Hydration Characteristics of Excess-sulfate Titanium Gypsum Slag Cement

-

摘要:

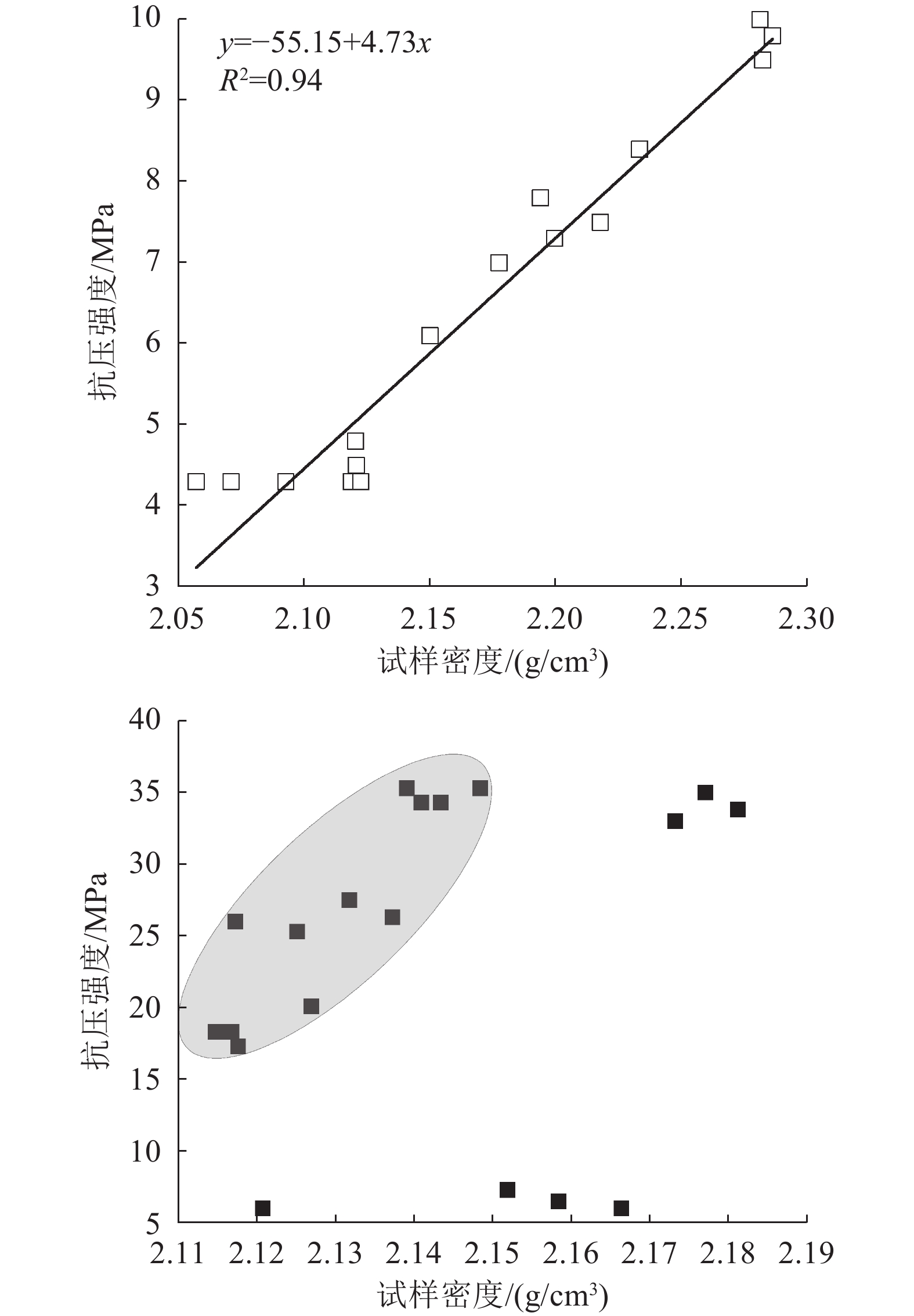

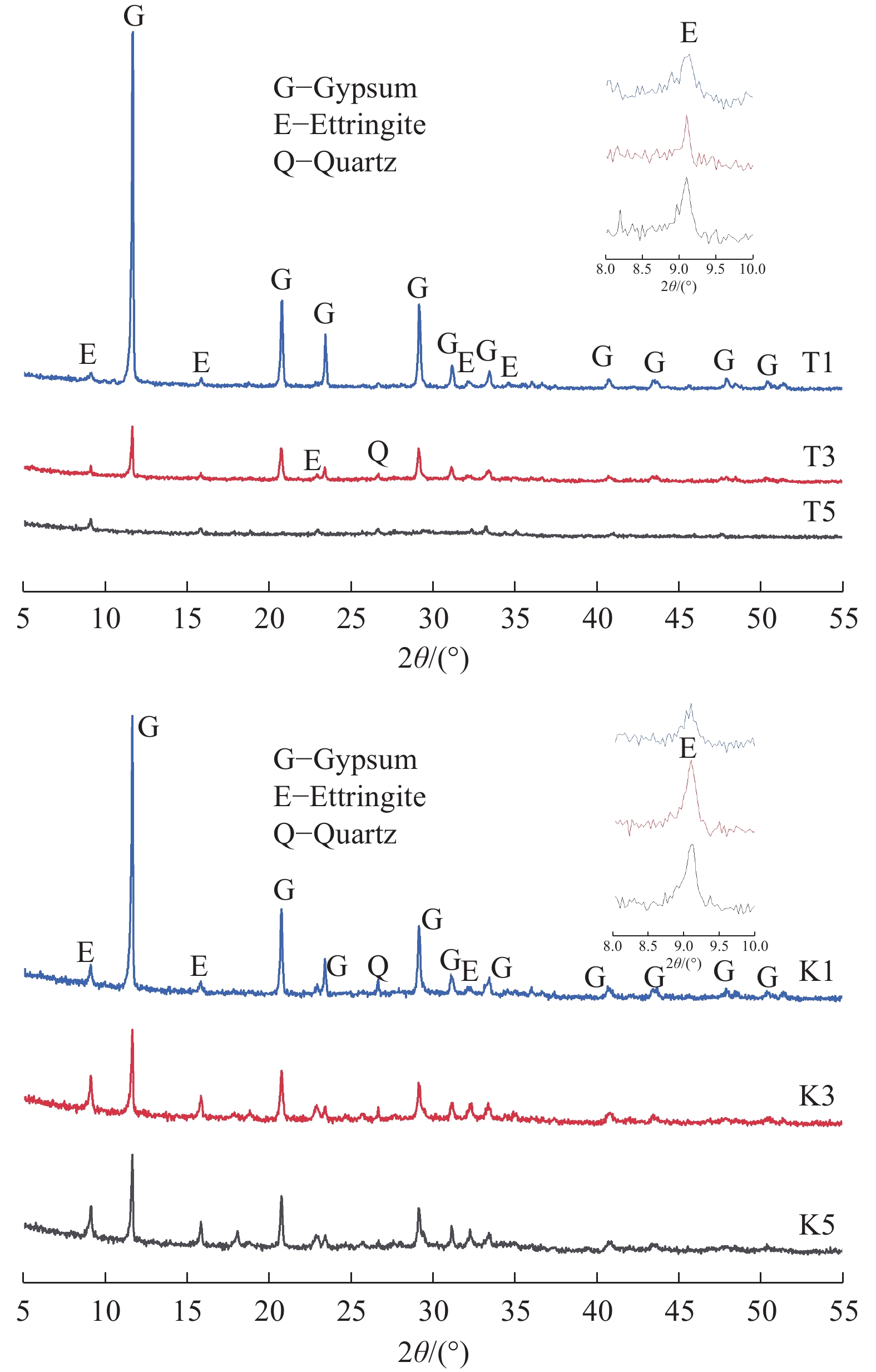

这是一篇矿物材料领域的论文。借鉴工业副产石膏与矿渣复合制备胶凝材料的经验,设计了若干组过硫钛石膏矿渣水泥,对该水泥的标准稠度用水量、凝结时间、力学性能和耐水性进行了研究,并对水化产物进行了XRD和SEM分析。结果表明,钛石膏会增大标准稠度用水量,并延长凝结时间,对力学性能和耐水性均有不利影响。通过适当增加熟料掺量可以弥补钛石膏的不利影响,当熟料掺量达到25%时,复合胶凝材料的28 d抗压强度达到30 MPa。在钛石膏和熟料掺量较高的实验组中,水化产物主要以钙矾石和水化硅(铝)酸钙为主,而矿渣掺量较高和熟料掺量较低的实验组中,水化产物主要是无定形水化硅(铝)酸钙。

Abstract:This is an article in the field of mineral materials. Based on the experience of cementing materials composited with industrial by-product gypsum and slag , several sets of excess-sulfate titanium gypsum slag cement were designed, and the water requirement of normal consistency, setting time, mechanical properties and water resistance of the cement were studied, and the hydration products were analyzed by XRD and SEM. The results show that titanium gypsum can increase the water requirement of normal consistency and prolong the setting time, which has an adverse effect on the mechanical properties and water resistance. The adverse effect of titanium gypsum can be compensated by increasing the content of clinker appropriately. When the content of clinker is 25%, the compressive strength of composite cementing material can reach 30 MPa at 28 d. In the experimental group with higher titanium gypsum or clinker content, the hydration products were mainly ettringite and calcium silicate/aluminate hydrate, while in the experimental group with higher content of slag and lower content of clinker, the hydration products were mainly amorphous calcium silicate/aluminate hydrate.

-

Key words:

- Mineral materials /

- Titanium gypsum /

- Slag /

- Ettringite /

- Calcium silicate/aluminate hydrate

-

-

表 1 原材料的XRF分析结果/%

Table 1. XRF analysis results of raw materials

成分 CaO SiO2 TiO2 Al2O3 MgO Fe2O3 SO3 P2O5 Na2O K2O MnO 矿渣 28.06 27.76 15.69 13.57 6.13 4.22 2.41 0.05 0.81 0.55 0.45 钛石膏 36.22 2.90 1.20 1.58 1.62 13.56 41.95 0.37 0.10 0.07 0.27 熟料 68.17 18.54 0.67 4.44 1.40 3.57 1.68 0.12 0.31 0.83 0.10 表 2 原料的基本性能

Table 2. Basic properties of raw materials

原料 密度/(g/cm3) 堆积孔隙率/% 比表面积/(m2/kg) 矿渣 2.96 0.536 500.4 钛石膏 2.38 0.498 676.8 熟料 3.08 0.483 378.4 表 3 实验配合比/%

Table 3. Test mix ratios

组号 钛石膏 矿渣 熟料 水灰比 T1 85 10 5 28.4 T2 65 30 5 28.4 T3 45 50 5 28.4 T4 25 70 5 28.4 T5 5 90 5 28.4 K1 40 55 5 28.4 K2 40 50 10 28.4 K3 40 45 15 28.4 K4 40 40 20 28.4 K5 40 35 25 28.4 表 4 标准稠度用水和凝结时间测定结果

Table 4. Determination results of standard consistency water and setting time

组号 标准稠度用水量/% 初凝时间/min 终凝时间/min T1 31.7 264 451 T2 29.3 250 442 T3 28.7 248 421 T4 28.3 228 430 T5 28.0 191 401 K1 28.3 248 421 K2 28.3 214 371 K3 27.7 207 361 K4 27.3 153 307 K5 27.0 138 304 -

[1] 刘洪, 郝朝阳, 朱静平. 钛白石膏的开发利用进展[J]. 矿产综合利用, 2011(1):36-38.LIU H, HAO C Y, ZHU J P. Progress in exploitation and utilization of titanium gypsum[J]. Multipurpose Utilization of Mineral Resources, 2011(1):36-38. doi: 10.3969/j.issn.1000-6532.2011.01.010

LIU H, HAO C Y, ZHU J P. Progress in exploitation and utilization of titanium gypsum[J]. Multipurpose Utilization of Mineral Resources, 2011(1):36-38. doi: 10.3969/j.issn.1000-6532.2011.01.010

[2] O RAHMANI. An experimental study of accelerated mineral carbonation of industrial waste red gypsum for CO2 sequestration[J]. Journal of CO2 Utilization, 2020(35):265-671.

[3] ZHAI W W, DAI Y X, ZHAO W L , et al. Simultaneous immobilization of the cadmium, lead and arsenic in paddy soils amended with titanium gypsum[J]. Environmental Pollution, 2020(258): 1-10.

[4] LI J W, WANG W L, WU D, et al. Preparation of sulfoaluminate cementitious material using harmful titanium gypsum: material properties and heavy metal immobilization characteristics[J]. Waste Disposal & Sustainable Energy, 2020(2):127-137.

[5] ZHANG J F, YAN Y, HU Z H, et al. Properties and hydration behavior of Ti-extracted residues-red gypsum based cementitious materials[J]. Construction and Building Materials, 2019(218):610-617.

[6] N A ROSILI, H A AZIZ, M R SELAMAT, et al. A mixture of sewage sludge and red gypsum as an alternative material for temporary landfill cover[J]. Journal of Environmental Managemen, 2020(263):1-9.

[7] A AZDARPOUR, M A KARAEI, H HAMIDI, et al. CO2 sequestration through direct aqueous mineral carbonation of red gypsum[J]. Petroleum, 2018(4):398-407.

[8] 李超宇, 陈爱军, 贾致荣, 等. 钛石膏掺量对碱激发胶凝材料强度与水稳定性的影响[J]. 山东理工大学学报(自然科学版), 2022(2):47-52+57.LI C Y, CHEN A J, JIA Z R, et al. The effect of titanium gypsum content on the strength and water stability of alkali-activated cementitious materials[J]. Journal of Shandong University of Technology( Natural Science Edition), 2022(2):47-52+57.

LI C Y, CHEN A J, JIA Z R, et al. The effect of titanium gypsum content on the strength and water stability of alkali-activated cementitious materials[J]. Journal of Shandong University of Technology( Natural Science Edition), 2022(2):47-52+57.

[9] 汪镜亮. 石膏及其制品的开发[J]. 矿产综合利用, 1993(2):22-30.WANG J L. Development of gypsum and its products[J]. Multipurpose Utilization of Mineral Resources, 1993(2):22-30.

WANG J L. Development of gypsum and its products[J]. Multipurpose Utilization of Mineral Resources, 1993(2):22-30.

[10] 倪孟杰. 水泥-钛石膏改良红层风化残积土的工程特性研究[D]. 合肥: 合肥工业大学, 2021.NI M J. Study on engineering characteristics of cement titanium gypsum inproving weathered residual soil in red bed[D]. Hefei: Hefei University of Technology, 2021.

NI M J. Study on engineering characteristics of cement titanium gypsum inproving weathered residual soil in red bed[D]. Hefei: Hefei University of Technology, 2021.

[11] 靳必强, 张婷婷, 朱静平, 等. 钛石膏的开发利用研究进展[J]. 矿产综合利用, 2020(3):28-32.JIN B Q, ZHANG T T, ZHU J P, et al. The development and research progress of titanium gypsum exploitation and utilization[J]. Multipurpose Utilization of Mineral Resources, 2020(3):28-32. doi: 10.3969/j.issn.1000-6532.2020.03.005

JIN B Q, ZHANG T T, ZHU J P, et al. The development and research progress of titanium gypsum exploitation and utilization[J]. Multipurpose Utilization of Mineral Resources, 2020(3):28-32. doi: 10.3969/j.issn.1000-6532.2020.03.005

[12] ZHANG J F, YAN Y, HU Z H. Preparation and characterization of foamed concrete with Ti-extracted residues and red gypsum[J]. Construction and Building Materials, 2018(171):109-119.

[13] 马正先, 郭浩, 杭鑫坤, 等. 应用改性的氟石膏制备专用砌筑材料[J]. 矿产综合利用, 2016(6):55-60.MA Z X, GUO H, HANG X K, et al. Research on preparing special masonry materials by using modified fluorgypsum[J]. Multipurpose Utilization of Mineral Resources, 2016(6):55-60.

MA Z X, GUO H, HANG X K, et al. Research on preparing special masonry materials by using modified fluorgypsum[J]. Multipurpose Utilization of Mineral Resources, 2016(6):55-60.

[14] M SINGH, M GARG. Activation of gypsum anhydrite-slag mixtures[J]. Cement and Concrete, 1995(25):332-338.

[15] HUANG Y, LIN Z S. Investigation on phosphogypsum–steel slag–granulated blast-furnace slag-limestone cement[J]. Construction and Building Materials, 2010(24):1296-1301.

[16] HUANG X Q, JIANG M M, ZHAO X R, et al. Mechanical properties and hydration mechanisms of high-strength fluorogypsum-blast furnace slag-based hydraulic cementitious binder[J]. Construction and Building Materials, 2016(127):137-143.

[17] 刘振东. 用黄石膏、水泥和FAC-1配制混凝土的研究[J]. 矿产综合利用, 2013(3):75-78.LIU Z D. Research on preparation of concrete with yellow gypsum, cementand FAC-1[J]. Multipurpose Utilization of Mineral Resources, 2013(3):75-78. doi: 10.3969/j.issn.1000-6532.2013.03.018

LIU Z D. Research on preparation of concrete with yellow gypsum, cementand FAC-1[J]. Multipurpose Utilization of Mineral Resources, 2013(3):75-78. doi: 10.3969/j.issn.1000-6532.2013.03.018

-

下载:

下载: