Research on the law of water inrush disasters in pipeline-type karst tunnels under the coupling effect of stress-seepage-damage

-

摘要:

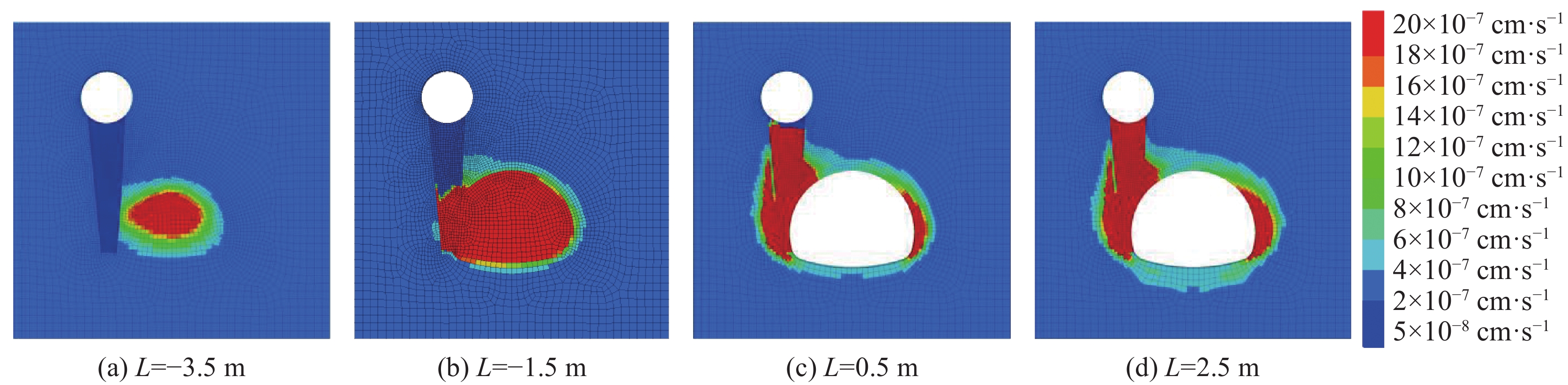

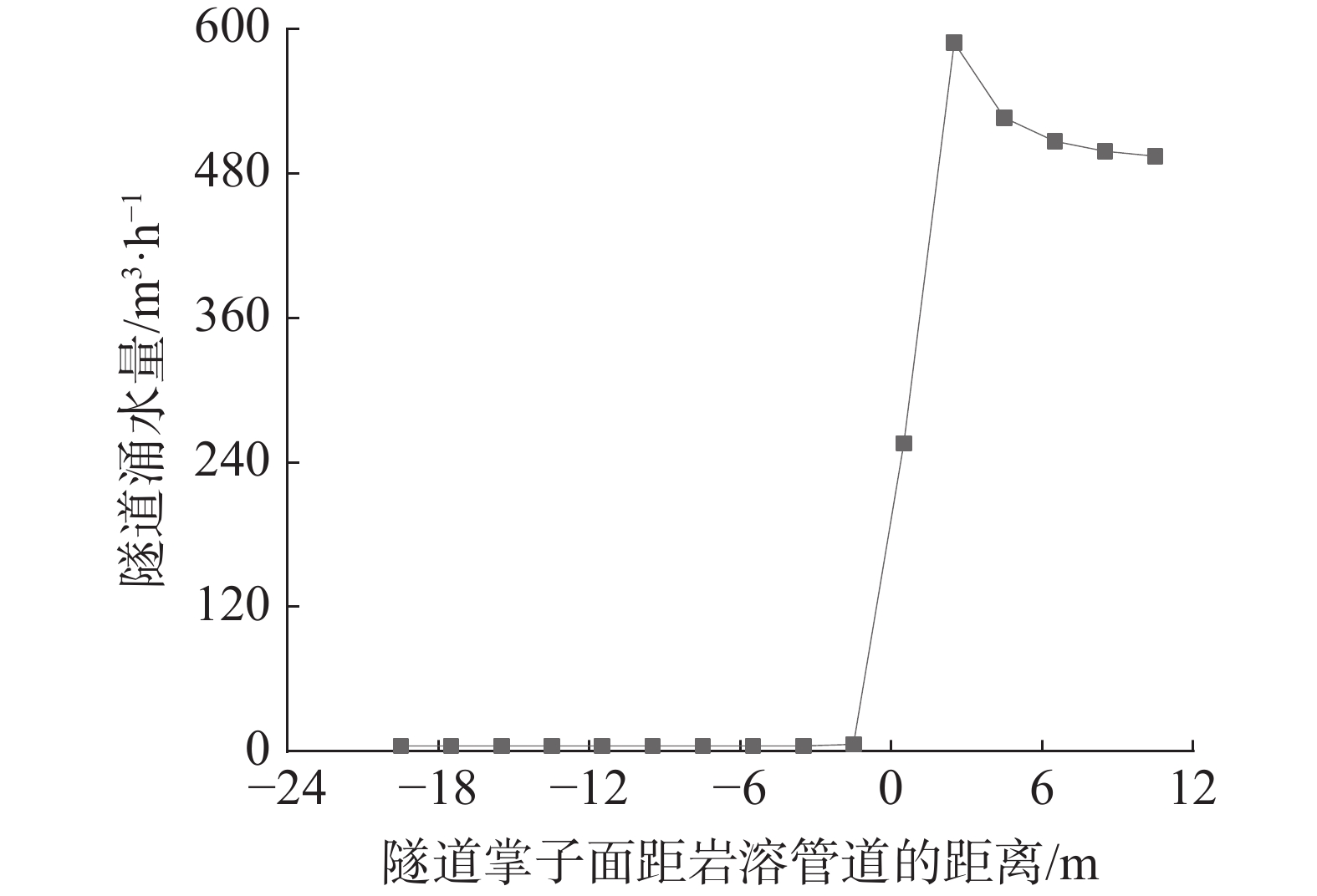

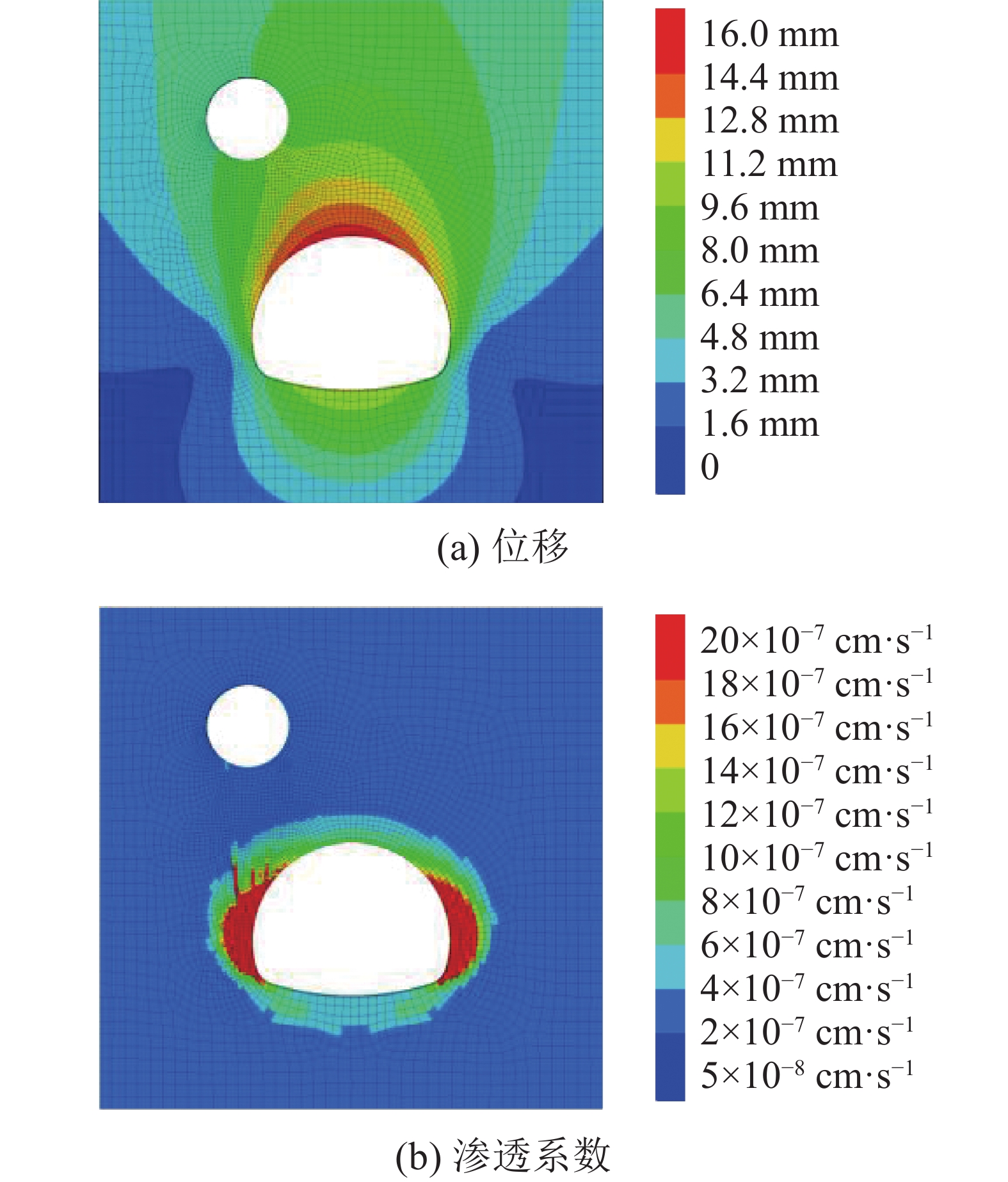

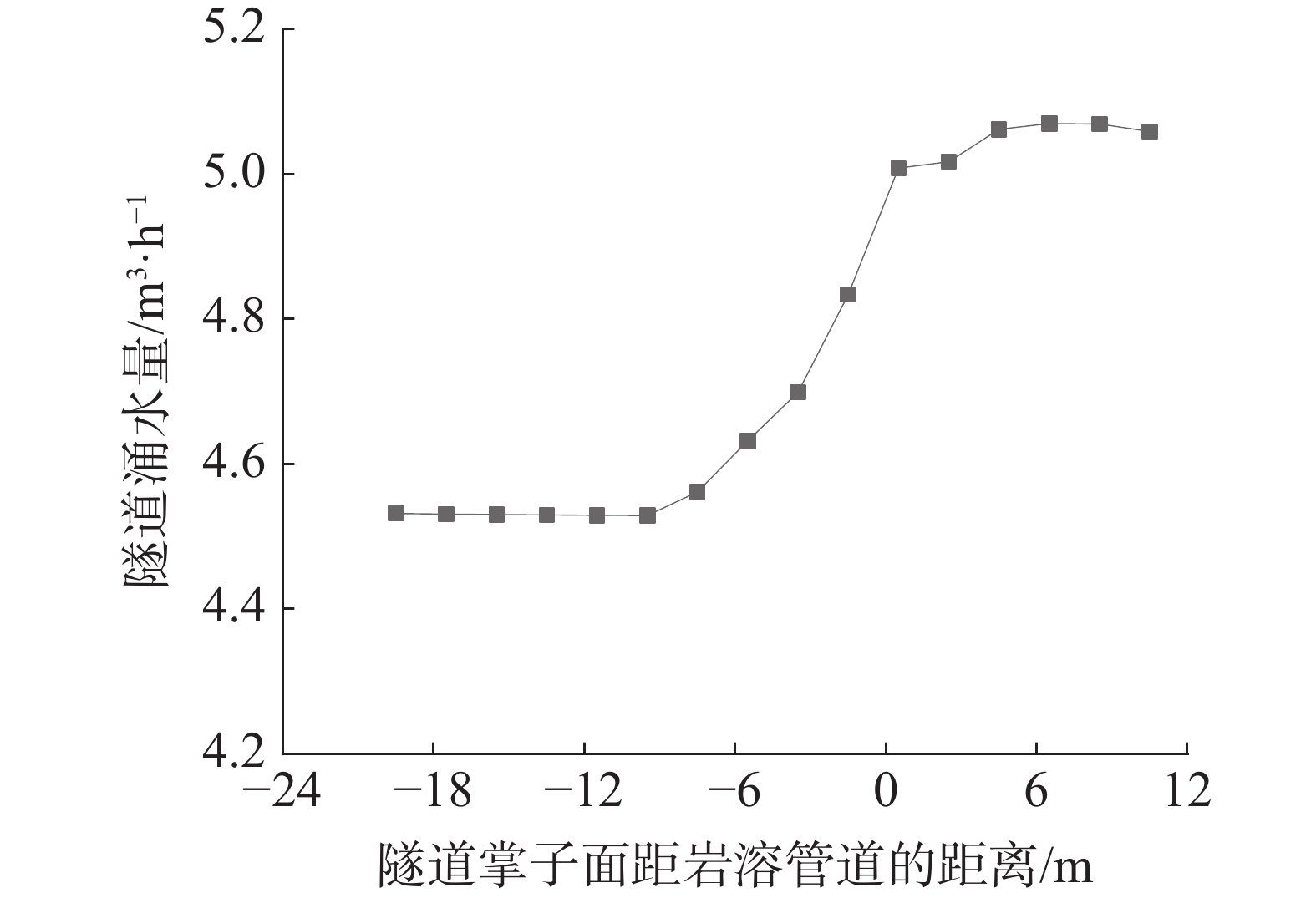

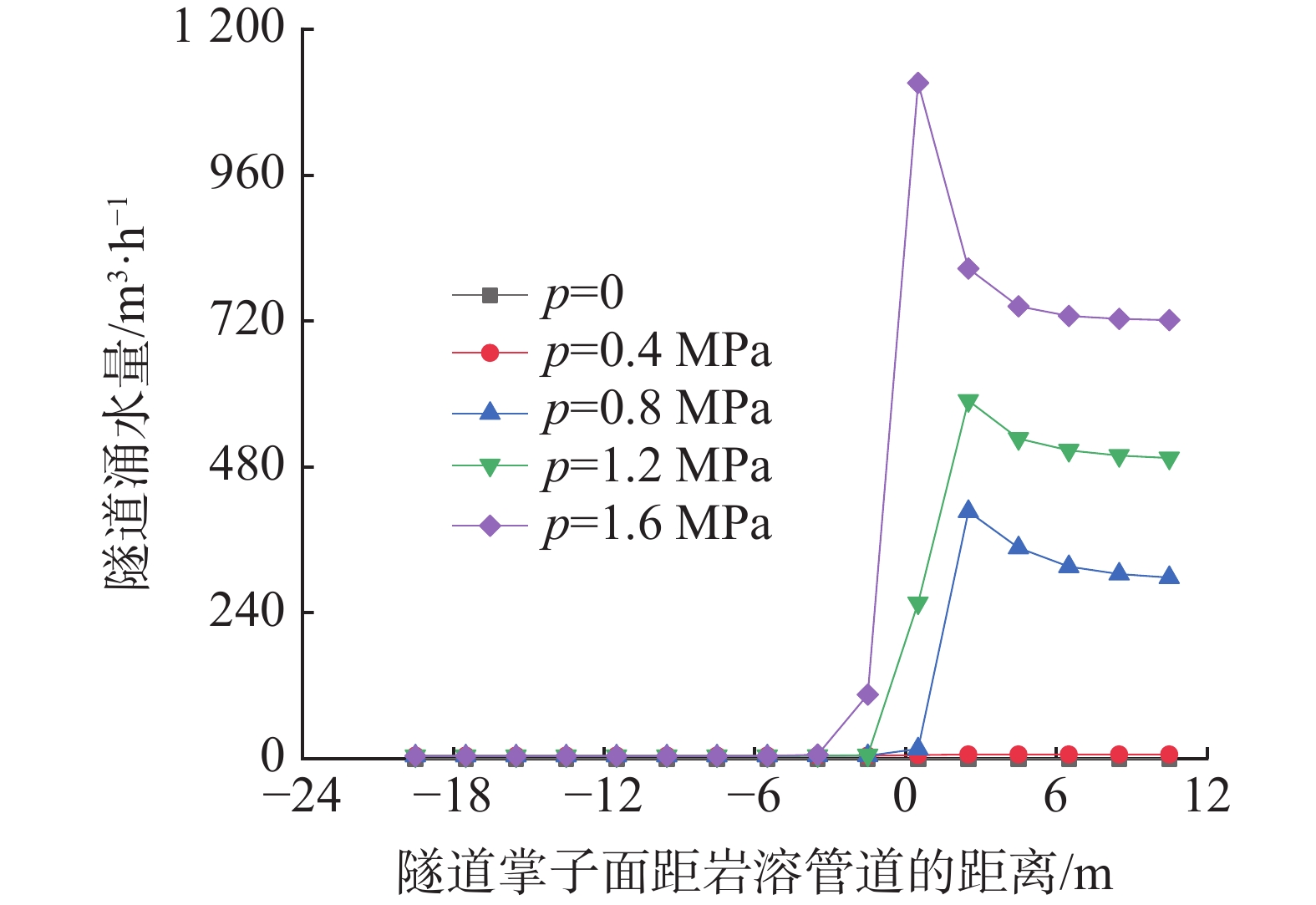

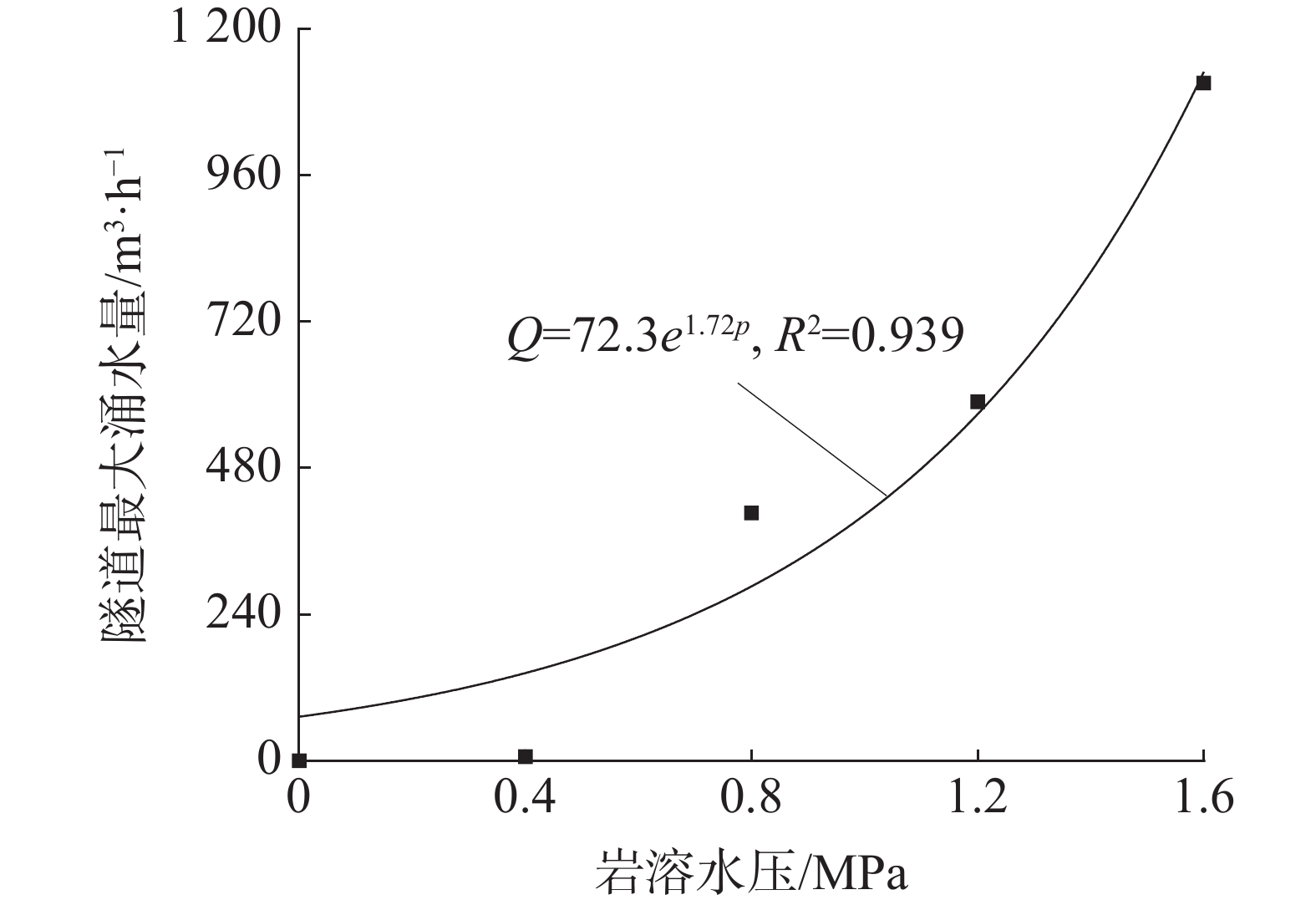

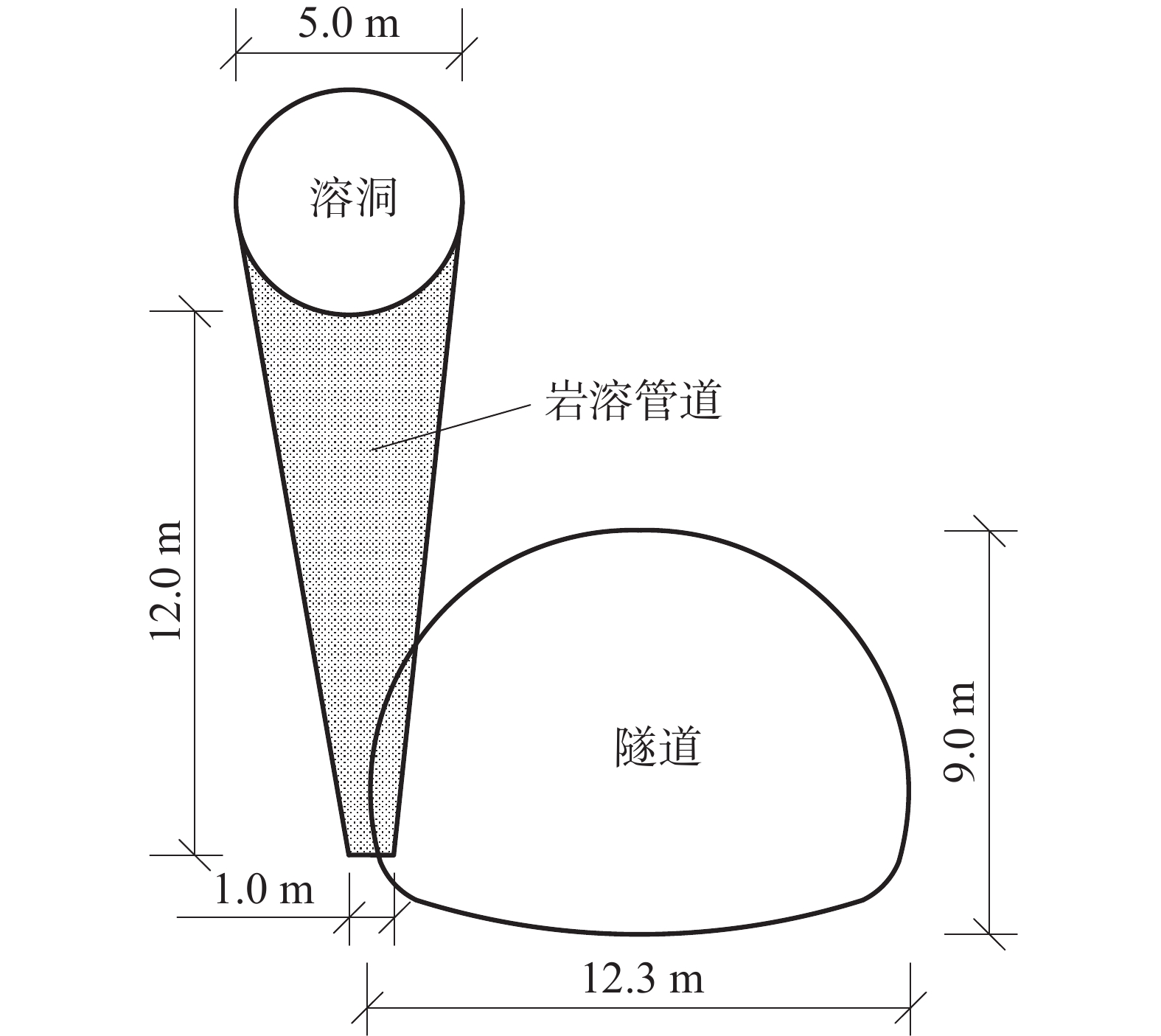

为研究管道型岩溶隧道的突水灾变规律,以毕节市大寨隧道为工程背景,考虑围岩的应力−渗流−损伤耦合作用,采用FLAC 3D对管道型岩溶隧道掘进过程中围岩位移、塑性区、渗透系数以及涌水量变化规律展开数值模拟研究,在此基础上了对比分析了无岩溶管道以及不同岩溶水压对隧道突水灾变特征的影响。数值模拟结果表明:(1)隧道掌子面距岩溶管道4 m以上时,隧道围岩稳定性良好,而隧道开挖一旦全部揭露岩溶管道,则管道内充填岩体会逐渐塑性屈服并发生整体滑移失稳,导致隧道出现突水突泥事故,这与实际工程状况保持一致。(2)管道型岩溶隧道掘进过程中的涌水量大致呈“S型曲线”变化,表现出很强的突发性和较大的体量性;(3)溶洞承压水通过岩溶管道向隧道内发生突水存在一个启动压力,只有超过这个启动压力,隧道才会发生突水突泥事故,且其突水量与岩溶水压呈现出明显的指数递增关系。

Abstract:With the strategy of "advancing the development of China's western regions", the construction of tunnels in karst areas has increased significantly. Among these tunnels, the karst pipeline is a kind of structure prone to disasters caused by the filling which is developed under the action of surface rainfall and groundwater dissolution. Generally, this kind of structure is small with sufficient water supply, so it is not easy to be found in the early geological survey. Once the karst pipeline is exposed by tunnel excavation, under the combined action of groundwater pressure and construction disturbance stress, the filling medium in the karst pipeline will be damaged, resulting in the decrease of its anti-sliding force and the increase of permeability. Consequently, it is easy to cause an accident of water and mud inrush. However, previous research rarely focuses on the sudden change of mechanical and permeability properties of surrounding rock and pipeline filling medium after the rock and medium have been damaged. This is inconsistent with the actual complex evolution process of water inrush disasters in pipeline-type karst tunnels.

Aiming at water inrush disasters in pipeline-type karst tunnels, some scholars take the influence of tunnel excavation disturbance into consideration, and study the evolution process and disaster mechanism of water inrush disasters in pipeline-type karst tunnels through theoretical analysis, physical model test and numerical simulation. Taking the different occurrence forms of karst pipelines into account, some other scholars analyze the influence of the location and size of karst pipeline development as well as the influence of the water level of water-bearing body on the safety of karst tunnel excavation by establishing a geological model of water inrush in karst pipelines. These research results greatly ensure the excavation safety of pipeline-type karst tunnels. However, they rarely focus on the mechanical and permeability properties of the surrounding rock and pipeline filling medium after they have been damaged.

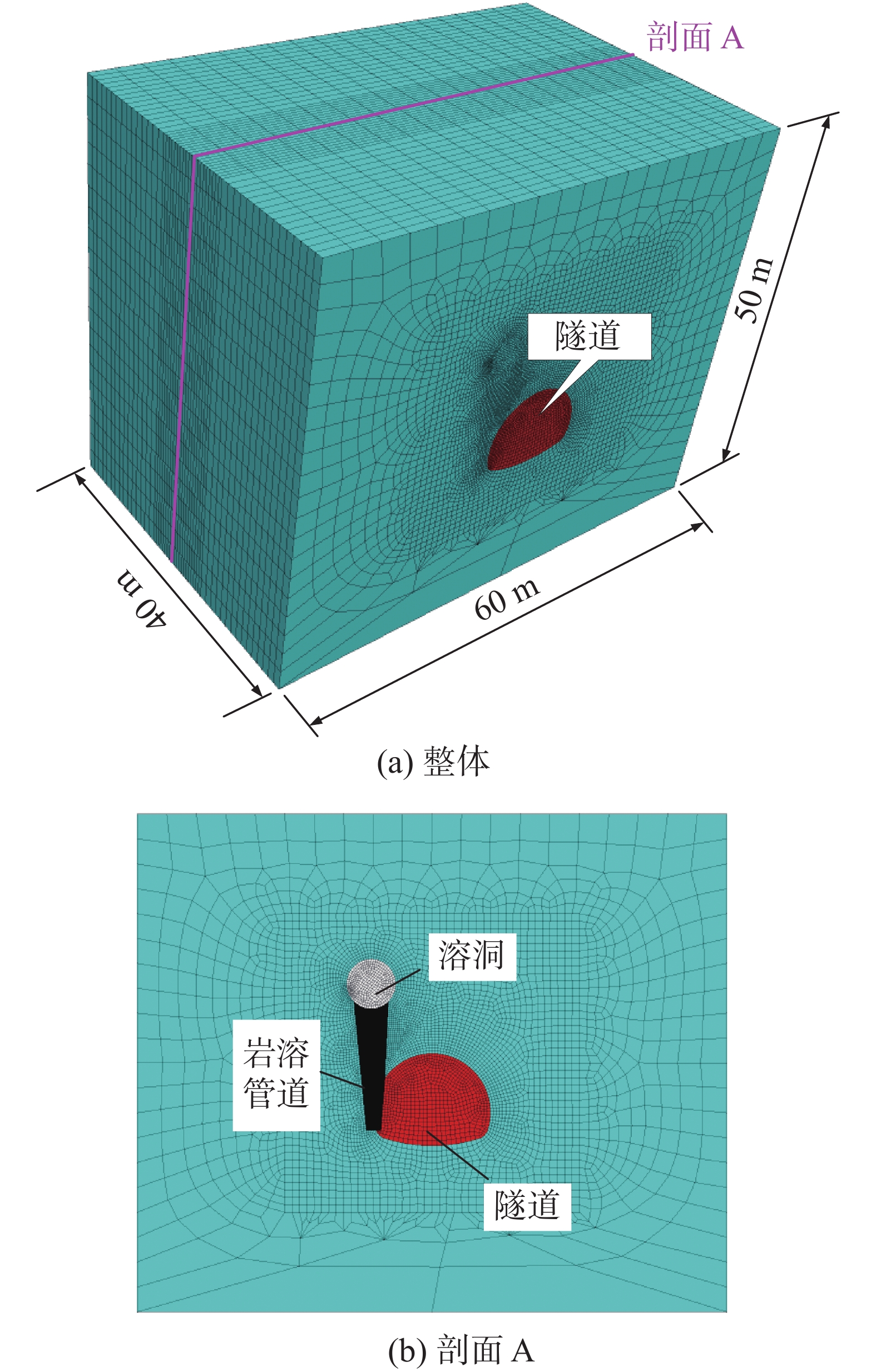

In this study, we took Dazhai Tunnel in Bijie City as an example and took the stress-seepage-damage coupling effect of surrounding rock into consideration to explore the law of water inrush disasters in pipeline-type karst tunnels. Furthermore, using FLAC 3D, we studied the displacement of surrounding rock, the plastic zone, the permeability coefficient and the variation law of water inrush during the tunneling process of pipeline-type karst tunnels. On this basis, we conducted a comparative study of the effects of karst-free pipelines and different karst water pressures on the characteristics of water inrush disasters in tunnels.

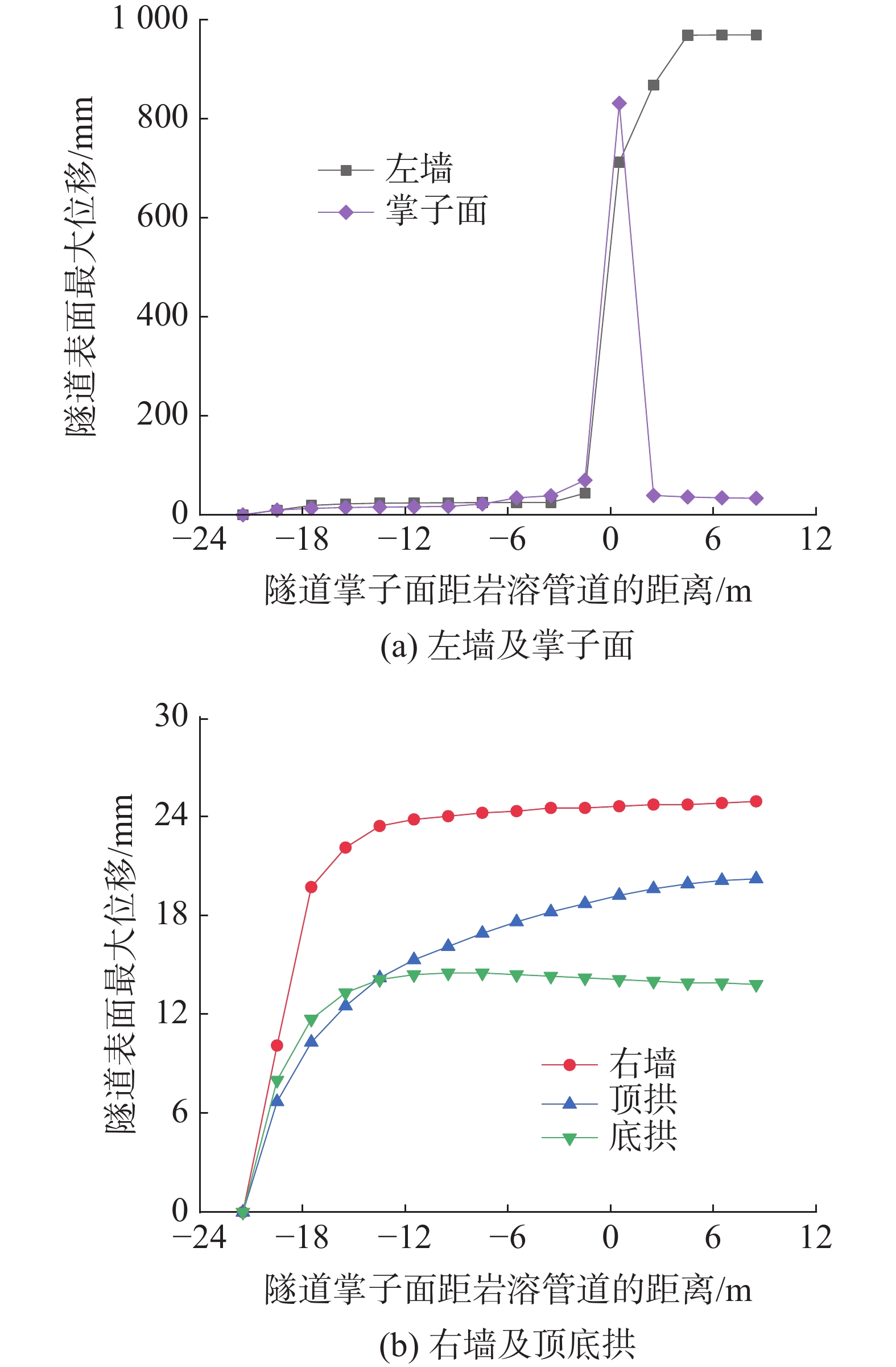

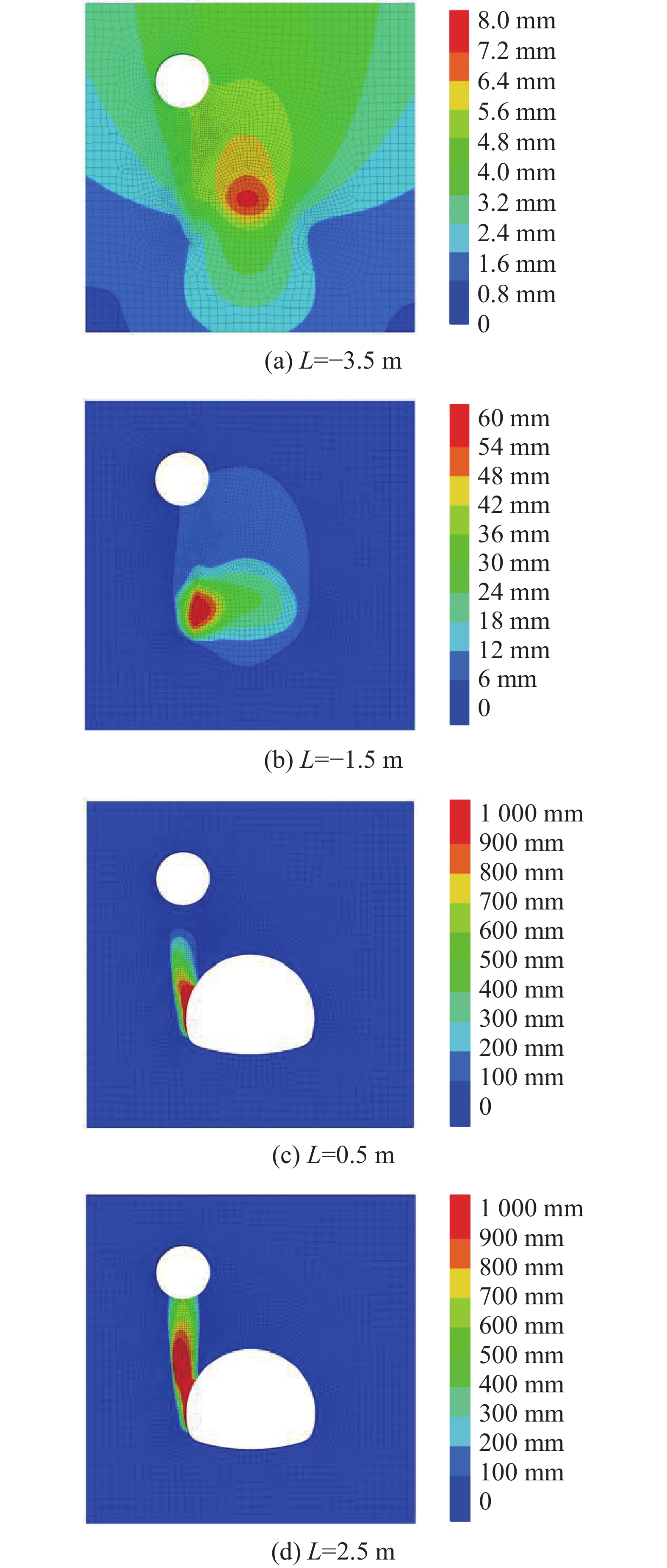

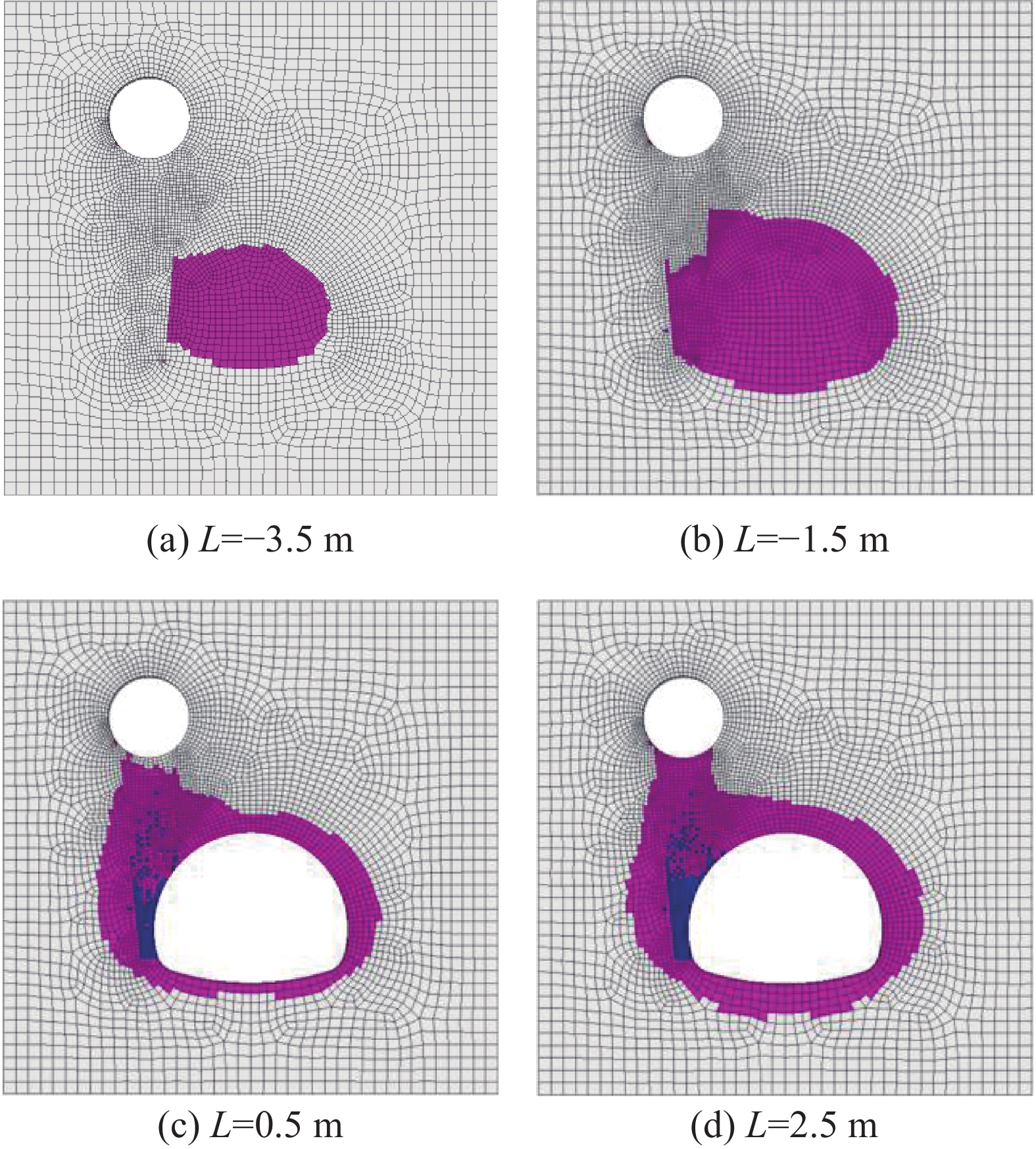

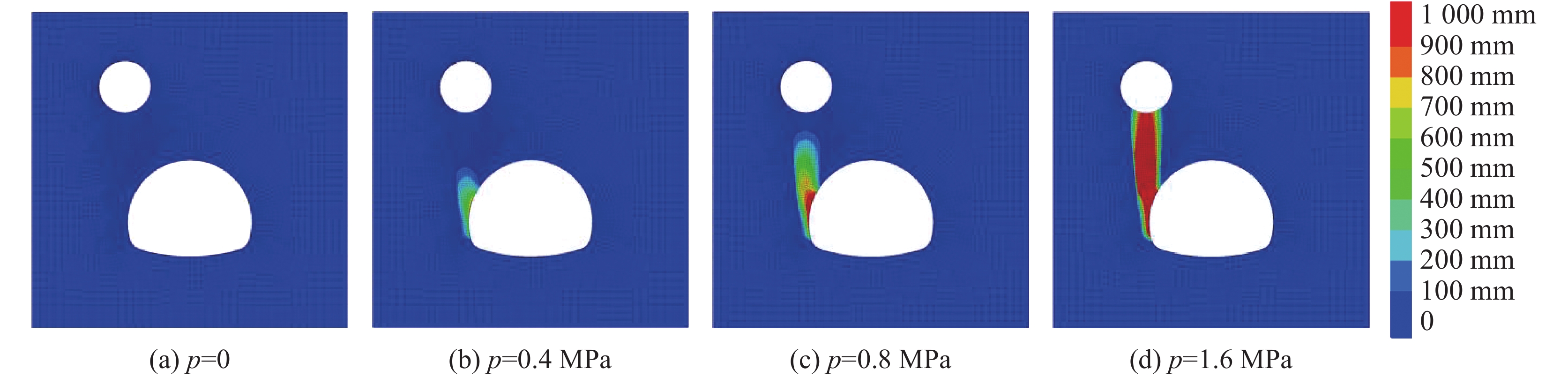

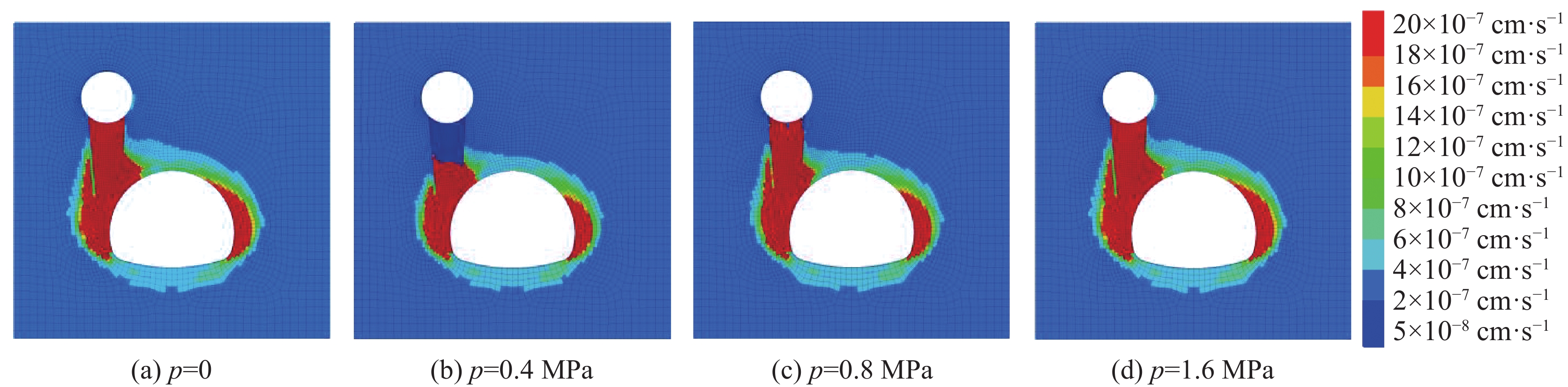

The numerical simulation results show that: (1) When the tunnel face is more than 4 m away from the karst pipeline, the maximum displacement of surrounding rock on the left wall, right wall, bottom arch, top arch and tunnel face will be stabilized at 25.0 mm, 24.5 mm, 14.1 mm, 18.2 mm and 34.1 mm respectively. However, once the karst pipeline is completely exposed by tunnel excavation, the filling rock body inside the karst pipeline will be prone to plastic yielding, and thus cause the overall slipping and instability. This phenomenon will result in accidents of water and mud inrush in tunnels. The result is consistent with the actual engineering situation, indicating the rationality of the mathematical model established under the coupling of stress-seepage-damage in this study. (2) The amount of water inflow during the tunneling process of the pipeline-type karst tunnel roughly changes in an "s-shaped" curve, showing strong suddenness and a large volume. When some karst pipelines are exposed by tunnel excavation, water inflow increases from 5.9 m3·h−1 to 256.0 m3·h−1; when all karst pipelines are exposed by tunnel excavation, water inflow reaches 588.7 m3·h−1. (3) If there are no karst pipelines, large displacement as well as large water inflow will not be generated by tunnel excavation through the karst cave when it is far away from the tunnel. This result indicates that the existence of karst pipelines provides a potential water-conducting channel for water inrush from karst cave to tunnel. (4) There is a starting pressure when a water inrush occurs from the karst pipeline to the tunnel. Only when the starting pressure is exceeded, will an accident of water and mud inrush occur in the tunnel, and the water inrush amount presents an obvious exponential increasing relationship with the karst water pressure.

-

Key words:

- karst pipeline /

- water inrush disaster /

- displacement /

- plastic zone /

- permeability coefficient /

- water inflow

-

-

表 1 岩溶隧道周边岩体的力学与渗透参数

Table 1. Mechanical and permeability parameters of rock mass around karst tunnel

岩体名称 初始弹性

模量/MPa残余弹性

模量/MPa泊松比 初始内

聚力/MPa残余内

聚力/MPa内摩擦

角/°抗拉强

度/MPa孔隙

率初始渗透

系数/cm·s−1α β Ⅳ级围岩 3 000 600 0.28 0.5 0.1 33 0.3 0.18 2.0×10−7 200 5.0 管道充填物 400 40 0.35 0.2 0.02 22 0.05 0.36 5.0×10−8 300 4.5 -

[1] 马国民, 张秀丽, 杨华清. 岩溶隧道突涌水机制及安全临界条件研究[J]. 安全与环境工程, 2022, 29(2):64-70. doi: 10.13578/j.cnki.issn.1671-1556.20210786

MA Guomin, ZHANG Xiuli, YANG Huaqing. Study on water inrush mechanism and safety critical conditions of karst tunnels[J]. Safety and Environmental Engineering, 2022, 29(2):64-70. doi: 10.13578/j.cnki.issn.1671-1556.20210786

[2] 武世燕. 岩溶区隧道隔水岩盘安全厚度预测[J]. 隧道建设(中英文), 2021, 41(12):2083-2092.

WU Shiyan. Prediction of safe thickness of water-insulating rock disks in tunnels in karst areas[J]. Tunnel Construction, 2021, 41(12):2083-2092.

[3] 庄金波, 杨翔. 圆梁山隧道岩溶管道群涌水处理技术[J]. 现代隧道技术, 2004(6):32-36. doi: 10.3969/j.issn.1009-6582.2004.06.007

ZHUANG Jinbo, YANG Xiang. The technique of tackling large-scale water-outburst from karst channels in Yuanliangshan Tunnel[J]. Modern Tunnelling Technology, 2004(6):32-36. doi: 10.3969/j.issn.1009-6582.2004.06.007

[4] 徐立新. 铁路隧道岩溶管道改道引排施工技术[J]. 铁道建筑技术, 2021(11):158-160+169. doi: 10.3969/j.issn.1009-4539.2021.11.033

XU Lixin. Construction technology of diversion and drainage of karst pipeline in railway tunnel[J]. Railway Construction Technology, 2021(11):158-160+169. doi: 10.3969/j.issn.1009-4539.2021.11.033

[5] 邹洋, 彭立敏, 张智勇, 雷明锋, 彭龙, 施成华. 基于突变理论的岩溶隧道拱顶安全厚度分析与失稳预测[J]. 铁道科学与工程学报, 2021, 18(10):2651-2659. doi: 10.19713/j.cnki.43-1423/u.T20201075

ZOU Yang, PENG Limin, ZHANG Zhiyong, LEI Mingfeng, PENG Long, SHI Chenghua. Safety thickness analysis and stability prediction of tunnel roof in karst region based on catastrophe theory[J]. Journal of Railway Science and Engineering, 2021, 18(10):2651-2659. doi: 10.19713/j.cnki.43-1423/u.T20201075

[6] 焦友军, 潘晓东, 曾洁, 任坤. 岩溶管道结构影响泉流量变化的数值模拟研究[J]. 中国岩溶, 2017, 36(5):736-742.

JIAO Youjun, PAN Xiaodong, ZENG Jie, REN Kun. Numerical modeling of the influence of karst-conduit structure on variation of spring flow[J]. Carsologica Sinica, 2017, 36(5):736-742.

[7] CHU Vietthuc. 公路隧道充填型岩溶管道突水灾变机理及演化过程数值分析[J]. 中南大学学报(自然科学版), 2016, 47(12):4173-4180.

CHU Vietthuc. Mechanism on water inrush disaster of filling karst piping and numerical analysis of evolutionary process in highway tunnel[J]. Journal of Central South University (Science and Technology), 2016, 47(12):4173-4180.

[8] 王健华, 李术才, 李利平, 许振浩. 隧道岩溶管道型突涌水动态演化特征及涌水量综合预测[J]. 岩土工程学报, 2018, 40(10):1880-1888.

WANG Jianhua, LI Shucai, LI Liping, XU Zhenhao. Dynamic evolution characteristics and prediction of water inflow of karst piping-type water inrush of tunnels[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(10):1880-1888.

[9] 周毅, 李术才, 李利平, 石少帅, 张乾青, 陈迪杨, 宋曙光. 隧道充填型岩溶管道渗透失稳突水机制三维流−固耦合模型试验研究[J]. 岩石力学与工程学报, 2015, 34(9):1739-1749.

ZHOU Yi, LI Shucai, LI Liping, SHI Shaoshuai, ZHANG Qianqing, CHEN Diyang, SONG Shuguang. 3D fluid-solid coupled model test on water-inrush in tunnel due to seepage from filled karst conduit[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(9):1739-1749.

[10] 周宗青. 隧道充填型致灾构造突水突泥灾变演化机理及工程应用[D]. 济南: 山东大学, 2016: 79-168.

ZHOU Zongqing. Evolutionary mechanism of water inrush through filling structures in tunnels and engineering applications [D]. Jinan: Shandong University, 2016: 79−168.

[11] 李利平. 高风险岩溶隧道突水灾变演化机理及其应用研究[D]. 济南: 山东大学土建与水利学院, 2009: 79−86.

LI Liping. Study on catastrophe evolution mechanism of karst water inrush and its engineering application of high risk karst tunnel[D]. Jinan: Shandong University. School of Civil Engineering, 2009: 79−86.

[12] 谭信荣, 樊浩博, 宋玉香, 刘勇, 杨海宏. 管道型岩溶隧道衬砌结构受力特征试验研究[J]. 地下空间与工程学报, 2021, 17(6):1847-1856.

TAN Xinrong, FAN Haobo, SONG Yuxiang, LIU Yong, YANG Haihong. Experimental study on the mechanical characteristics of the lining structure of pipe-type karst tunnel[J]. Chinese Journal of Underground Space and Engineering, 2021, 17(6):1847-1856.

[13] 黄震, 李仕杰, 赵奎, 吴锐, 钟文. 隧道充填岩溶管道滑移失稳突水机制[J]. 中南大学学报(自然科学版), 2019, 50(5):1119-1126.

HUANG Zhen, LI Shijie, ZHAO Kui, WU Rui, ZHONG Wen. Water inrush mechanism for slip instability of filled karst conduit in tunnels[J]. Journal of Central South University (Science and Technology), 2019, 50(5):1119-1126.

[14] 王青松. 充填型岩溶管道致灾机理研究[J]. 铁道建筑技术, 2021(12):1-4, 10. doi: 10.3969/j.issn.1009-4539.2021.12.001

WANG Qingsong. Study on mechanism of water inrush of filling karst piping[J]. Railway Construction Technology, 2021(12):1-4, 10. doi: 10.3969/j.issn.1009-4539.2021.12.001

[15] 贾善坡, 陈卫忠, 于洪丹, 李香玲. 泥岩隧道施工过程中渗流场与应力场全耦合损伤模型研究[J]. 岩土力学, 2009, 30(1):19-26. doi: 10.3969/j.issn.1000-7598.2009.01.003

JIA Shanpo, CHEN Weizhong, YU Hongdan, LI Xiangling. Research on seepage-stress coupling damage model of boom clay during tunneling[J]. Rock and Soil Mechanics, 2009, 30(1):19-26. doi: 10.3969/j.issn.1000-7598.2009.01.003

[16] 郑青青. 深埋岩溶隧道爆破开挖的围岩损伤机理与稳定性研究[D]. 武汉: 武汉理工大学, 2019: 36-40.

ZHENG Qingqing. Study on instability and water inrush mechanism of surrounding rock caused by blasting excavation of deep buried high-risk karst tunnel[D]. Wuhan: Wuhan University of Technology. 2019: 36-40.

[17] 经纬, 薛维培, 姚直书. 巷道围岩塑性软化区岩石内摩擦角与黏聚力变化规律[J]. 煤炭学报, 2018, 43(8):2203-2210.

JING Wei, XUE Weipei, YAO Zhishu. Variation of the internal friction angle and cohesion of the plastic softening zone rock in roadway surrounding rock[J]. Journal of China Coal Society, 2018, 43(8):2203-2210.

[18] 牛传星, 秦哲, 冯佰研, 付厚利. 水岩作用下蚀变岩力学性质损伤规律[J]. 长江科学院院报, 2016, 33(8):75-79. doi: 10.11988/ckyyb.20150590

NIU Chuanxing, QIN Zhe, FENG Baiyan, FU Houli. Regularity of the damage of altered rock’s mechanical properties under water-rock interaction[J]. Journal of Yangtze River Scientific Research Institute, 2016, 33(8):75-79. doi: 10.11988/ckyyb.20150590

[19] 张珂峰. 前伏溶洞巷道开挖突水数值模拟研究[J]. 现代隧道技术, 2020, 57(3):99-107. doi: 10.13807/j.cnki.mtt.2020.03.014

ZHANG Kefeng. Numerical simulation of water burst in roadway excavation with karst cave ahead[J]. Modern Tunnelling Technology, 2020, 57(3):99-107. doi: 10.13807/j.cnki.mtt.2020.03.014

[20] 中华人民共和国交通部. 公路隧道设计规范(JTG D70/2-2014)[S]. 北京: 人民交通出版社, 2014.

Ministry of Communications of the People’s Republic of China. Code for design of road tunnel[S]. Beijing: China Communications Press, 2014.

[21] 吕涛. 基于流固耦合的岩溶管道对水工隧洞围岩影响的数值分析研究[D]. 重庆: 重庆交通大学, 2011.

LV Tao. Numerical simulation of the influence of karst pipeline on hydraulic tunnels surrounding rock based on the fluid-solid coupling[D]. Chongqing: Chongqing Jiaotong University, 2011.

[22] 安文生. 管道型岩溶隧道突水涌泥致灾机理及处治技术研究—以大寨隧道为例[D]. 贵阳: 贵州大学, 2017.

AN Wensheng. The research of the mechanism and the treatment of the water bursting and mud surging in the pipeline karst tunnel: Take Dazhai tunnel as an example[D]. Guiyang: Guizhou University, 2017.

-

下载:

下载: