Process Test on Recovery of Fluorite and Strontium-barium Minerals from a Rare Earth Tailing Ore

-

摘要:

这是一篇矿物加工工程领域的论文。某稀土矿矿石中伴生萤石和锶钡矿物,由于该样品成分和嵌布关系复杂,矿物嵌布粒度细,且萤石和锶钡矿物浮选性质相近,常规药剂和工艺无法实现样品中伴生萤石和锶钡矿物的富集和分离,影响当地生态环境,造成国家矿产资源的重大浪费。针对该样品,开展浮选药剂优选和工艺优化,形成适于该稀土尾矿资源化利用的混合浮选-分离再提纯选矿工艺。研究结果表明,针对SrO品位为8%,CaF2品位为16%的稀土尾矿,经混合浮选-再分离提纯工艺可以得到品位为90%的萤石精矿和锶钡混合精矿纯度90%的锶钡精矿,研究结果可以为同类型尾矿资源化利用提供借鉴。

Abstract:This is an article in the field of mineral processing engineering.Tailings in China are rich in strontium-barium-bearing minerals and fluorite minerals. Due to the complex distribution relationship of the minerals, it’s very difficult to recover the minerals. In this article, the mixed flotation and separation beneficiation process was developed for the utilization of the tailings. The research results indicate that for the tailings with 8% SrO grade and 16% CaF2 grade, the fluorite concentrate with 91% CaF2 grade and the strontium-barium bearing mineral concentrate with more than 90% mineral purity can be obtained. The research results can provide technical support for tailings resource utilization, reduction and harmlessness in China.

-

-

表 1 样品主要化学成分分析结果/%

Table 1. Analysis results of main chemical composition of the samples

TREO SrO CaF2 BaO SiO2 Al2O3 MgO Fe2O3 S K2O MnO Ti ThO2 Zn Pb 1.70 8.72 18.80 2.33 26.66 5.66 0.53 2.60 3.8 2.24 0.20 0.31 0.007 3 0.023 0.17 表 2 样品矿物组成及相对含量

Table 2. Mineral composition and relative content of the samples

矿物 重晶石 天青石 钡锶互含硫酸盐 氟碳铈镧 氟碳钙铈镧 角闪石 黄铁矿 方铅矿 磷灰石 含量/% 0.25 6.45 11.82 1.87 0.68 0.51 0.5 0.3 0.1 矿物 萤石 石英 辉石 方解石 碳酸锶矿 赤褐铁矿 长石 云母 绿泥石 含量/% 18.1 11.36 0.36 10.82 0.86 2.7 28.12 5.46 0.29 表 3 重选探索实验结果

Table 3. Test results of the gravity beneficiation

重选设备 产品名称 产率/% 品位/% 回收率/% CaF2 SrO CaF2 SrO 尼克森重选 重选精矿 19.33 21.08 18.18 22.21 45.02 重选尾矿 80.67 17.69 5.32 77.79 54.98 给矿 100.00 18.35 7.81 100.00 100.00 摇床重选 重选精矿 6.65 15.33 24.97 5.49 21.85 重选中1 39.03 22.67 8.08 47.61 41.49 重选尾矿 54.32 16.05 5.13 46.90 36.66 给矿 100.00 18.59 7.60 100.00 100.00 表 4 混浮-分离浮选开路实验结果

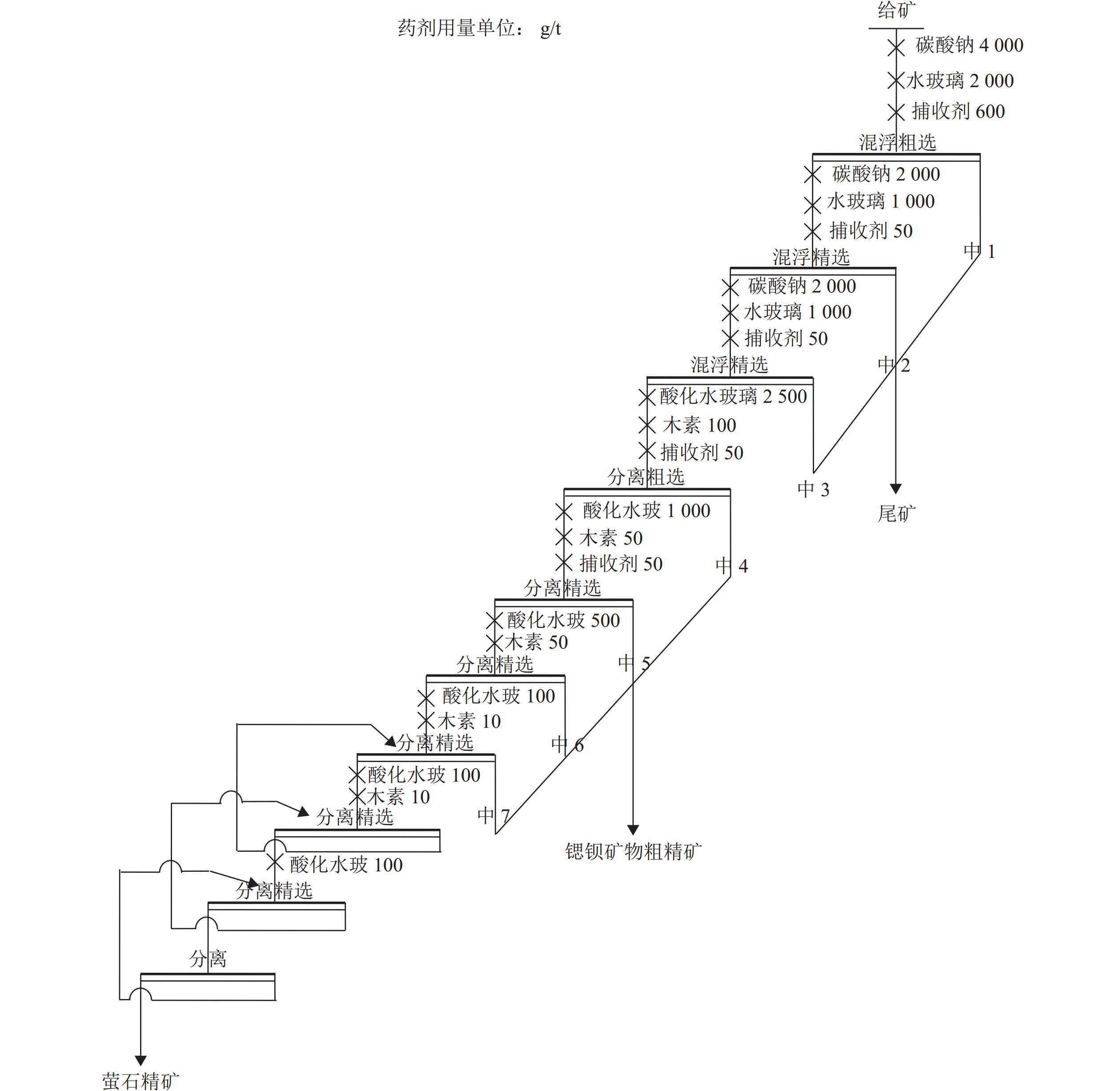

Table 4. Results of open-circuit tests

产品名称 产率/% 品位/% 回收率/% CaF2 SrO CaF2 SrO 精矿 7.92 91.62 1.51 38.90 1.52 中7 0.87 64.88 3.28 3.03 0.36 中6 1.34 58.12 6.39 4.17 1.09 中5 2.66 44.57 7.59 6.36 2.56 中4 3.86 29.16 9.76 6.04 4.78 中3 6.66 25.04 14.47 8.94 12.22 中2 9.06 19.67 19.25 9.56 22.14 中1 17.63 15.33 17.98 14.49 40.23 尾矿3 5.28 10.82 6.88 3.07 4.61 尾矿2 9.18 5.03 5.09 2.48 5.93 尾矿1 35.54 1.56 1.01 2.97 4.55 给矿 100.00 18.65 7.88 100.00 100.00 表 5 混浮-分离浮选闭路实验结果

Table 5. Results of closed-circuit tests

产品名称 产率/% 品位/% 回收率/% CaF2 SrO CaF2 SrO 萤石精矿 8.80 90.78 1.41 42.55 1.47 萤石尾矿 7.93 37.16 8.76 15.70 8.26 锶钡粗精 33.50 18.60 18.96 33.21 75.53 尾矿 49.77 3.22 2.49 8.54 14.74 给矿 100.00 18.77 8.41 100.00 100.00 表 6 萤石精矿产品/%

Table 6. Fluorite concentrate products

CaF2 REO SrO Fe2O3 SiO2 Al2O3 BaO K2O P2O5 PbO CuO 90.78 2.50 1.41 0.12 0.92 0.09 0.29 0.04 0.097 0.19 0.02 表 7 重选实验结果

Table 7. Test results of the gravity beneficiation

产品名称 产率/% SrO品位/% SrO回收率/% 重选精矿 18.14 33.83 35.85 重选尾矿 81.86 15.42 64.15 给矿 100.00 18.76 100.00 表 8 锶钡精矿化学多项分析结果/%

Table 8. Analysis results of main chemical composition of the concentrate

SrO BaO SO3 CaF2 Fe2O3 SiO2 Al2O3 NaO K2O MgO PbO 33.83 20.95 37.20 2.14 0.19 0.31 0.0071 0.068 0.016 0.016 0.011 -

[1] 陈军元, 刘艳飞, 颜玲亚. 萤石资源现状及战略性价值分析[J]. 矿产保护与利用, 2019(6):62-68.CHEN J Y, LIU Y F, YAN L Y. Research on development trend of strategic nonmetallic minerals such as graphite and fluorite[J]. Multipurpose Utilization of Mineral Resources, 2019(6):62-68.

CHEN J Y, LIU Y F, YAN L Y. Research on development trend of strategic nonmetallic minerals such as graphite and fluorite[J]. Multipurpose Utilization of Mineral Resources, 2019(6):62-68.

[2] 李敬, 张寿庭, 商朋强. 我国氟化工行业应寻求差异化发展[J]. 化工管理, 2014, 28:32.LI J, ZHANG S T, SHANG P Q. Present situation and analysis of strategic value of fluorite resource[J]. Conservation and Utilization of Mineral Resources, 2014, 28:32. doi: 10.3969/j.issn.1008-4800.2014.01.011

LI J, ZHANG S T, SHANG P Q. Present situation and analysis of strategic value of fluorite resource[J]. Conservation and Utilization of Mineral Resources, 2014, 28:32. doi: 10.3969/j.issn.1008-4800.2014.01.011

[3] 何宇, 刘作华, 栾进华, 等. 锶废渣直接制备锶钡铁氧体材料研究[J]. 功能材料, 2021(4):4007-4011.HE Y, LIU Z H, LUAN J H, et al. Preparation of strontium barium ferrite material with strontium waste residue by direct method[J]. Journal of Functional Materials, 2021(4):4007-4011 doi: 10.3969/j.issn.1001-9731.2021.04.002

HE Y, LIU Z H, LUAN J H, et al. Preparation of strontium barium ferrite material with strontium waste residue by direct method[J]. Journal of Functional Materials, 2021(4):4007-4011 doi: 10.3969/j.issn.1001-9731.2021.04.002

[4] 朱志敏, 罗丽萍, 曾令熙. 四川德昌大陆槽稀土矿工艺矿物学[J]. 矿产综合利用, 2016(5):76-79.ZHU Z M, LUO L P, ZENG L X. The process mineralogy of the Dalucao REE deposit in the Sichuan Province[J]. Multipurpose Utilization of Mineral Resources, 2016(5):76-79. doi: 10.3969/j.issn.1000-6532.2016.05.018

ZHU Z M, LUO L P, ZENG L X. The process mineralogy of the Dalucao REE deposit in the Sichuan Province[J]. Multipurpose Utilization of Mineral Resources, 2016(5):76-79. doi: 10.3969/j.issn.1000-6532.2016.05.018

[5] 曾小波, 印万忠. 共伴生型萤石矿浮选研究进展与展望[J]. 矿产综合利用, 2021(1):1-7.ZENG X B, YIN W Z. Research progress and prospect of flotation of associated fluorite minerals[J]. Multipurpose Utilization of Mineral Resources, 2021(1):1-7. doi: 10.3969/j.issn.1000-6532.2021.01.001

ZENG X B, YIN W Z. Research progress and prospect of flotation of associated fluorite minerals[J]. Multipurpose Utilization of Mineral Resources, 2021(1):1-7. doi: 10.3969/j.issn.1000-6532.2021.01.001

[6] 李伦, 曾小波, 严伟平, 等. 新疆某低品位萤石矿浮选实验研究[J]. 矿产综合利用, 2023(4):127-132.LI L, ZENG X B, YAN W P, et al. Flotation of a low grade fluorite ore in Xinjiang multipurpose utilization of mineral resources[J]. Multipurpose Utilization of Mineral Resources, 2023(4):127-132. doi: 10.3969/j.issn.1000-6532.2023.04.019

LI L, ZENG X B, YAN W P, et al. Flotation of a low grade fluorite ore in Xinjiang multipurpose utilization of mineral resources[J]. Multipurpose Utilization of Mineral Resources, 2023(4):127-132. doi: 10.3969/j.issn.1000-6532.2023.04.019

[7] 汤家焰, 张少杰, 张静茹. 碳酸钠对细粒萤石和石英的分散作用机理[J]. 非金属矿, 2020, 43(6):17-20.TANG J Y, ZHANG S J, ZHANG J R. Dispersion mechanism of sodium carbonate on fine fluorite and quartz[J]. Non-Metallic Mines, 2020, 43(6):17-20. doi: 10.3969/j.issn.1000-8098.2020.06.005

TANG J Y, ZHANG S J, ZHANG J R. Dispersion mechanism of sodium carbonate on fine fluorite and quartz[J]. Non-Metallic Mines, 2020, 43(6):17-20. doi: 10.3969/j.issn.1000-8098.2020.06.005

[8] 汤家焰, 张静茹, 祝雯. 硅酸钠对细粒萤石和石英的分散作用机理[J]. 矿冶工程, 2021, 41(5):63-67.TANG J Y, ZHANG J R, ZHU W. Dispersion mechanism of sodium silicate on fine fluorite and quartz[J]. Mining and Metallurgical Engineering, 2021, 41(5):63-67. doi: 10.3969/j.issn.0253-6099.2021.05.015

TANG J Y, ZHANG J R, ZHU W. Dispersion mechanism of sodium silicate on fine fluorite and quartz[J]. Mining and Metallurgical Engineering, 2021, 41(5):63-67. doi: 10.3969/j.issn.0253-6099.2021.05.015

[9] 蒋海勇, 张发明, 陈志杰. 酸化水玻璃对重晶石与白云石浮选分离行为的影响[J]. 矿产综合利用, 2022(2):121-126.JANG H Y, ZHANG F M, CHEN Z J. The effect of acidized sodium silicate on flotation separation behavior of barite and dolomite[J]. Multipurpose Utilization of Mineral Resources, 2022(2):121-126. doi: 10.3969/j.issn.1000-6532.2022.02.022

JANG H Y, ZHANG F M, CHEN Z J. The effect of acidized sodium silicate on flotation separation behavior of barite and dolomite[J]. Multipurpose Utilization of Mineral Resources, 2022(2):121-126. doi: 10.3969/j.issn.1000-6532.2022.02.022

-

下载:

下载: