Optimization and Discrete Element Simulation Analysis of Primary Stage of Ball Mill in Baixiangshan Iron Processing Plant, Anhui, China

-

摘要:

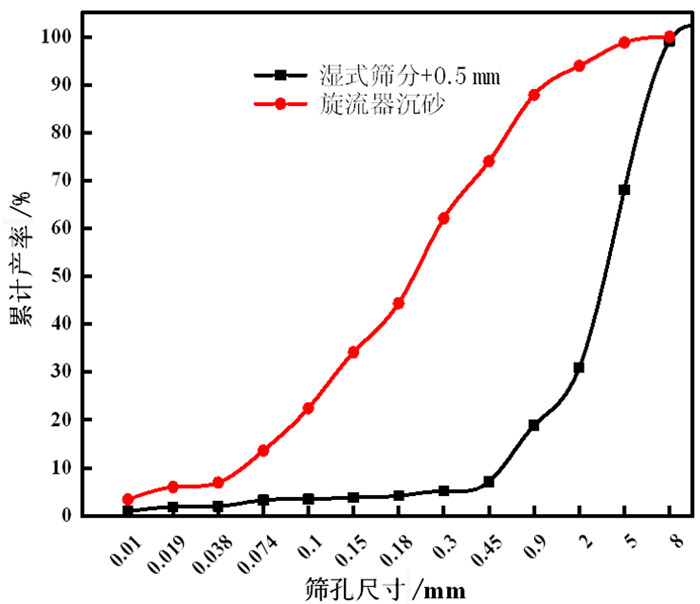

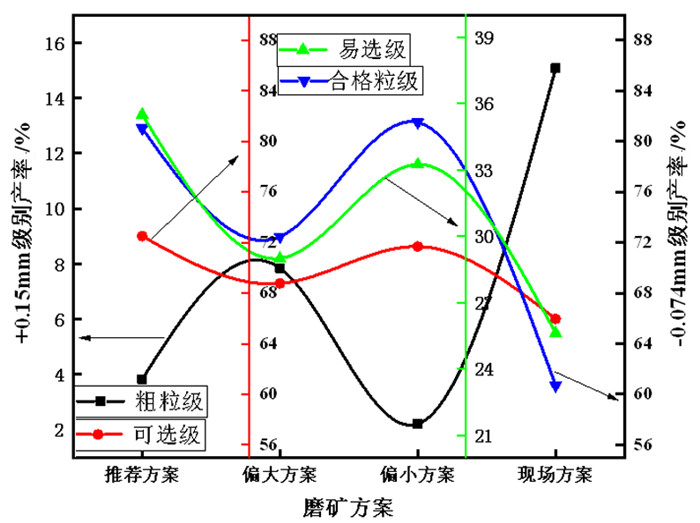

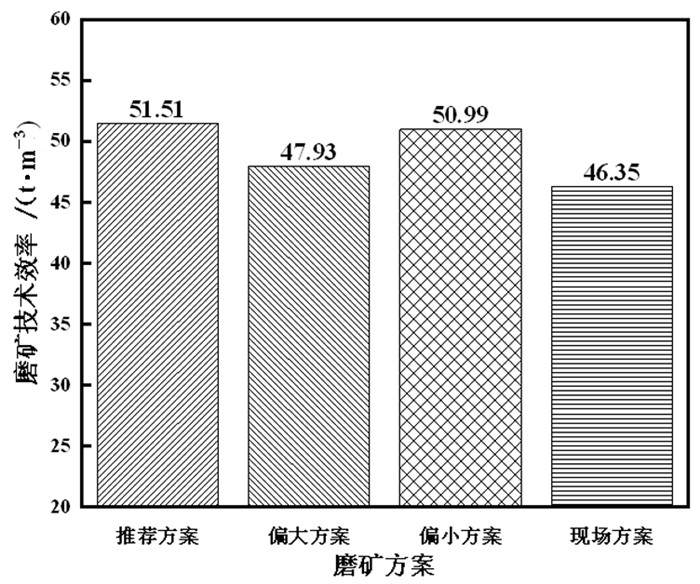

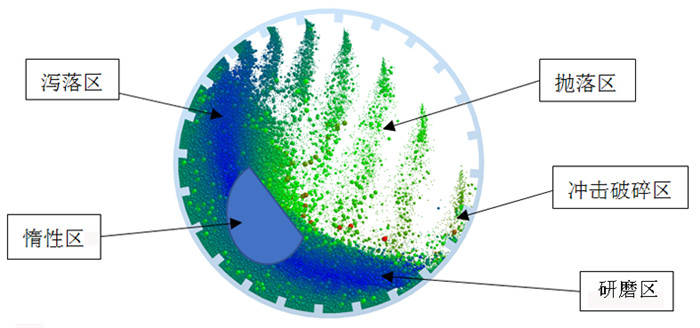

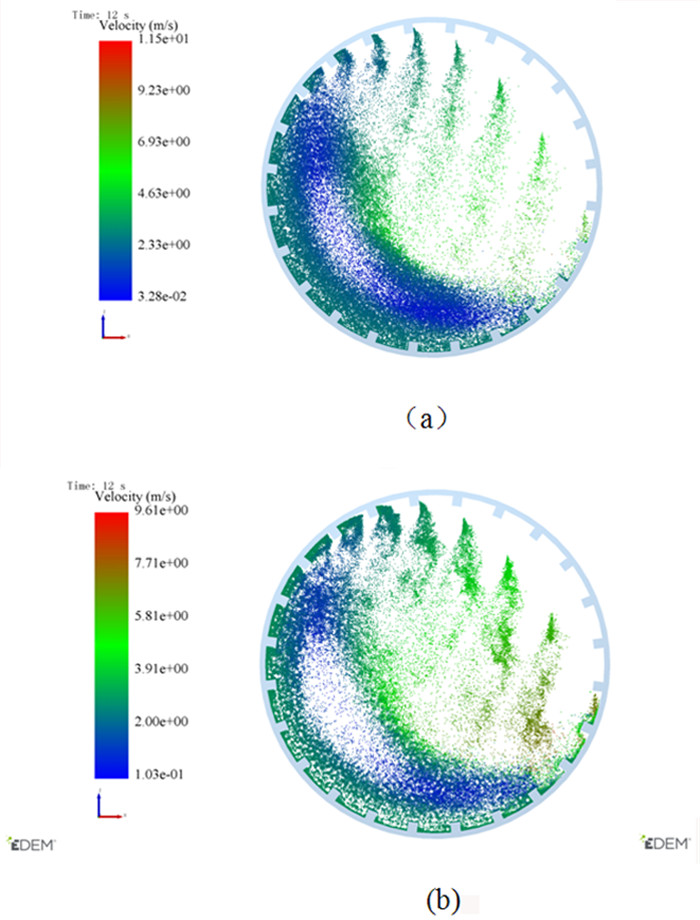

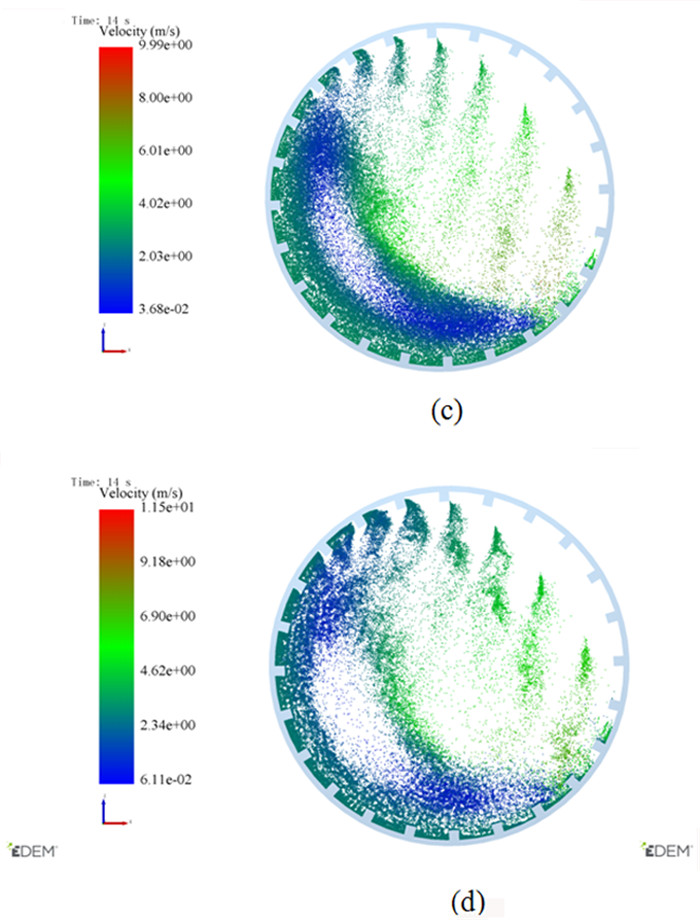

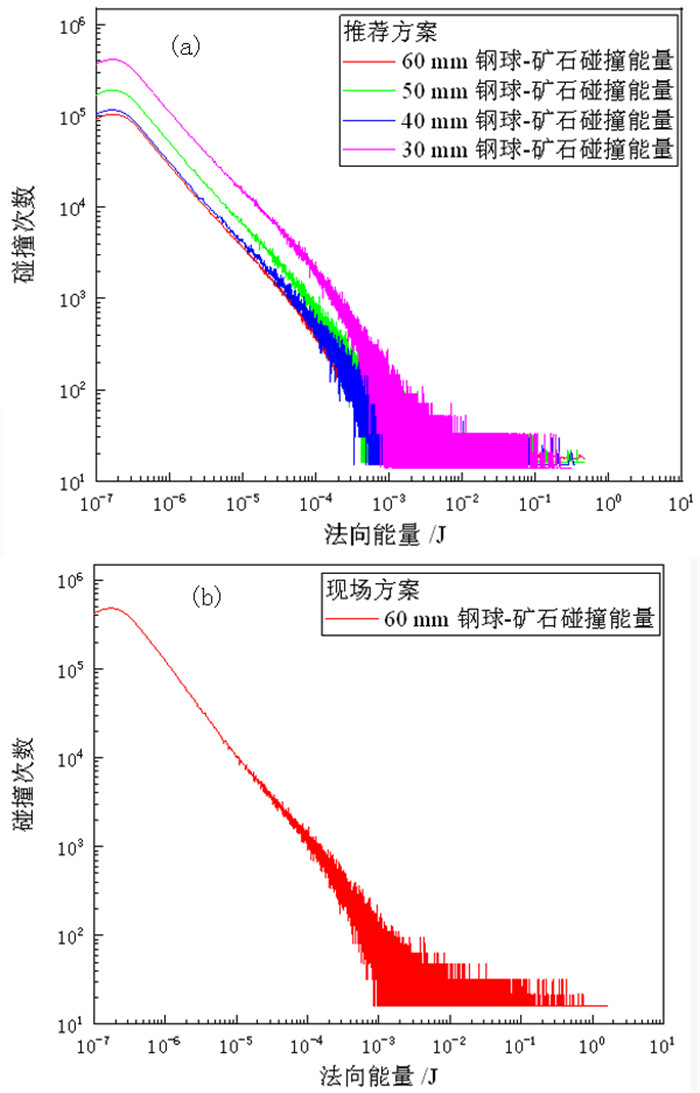

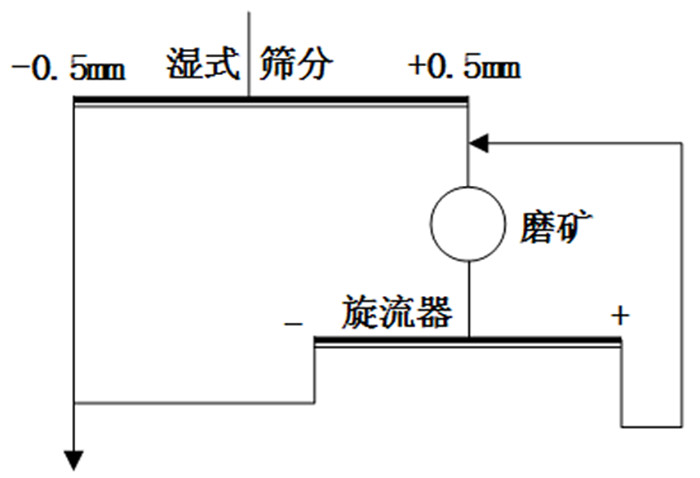

针对安徽白象山铁选厂一段球磨指标进行优化试验研究,对矿石进行力学性质测定、球磨机给矿筛分,按照段式球径半理论公式初步确定推荐方案为m(Φ60):m(Φ50):m(Φ40):m(Φ30)=20:30:15:35,设置偏大及偏小方案作为对比,通过磨矿对比试验得出,推荐方案较现场方案+0.15 mm级别产率下降11.24百分点,(-0.15+0.10) mm、(-0.074+0.019) mm级别产率分别提高6.55百分点、9.88百分点,磨矿技术效率提高7.57百分点;离散元仿真结果表明,推荐方案法向碰撞能量较现场方案仅降低4.15百分点,切向碰撞能量较现场提高69.04百分点,综合比较推荐方案全面优于现场方案。

Abstract:A pilot study was conducted to optimize the ball milling index of primary stage of the iron processing plant in Baixiangshan, Anhui Province, by measuring the mechanical properties of the ore, screening before ball mill feed. The recommended solution was initially determined as m(Φ60) : m(Φ50) : m(Φ40) : m(Φ30)=20 : 30 : 15 : 35 according to the semi-theoretical formula of segmental ball diameter, and set the big and small solutions as a comparison, and through the grinding comparison test, it was found that the yield of +0.15 mm level decreases by 11.24%, the yield of -0.15+0.10 mm and -0.074+0.019 mm level increases by 6.55% and 9.88% respectively, and the technical efficiency of grinding increases by 7.57%. The discrete element simulation results show that the normal collision energy of the recommended solution is only 4.15% lower than that of the field solution. The normal collision energy of the recommended solution is only 4.15% lower than that of the on-site solution, and the tangential collision energy is 69.04% higher than that of the on-site solution. The recommended solution is better than the on-site solution in a comprehensive comparison.

-

Key words:

- iron ore /

- grinding /

- precise ball distribution /

- index optimization /

- discrete elements

-

-

表 1 离散元接触参数设定

Table 1. Contact parameter setting of the discrete elements

接触类型 钢球-钢球 钢球-矿石 矿石-矿石 碰撞恢复系数 0.70 0.40 0.35 静摩擦系数 0.25 0.50 0.68 滚动摩擦系数 0.03 0.05 0.30 表 2 离散元颗粒参数设定

Table 2. Particle parameter setting of the discrete elements

颗粒名称 密度/(kg·m-3) 表面积/m2 体积/m3 质量/kg 60 mm钢球 7800 0.0113 1.13E-04 0.8821 50 mm钢球 7800 0.0254 6.54E-05 0.5105 40 mm钢球 7800 0.0154 3.35E-05 0.2614 30 mm钢球 7800 0.0028 1.41E-05 0.1110 3 mm矿石颗粒 3930 2.83E-05 1.14E-08 5.60E-05 表 3 力学性质测定结果

Table 3. Results of mechanical properties test

矿石编号 1# 2# 3# 4# 5# 6# 7# 8# 9# 均值 密度/(g·cm-3) 3.78 4.03 3.71 3.56 4.16 4.09 3.41 4.31 4.28 3.93 泊松比 0.15 0.18 0.16 0.33 0.46 0.19 0.24 0.32 0.40 0.27 静弹性模量/104 MPa 1.76 2.70 4.28 6.75 8.54 6.95 1.73 3.40 4.14 4.47 单轴抗压强度/MPa 34.50 36.23 113.70 96.87 28.50 92.03 37.17 63.50 53.77 68.67 表 4 推荐方案配比确定

Table 4. Determination of the recommended program ratio

级别/mm 全给矿产率/% 扣除-0.15 mm后待磨产率γ/% 各组适宜球径/mm 推荐比例 +2 14.18 20.32 60 20 -2+0.45 19.83 29.28 50 30 -0.45+0.3 10.61 15.21 40 15 -0.3+0.15 24.55 35.19 30 35 -0.15 30.23 —— —— —— 合计 100.00 100.00 —— 100 表 5 磨矿介质配比方案

Table 5. Scheme of the grinding medium ratio

配比方案 介质比例 平均球径 推荐方案 m(Φ60):m(Φ50):m(Φ40):m(Φ30)=20:30:15:35 43.5 mm 偏大方案 m(Φ60):m(Φ50):m(Φ40)=30:40:30 50.0 mm 偏小方案 m(Φ50):m(Φ40):m(Φ30)=30:40:30 40.0 mm 现场方案 m(Φ60)=100 60.0 mm 表 6 推荐及现场方案切向能量、法向能量统计

Table 6. Tangential energy and normal phase energy statistics of recommended and on-site plans

接触类型 推荐方案 现场方案 切向能量/J 法向能量/J 切向能量/J 法向能量/J 60 mm钢球-矿石 1 700 620 6 240 6 740 50 mm钢球-矿石 2 618 1 230 —— —— 40 mm钢球-矿石 1 980 895 —— —— 30 mm钢球-矿石 4 250 3 710 —— —— 总和 10 548 6 455 6 240 6 740 -

[1] 吕晓艳. 铁矿选矿技术和工艺方法探讨[J]. 中国金属通报, 2018(7): 216-218. doi: 10.3969/j.issn.1672-1667.2018.07.131

LYN X Y. Exploration of iron ore beneficiation technology and process methods[J]. China Metal Bulletin, 2018(7): 216-218. doi: 10.3969/j.issn.1672-1667.2018.07.131

[2] 张亚明, 王雪峰, 李文超. 铁矿资源综合利用效益评价体系研究[J]. 中国国土资源经济, 2019, 32(4): 43-48. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDKJ201904010.htm

ZHANG Y M, WANG X F, LI W C. Research on the evaluation system of the benefit of comprehensive utilization of iron ore resources[J]. China Land and Resources Economy, 2019, 32(4): 43-48. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDKJ201904010.htm

[3] 赵立群, 王春女, 张敏, 等. 中国铁矿资源勘查开发现状及供需形势分析[J]. 地质与勘探, 2020, 56(3): 635-643. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202003016.htm

ZHAO L Q, WANG C N, ZHANG M, et al. Analysis of the current situation of iron ore resources exploration and development and supply and demand situation in China[J]. Geology and Exploration, 2020, 56(3): 635-643. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202003016.htm

[4] 姜雪薇. 中国铁矿行业发展现状及前景分析[J]. 中国金属通报, 2017(7): 161-160. https://www.cnki.com.cn/Article/CJFDTOTAL-JSTB201707078.htm

JIANG X W. Analysis of the development status and prospect of China's iron ore industry[J]. China Metal Bulletin, 2017(7): 161-160. https://www.cnki.com.cn/Article/CJFDTOTAL-JSTB201707078.htm

[5] 杨松荣, 蒋仲亚. 碎磨工艺及应用[M]. 北京: 冶金工业出版社, 2013.

YANG S R, JIANG Z Y. Crushing and grinding processes and applications[M]. Beijing: Metallurgical Industry Press, 2013.

[6] 毛勇, 王泽红, 田鹏程, 等. 磨矿对矿物浮选行为的影响及助磨剂的作用[J]. 矿产保护与利用, 2020, 40(6): 162-168. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=3c58c3f9-9843-4989-a5ed-254c7345407d

MAO Y, WANG Z H, TIAN P C, et al. Effect of grinding on mineral flotation behavior and the role of grinding aids[J]. Conservation and Utilization of Mineral Resources, 2020, 40(6): 162-168. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=3c58c3f9-9843-4989-a5ed-254c7345407d

[7] 黄子杰, 孙伟, 高志勇. 磨矿对矿物表面性质和浮选行为的影响[J]. 中国有色金属学报, 2019, 29(11): 2671-2680. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201911024.htm

HUANG Z J, SUN W, GAO Z Y. Effect of grinding on surface properties and flotation behavior of minerals[J]. Chinese Journal of Nonferrous Metals, 2019, 29(11): 2671-2680. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201911024.htm

[8] 聂梦宇, 韩跃新, 李艳军. 磨矿介质对闪锌矿浮选行为的影响研究[J]. 金属矿山, 2019(2): 163-167. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201902033.htm

NIE M N, HAN Y X, LI Y J. Study on the influence of grinding media on the flotation behavior of sphalerite[J]. Metal Mine, 2019(2): 163-167. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201902033.htm

[9] 刘志伟. 磨机磨矿效率影响因素分析[J]. 有色金属(选矿部分), 2018(4): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201804014.htm

LIU Z W. Analysis of factors affecting grinding efficiency of mill[J]. Nonferrous Metals (Mineral Processing Part), 2018(4): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201804014.htm

[10] 陈勇, 宋永胜, 温建康, 等. 磨矿介质运动状态对锡石多金属硫化物选择性磨矿的影响[J]. 中国矿业, 2021, 30(12): 128-133. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA202112020.htm

CHEN Y, SONG Y S, WEN J K, et al. Effect of grinding media motion state on selective grinding of cassiterite polymetallic sulfides[J]. China Mining, 2021, 30(12): 128-133. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA202112020.htm

[11] 刘凤春, 崔振坤, 丁明星. 磨矿介质对磨矿细度的影响[J]. 山东理工大学学报(自然科学版), 2021, 35(6): 63-66. https://www.cnki.com.cn/Article/CJFDTOTAL-SDGC202106013.htm

LIU F C, CUI Z K, DING M X. Effect of grinding media on grinding fineness[J]. Journal of Shandong University of Technology (Natural Science Edition), 2021, 35(6): 63-66. https://www.cnki.com.cn/Article/CJFDTOTAL-SDGC202106013.htm

[12] 王德金, 刘少君, 杨健. 磨矿作业在实际生产中影响磨矿效率的因素分析[J]. 世界有色金属, 2020(13): 211-212. https://www.cnki.com.cn/Article/CJFDTOTAL-COLO202013098.htm

WANG D J, LIU S J, YANG J. Analysis of factors affecting grinding efficiency of grinding operations in actual production[J]. World Nonferrous Metals, 2020(13): 211-212. https://www.cnki.com.cn/Article/CJFDTOTAL-COLO202013098.htm

[13] 蔡爽, 蔡威, 滕桂平, 等. 矿浆浓度及粒度组成对某锌浸出渣分离粒度及磨矿参数的影响[J]. 矿产综合利用, 2018(4): 46-49+36. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201804010.htm

CAI S, CAI W, TENG G P, et al. Influence of slurry concentration and particle size composition on the separation particle size and grinding parameters of a zinc leaching slag[J]. Mineral Comprehensive Utilization, 2018(4): 46-49+36. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201804010.htm

[14] 王继生, 卢建坤, 马伟, 等. 衬板形状对大型球磨机磨矿效率的影响[J]. 矿山机械, 2013, 41(8): 68-72. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201308023.htm

WANG J S, LV J K, MA W, et al. Effect of liner shape on grinding efficiency of large ball mill[J]. Mining Machinery, 2013, 41(8): 68-72. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201308023.htm

[15] 李国宗. 球磨机筒体衬板形状对磨矿生产率影响的探讨[J]. 铜业工程, 2001(4): 65-66. https://www.cnki.com.cn/Article/CJFDTOTAL-TYGC200104023.htm

LI G Z. Exploration of the influence of ball mill cylinder liner shape on grinding productivity[J]. Copper Engineering, 2001(4): 65-66. https://www.cnki.com.cn/Article/CJFDTOTAL-TYGC200104023.htm

[16] 张祖刚, 毕兵兵, 周润, 等. 球磨机精确化装补球应用实践[J]. 现代矿业, 2017, 33(12): 149-151. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201712044.htm

ZHANG Z G, BI B B, ZHOU R, et al. Application practice of precise ball loading and replenishment in ball mill[J]. Modern Mining, 2017, 33(12): 149-151. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201712044.htm

[17] 汪太平, 肖庆飞, 李博, 等. 精确化装补球制度在冬瓜山铜矿的应用研究[J]. 昆明理工大学学报(自然科学版), 2015, 40(4): 23-27. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG201504006.htm

WANG T P, XIAO Q F, LI B, et al. Study on the application of precise loading and replenishment ball system in Dongguashan copper mine[J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2015, 40(4): 23-27. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG201504006.htm

[18] 康怀斌, 肖庆飞, 秦洪训, 等. 精确化装补球方法在大尹格庄金矿中的应用研究[J]. 黄金, 2015, 36(6): 53-56. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ201506014.htm

KANG H B, XIAO Q F, QIN H X, et al. Study on the application of precise loading and replenishment ball method in Dayingzhuang gold mine[J]. Gold, 2015, 36(6): 53-56. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ201506014.htm

[19] 罗春梅, 郭永杰, 段希祥. 精确化装补球方法对选矿指标影响的研究[J]. 矿冶, 2008, 17(4): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ200804006.htm

LUO C M, GUO Y J, DUAN X X. Study on the effect of precise ball loading and replenishment method on the beneficiation index[J]. Mineralogy, 2008, 17(4): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ200804006.htm

[20] 段希祥. 碎矿与磨矿[M]. 北京: 冶金工业出版社, 2012: 210-213.

DUAN X X. Ore crushing and grinding[M]. Beijing: Metallurgical Industry Press, 2012: 210-213.

[21] OWEN P, CLEARY P W. The relationship between charge shape characteristics and fill level and lifter height for a SAG mill[J]. Minerals Engineering, 2015, 83: 19-32 https://www.sciencedirect.com/science/article/pii/S0892687515300583

[22] 路和, 戴丽莉, 姚荣斌, 等. 球磨机研磨介质冲击特性和碰撞能量分布特性研究[J]. 有色金属(选矿部分), 2018(6): 77-81. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201806015.htm

LU H, DAI L L, YAO R B, et al. Research on impact characteristics and collision energy distribution characteristics of ball mill grinding media[J]. Nonferrous metals (mineral processing part), 2018(6): 77-81. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201806015.htm

[23] 李腾飞, 林蜀勇, 张博, 等. 不同转速率下球磨机内钢球的碰撞研究[J]. 中南大学学报(自然科学版), 2019, 50(2): 251-256. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201902001.htm

LI T F, LIN S Y, ZHANG B, et al. Study on the collision of steel balls in ball mills at different rotation rates[J]. Journal of Central South University (Natural Science Edition), 2019, 50(2): 251-256. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201902001.htm

-

下载:

下载: