Research on Stirring Grinding-Magnetic Separation-Reverse Flotation Process of Preconcentration Mixed Magnetic Concentrate in Anqian

-

摘要:

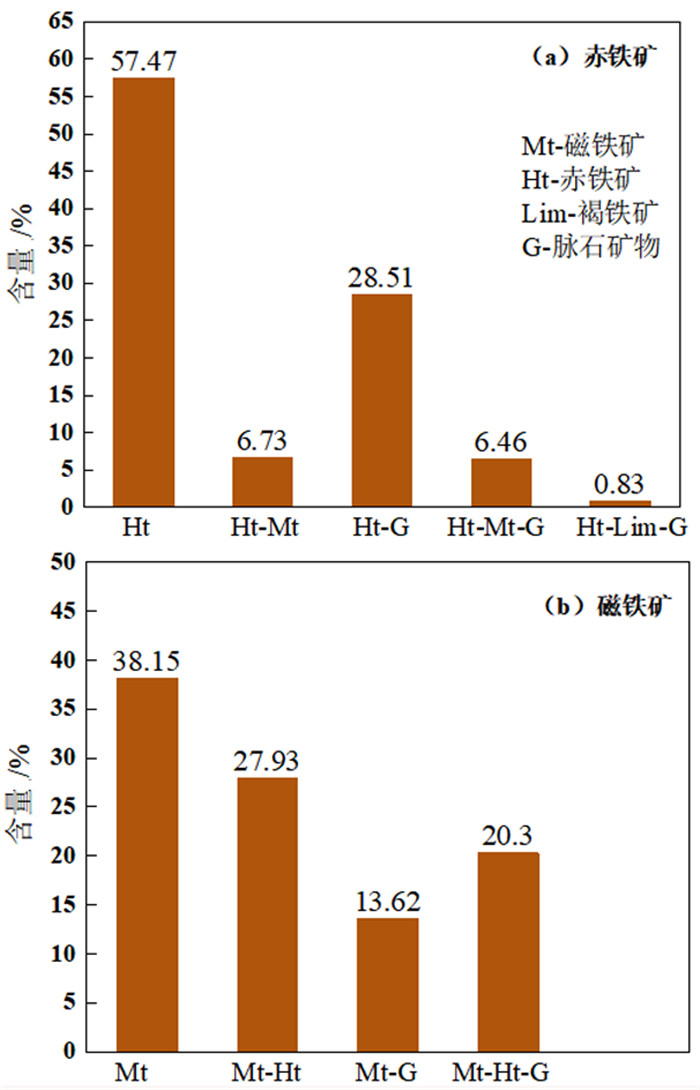

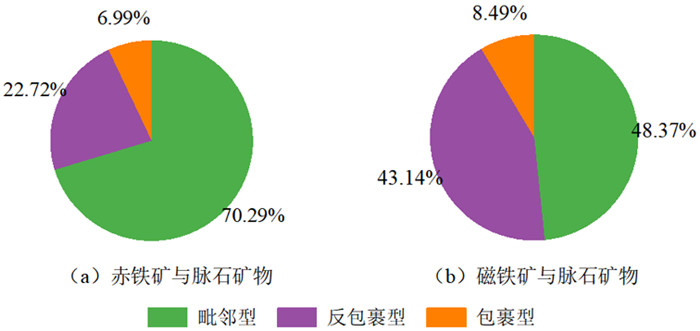

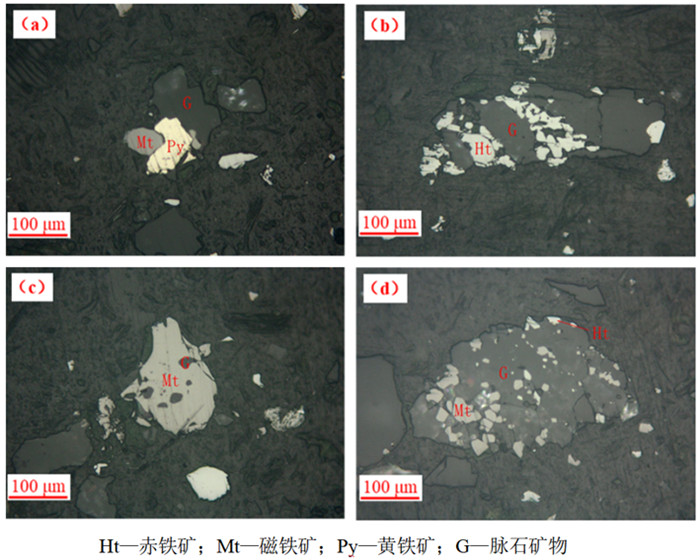

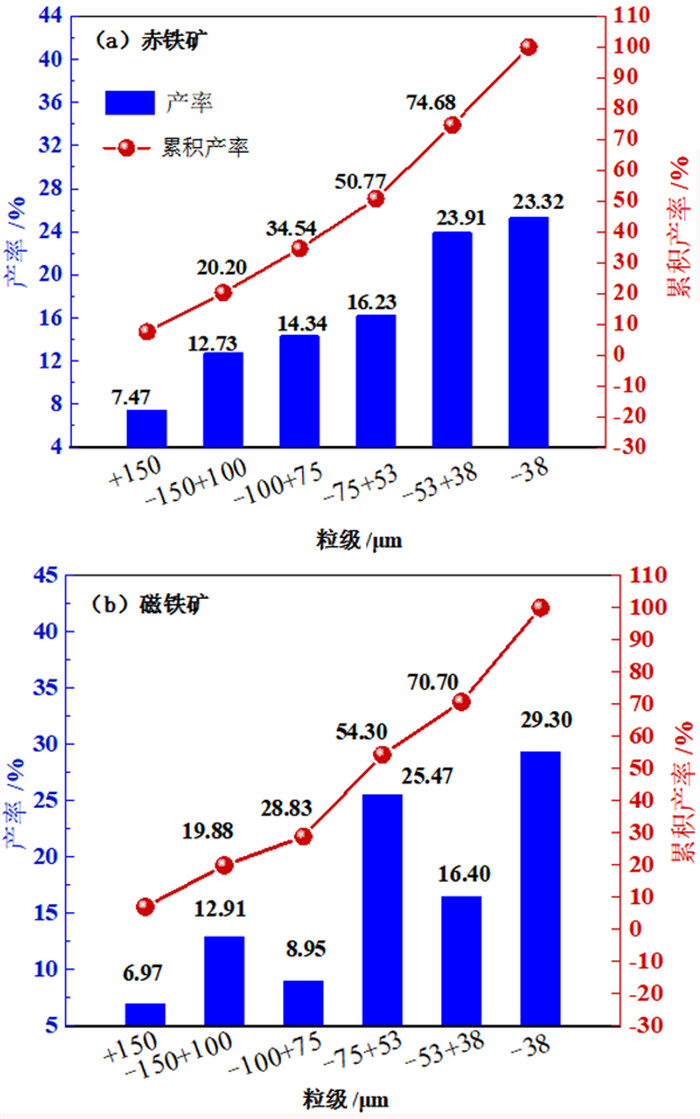

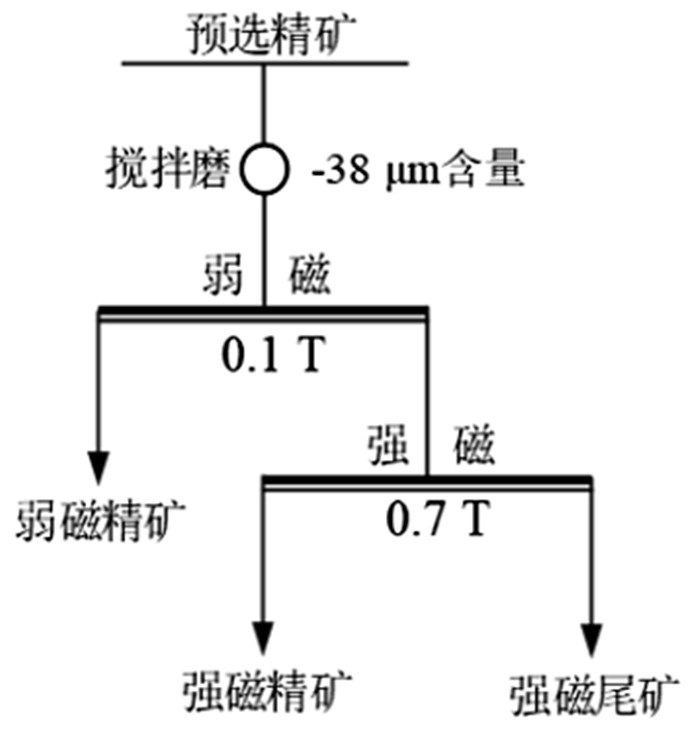

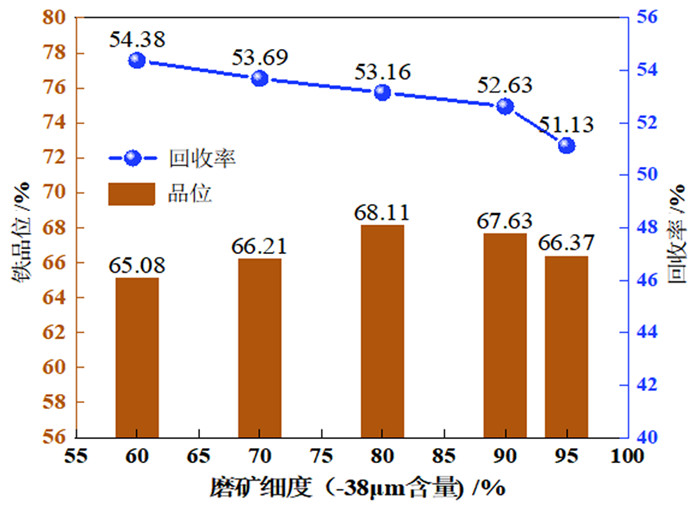

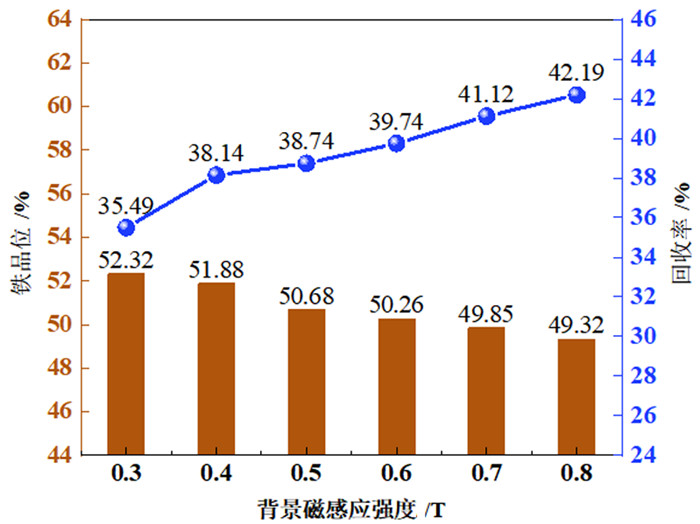

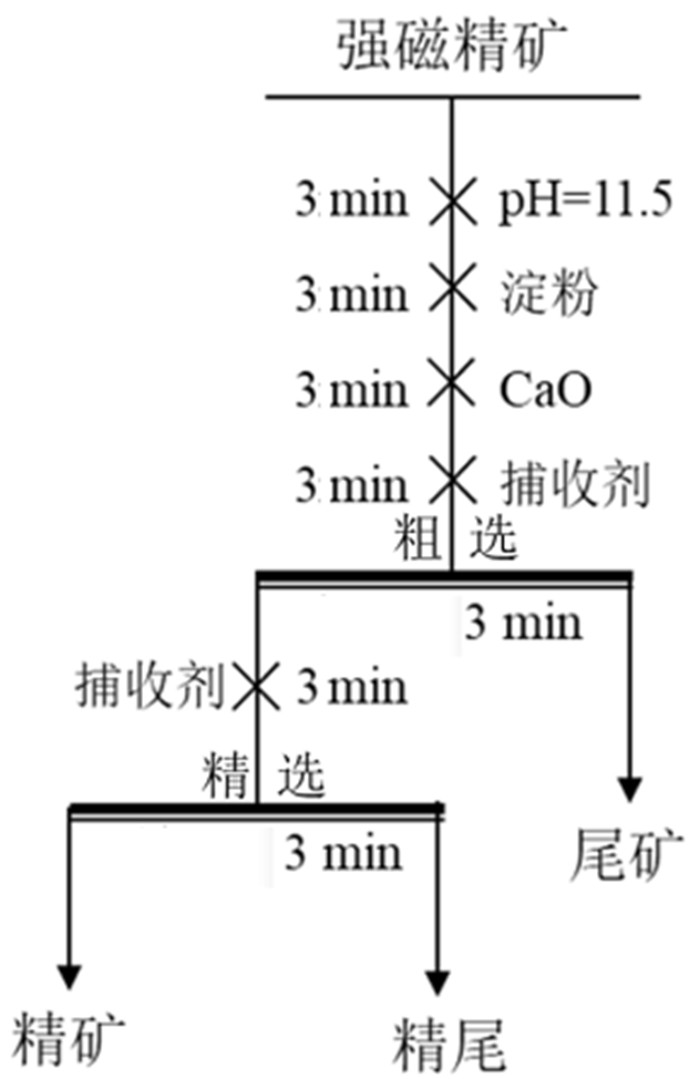

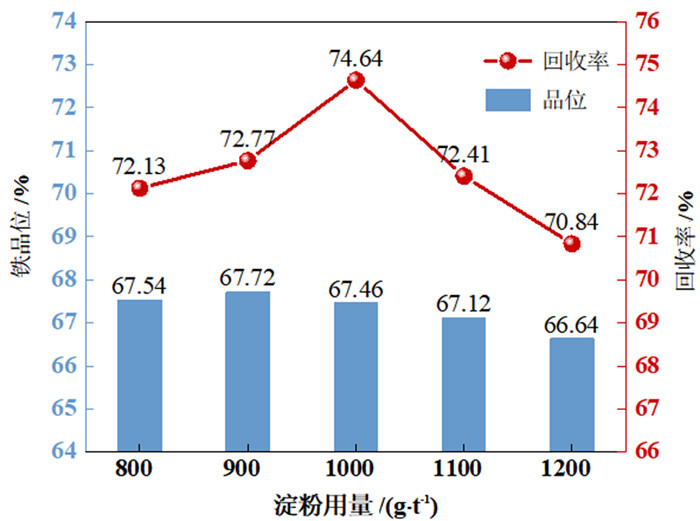

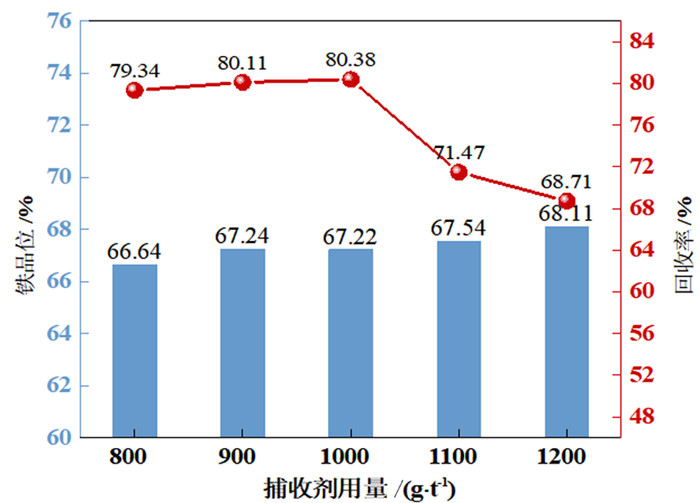

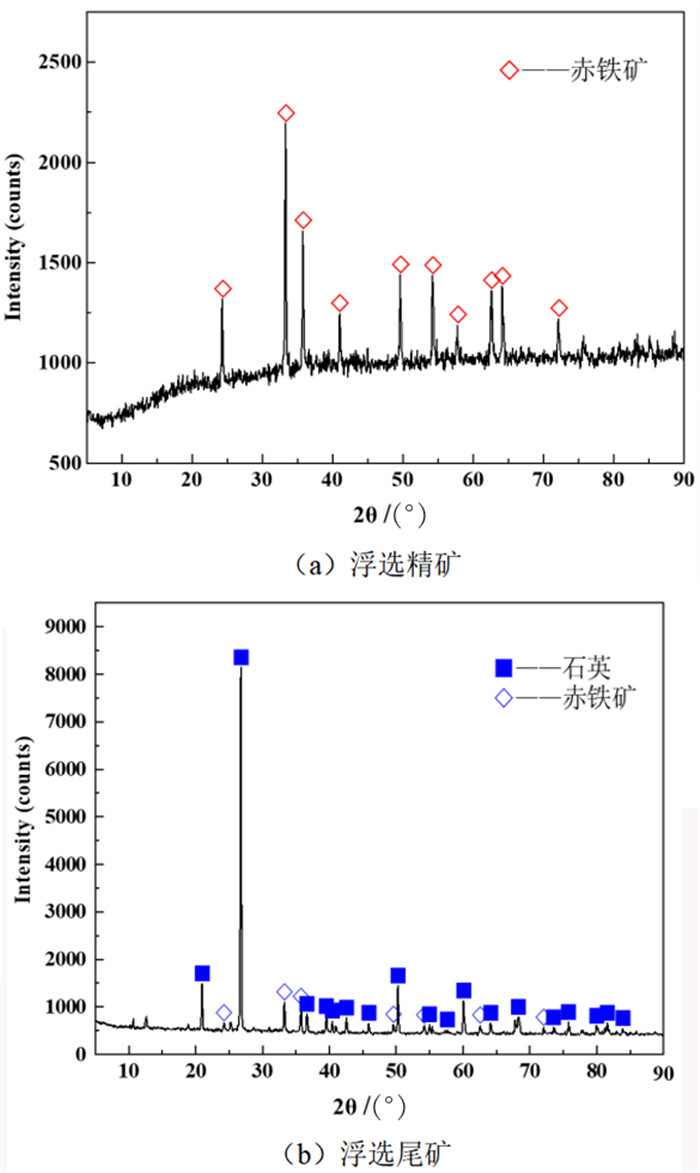

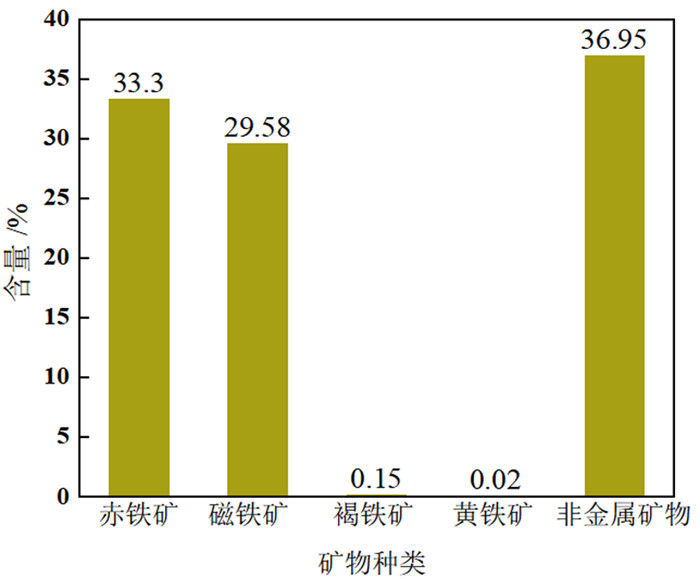

随着鞍千入选矿石性质的变化,原有的工艺流程暴露出一些问题,如重选精矿品位低、浮选尾矿损失大等。针对鞍千半自磨—湿式预选的混磁铁精矿,进行了详细的工艺矿物学研究,并确定了搅拌磨细磨—磁选—反浮选短流程工艺。研究结果表明,混磁精矿中铁品位为42.91%,主要含铁矿物为磁铁矿和赤铁矿,其他金属矿物为少量黄铁矿,赤铁矿和磁铁矿与脉石矿物结合形成的连生体含量较多,且在细粒级中分布率均较高;在此基础上确定了搅拌磨细磨—弱磁选—弱磁尾矿强磁选—强磁精矿一次粗选一次精选三次扫选的工艺流程,弱磁精矿和反浮选精矿合并得到的综合精矿TFe品位67.68%、回收率91.88%,综合尾矿TFe品位为8.83%。本研究对于鞍山式赤铁矿石流程的优化具有重要的指导意义。

Abstract:With the change of ore properties in Anqian, the old process has exposed some problems, such as low grade of gravity concentrate, large loss of iron in flotation tailings and so on. A detailed process mineralogy study was carried out on the mixed magnetic concentrate of semi self-grinding-wet preconcentration in Anqian, and a short process of stirred mill -magnetic separation - reverse flotation was determined. The Fe grade of mixed magnetic concentrate was 42.91%, and the main useful minerals were hematite and magnetite, which were mainly in the form of medium and fine particles. The content of the intergrowths formed by the combination of hematite, magnetite and gangue minerals was high. On this basis, the technological process of stirring fine grinding-low-intensity magnetic separation-high-intensity magnetic separation for tailings in low-intensity magnetic separation-reverse flotation (one roughing, one cleaning and three scavenging) for concentrate in high-intensity magnetic separation was determined. The TFe grade and recovery of comprehensive concentrate obtained by combining weak magnetic concentrate and reverse flotation concentrate was 67.68%, 91.88%, respectively. The TFe grade of comprehensive tailings was 8.83%. This study has important guiding significance for the optimization of Anshan hematite ore process.

-

-

表 1 预选混磁精矿化学成分分析

Table 1. Analysis of chemical composition of pre separation mixed magnetic concentrate

/% 成分 TFe FeO SiO2 Al2O3 CaO MgO S P 烧失 含量 42.91 8.95 36.40 0.34 0.26 0.31 0.009 0.015 0.91 表 2 铁物相分析

Table 2. Iron chemical phase analysis of the ore

/% 铁物相 含量 分布率 磁铁矿中铁 21.77 50.73 赤(褐)铁矿中铁 20.51 47.80 碳酸铁中铁 0.28 0.65 硅酸铁中铁 0.24 0.55 硫化铁中铁 0.11 0.27 总铁 42.91 100.00 表 3 强磁精矿反浮选闭路试验结果

Table 3. Close circuit test results of reverse flotation for concentrate in the high intensity magnetic separation

/% 产品名称 作业产率 TFe品位 回收率 浮选精矿 70.86 67.15 93.59 浮选尾矿 29.14 11.19 6.41 合计 100.00 50.84 100.00 表 4 选矿综合指标

Table 4. Comprehensive index of beneficiation

/% 产品名称 产率(对原矿) TFe品位 回收率(对原矿) 弱磁精矿 综合精矿 34.62 60.55 68.08 67.68 52.24 91.88 浮选精矿 70.86(对作业)×36.59/100 67.15 93.59(对作业)×42.35/100 浮选尾矿 综合尾矿 29.14(对作业)×36.59/100 39.45 11.19 8.83 6.41(对作业)×42.35/100 8.12 强磁尾矿 28.79 7.96 5.41 表 5 浮选精矿化学成分分析结果

Table 5. Analysis results of chemical composition of flotation concentrate

/% 成分 TFe FeO SiO2 Al2O3 CaO MgO S P 烧失 含量 67.15 0.94 2.87 0.26 0.21 0.24 0.015 0.009 0.66 表 6 浮选尾矿化学成分分析结果

Table 6. Analysis of chemical composition of flotation tails

/% 成分 TFe FeO SiO2 Al2O3 CaO MgO S P 烧失 含量 11.19 1.91 67.04 0.76 0.58 1.09 0.005 0.011 1.64 表 7 强磁选尾矿化学成分分析结果

Table 7. Chemical composition analysis for tailings in the high intensity magnetic separation

/% 成分 TFe FeO SiO2 Al2O3 CaO MgO S P 烧失 含量 8.07 3.20 81.57 0.60 0.05 0.41 0.030 0.045 0.34 表 8 强磁选尾矿铁物相分析结果

Table 8. Iron chemical phase analysis of tailings in the high intensity magnetic separation

/% 物相 磁性铁中的铁 碳酸铁中的铁 赤褐铁中的铁 硫化铁中的铁 硅酸铁中的铁 总铁 含量/% 0.00 0.22 6.85 0.20 0.86 8.07 分布率/% 0.00 2.71 84.26 2.46 10.58 100.00 -

[1] 韩跃新, 孙永升, 李艳军, 等. 我国铁矿选矿技术最新进展[J]. 金属矿山, 2015(2): 1-11. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201502002.htm

HAN Y X, SUN Y S, LI Y J, et al. New development on mineral processing technology of iron ore resources in China[J]. Metal Mine, 2015(2): 1-11. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201502002.htm

[2] 唐雪峰. 难处理赤铁矿选矿技术研究现状和发展趋势[J]. 现代矿业, 2014(3): 14-19. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201403011.htm

TANG X F. Research status and development trend of beneficiation technology on complex hematite[J]. Modern Mining, 2014(3): 14-19. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201403011.htm

[3] 张翔. 浅谈我国铁矿资源安全的现状和对策[J]. 福建冶金, 2021, 50(3): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-FJYJ202103016.htm

ZHANG X. The present situation and countermeasures of iron ore resource safety in China[J]. Fujian Metallurgy, 2021, 50(3): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-FJYJ202103016.htm

[4] 武秋杰, 吕振福, 曹进成. 我国铁矿大型资源基地开发利用现状研究[J]. 现代矿业, 2020, 36(8): 113-115+138. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB202008040.htm

WU Q J, LV Z F, CAO J C. Research on the development and utilization of iron ore large resource bases in China[J]. Modern Mining, 2020, 36(8): 113-115+138. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB202008040.htm

[5] 赵立群, 王春女, 张敏, 等. 中国铁矿资源勘查开发现状及供需形势分析[J]. 地质与勘探, 2020, 56(3): 635-643. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202003016.htm

ZHAO L Q, WANG C N, ZHANG M, et al. Current exploration status and supply-demand situation of iron ore resources in China Mainland[J]. Geology and Exploration, 2020, 56(3): 635-643. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKT202003016.htm

[6] 罗小利. 我国铁矿资源勘查开发现状及对策建议[J]. 现代矿业, 2019, 35(12): 28-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201912010.htm

LUO X L. Exploration and development status and policy recommendations of iron ore resources in China[J]. Modern Mining, 2019, 35(12): 28-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201912010.htm

[7] 胡国辉, 张廷龙, 宋现洲, 等. 新型陶瓷球在大型立式搅拌磨上的应用初探[J]. 矿山机械, 2018, 46(10): 30-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201810009.htm

HU G H, ZHANG T L, SONG X Z, et al. Research on application of new-type ceramic ball in large vertical stirring mill[J]. Mining & Processing Equipment, 2018, 46(10): 30-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201810009.htm

[8] 史达, 刘杰, 侯鹏程, 等. 鞍千预选铁精矿陶瓷球搅拌磨再选试验研究[J]. 中国矿业, 2021, 30(7): 140-145. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA202107021.htm

SHI D, LIU J, HOU P C, et al. Experimental study on ceramic ball stirred mill in anqian pre-selected concentrate re-election[J]. China Mining Magazine, 2021, 30(7): 140-145. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA202107021.htm

[9] 苏兴国, 杨光, 陈国荣, 等. 东鞍山混磁精矿搅拌磨与球磨对比试验[J]. 矿产保护与利用, 2021, 41(1): 113-121. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=24791ef4-fa70-404c-bc73-dfae2ff11490

SU X G, YANG G, CHEN G R, et al. Optimization test of stirred mill for mixed magnetic concentrate from Donganshan[J]. Conservation and Utilization of Mineral, 2021, 41(1): 113-121. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=24791ef4-fa70-404c-bc73-dfae2ff11490

[10] 鲁荣林. 东鞍山铁矿矿石工艺矿物学特征研究[J]. 金属矿山, 2004(9): 40-41. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS200409013.htm

LU R L. Study on characteristics of technological mineralogy of Donganshan Iron Mine's ore[J]. Metal Mine, 2004(9): 40-41. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS200409013.htm

[11] 宫贵臣, 韩跃新, 李艳军. 辽宁某铁矿石工艺矿物学研究[J]. 矿产综合利用, 2018(2): 77-80. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201802017.htm

GONG G C, HAN Y X, LI Y J. Study on process mineralogy for an iron ore from Liaoning Province[J]. Multipurpose Utilization of Mineral Resources, 2018(2): 77-80. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201802017.htm

[12] 王彦, 李艳军. 某菱锰矿石工艺矿物学研究[J]. 金属矿山, 2019(2): 188-191. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201902038.htm

WANG Y, LI Y J. Research on process mineralogy of a carbonaceous rhodochrosite Ore[J]. Metal Mine, 2019(2): 188-191. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201902038.htm

[13] 赵玉卿, 应永朋, 熊艳, 等. BPMA在某低品位铌钽矿工艺矿物学研究中的应用[J]. 矿产综合利用, 2021(5): 129-134. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL202105020.htm

ZHAO Y Q, YING Y P, XIONG Y, et al. Application of BPMA in process mineralogy of a low-grade Nb-Ta ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 129-134. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL202105020.htm

-

下载:

下载: