Modification and Industrial Application of Liners of Semi−autogenous Grinding Mill Based on Orthogonal Design and Discrete Element Method

-

摘要:

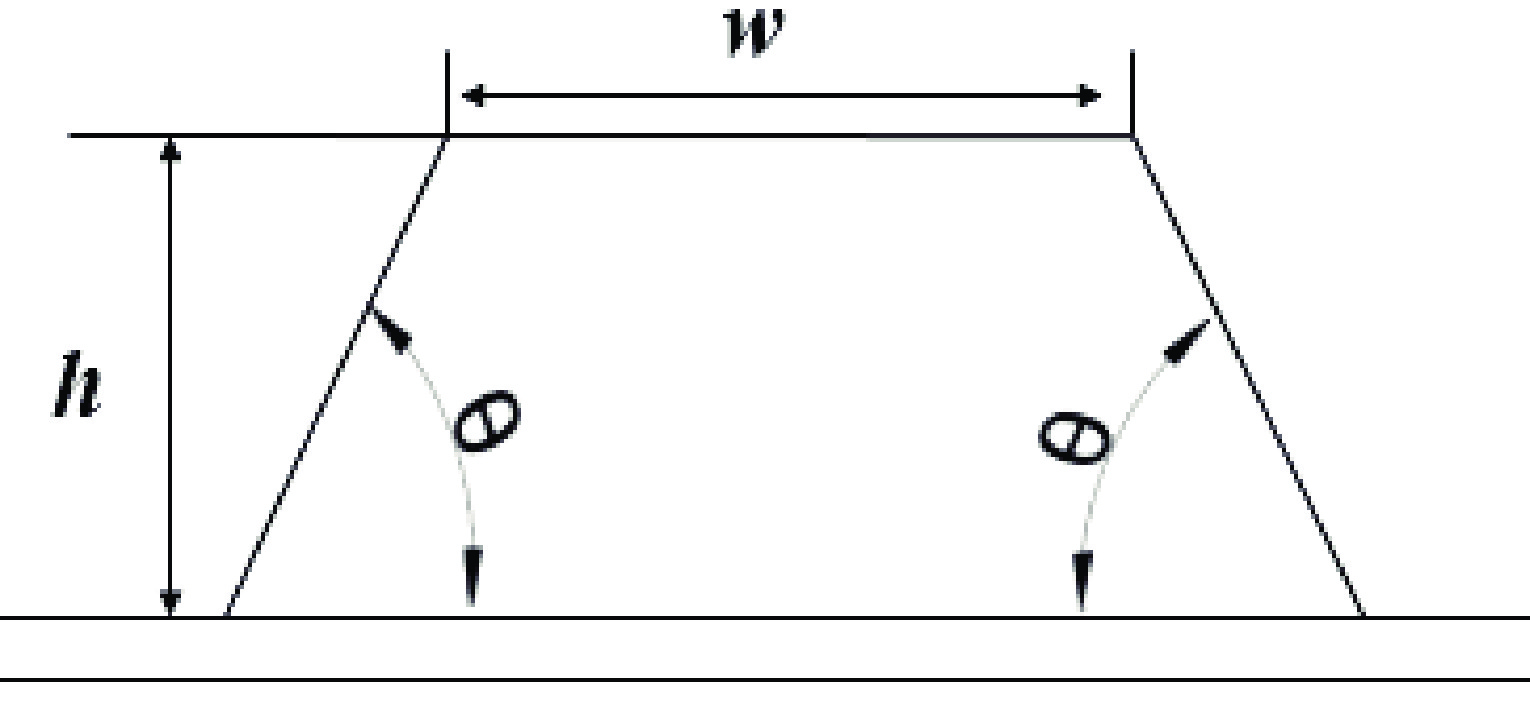

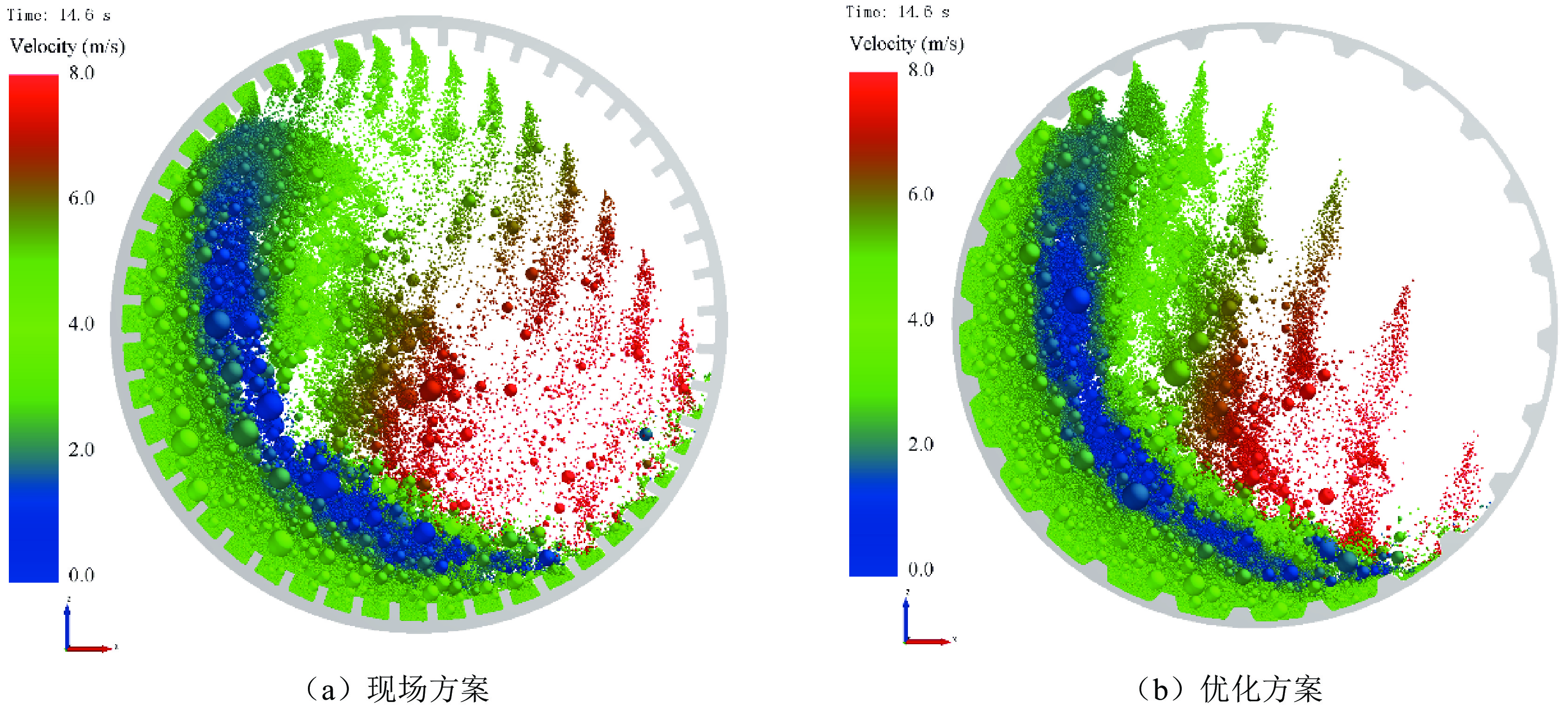

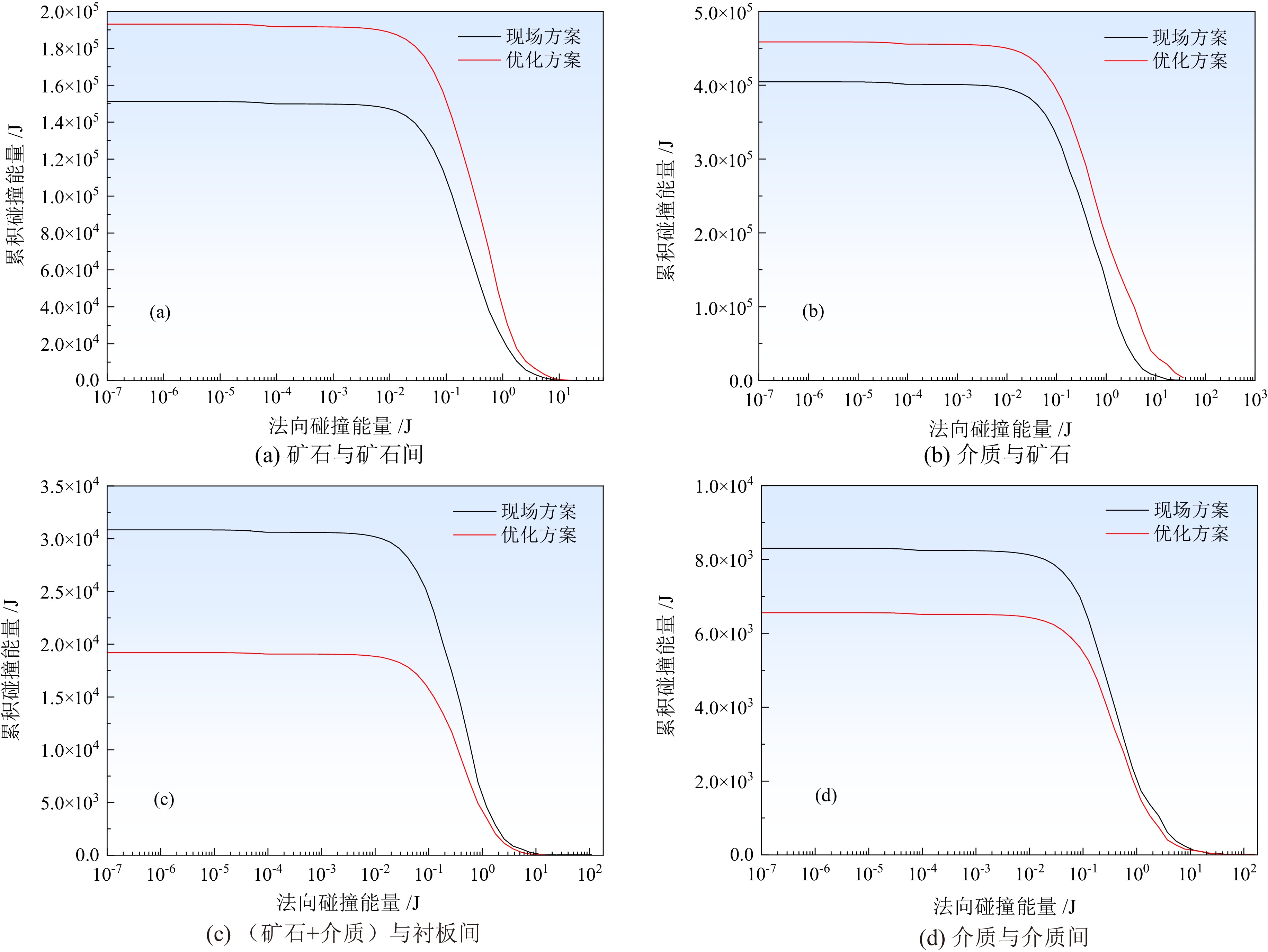

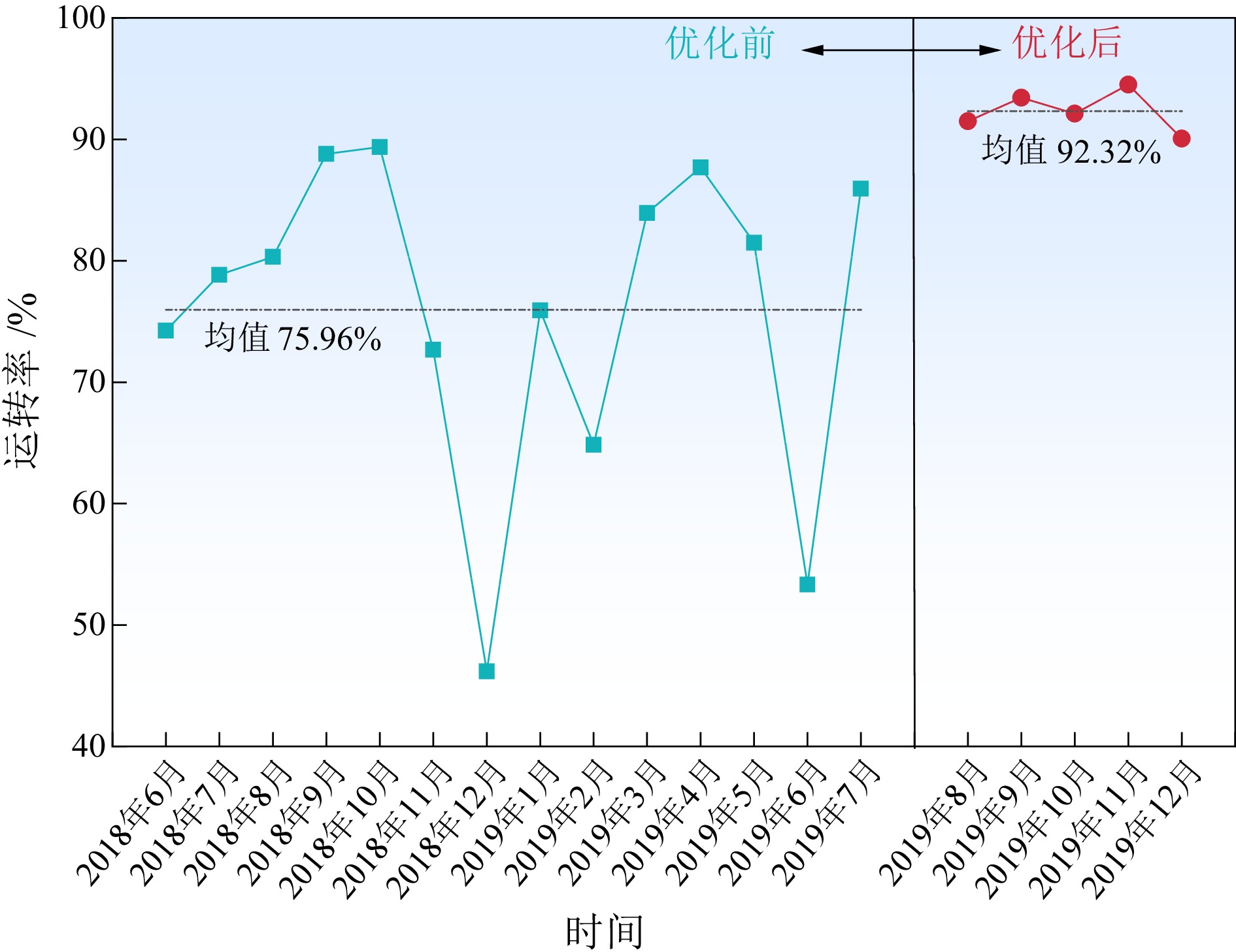

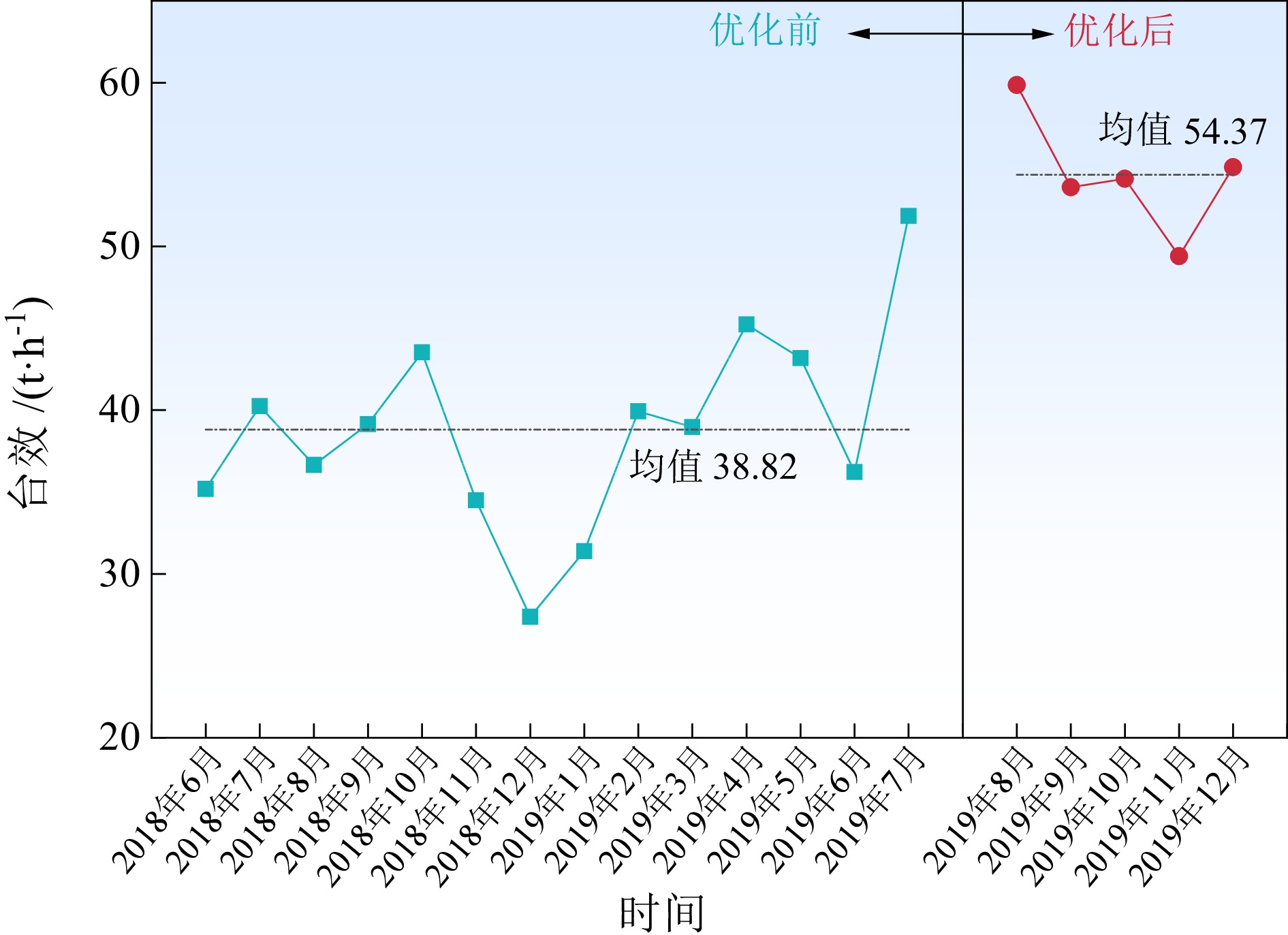

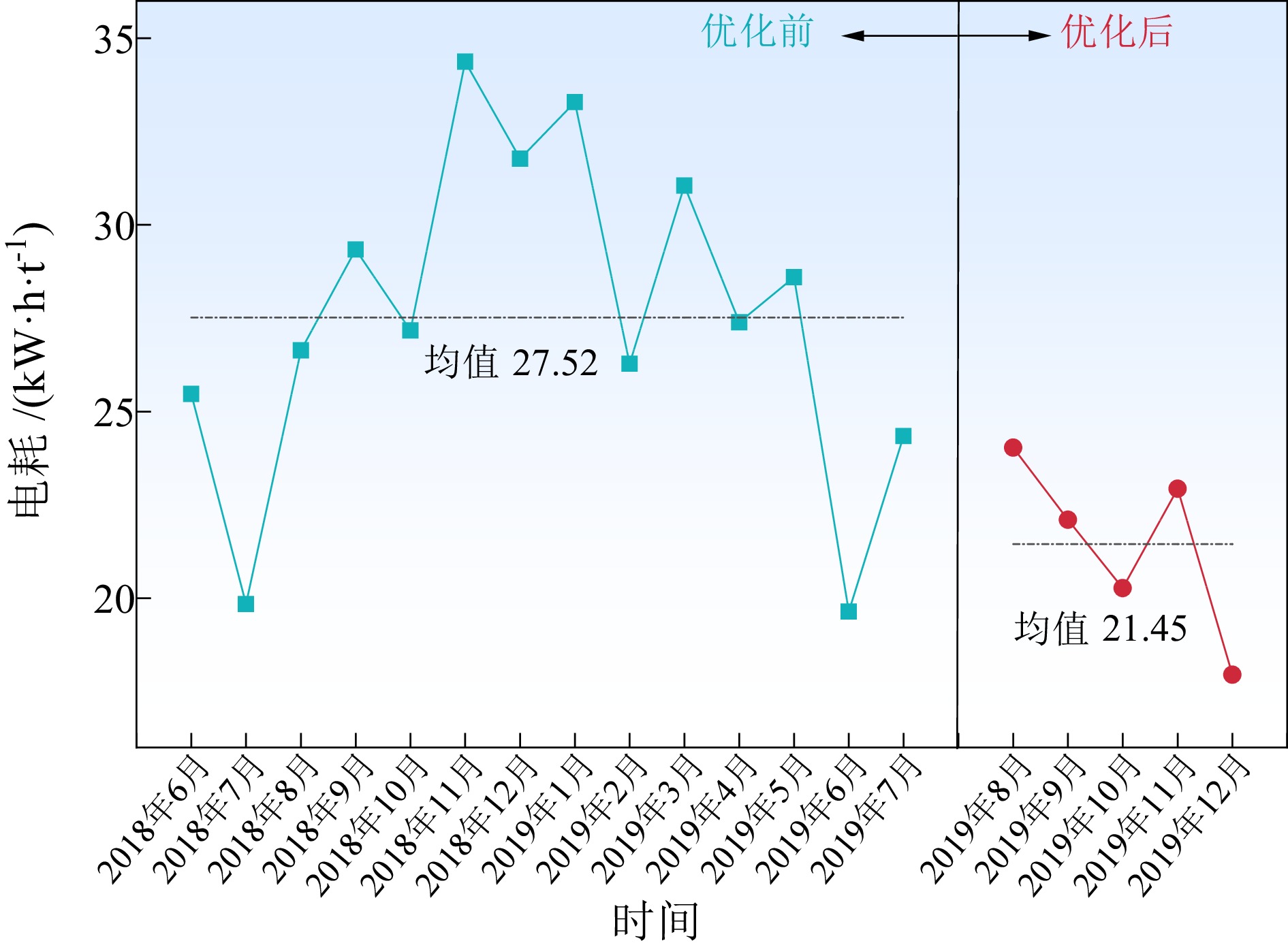

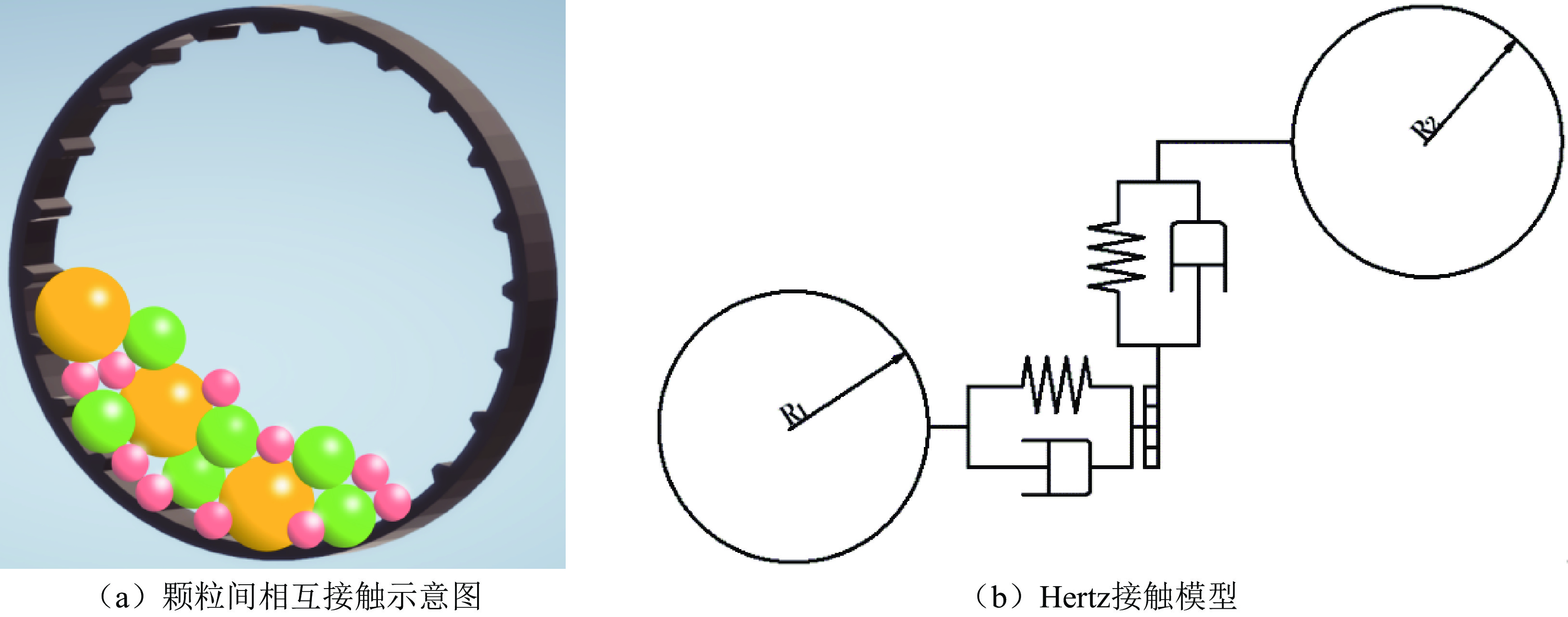

针对新疆某选厂Φ5.5 m×1.8 m半自磨机筒体衬板易磨损、断裂等问题,首先基于正交试验确定其筒体衬板的最优结构参数,其次运用离散元法模拟现场半自磨机的运行过程,对比研究在不同衬板结构参数下(提升条高度、宽度与面角)半自磨机内颗粒运动及内部碰撞能量的变化规律,最后通过工业试验验证优化方案的可行性。研究结果表明:适宜的提升条参数组合可有效优化磨机内颗粒的运动状态,增加钢球—矿石、矿石—矿石的有用碰撞,减少因无用碰撞引起的衬板或磨矿介质的损耗,进而改善半自磨机的运行参数。经正交试验确定最优的衬板提升条参数组合为高度190 mm、宽度140 mm和面角60°。由工业试验验证,优化后的衬板使用寿命、磨机运转率与台效较优化前分别提高了51 d、16.36百分点、15.55 t/h,磨机电耗较优化前降低了6.07 kW·h/t。试验结果证明了正交设计法和离散元法的联合应用在半自磨机筒体衬板形状优化过程的可靠性及优越性。

Abstract:In order to solve the problem that the liners of Φ5.5 m×1.8 m SAG mill were easy to wear and fracture in a concentrator in Xinjiang. Firstly, the optimum structural parameters of cylinder liners were determined by the orthogonal test. Secondly, The discrete element method (DEM) was used to simulate the real operation of SAG mills. Based on the different structural parameters of cylinder liners (height, width and angle of lifter bars), the motion of particles and the change of collision energy in SAG mills were studied. Finally, the feasibility of the optimization scheme was verified by industrial tests. The results showed that a suitable parameters of the liners can effectively optimize the motion of particles in the mill, increase the effective collision of ball to ore and ore to ore, reduce the wear of liners or grinding media caused by invalid collision, and thus improve the operating parameters of the semi-autogenous mill. The optimum parameters of the lifter bars were determined by orthogonal experiment to be 190 mm in height, 140 mm in width and 60 ° in angle. The optimum parameters of liners were used to carry out industrial tests. The results showed that the optimized liner service life, mill operation rate and efficiency were increased by 51 days, 16.36% and 15.55 t/h, and the mill power consumption decreased by 6.07 kW·h/t. The results verified the reliability and superiority of the discrete element method and the orthogonal design method in the modification of the cylinder liners.

-

-

表 1 因素水平

Table 1. Factor level

因素 水平 高度A /mm 宽度B /mm 面角C /(°) 1 160 120 50 2 190 140 60 3 220 160 70 表 2 正交设计试验方案

Table 2. Orthogonal design experimental scheme

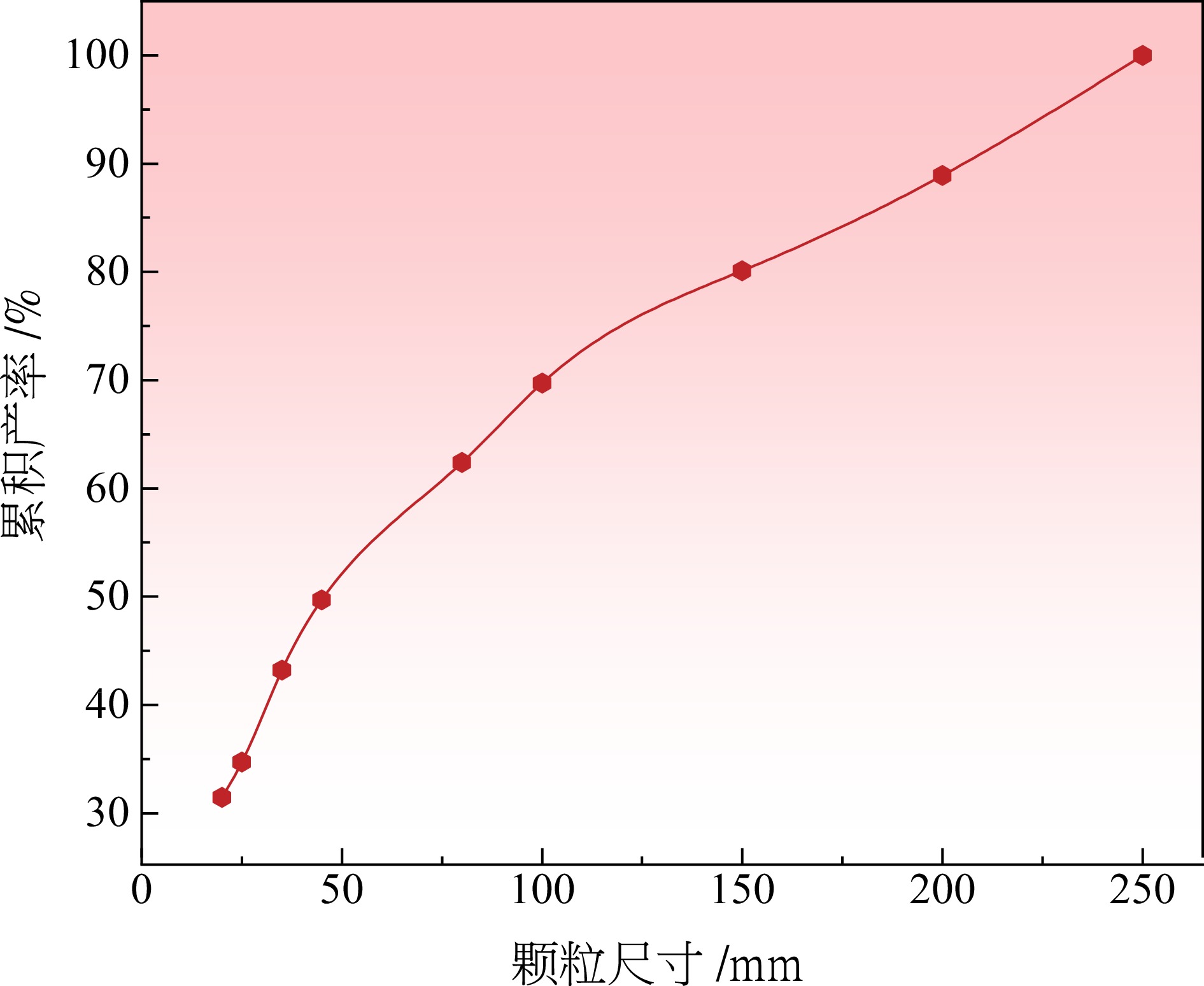

方案 参数 A B C 1 3 1 3 2 2 3 1 3 1 3 3 4 3 2 1 5 3 3 2 6 2 2 3 7 2 1 2 8 1 2 2 9 1 1 1 表 3 仿真试验矿石颗粒参数

Table 3. Simulation experiment ore particle parameters

颗粒尺寸/mm 填充质量/kg 单个颗粒质量/kg 单个颗粒体积/m3 颗粒数量/个 250 400.99 28.64 0.00818 14 200 319.28 14.51 0.00418 22 150 373.88 6.03 0.00176 62 100 266.12 1.76 0.00052 151 80 459.57 0.90 0.00026 510 45 233.94 0.16 0.00005 1459 35 307.71 0.075 0.00002 4079 25 117.88 0.027 0.000008 4288 20 1136.45 0.014 0.000004 80746 总计 3615.82 — — 91331 表 4 衬板与矿石本征参数

Table 4. Intrinsic parameters of liner and ore

名称 衬板 矿石 容重 /(kg·m-3) 7800 3360 静弹性模量 /Pa 1.82×1011 3.31×1010 泊松比 0.30 0.26 表 5 材料的基本接触参数

Table 5. Coefficient of restitution of the materials

颗粒模型 恢复系数 静摩擦系数 滚动摩擦系数 钢−钢(钢球、衬板) 0.70 0.20 0.01 矿石−钢(钢球、衬板) 0.41 0.50 0.25 矿石−矿石 0.35 0.56 0.05 表 6 试验结果

Table 6. Experiment results

方案 参数 高度A /mm 宽度B /mm 面角C /(°) 衬板受撞

能量占比/%1 3(220) 1(120) 3(70) 3.85 2 2(190) 3(160) 1(50) 3.62 3 1(160) 3(160) 3(70) 3.87 4 3(220) 2(140) 1(50) 3.77 5 3(220) 3(160) 2(60) 3.20 6 2(190) 2(140) 3(70) 3.38 7 2(190) 1(120) 2(60) 2.83 8 1(160) 2(140) 2(60) 3.07 9 1(160) 1(120) 1(50) 4.12 表 7 方差分析

Table 7. Analysis of variance

变量 离差平方和 自由度 均方差 F 显著性P 修正模型 1.455 6 0.243 52.343 0.019 截距 111.725 1 111.725 24113.288 0.000 高度A 0.283 2 0.142 30.583 0.032 宽度B 0.063 2 0.032 6.827 0.128 面角C 1.108 2 0.554 119.619 0.008 误差 0.009 2 0.005 — — 总计 113.189 8 — — — 表 8 极差分析

Table 8. Range analysis

数值 参数 高度 A /mm 宽度B /mm 面角C /(°) K1 11.06 10.8 11.51 K2 9.83 10.22 9.1 K3 10.82 10.69 11.1

3.69 3.6 3.84

3.28 3.41 3.03

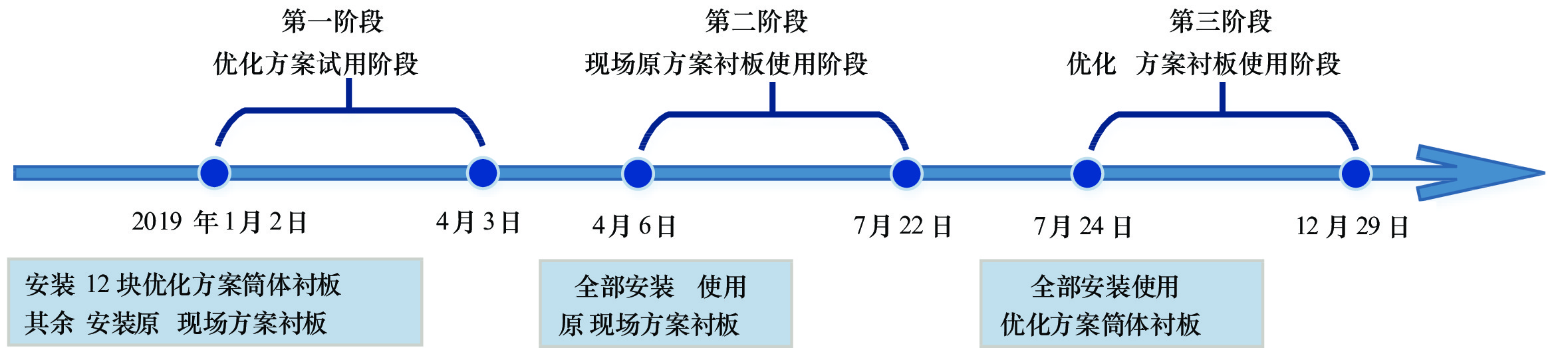

3.61 3.56 3.7 R 0.41 0.19 0.81 表 9 工业试验中筒体衬板使用寿命统计

Table 9. Statistics on the service life of liners in industrial experiments

方案 开始时间 整体更换时间 使用时间/d 年使用量/套 年成本/万元 现场方案 2019年4月6日 2019年7月22日 108 3.60 403.20 优化方案 2019年7月24日 2019年12月29日 159 2.26 325.44 优化方案与现场方案差值 — — +51 −1.34 −77.76 -

[1] 黄国智, 方启学, 任翔, 等. 全自磨半自磨磨矿技术: 第1版[M]. 北京: 冶金工业出版社, 2018: 10−52.

HUANG G Z, FANG Q X, REN X, et al. Fully and semi-autogenous grinding: 1st ed[M]. Beijing: Metallurgical Industry Press, 2018: 10−52.

[2] XU L, LUO K, ZHAO Y Z. Numerical prediction of wear in SAG mills based on DEM simulations[J]. Powder Technology, 2018, 329: 353−363. doi: 10.1016/j.powtec.2018.02.004

[3] WEERASEKARA N S, POWELL L S, CLEARY P W, et al. The contribution of DEM to the science of comminution[J]. Powder Technology, 2013, 248: 3−24. doi: 10.1016/j.powtec.2013.05.032

[4] 王莹. 半自磨机衬板用耐磨蚀合金钢的研究[D]. 广州: 暨南大学化学与材料学院, 2018: 1−11.

WANG Y. Research of corrosion-abrasion resistant alloy steels for semi-autogenous mill liner plates[D]. Guangzhou: Jinan University, College of Chemistry and Materials Science, 2018: 1−11.

[5] 宗路, 郭晋, 蔡改贫, 等. 基于衬板参数的半自磨机破碎能耗分析[J]. 中国粉体技术, 2018, 24(3): 81−87.

ZONG L, GUO J, CAI G P, et al. Analysis of crushing energy consumption of semi-autogenous mill based on liner parameters[J]. China Powder Science and Technology, 2018, 24(3): 81−87.

[6] LVOV V, CHITALOV L. Semi-autogenous wet grinding modeling with CFD-DEM[J]. Minerals, 2021, 11(5): 1−12.

[7] 刘建平. 半自磨机筒体衬板结构的模拟优化研究[J]. 矿山机械, 2021, 49(12): 27−32.

LIU J P. Research on simulation and structural optimization of shell liner of SAG mill[J]. Mining & Processing Equipment, 2021, 49(12): 27−32.

[8] XIE C H, ZHAO Y, SONG T, et al. Investigation of the effect of filling level on the wear and vibration of a SAG mill by DEM[J]. Particuology, 2021, 63: 24−34.

[9] PEDRO P, RODRIGO M, ANDERSON S, et al. Surface breakage of fired iron ore pellets by impact[J]. Powder Technology, 2019, 342: 735−743. doi: 10.1016/j.powtec.2018.10.044

[10] 孟庆霞, 潘庆. 基于离散元磨损模拟的半自磨机提升器结构优化[J]. 矿山机械, 2020, 48(11): 37−40.

MENG Q X, PAN Q. Structural optimization on lifter of semi-autogenous grinding mill based on discrete element wear simulation[J]. Mining & Processing Equipment, 2020, 48(11): 37−40.

[11] POWELL M S, WEERASEKARA N S, COLE S, et al. DEM modelling of liner evolution and its influence on grinding rate in ball mills[J]. Minerals Engineering, 2010, 24(3): 341−351.

[12] COLLINAO E, DAVILA P, IRARRAZABAL R, et al. Continuous improvement in SAG mill liner design using new technologies[J]. ⅩⅩⅦ International Mineral Processing Congress, 2014, 68(10): 2061−2080.

[13] 杜强. 基于离散元的大型半自磨机筒体衬板磨损分析[J]. 矿山机械, 2015, 43(1): 62−66.

DU Q. Wearing analysis of shell liner in large SAG mill based on DEM[J]. Mining & Processing Equipment, 2015, 43(1): 62−66.

[14] CLEARY P W, OWEN P. Effect of liner design on performance of a HICOMR mill over the predicted liner life cycle[J]. International Journal of Mineral Processing, 2015, 134: 11−22. doi: 10.1016/j.minpro.2014.11.003

[15] 许磊, 罗坤, 赵永志, 等. 物料粒径对半自磨机衬板磨损的影响[J]. 浙江大学学报(工学版), 2019, 53(12): 2255−2263.

XU L, LUO K, ZHAO Y Z, et al. Effect of particle size on liner wear in semi-autogenous mill[J]. Journal of Zhejiang University(Engineering Science), 2019, 53(12): 2255−2263.

[16] YONG X, K. D. Kafui, C. Thornton, et al. Effects of material properties on granular flow in a silo using DEM simulation[J]. Particulate Science and Technology, 2002, 20(2): 109−124. doi: 10.1080/02726350215338

[17] YANG D, B. FATAHI, H. KHABBAZ, et al. Influence of particle contact models on soil response of poorly graded sand during cavity expansion in discrete element simulation[J]. Rock Mechanics and Geotechnical Engineering, 2018, 10(6): 1154−1170. doi: 10.1016/j.jrmge.2018.03.009

[18] ROYSTON D. Semi-autogenous grinding (SAG) mill liner design and development[J]. Minerals & Metallurgical Processing, 2007, 24(3): 121−132.

[19] 汪滋润. 黏结理论及离散元法在半自磨机衬板设计中的应用研究[D]. 昆明: 昆明理工大学, 2017: 41-45.

WANG Z R. Design of SAG mill liner based on bond theory and discrete element method[D]. Kunming: Kunming University of Science and Technology, 2017: 41−45.

[20] 郝拉娣, 于化东. 正交试验设计表的使用分析[J]. 编辑学报, 2005(5): 334−335.

HAO L D, YU H D. On use of orthogonal experimental design[J]. Acta Editologica, 2005(5): 334−335.

[21] 黄伯强, 李启才. 带交互作用的双因素方差分析的线性回归建模[J]. 统计与决策, 2021, 37(1): 10−15.

HUANG B Q, LI Q C. Linear regression modeling of two-factor ANOVA with interaction[J]. Statistics & Decision, 2021, 37(1): 10−15.

[22] 贾永军. 延长半自磨机筒体衬板使用寿命的途径[J]. 中国矿山工程, 2019, 48(5): 44−46+55.

JIA Y J. Ways to prolong the service life of cylinder liner of semi−autogenous mill[J]. China Mine Engineering, 2019, 48(5): 44−46+55.

[23] 金建国. 提高半自磨系统运转效率的分析及措施[J]. 铜业工程, 2012(1): 54−56+60.

JIN J G. The analysis and measures on increasing the running efficiency of semi-auto mill system[J]. Copper Engineering, 2012(1): 54−56+60.

[24] 邓禾淼. 冬瓜山铜矿提高半自磨机处理能力的生产实践[J]. 有色金属(选矿部分), 2010(4): 36−38+42.

DENG H M. The industry practice on improvement treatment capacity of SAG mill in Dongguashan copper[J]. Nonferrous Metals(Mineral Processing Section), 2010(4): 36−38+42.

[25] 刘瑜. 柿竹园多金属矿1500吨/日选矿厂磨矿过程优化试验研究[D]. 赣州: 江西理工大学, 2015: 41−51.

LIU Y. Experimental study on grinding process optimization of Shizhuyuan 1500-tpd polymetallic mineral processing plant[D]. Ganzhou: Jiangxi University of Science and Technology, 2015: 41−51.

-

下载:

下载: