Preparation of High Strength Ceramic Materials from Titanium-bearing Blast Furnace Slags

-

摘要:

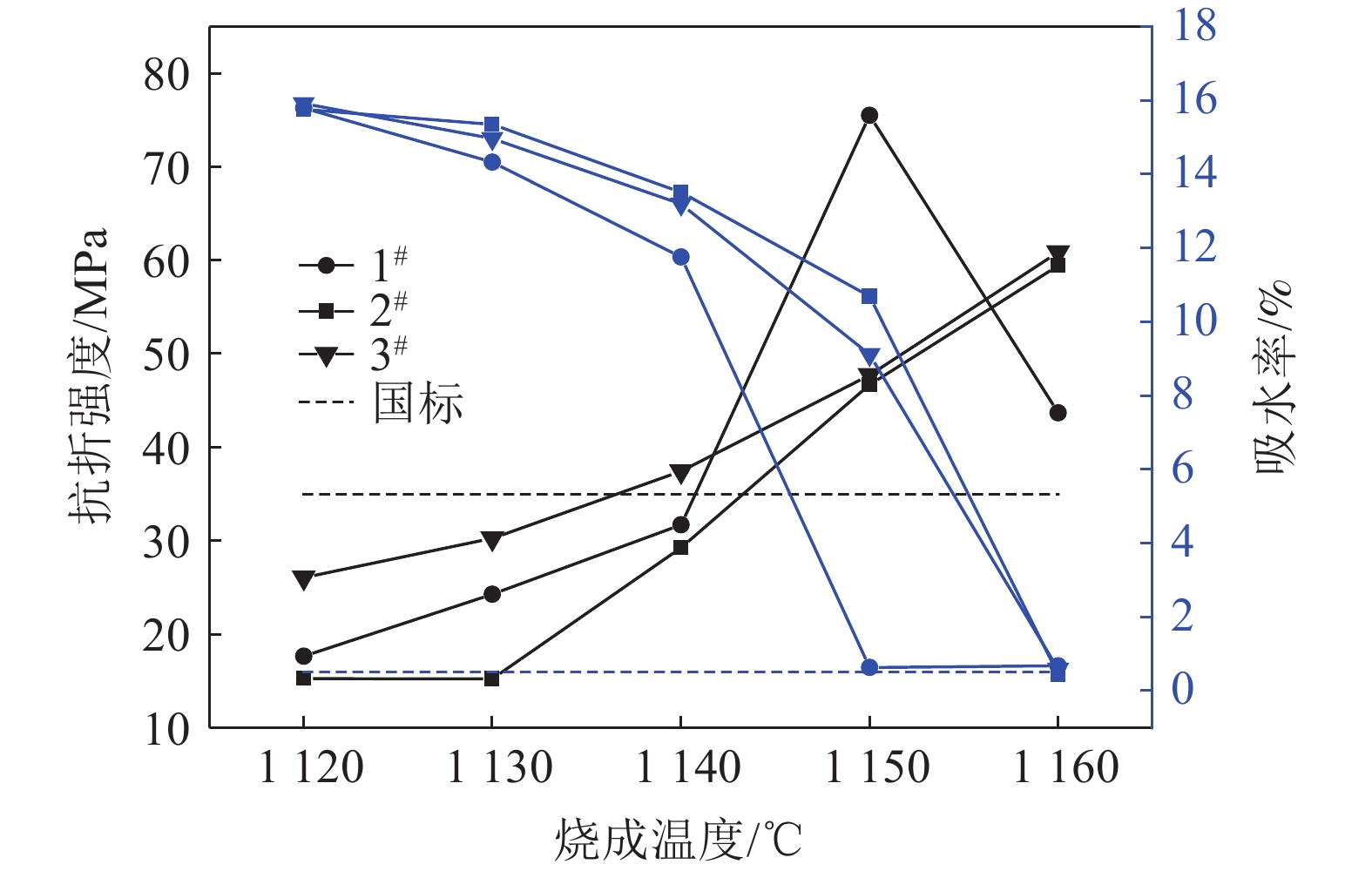

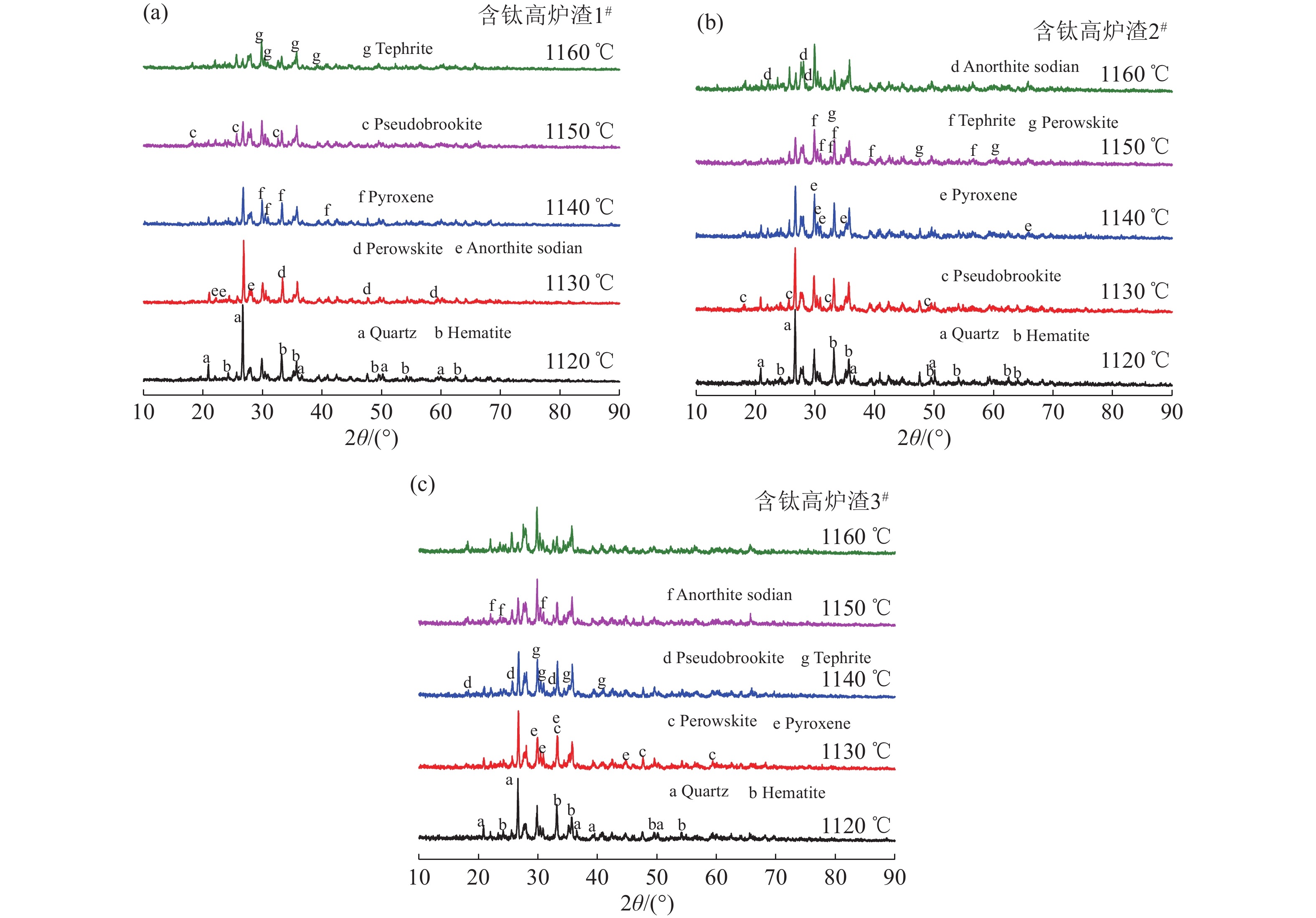

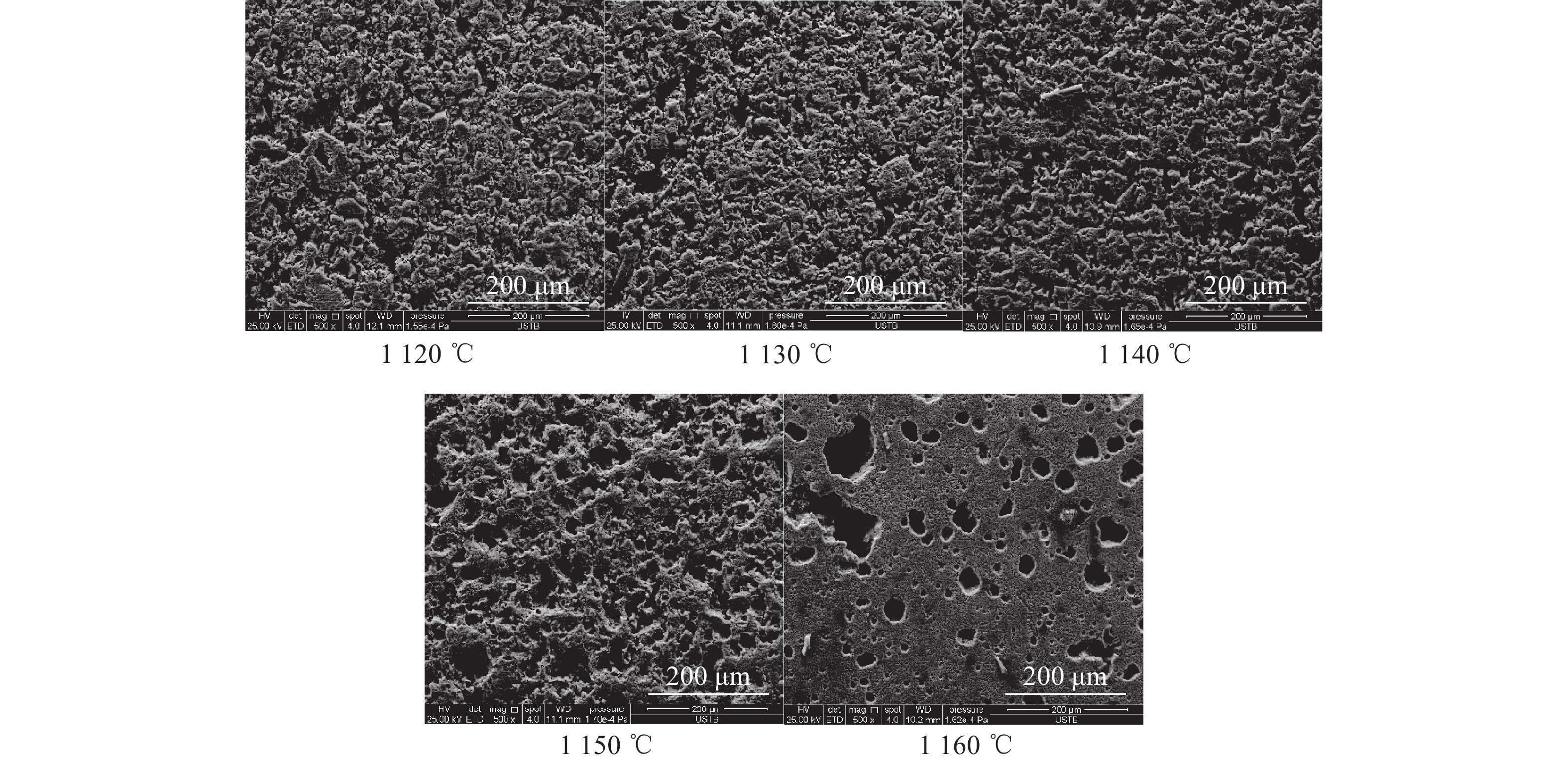

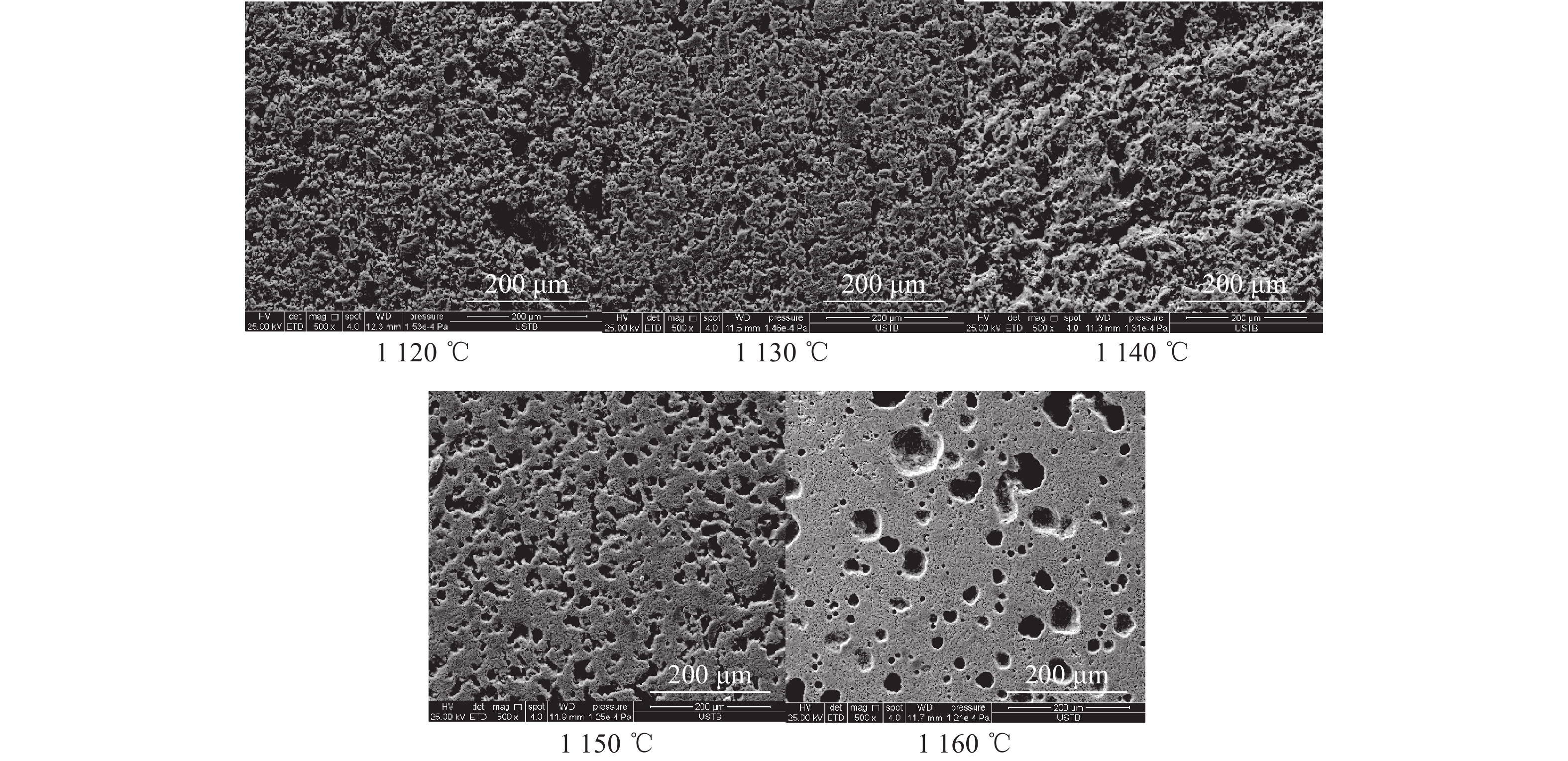

这是一篇矿物材料领域的论文。为了探索含钛高炉渣在陶瓷领域的大宗和高值的应用,通过基于CaO-SiO2-MgO(15%)-Al2O3相图设计,和对制备试样的物理性能、物相组成、微观结构分析,证实了用含钛高炉渣可以制备高强度的陶瓷材料。所制备的高强度陶瓷,属于低硅辉石质陶瓷,主要物相为辉石、碱玄岩钙钠长石、钙钛矿和铁板钛矿,其中辉石的含量随烧成温度的升高而逐渐增大,钙钛矿源自于原料,随烧成温度的提高而逐渐减少。钙钛矿分解后的Ti元素固溶于辉石中,但未能实现替代Si的位置,而是存在于M1的位置,Ti元素的固溶于辉石和碱玄岩中,提高试样的烧结温度。本文较佳的陶瓷试样中的含钛高炉渣掺量高达55%,其强度可达75.51 MPa,高于标准35 MPa;较佳烧结温度为1 150 ℃,利于节能生产,论证了利用含钛高炉渣制备高强陶瓷材料的可行,为含钛高炉渣在陶瓷领域的应用提供理论基础。

Abstract:This is an article in the field of mineral materials. In order to explore the large-scale and high-value application of titanium-containing blast furnace slags in the ceramic field, through the design based on CaO-SiO2-MgO(15%)-Al2O3 phase diagram, and the analysis of the physical properties, phase composition and microstructure of the prepared samples, the preparation of high-strength ceramic materials with titanium-containing blast furnace slag was realized. The prepared high-strength ceramics belong to low-silica pyroxene ceramics, and the main phases are pyroxene, albite, perovskite and brookite, in which the amount of pyroxene increases gradually with the increase of sintering temperature, while perovskite comes from raw materials and decreases gradually with the increase of sintering temperature. Ti element after perovskite decomposition is solid-soluble in pyroxene, which can′t replace Si, but exists in M1. Ti element is solid-soluble in pyroxene and alkali basalt, which increases the sintering temperature of the sample. The content of titanium-bearing blast furnace slags in the best ceramic sample in this paper is as high as 55%, and its strength can reach 75.51 MPa, which is 35 MPa higher than the standard. The optimum sintering temperature is 1 150 ℃, which is beneficial to energy-saving production. The feasibility of preparing high-strength ceramic materials with titanium-containing blast furnace slag is demonstrated, which provides a theoretical basis for the application of titanium-containing blast furnace slags in ceramic field.

-

-

表 1 实验原料的化学组成/%

Table 1. Chemical composition of the test raw materials

原料 CaO Al2O3 SiO2 MgO Fe2O3 TiO2 Cr2O3 Na2O K2O 合计 含钛高炉渣 27.67 11.34 25.90 8.03 3.42 21.09 0.12 0.29 0.74 98.60 石英 0.06 0.75 98.56 0.03 0.17 0.11 0.00 0.00 0.27 99.95 滑石 3.57 0.25 61.77 34.00 0.23 0.00 0.00 0.00 0.02 99.84 粘土 7.65 17.54 62.34 4.98 2.87 0.18 0.04 0.38 3.50 99.48 表 2 实验原料配比

Table 2. Experimental raw material proportioning system

编号 含钛高炉渣 石英 滑石 莱阳土 1# 55% 5% 25% 15% 2# 60% 5% 20% 15% 3# 60% 0% 25% 15% 表 3 含钛高炉渣陶瓷主要物相组成

Table 3. Main phase composition of Ti-bearing blast furnace slag ceramics

名称 化学式 石英 Quartz SiO2 赤铁矿 Hematite Fe2O3 钙钛矿 Perowskite CaTiO3 铁板钛矿 Pseudobrookite Fe2Ti2O5 钙钠长石 Anorthite sodian (Na0.45Ca0.55)(Al1.55Si2.45)O8 辉石(Pyroxene) Pyroxene Mg0.89Fe0.08Al0.20Cr0.04Ti0.01Ca0.76Na0.10Si1.92O6 Augite Ca(Mg0.7Al0.3)((Si1.7Al0.3)O6) Augite Mg0.927Ca0.818Al0.078Fe0.069Na0.06Cr0.04Ti0.008Si2O6 Fassaite Ca0.968Mg0.578Fe0.230Ti0.059Al0.433Si1.728O6 Diopside CaMgSi2O6 Diopside ferroan (Mg0.992Fe0.008)(Ca0.999Mg0.03)Si2O6 碱玄岩 Tephrite (Mg,Fe,Al,Ti)(Ca,Na,Fe,Mg)(SiAl)2O6 Phonotephrite (Mg,Fe,Al,Ti,Cr)(Ca,Na,Fe,Mg)(SiAl)2O6 Alkali basalt (Mg,Fe,Al,Ti)(Ca,Na,Fe)(SiAl)2O6 -

[1] 高洋. 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019(1):6-10.GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10.

GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10.

[2] 罗同俊, 王杜槟, 陈启超, 等. 川威高钛矿渣性能分析研究[J]. 矿产综合利用, 2019(5):94-97.LUO T J, WANG D B, CHEN Q C, et al. Research on Chuanwei high titanium slag[J]. Multipurpose Utilization of Mineral Resources, 2019(5):94-97.

LUO T J, WANG D B, CHEN Q C, et al. Research on Chuanwei high titanium slag[J]. Multipurpose Utilization of Mineral Resources, 2019(5):94-97.

[3] 许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021(1):23-31.XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31.

XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31.

[4] 严芳, 李春, 梁斌. 水淬含钛高炉渣二段酸解工艺[J]. 过程工程学报, 2006(6):413-417.YAN F, LI C, LIANG B. A two-stage sulfuric acid leaching process of Ti-bearing blast furnace slag[J]. The Chinese Journal of Process Engineering, 2006(6):413-417.

YAN F, LI C, LIANG B. A two-stage sulfuric acid leaching process of Ti-bearing blast furnace slag[J]. The Chinese Journal of Process Engineering, 2006(6):413-417.

[5] 周志明, 张丙怀, 朱子宗. 高钛型高炉渣的渣钛分离试验[J]. 钢铁钒钛, 1999, 20(4):35-38.ZHOU Z M, ZHANG B H, ZHU Z Z. A test of titania separation from high titania bearing blast furnace slag[J]. Iron Steel Vandium Titanium, 1999, 20(4):35-38.

ZHOU Z M, ZHANG B H, ZHU Z Z. A test of titania separation from high titania bearing blast furnace slag[J]. Iron Steel Vandium Titanium, 1999, 20(4):35-38.

[6] 李慧, 仇永全, 杨则器. 等离子炉碳(氮)化处理高钛高炉渣[J]. 工程科学学报, 1996, 18(3):231-235.LI H, QIU Y Q, YANG Z Q. Carbaoization (nitrognation) for titanium-bearing blast furnace slag by plasma furnace[J]. Journal of University of Science and Technology Beijing, 1996, 18(3):231-235.

LI H, QIU Y Q, YANG Z Q. Carbaoization (nitrognation) for titanium-bearing blast furnace slag by plasma furnace[J]. Journal of University of Science and Technology Beijing, 1996, 18(3):231-235.

[7] 成海芳, 文书明, 殷志勇. 高炉渣综合利用的研究进展[J]. 现代矿业, 2006(9):21-23.CHENG H F, WEN S M, YIN Z Y. Development of study on the comprehensive utilization of blast furnace slag[J]. Express Information of Mining Industry, 2006(9):21-23.

CHENG H F, WEN S M, YIN Z Y. Development of study on the comprehensive utilization of blast furnace slag[J]. Express Information of Mining Industry, 2006(9):21-23.

[8] 霍红英, 李瑞萍. 高钛型高炉渣光催化材料研究进展[J]. 矿产综合利用, 2020(4):36-41.HUO H Y, LI R P. Research process on photocatalytic materials of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2020(4):36-41.

HUO H Y, LI R P. Research process on photocatalytic materials of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2020(4):36-41.

[9] 陈蓓, 魏瑞航, 罗启泉, 等. 高炉钛渣和废玻璃生产矿渣微晶玻璃的研究[J]. 重庆大学学报自然科学版, 1992, 15(4):62-67.CHEN B, WEI R H, LUO Q Q, et al. Slag crystallizing glass produced by using titanium slag and cullet[J]. Journal of Chongqing University, 1992, 15(4):62-67.

CHEN B, WEI R H, LUO Q Q, et al. Slag crystallizing glass produced by using titanium slag and cullet[J]. Journal of Chongqing University, 1992, 15(4):62-67.

[10] 倪建娣, 陈文燕, 叶树峰, 等. 高炉渣基矿物聚合材料的制备及其对铅离子的固定[J]. 现代地质, 2008, 22(5):852-856.NI J D, CHEN W Y, YE S F, et al. Preparation and Pb2+ immobilization behaviors of blast furnace slag based geopolymer[J]. Geoscience, 2008, 22(5):852-856.

NI J D, CHEN W Y, YE S F, et al. Preparation and Pb2+ immobilization behaviors of blast furnace slag based geopolymer[J]. Geoscience, 2008, 22(5):852-856.

[11] 赵立华. 利用钢渣制备高钙高铁陶瓷的基础及应用研究[D]. 北京: 北京科技大学, 2017.ZHAO L H. Study on mechnisam and application of calcium-rich and iron-rich ceramics from steel slag[D]. Beijing: University of Science Technology Beijing, 2017.

ZHAO L H. Study on mechnisam and application of calcium-rich and iron-rich ceramics from steel slag[D]. Beijing: University of Science Technology Beijing, 2017.

[12] 裴德健. 利用冶金渣制备硅钙基多元体系陶瓷的机理及应用研究[D]. 北京: 北京科技大学, 2019.PEI D J. Study on the mechanism and application of Si-Ca multicomponent ceramics prepared from metallurgical slags[D]. Beijing: University of Science Technology Beijing, 2019.

PEI D J. Study on the mechanism and application of Si-Ca multicomponent ceramics prepared from metallurgical slags[D]. Beijing: University of Science Technology Beijing, 2019.

[13] EISENHŨTTENLEUTE V D. Slag atlas[M]. Gemany: Verlag Stahleisen, 1995.

-

下载:

下载: