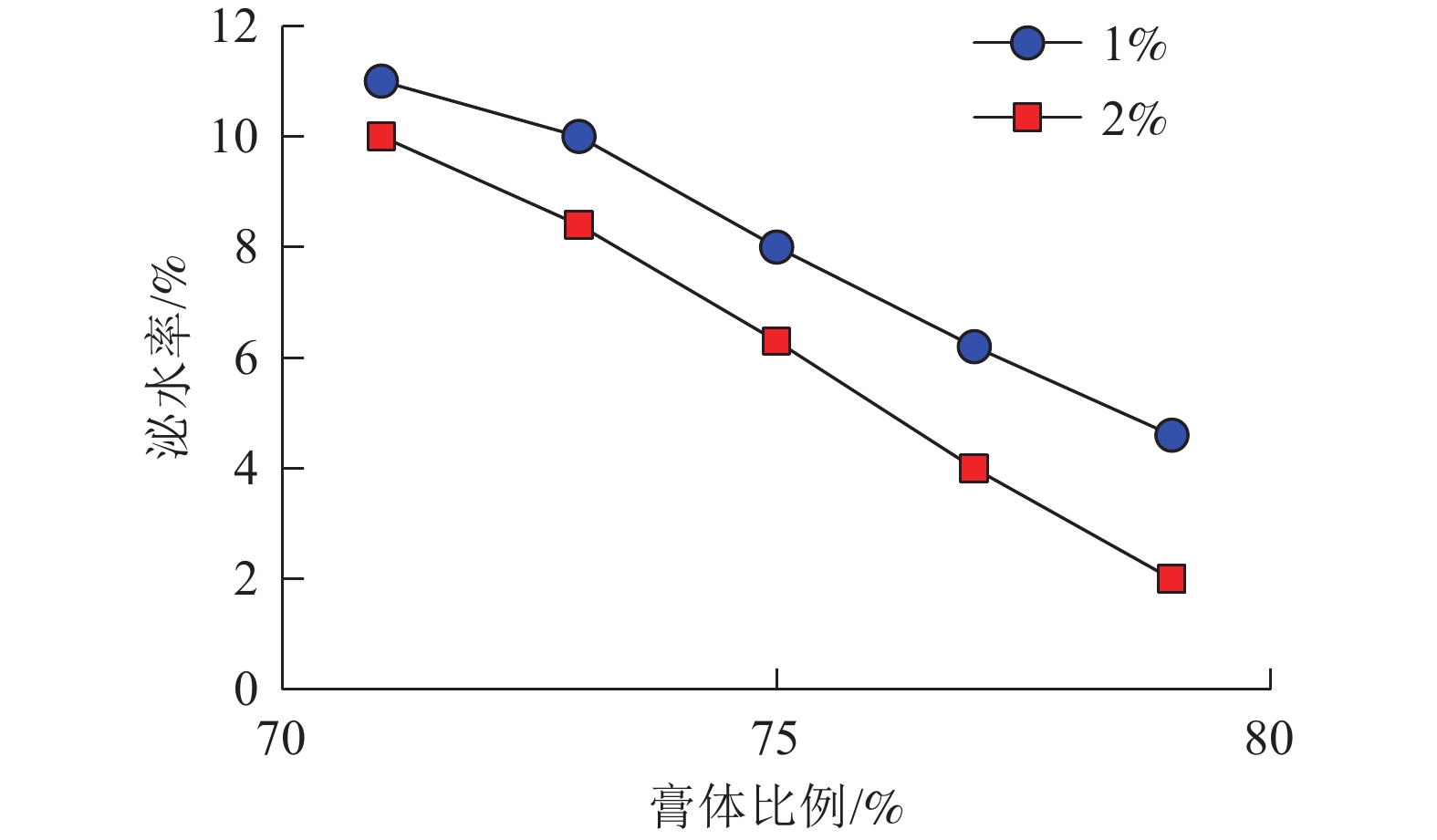

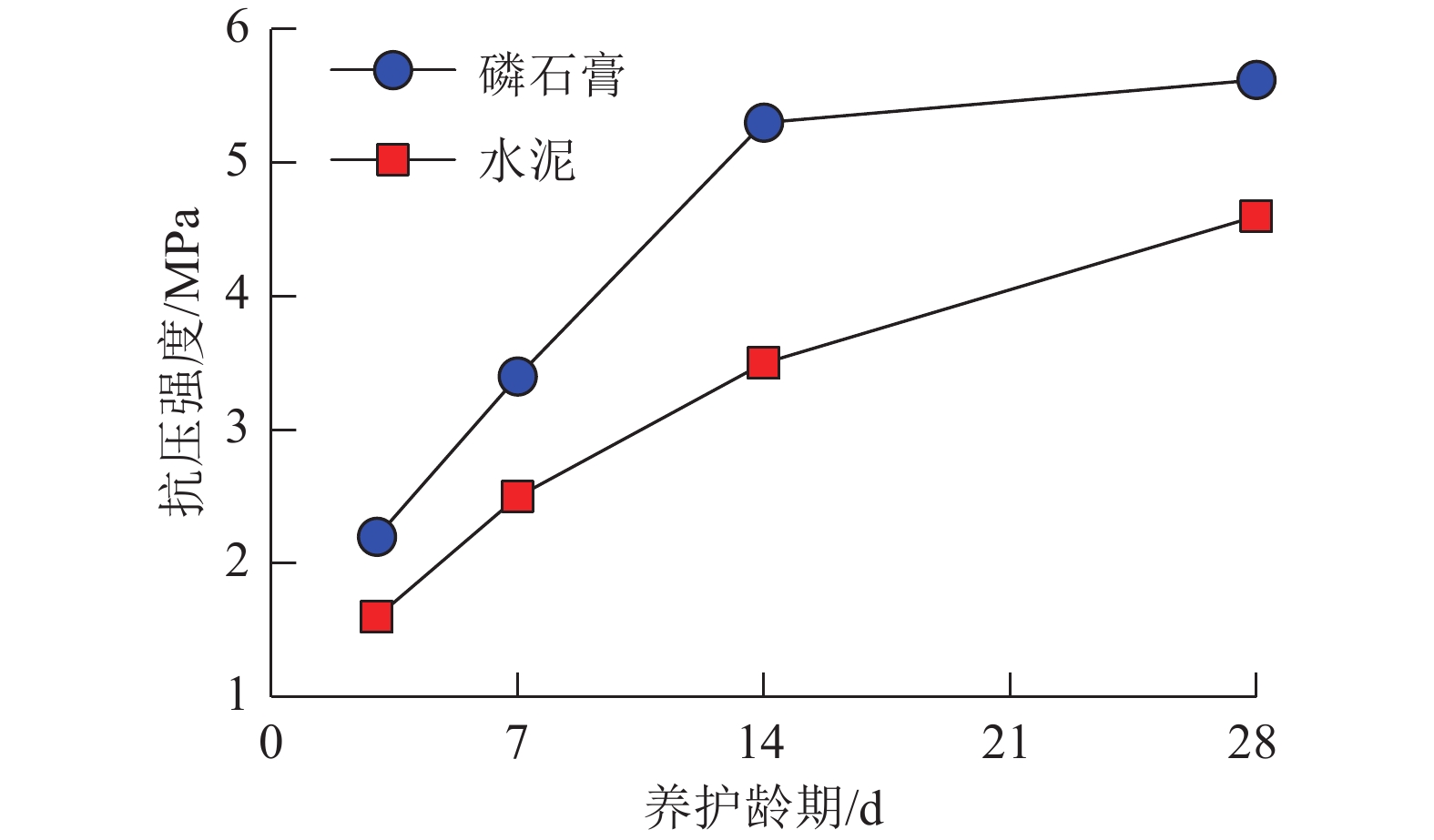

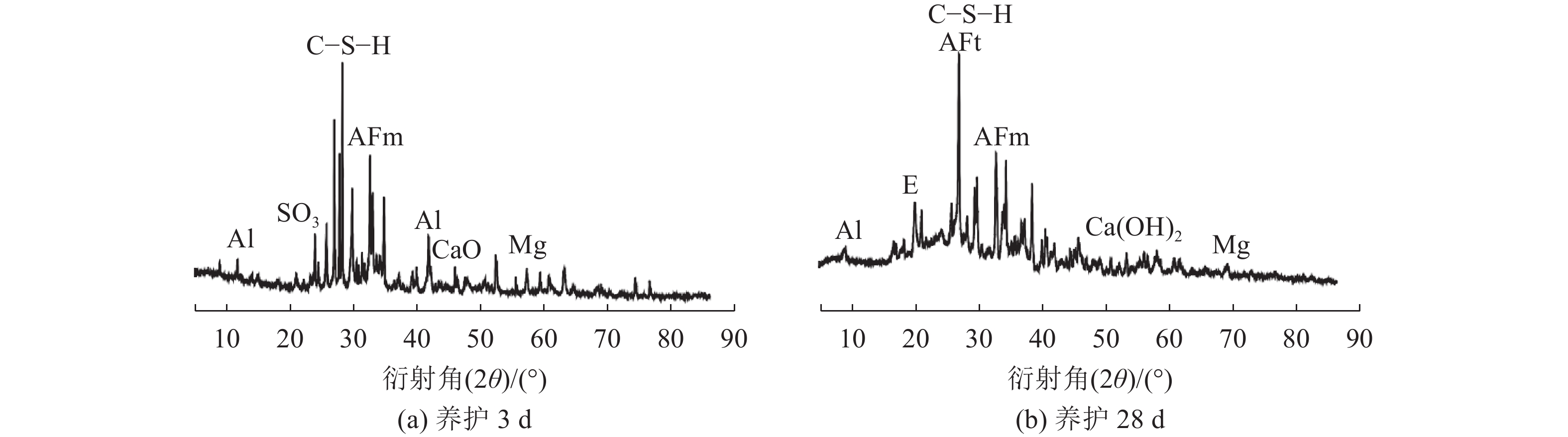

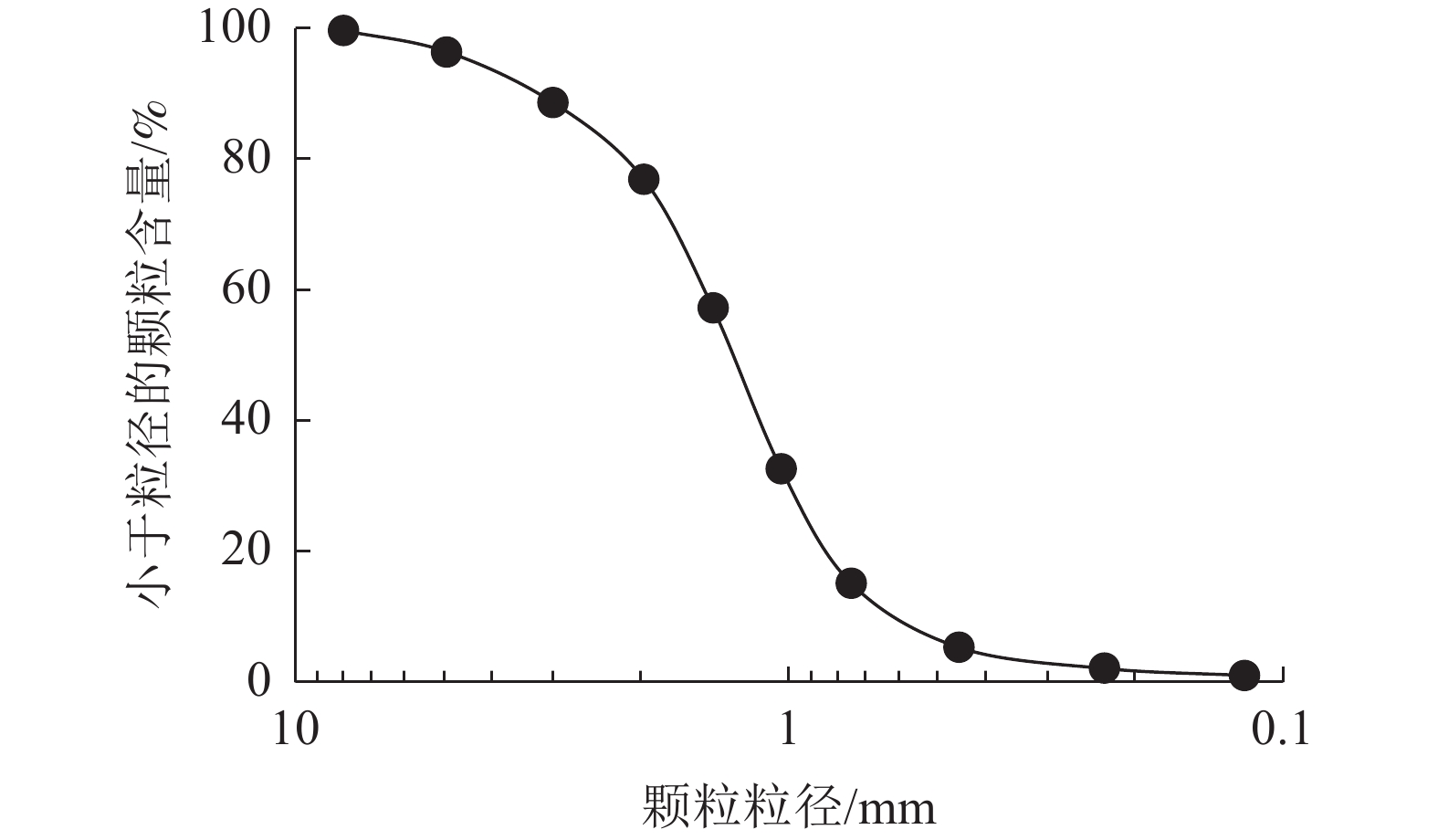

这是一篇陶瓷及复合材料领域的论文。为了提高矿物资源综合利用率与充填采矿工艺,以磷石膏、水泥与尾矿砂等矿物固体废料为集料制备矿山充填体材料,开展料浆综合找工作性能、矿物成分与微观形态的分析研究,结合分子动力学模拟对水化物分子结构进行讨论。结果发现:磷石膏的掺入使得水泥基充填料的坍落度显著提高,泌水率下降,抗压强度表现出上升趋势,随养护时间增加,材料强度值显著提高;养护28 d的磷石膏改性充填体的强度值约为水泥基充填的1.2倍;磷石膏改性充填料中的水化硅酸钙与钙矾石为主要水化产物;扫描电子显微镜图像显示磷石膏改性充填料的微观结构较为致密,微裂隙较少;数值模拟结果表明水化硅酸钙的弹性模量明显高于钙矾石,提高充填料强度性能的关键在于促进水化硅酸钙的形成。

Abstract:This is an article in the field of ceramics and composites. In order to improve the comprehensive utilization of mineral resources and mining technology, mine filling materials are prepared from mineral solid wastes such as phosphogypsum, cement and tailing sands as aggregates, analytical studies of the slurry's comprehensive search performance, mineral composition and microscopic morphology are carried out, and the molecular structure of hydrides is discussed in conjunction with molecular dynamics simulations. The results showed that the addition of phosphogypsum significantly increased the slump of the modified filler, decreased the bleeding rate, and the compressive strength showed a rising trend. The strength value of the modified filler increased significantly with the curing time. The strength of phosphogypsum modified backfill after curing for 28 d is about 1.2 times that of cement backfill. Calcium silicate hydrate and ettringite in phosphogypsum modified filling materials are the main hydration products. SEM image shows that the microstructure of phosphogypsum modified filling materials is relatively compact and there are few micro-cracks. The numerical simulation results show that the elastic modulus of calcium silicate hydrate is higher than that of ettringite. The key to improving the strength of filling material is to promote the formation of calcium silicate hydrate.

-

-

表 1 不同物料的化学组成/%

Table 1. Chemical composition of different materials

物料 CaO SiO2 SO3 Al3O2 MgO Fe3O2 Na2O P2O3 其他 磷石膏 37.1 5.3 42.5 5.7 3.3 0 0 2.2 2.9 水泥 63.8 16.5 0 8.5 4.5 4.1 0 0 2.6 尾矿砂 17.1 38.6 0 18.4 0 23.2 0 0 2.7 表 2 充填料分子动力学优化前后的力学参数

Table 2. Mechanical parameters before and after molecular dynamics optimization

力学指标 Aft C-S-H AC-1 AC-2 弹性模量/GPa 2.3 37.6 27.5 31.7 体积模量/GPa 6.5 13.8 11.9 15.2 泊松比 0.39 0.28 0.21 0.24 -

[1] 卢君勇, 吴浪, 阳开, 等. 龙四川省马边老河坝磷矿重金属污染分析[J]. 矿产综合利用, 2022(2):187-193.LU J Y, WU L, YANG K, et al. Analysis of heavy metal pollution in the environment of Laoheba phosphate mine in Mabian Rregion, Sichuan province[J]. Multipurpose Utilization of Mineral Resources, 2022(2):187-193.

LU J Y, WU L, YANG K, et al. Analysis of heavy metal pollution in the environment of Laoheba phosphate mine in Mabian Rregion, Sichuan province[J]. Multipurpose Utilization of Mineral Resources, 2022(2):187-193.

[2] 李夕兵, 刘冰, 姚金蕊, 等. 全磷废料绿色充填理论与实践[J]. 中国有色金属学报, 2018, 28(9):1845-1865.LI X B, LIU B, YAO J R, et al. Theory and practice of green filling of all-phosphorus waste[J]. China Journal of Nonferrous Metals, 2018, 28(9):1845-1865.

LI X B, LIU B, YAO J R, et al. Theory and practice of green filling of all-phosphorus waste[J]. China Journal of Nonferrous Metals, 2018, 28(9):1845-1865.

[3] 卓庆奉, 巴蕾, 王奇峰. 掺粉煤灰的混合充填骨料配比优化实验[J]. 矿产综合利用, 2021(3):187-192.ZHUO Q F, BA L, WANG Q F. Optimum experiment of aggregate proportion for mixed filling with fly ash[J]. Multipurpose Utilization of Mineral Resources, 2021(3):187-192.

ZHUO Q F, BA L, WANG Q F. Optimum experiment of aggregate proportion for mixed filling with fly ash[J]. Multipurpose Utilization of Mineral Resources, 2021(3):187-192.

[4] 张友锋, 付玉华. 基于正交实验充填体力学性能及配比优化研究[J]. 有色金属工程, 2021, 11(10):114-122.ZHANG Y F, FU Y H. Optimization study of mechanical properties and proportioning of filling body based on orthogonal experiment[J]. Nonferrous Metal Engineering, 2021, 11(10):114-122.

ZHANG Y F, FU Y H. Optimization study of mechanical properties and proportioning of filling body based on orthogonal experiment[J]. Nonferrous Metal Engineering, 2021, 11(10):114-122.

[5] 王圳, 张均, 陈芳, 等. 贵州省磷矿固体废弃物治理现状与建议[J]. 矿产综合利用, 2019(1): 11-15.WANG Z , ZHANG J, CHEN F, et al. Present situation and suggestion of management of phosphate rock solid waste[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 11-15.

WANG Z , ZHANG J, CHEN F, et al. Present situation and suggestion of management of phosphate rock solid waste[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 11-15.

[6] 冯国瑞, 贾学强, 郭育霞, 等. 废弃混凝土粗骨料对充填膏体性能的影响[J]. 煤炭学报, 2015, 40(6):1320-1325.FENG G R, JIA X Q, GUO Y X, et al. Influence of waste concrete coarse aggregate on the performance of filling paste[J]. Journal of Coal, 2015, 40(6):1320-1325.

FENG G R, JIA X Q, GUO Y X, et al. Influence of waste concrete coarse aggregate on the performance of filling paste[J]. Journal of Coal, 2015, 40(6):1320-1325.

[7] 兰文涛, 吴爱祥, 王贻明. 凝水膨胀充填复合材料的配比优化与形成机制[J]. 复合材料学报, 2019, 36(6):1536-1545.LAN W T, WU A X, WANG Y M. Ratio optimization and formation mechanism of condensate swelling filled composites[J]. Journal of Composite Materials, 2019, 36(6):1536-1545.

LAN W T, WU A X, WANG Y M. Ratio optimization and formation mechanism of condensate swelling filled composites[J]. Journal of Composite Materials, 2019, 36(6):1536-1545.

[8] 杨晓炳, 王永定, 高谦, 等. 利用脱硫灰渣和粉煤灰开发充填胶凝材料[J]. 矿产综合利用, 2019(4):130-134.YANG X B, WANG Y D, GAO Q, et al. Research on a new cementitious materials with desulphurization ash and fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(4):130-134.

YANG X B, WANG Y D, GAO Q, et al. Research on a new cementitious materials with desulphurization ash and fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(4):130-134.

[9] 姜关照, 吴爱祥, 王贻明, 等. 生石灰对半水磷石膏充填胶凝材料性能影响[J]. 硅酸盐学报, 2020, 48(1):86-93.JIANG G Z, WU A X, WANG Y M, et al. Effect of quicklime on the properties of semi-anhydrous phosphogypsum-filled cementitious materials[J]. Journal of Silicate, 2020, 48(1):86-93.

JIANG G Z, WU A X, WANG Y M, et al. Effect of quicklime on the properties of semi-anhydrous phosphogypsum-filled cementitious materials[J]. Journal of Silicate, 2020, 48(1):86-93.

[10] 单志伟, 李凤久, 刘立伟, 等. 超细粉磨活化河北某磷矿粉实验研究[J]. 矿产综合利用, 2020(2):55-59.SHAN Z W, LI F J, LIU L W, et al. Experimental study on activation of a phosphate rock powder in Hebei by ultrafine grinding[J]. Multipurpose Utilization of Mineral Resources, 2020(2):55-59.

SHAN Z W, LI F J, LIU L W, et al. Experimental study on activation of a phosphate rock powder in Hebei by ultrafine grinding[J]. Multipurpose Utilization of Mineral Resources, 2020(2):55-59.

-

下载:

下载: