Enhanced Flotation of Coal Slime with ST-diesel Microemulsion

-

摘要:

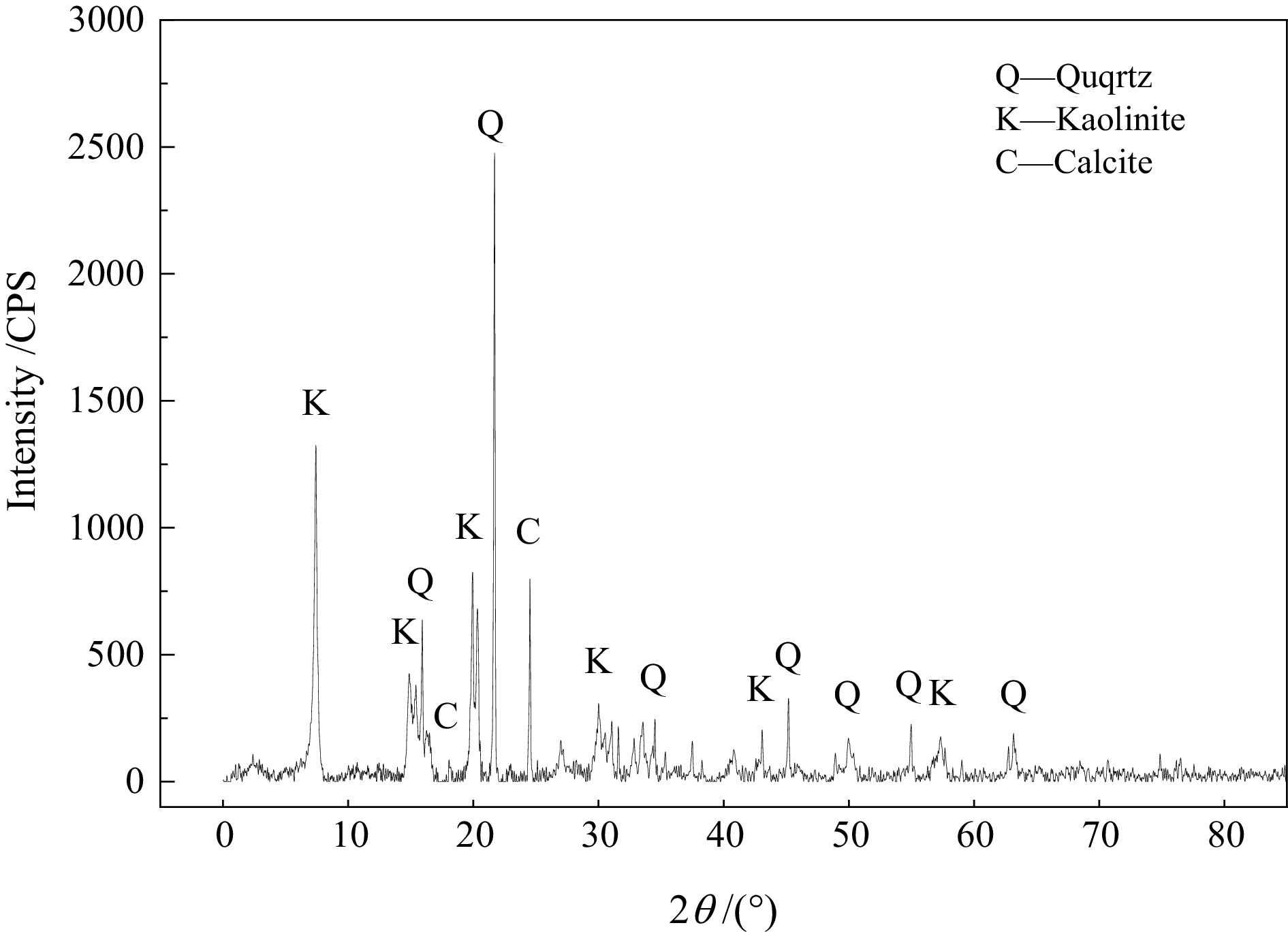

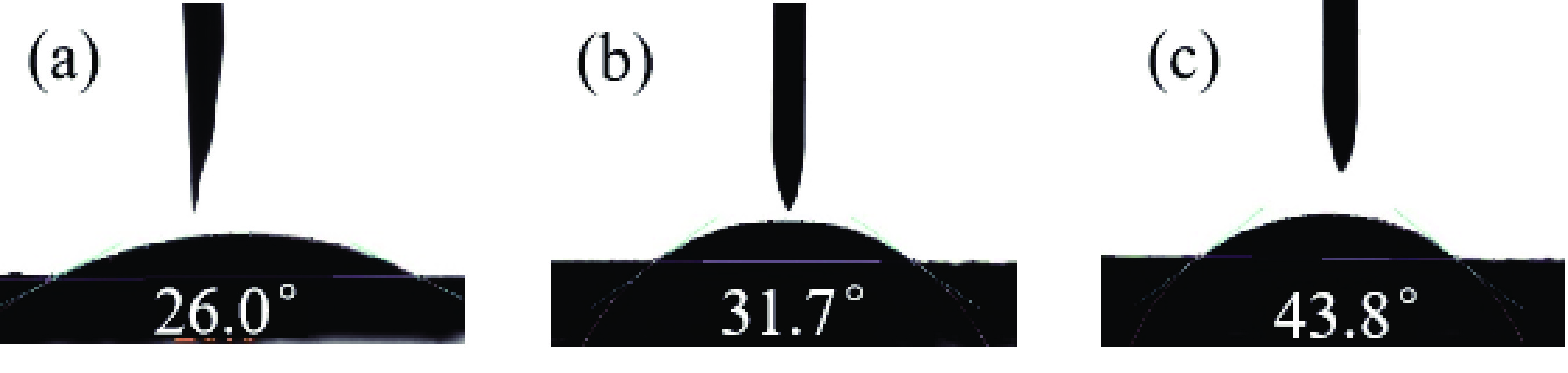

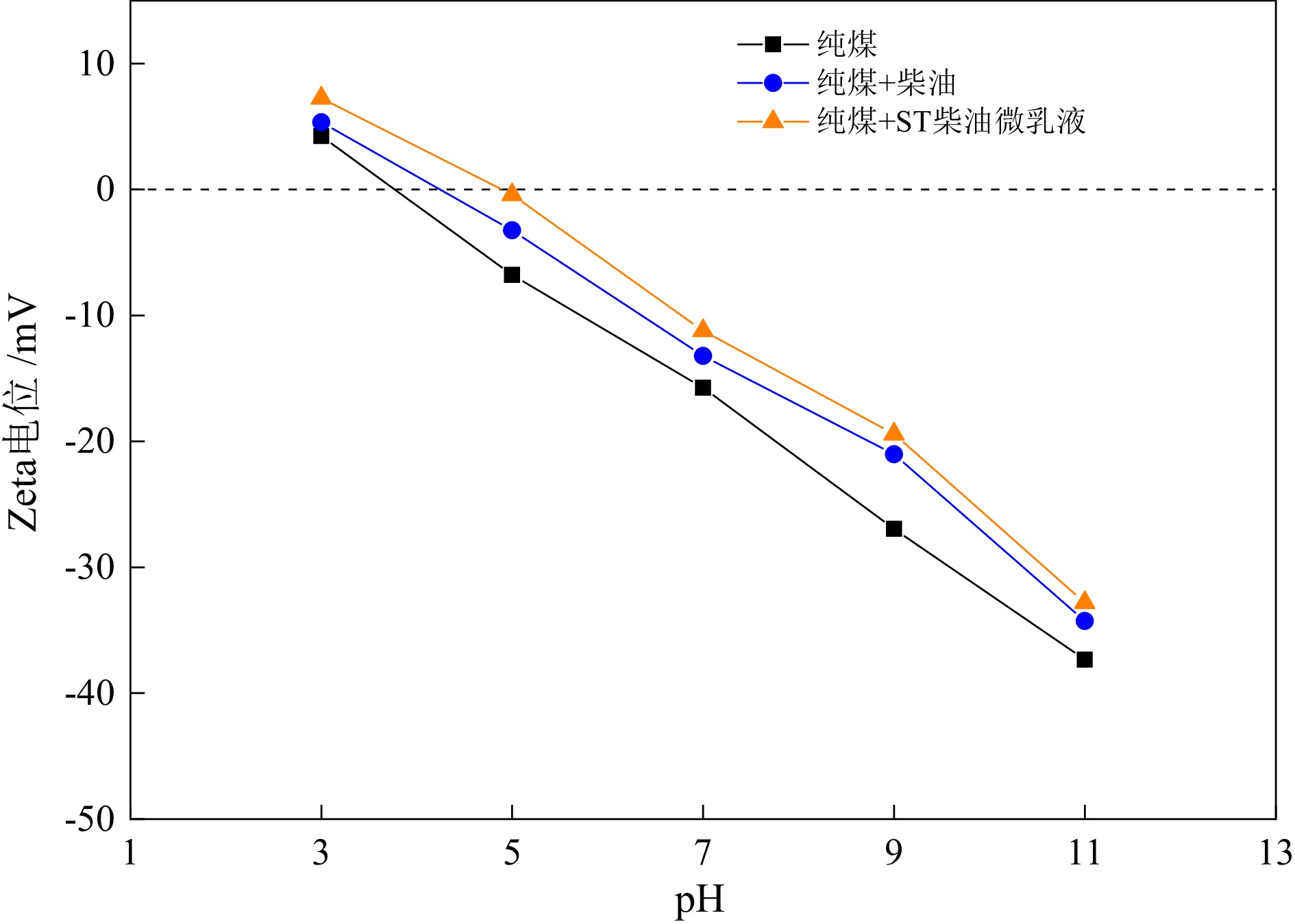

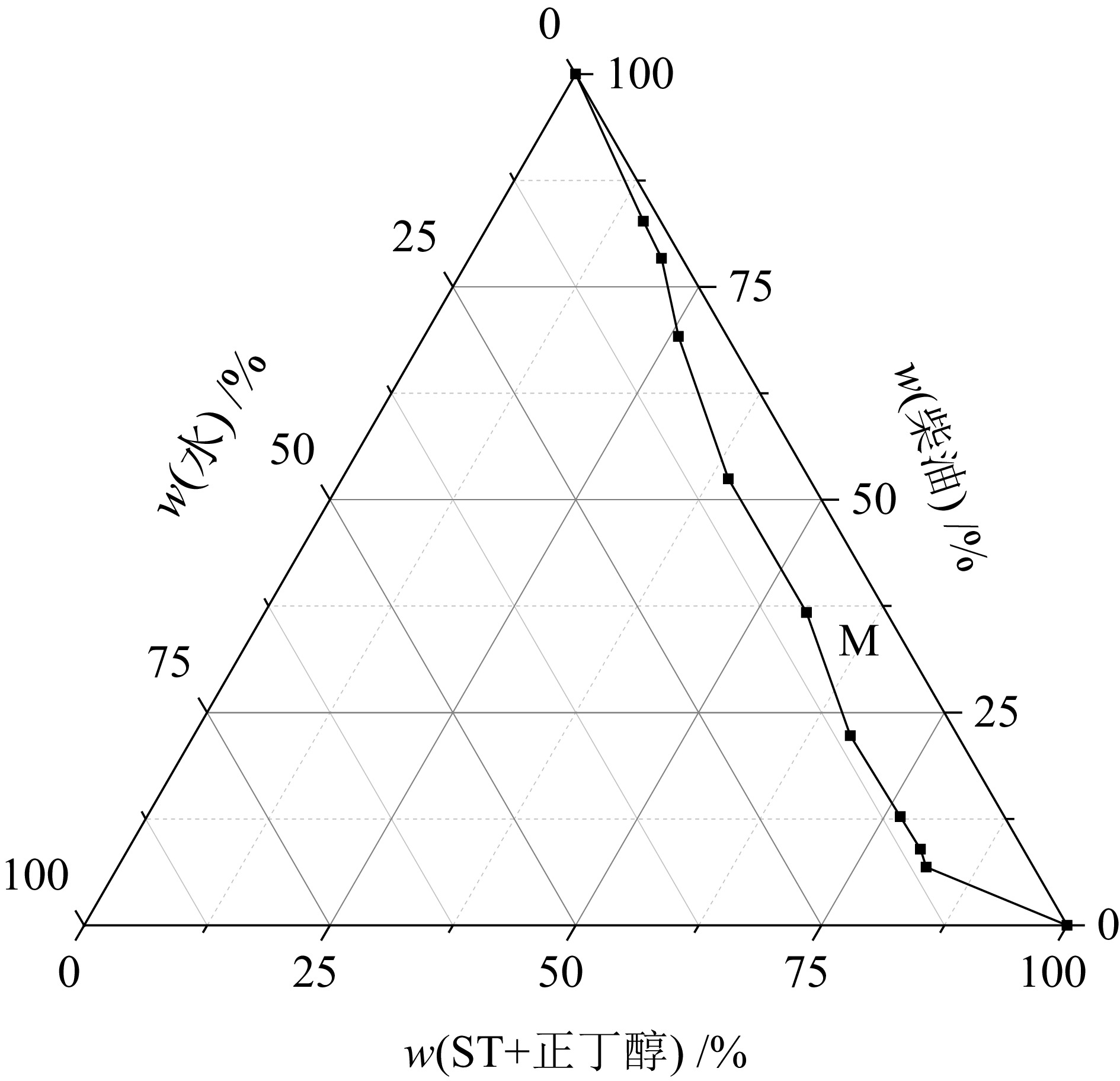

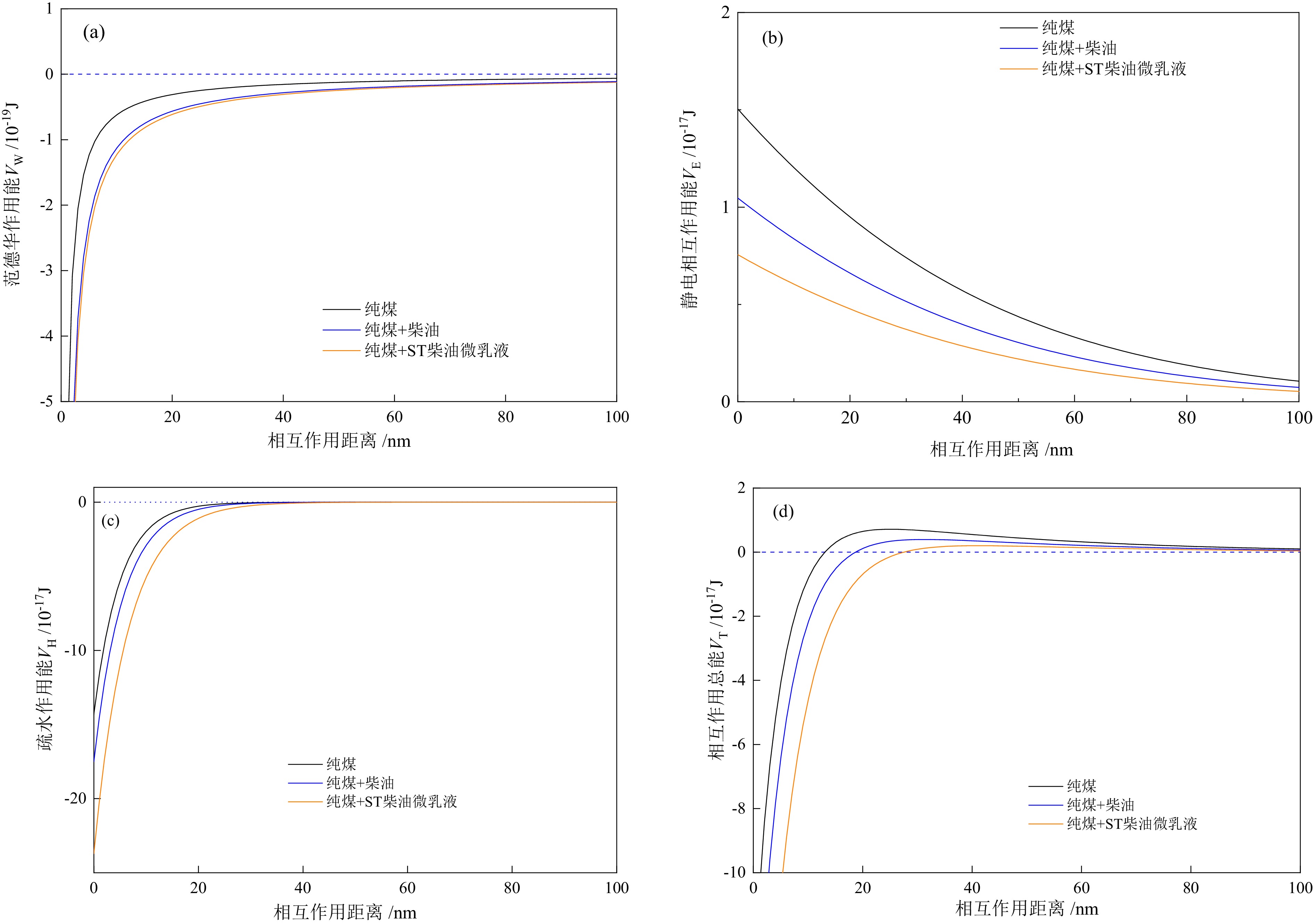

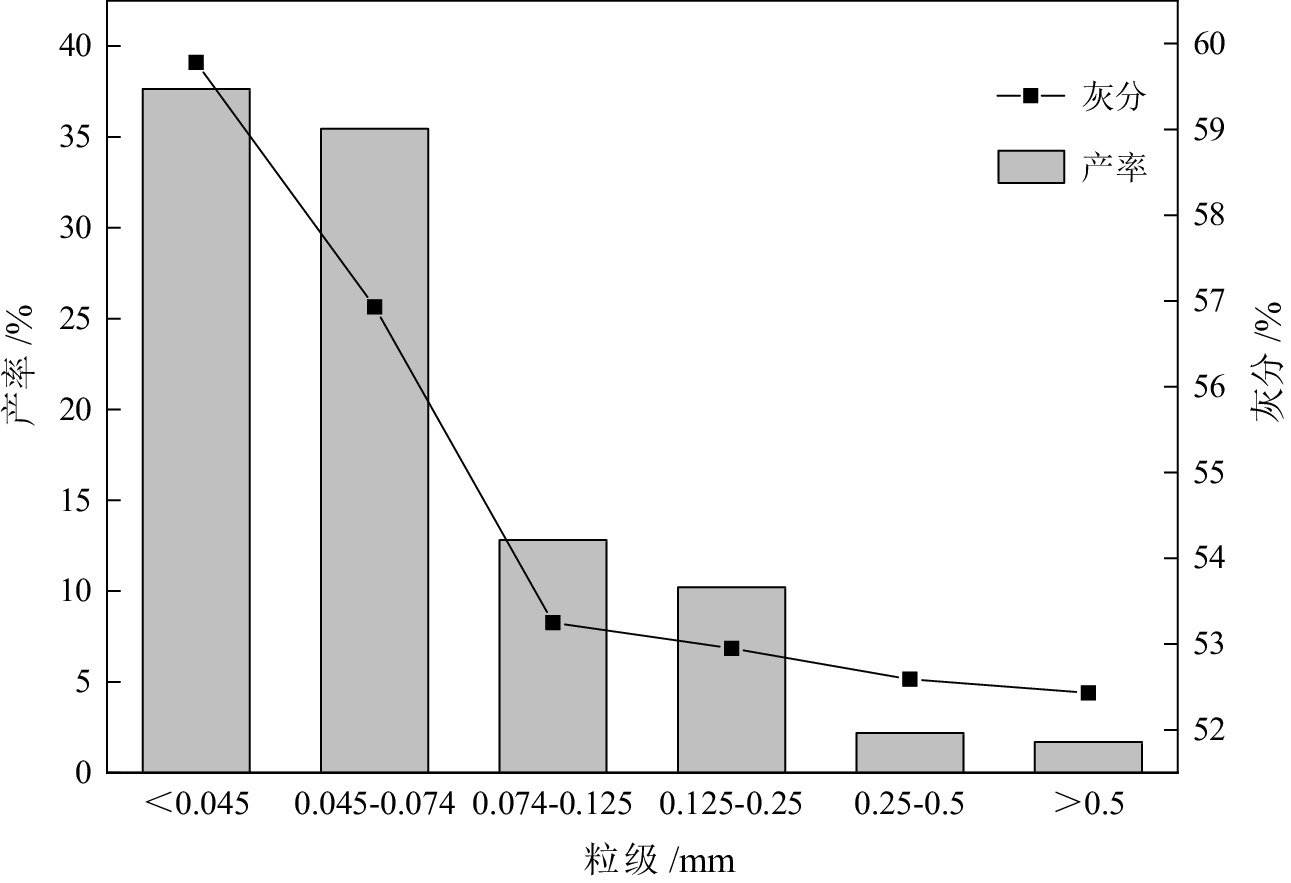

柴油作为煤泥浮选的捕收剂,分散及捕收效果差、用量大。为提高柴油的分散及捕收性能,采用Span80和Tween80两种表面活性剂对煤泥浮选柴油捕收剂进行乳化,配制出液滴粒径小于100 nm的新型捕收剂ST-柴油微乳液。通过单元浮选试验研究了煤泥浮选指标的提升效果;通过接触角测试、Zeta电位分析、红外光谱分析、EDLVO理论计算等手段探讨了微乳液在煤泥表面的作用机理。ST−柴油微乳液作煤泥捕收剂时浮选效果较好,可燃体回收率可达68.13%,比柴油作捕收剂时高9.23百分点。与柴油相比,ST−柴油微乳液处理后纯煤表面接触角提高17.3°;表面Zeta电位绝对值减小;煤颗粒间相互作用总能VT的能垒降低,有利于颗粒间凝聚;表面活性剂与煤泥表面含氧官能团发生物理吸附,提高了煤粒表面疏水性。ST−柴油微乳液可作为一种新型高效的煤泥浮选捕收剂。

Abstract:As a collector for coal slime flotation, diesel oil has poor dispersion and collection effect and large dosage. In order to improve the dispersion and collection performance of diesel oil. Two surfactants, Span80 and Tween80, are used to emulsify diesel collector for coal slime flotation. A new collector ST-diesel microemulsion with droplet size less than 100 nm is being prepared. The improvement effect of slime flotation index is studied by unit flotation test. The mechanism of microemulsion on the surface of coal slime is discussed by means of contact angle test, Zeta potential analysis, infrared spectrum analysis and EDLVO theoretical calculation. When ST-diesel microemulsion is used as coal slime collector, the flotation effect is better, and the recovery rate of combustible body can reach 68.13% which is 9.23 percent higher than diesel collector. The contact angle of pure coal surface increased by 17.3° after ST-diesel microemulsion treatment compared with diesel. The absolute value of surface Zeta potential decreases. The energy barrier of the total energy VT of the interaction between coal particles is reduced, which is beneficial to the agglomeration between particles. The physical adsorption of surfactant and oxygen-containing functional groups on the surface of coal slime improves the surface hydrophobicity of coal particles. The ST-diesel microemulsion can be used as a new and efficient collector for coal slime flotation.

-

Key words:

- coal slime /

- flotation /

- diesel oil /

- surfactant /

- microemulsion

-

-

表 1 煤泥的工业分析和元素分析

Table 1. Industrial analysis and elemental analysis of coal slime

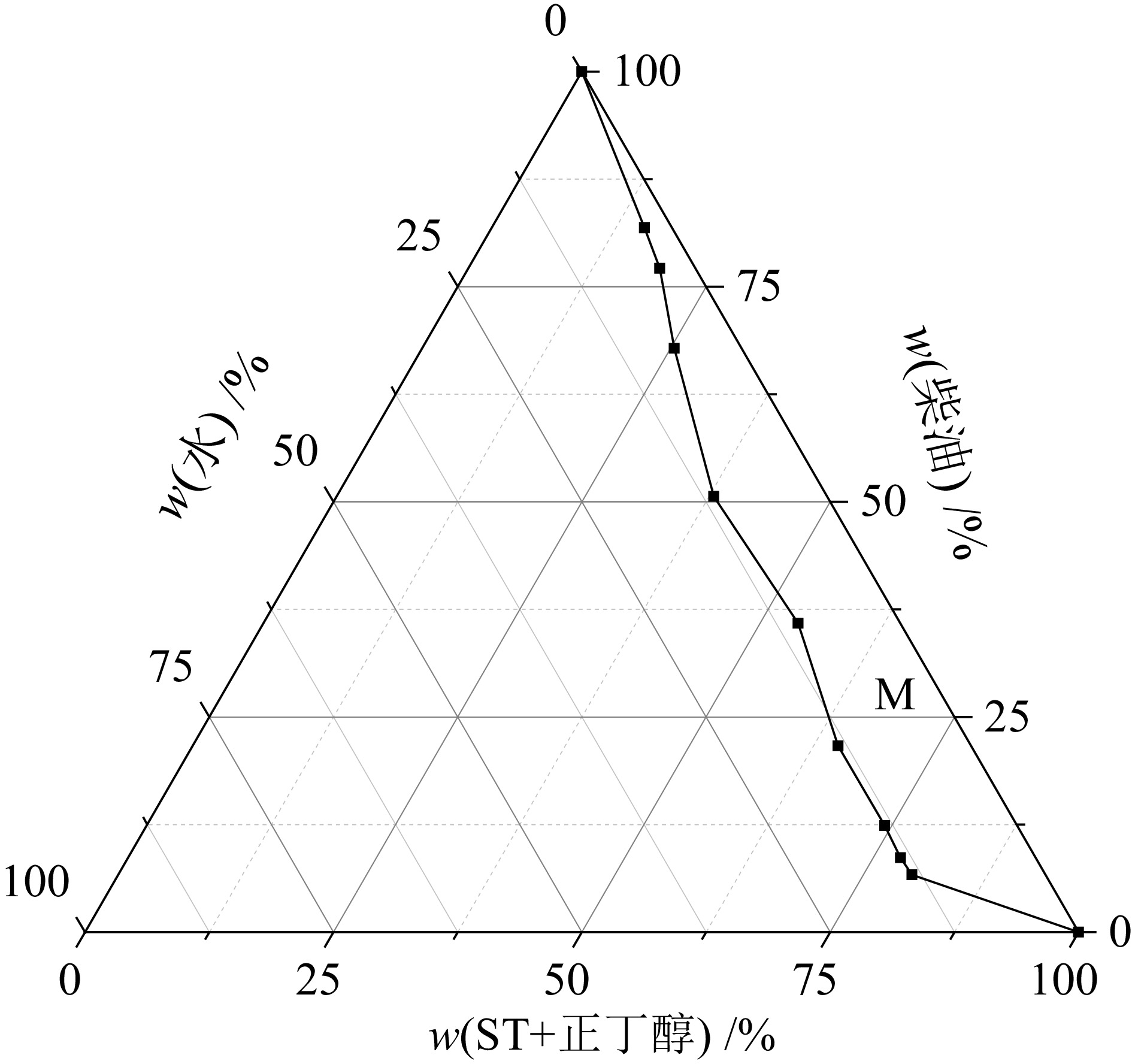

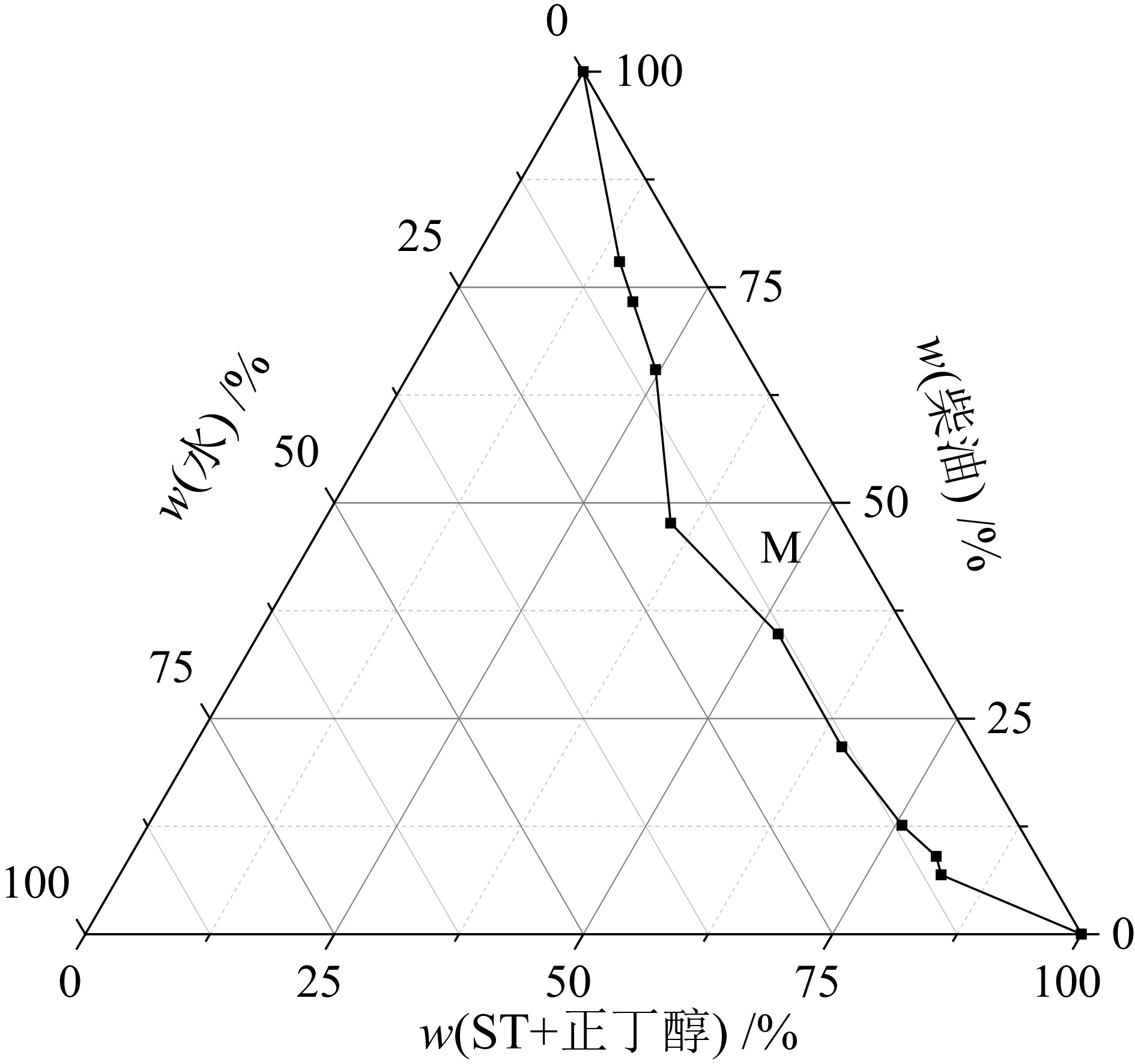

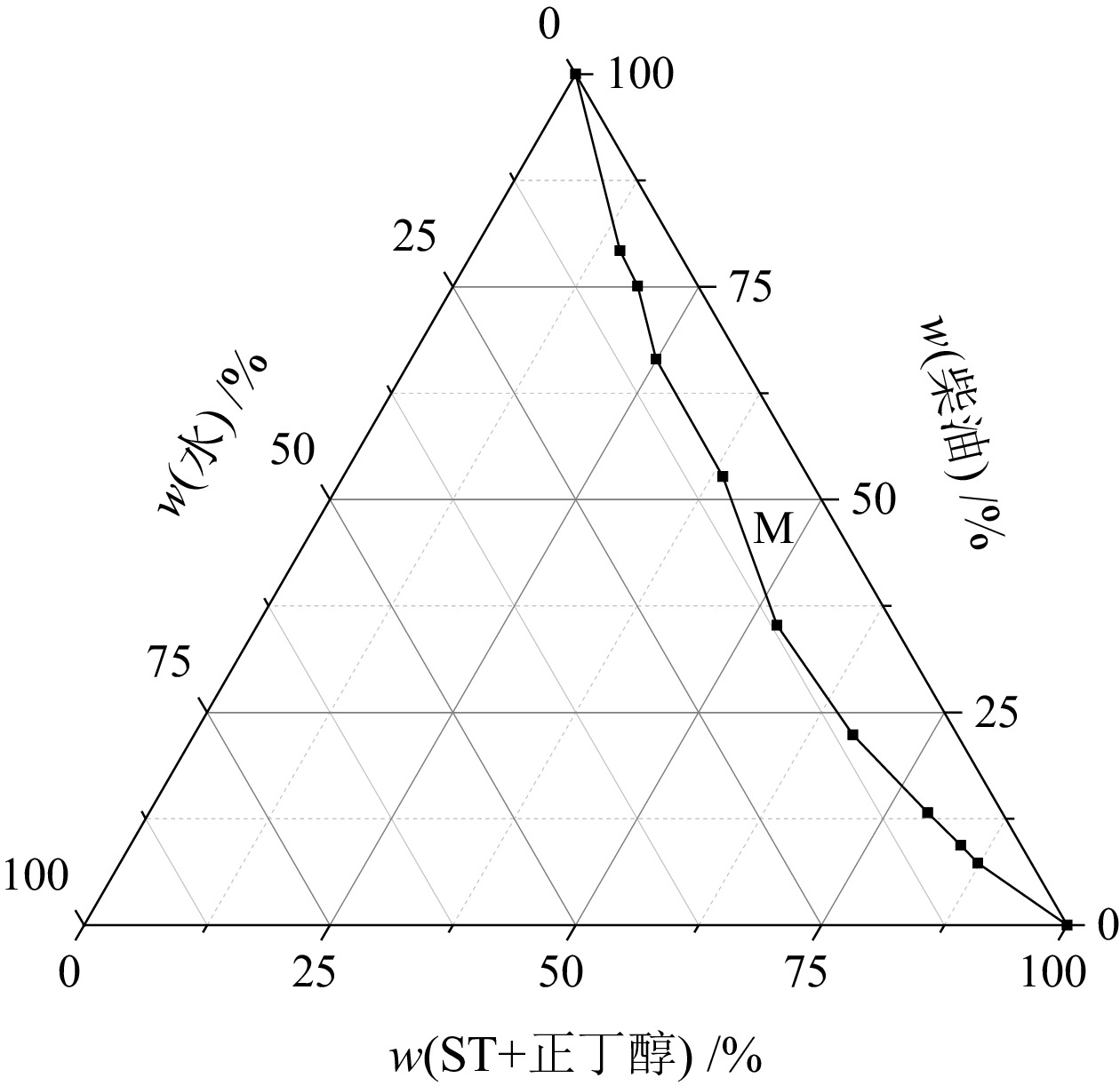

工业分析/% 元素分析/% Mad Aad Vad FCad Cad Had Oad Nad Sad 1.66 56.91 15.84 25.59 32.27 2.59 9.21 0.92 0.23 表 2 不同HLB值的ST−柴油微乳液三元相图微乳区面积

Table 2. Microemulsion area of ST microemulsion ternary phase diagram with different HLB values

HLB值 6 7 8 9 微乳区面积 635 819 1013 773 表 3 液滴平均粒径

Table 3. Average droplet size

种类 柴油 ST-柴油微乳液 平均粒径/nm 1648.4 94.2 -

[1] 李琳, 刘炯天, 王运来, 等. 阴-非离子表面活性剂微乳捕收剂的制备及应用[J]. 煤炭学报, 2014, 39(11): 2315−2320.

LI L, LIU J T, WANG Y L, et al. Preparation and application of anionic-nonionic surfactant microemulsified collector[J]. Journal of China Coal Society, 2014, 39(11): 2315−2320.

[2] Arriagada S, Acua C, Vera M. New technology to improve the recovery of fine particles in froth flotation based on using hydrophobized glass bubbles[J]. Minerals Engineering, 2020, 156.

[3] 陈奎, 宋璨奡, 曹曦, 等. 废轮胎热解制备煤泥浮选捕收剂的试验研究[J]. 煤炭科学技术, 2011, 39(2): 115−118.

CHEN K, SONG C A, CAO X, et al. Experiment study on waste tyre pyrolysis to prepare collector of slime floatation[J]. Coal Science and Technology, 2011, 39(2): 115−118.

[4] 杨自立. 基于细泥絮凝的高灰细粒煤脱灰过程界面作用机制[D]. 徐州: 中国矿业大学, 2022.

YANG Z L. Interface mechanism of high-ash coal slime deashing process based on fine mud flocculation[D]. Xuzhou: China University of Mining and Technology, 2022.

[5] XIA W, ZHOU C, PENG Y. Enhancing flotation cleaning of intruded coal dry-ground with heavy oil[J]. Journal of Cleaner Production, 2017, 161.

[6] ATESOK G, BOYLU F, CELIK M S. Carrier flotation for desulfurization and deashing of difficult-to-float coals[J]. Minerals Engineering, 2001(6): 14.

[7] 于跃先, 马力强, 张仲玲, 等. ZS乳化药剂对褐煤半焦浮选结果的影响及机理分析[J]. 煤炭科学技术, 2016, 44(3): 184−187.

YU Y X, MA L Q, ZHANG Z L, et al. Analysis of emulsified ZS reagent effect on flotation results of lignite semi-coke and its mechanism[J]. Coal Science and Technology, 2016, 44(3): 184−187.

[8] WANG T, XIA W, LIANG L, et al. The coalescence of bubbles immersed in liquid and at the liquid–gas interface[J]. Minerals Engineering, 2019, 142: 105924. doi: 10.1016/j.mineng.2019.105924

[9] 白娅娜, 朱书全, 解维伟, 等. 乳化柴油捕收剂的浮选试验研究[J]. 煤炭科学技术, 2009, 37(1): 117−121.

BAI Y N, ZHU S Q, XIE W W, et al. Research on flotation test of emulsified diesel collector[J]. Coal Science and Technology, 2009, 37(1): 117−121.

[10] 任聪, 樊民强, 李志红, 等. 复配药剂浮选低阶煤泥的效能研究[J]. 煤炭科学技术, 2020, 48(S1): 242−247.

REN C, FAN M Q, LI Z H, et al. Efficiency of compound reagents flotation of low-rank coal slime[J]. Coal Science and Technology, 2020, 48(S1): 242−247.

[11] 王驰, 崔广文. Gemini表面活性剂在地沟油制备微乳捕收剂中的应用[J]. 煤炭工程, 2019, 51(3): 130−135.

WANG C, CUN G W. Application of gemini surfactant in preparation of micro-emulsion collector made from swill-cooked dirty oil[J]. Coal Engineering, 2019, 51(3): 130−135.

[12] 李志斌. 柴油乳化及其对浮选影响的研究[D]. 北京: 煤炭科学研究总院, 2017.

LI Z B. Study on the emulsification of diesel oil and its effects on floation efficiency[D]. Beijing: Coal Research Institute, 2017.

[13] 张瑞英. 新型煤用捕收剂PCF捕收性能试验研究[J]. 煤炭科学技术, 2011, 39(6): 125−128.

ZHANG R Y. Experiment study on capture performance of new coal capturer PCF[J]. Coal Science and Technology, 2011, 39(6): 125−128.

[14] CHANG Z, CHEN X, PENG Y. The interaction between diesel and surfactant Triton X-100 and their adsorption on coal surfaces with different degrees of oxidation[J]. Powder Technology, 2019, 342: 840−847. doi: 10.1016/j.powtec.2018.10.047

[15] 李琳, 贺萌, 李晓腾, 等. 生物基微乳捕收剂的制备及其在煤泥浮选中的应用[J]. 中国矿业大学学报, 2022, 51(4): 779−790.

LI L, HE M, LI X T, et al. Preparation of bio-based microemulsion collector and its application in coal slime flotation[J]. Journal of China University of Mining & Technology, 2022, 51(4): 779−790.

[16] 黄波, 徐宏祥, 李旭林. 微乳型捕收剂的稳定性和浮选性能的试验研究[J]. 煤炭学报, 2019, 44(9): 2878−2885.

HUANG B, XUN H X, LI X L. Experimental study on stability and flotation performance of micro-emulsion collector[J]. Journal of China Coal Society, 2019, 44(9): 2878−2885.

[17] ZHAO X, TANG Y, ZHAO B, et al. Collecting behaviors of high internal phase (HIP) emulsion in flotation of ultrafine high-ash content coal slime[J]. International Journal of Coal Preparation and Utilization, 2022, 42(9).

[18] 赵学敏. 基于煤油与起泡剂的微乳液配制及其煤泥浮选效果研究[D]. 太原: 太原理工大学, 2017.

ZHAO X M. Preparation of microemulsified collector based on kerosene and foaming agent and application in coal flotation[D], Taiyuan: Taiyuan University of Technology, 2017.

[19] 刘腾飞, 冯莉. 添加剂对乳化柴油捕收剂稳定性的影响[J]. 实验室研究与探索, 2012, 31(12): 19-23.

LIU T F, FENG L. Effect of additives on the stability of emulsified diesel collector[J]. Research and Exploration in Laboratory, 2012, 31(12): 19-23.

[20] 史建平. WL浮选捕收剂的研制及应用[J]. 煤炭加工与综合利用, 2009(2): 17−21.

SHI J P. Development and application of WL flotation collector[J]. Coal Processing & Comprehensive Utilization, 2009(2): 17−21.

[21] XIE W, CAO G, REN X, et al. Effect of flotation promoter on the rate of coal slime flotation[J]. Journal of Mining Scinece, 2014, 50(3).

[22] YOU X, LI L, LIU J, et al. Investigation of particle collection and flotation kinetics within the Jameson cell downcomer[J]. Powder Technology, 2017, 310.

[23] 解维伟. 煤乳化浮选药剂的制备与应用机理研究[D]. 北京: 中国矿业大学, 2009.

XIE W W. Research on the preparation and application mechanism of the emulsified coal floatation agent[D]. Beijing: China University of Mining and Technology, 2009.

-

下载:

下载: