Optimization of Barrel Liner Modification of Ball Mill Based on Discrete Element Method

-

摘要:

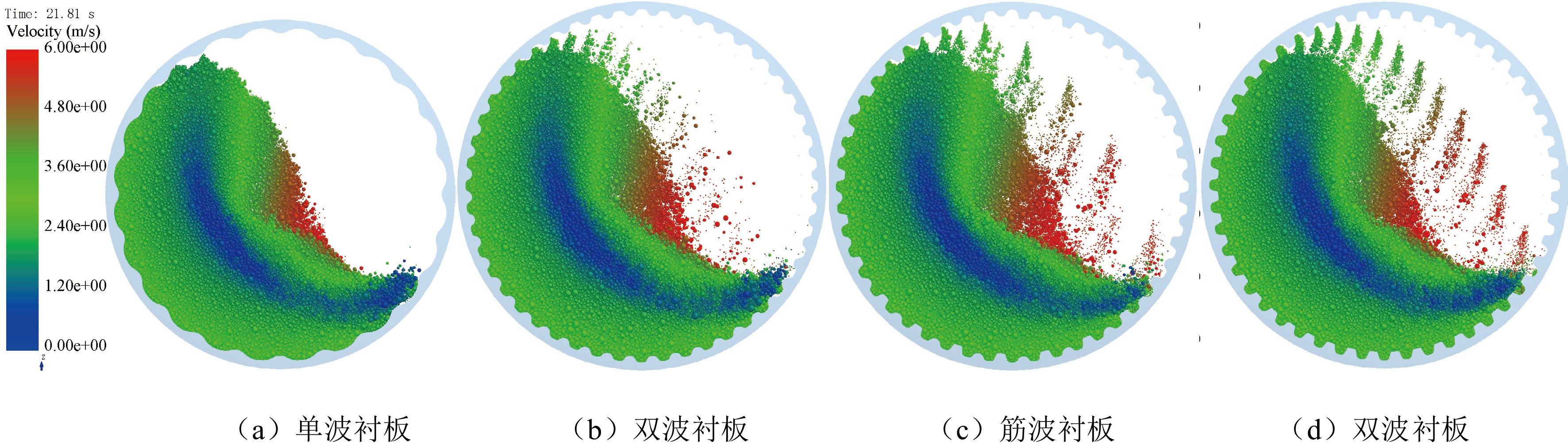

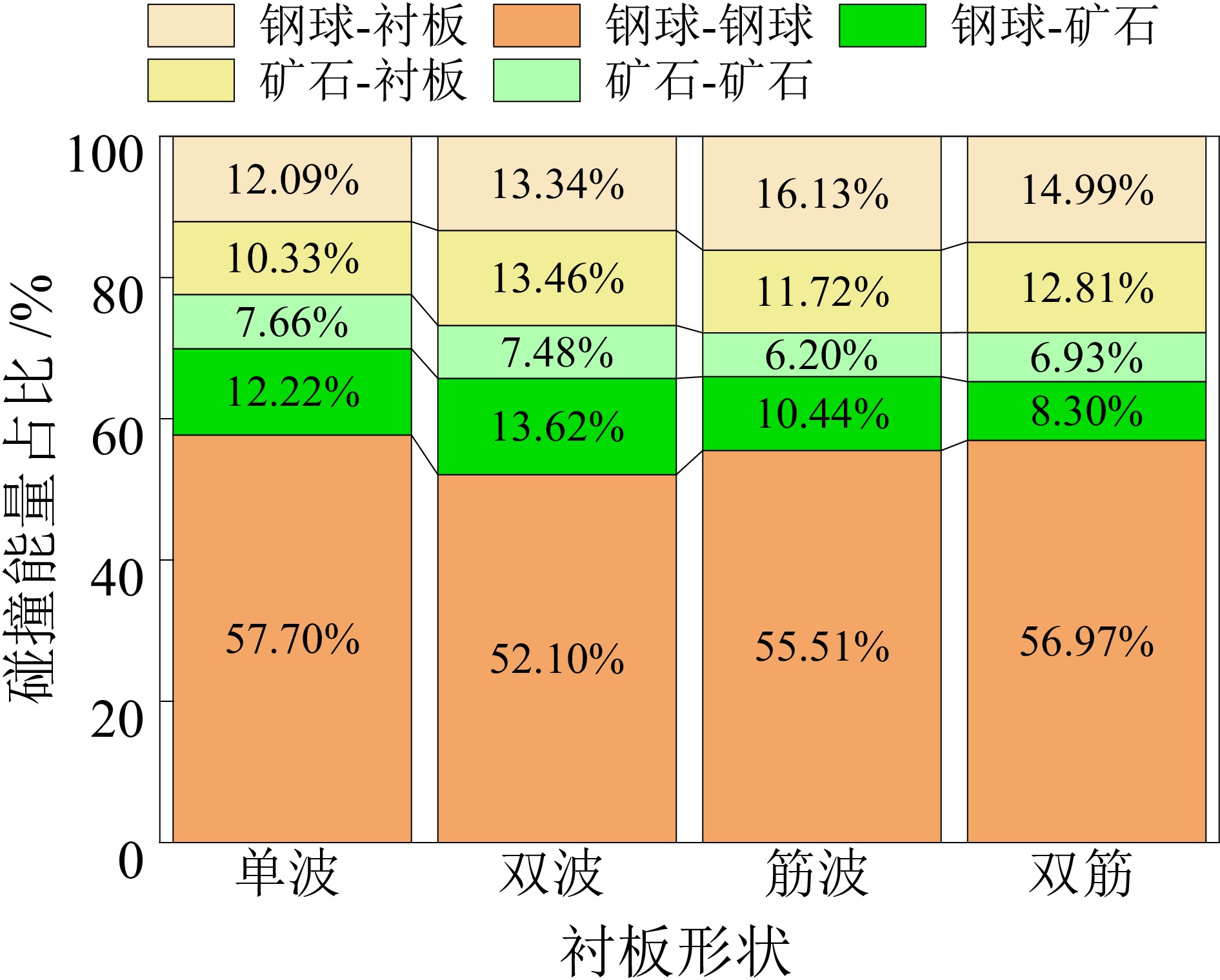

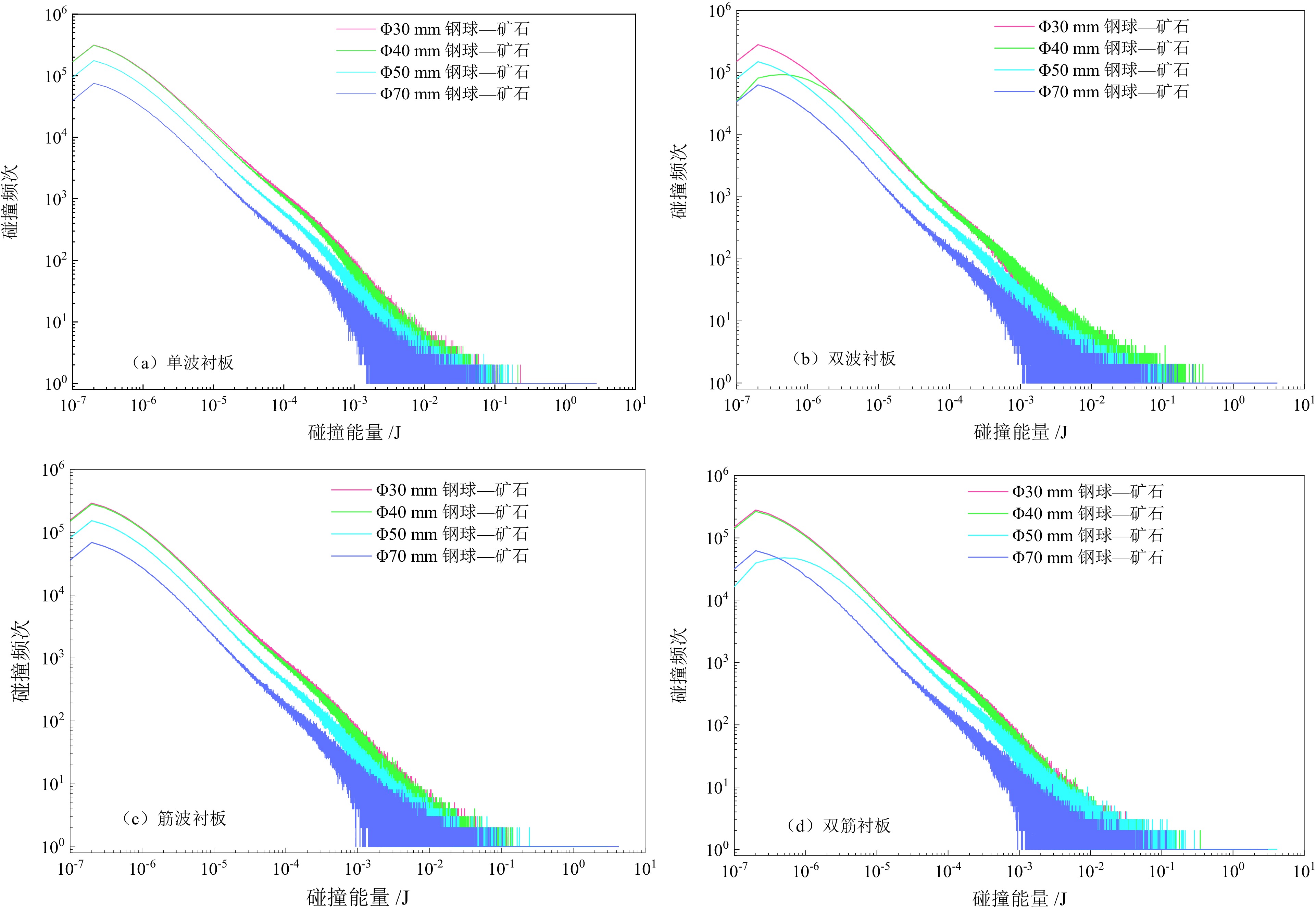

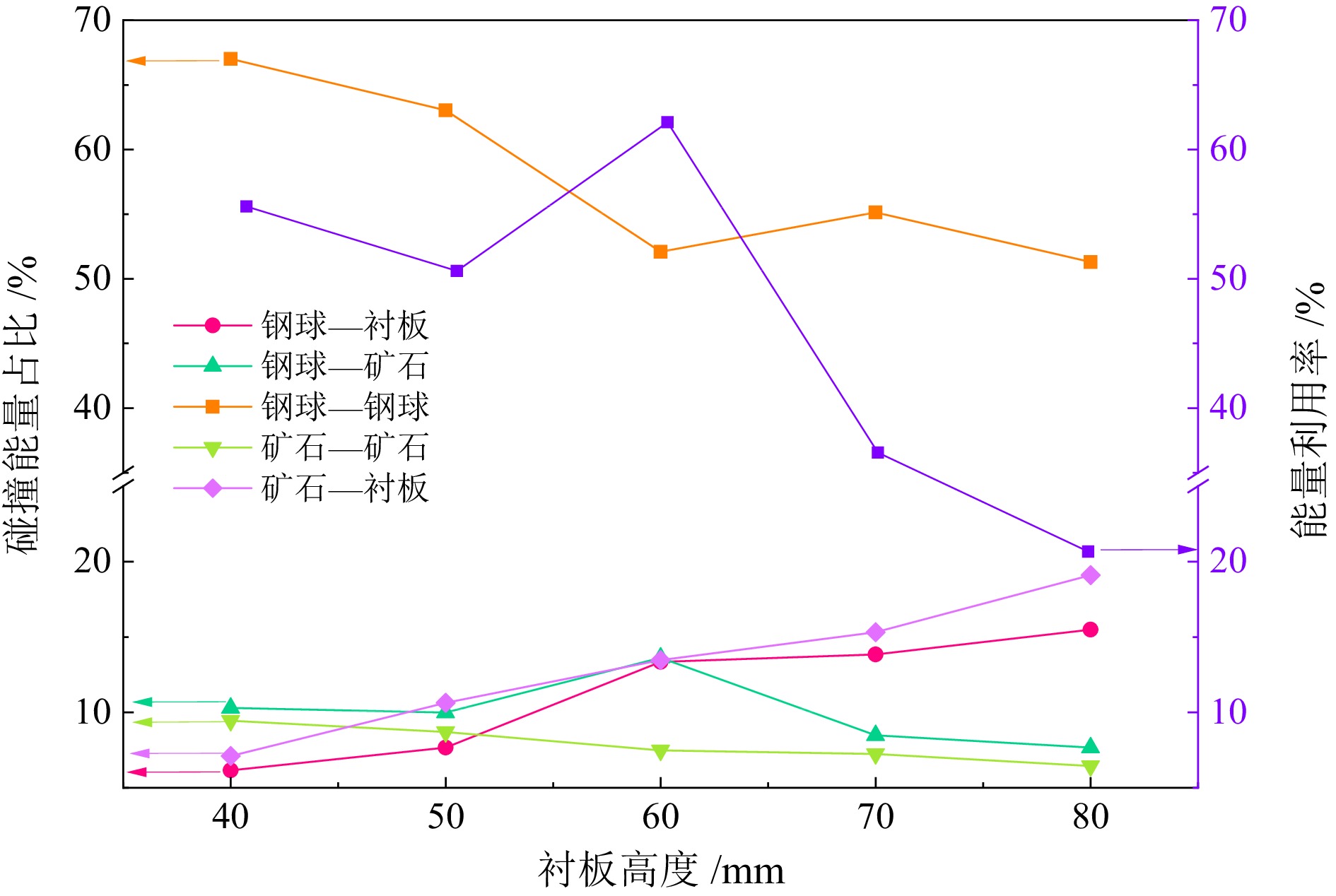

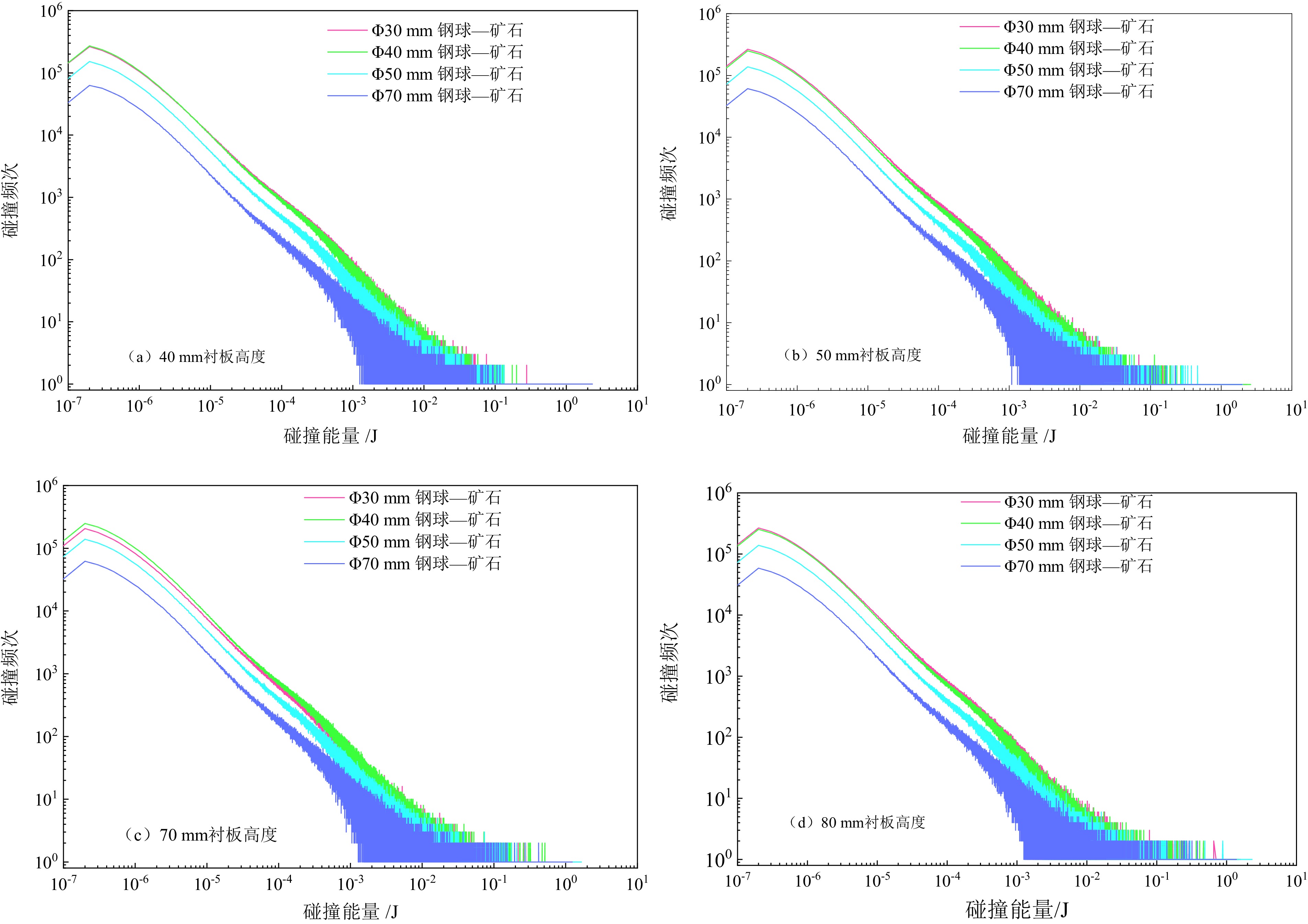

针对球磨机内能量利用率低、磨矿钢耗高的问题,基于离散元法(DEM)仿真分析了不同衬板结构及衬板高度时钢球在磨机内的运动状态及碰撞能量分布。研究结果表明:衬板结构及高度会显著影响磨机内颗粒的运动状态和能量分布;不平滑衬板(筋波衬板和双筋衬板)提升载荷的作用强于平滑型衬板(单波衬板和双波衬板),但不平滑型衬板的球磨机内钢球对衬板的冲击作用较强,会增加衬板的磨损;平滑型衬板中,双波衬板能量分布最合理,其钢球−钢球的碰撞能量最低,为52.10%,能量利用率(钢球−矿石和矿石−矿石的碰撞能量之和在磨机碰撞总能量中的占比)最高,为21.10%。随着衬板高度逐渐增加,高速运动的钢球数量增多,大量的钢球冲击裸露衬板会加快衬板的磨损;磨机内的碰撞总能量随着衬板高度的升高而增加,且钢球−衬板和矿石−衬板的碰撞能量也在增加,能量利用率在衬板高度为60 mm时最高,为21.10%,说明衬板高度在60 mm时最佳。因此,选择适宜的衬板结构和衬板高度,能优化磨机的能量利用率,改善磨矿环境、降低钢耗和节约磨矿成本。

Abstract:Aiming at the problems of low energy utilization rate and high grinding steel consumption in the ball mill, the motion state and collision energy distribution of steel balls under different liner structures and liner heights were analyzed based on discrete element method (DEM). The results showed that the structure and height of the liner significantly affected the motion state and energy distribution of particles in the mill. The effect of rough liners (rib liners and double rib liners) on load lifting was stronger than that of smooth liners (single wave liners and double wave liners), but leaving profound impact of steel balls on the liners in the ball mill of rough liners and increasing the wear. Among the smooth liners, the double wave liner had the most reasonable energy distribution, with the lowest 52.10% steel ball−steel ball collision energy, and the highest 21.10% energy utilization rate (the sum of the collision energy of steel ball−ore and ore−ore in the total collision energy of the mill). With the gradual increase of the liner height, the number of steel balls moving at high speed may increase, and the impact of a large number of steel balls on the exposed liner would accelerate the wear. The total collision energy in the mill increased with the expansion of liner height, with the incremental collision energy of steel ball−liner and ore−liner, bringing the highest 21.10% energy utilization rate at 60 mm liner height, indicating that the best liner height at 60 mm. Therefore, the selection of the appropriate liner structure and liner height could optimize the energy utilization of the mill, improve the grinding environment, reduce steel consumption and save grinding costs.

-

Key words:

- ball mill /

- liner shape /

- liner height /

- collision energy distribution /

- DEM

-

-

表 1 Φ3.6 m×4.5 m球磨机工作参数

Table 1. Working parameters of Φ3.6 m×4.5 m ball mill

参数 Value 球磨机直径/m 3.6 球磨机参数/m 4.5 钢球充填率/% 41 最大钢球直径/mm 70 转速率/(r·min−1) 17.29 表 2 离散元模拟仿真参数

Table 2. Discrete element simulation parameters

参数 数值 矿石密度/(kg·m−3) 3250 钢球密度/(kg·m−3) 7800 矿石泊松比 0.16 钢球泊松比 0.30 矿石杨氏模量/Pa 2.07×1010 钢球杨氏模量/Pa 7.00×1010 恢复系数(矿石−矿石) 0.35 恢复系数(矿石−钢球) 0.40 恢复系数(钢球−钢球) 0.70 静摩擦系数(矿石−矿石) 0.68 静摩擦系数(矿石−钢球) 0.50 静摩擦系数(钢球−钢球) 0.25 滚动摩擦系数(矿石−矿石) 0.30 滚动摩擦系数(矿石−钢球) 0.05 滚动摩擦系数(钢球−钢球) 0.03 -

[1] WANG M H, YANG R Y, YU A B. DEM investigation of energy distribution and particle breakage in tumbling ball mills[J]. Powder Technology, 2012, 223: 83−91. doi: 10.1016/j.powtec.2011.07.024

[2] 尹自信. 球磨机铁矿石颗粒破碎及粒度分布行为研究[D]. 北京: 中国矿业大学, 2020: 1−5.

YIN Z X. Study of iron ore particle crushing and particle size distribution behavior in ball mill[D]. Beijing: China University of Mining and Technology, 2020: 1−5.

[3] B DOMINIK, P PHILIPPE. A generic wear prediction procedure based on the discrete element method for ball mill liners in the cement industry[J]. Minerals Engineering, 2017, 109: 55−79. doi: 10.1016/j.mineng.2017.02.014

[4] T PAUL, F JOCHEN, P MALCOLM, et al. Designing liners for performance not life[J]. Minerals Engineering, 2013, 43-44: 22−28. doi: 10.1016/j.mineng.2012.07.004

[5] 赵亮, 王裕龙. 球磨机衬板形状对工作效率的影响分析[J]. 科技创新与应用, 2017, 193(9): 126.

ZHAO L, WANG Y L. Analysis of the influence of ball mill liner shape on work efficiency[J]. Science and Technology Innovation and Application, 2017, 193(9): 126.

[6] 张谦. 基于离散元法的喀拉通克Φ5.5 m×1.8 m半自磨机筒体衬板形状优化及应用[D]. 昆明: 昆明理工大学, 2021: 20−22.

ZHANG Q. Optimization of cylinder liner shape of Karatunk Φ5.5 m×1.8 m semi−autogenous mill based on discrete element method and its application [D]. Kunming: Kunming University of Technology, 2021: 20−22.

[7] P W CLEARY, R D MORRISON, D MATT. Prediction of slurry grinding due to media and coarse rock interactions in a 3D pilot SAG mill using a coupled DEM + SPH model[J]. Minerals Engineering, 2020, 159: 1023−1036.

[8] J I PEREIRA, P C MACHADO, J J PENAGOS, et al. Wear characterization from field and laboratory tests of pearlitic steels used for SAG mill liners[J]. Wear, 2017, 376/377: 37−45. doi: 10.1016/j.wear.2017.01.094

[9] P W CLEARY, O PHIL. Development of models relating charge shape and power draw to SAG mill operating parameters and their use in devising mill operating strategies to account for liner wear[J]. Minerals Engineering, 2018, 117: 42−62. doi: 10.1016/j.mineng.2017.12.007

[10] S H HONG, B K KIM. Effects of lifter bars on the ball motion and aluminum foil milling in tumbler ball mill[J]. Materials Letters, 2002, 57(2): 275−279. doi: 10.1016/S0167-577X(02)00778-4

[11] O HLUNGWANI, J RIKHOTSO, H DONG, et al. Further validation of DEM modeling of milling: effects of liner profile and mill speed[J]. Minerals Engineering, 2003, 16: 993−998. doi: 10.1016/j.mineng.2003.07.003

[12] 刘建平, 姬建钢, 陈松战, 等. 一种半自磨机筒体衬板的优化设计[J]. 矿山机械, 2014, 42(10): 81−83.

LIU J P, JI J G, CHEN S Z, et al. Optimal design of cylinder liner of semi−automatic mill[J]. Mining Machinery, 2014, 42(10): 81−83.

[13] 李占长, 黄雨, 付向上, 等. 大型半自磨机衬板的选材与制备[J]. 铸造技术, 2019, 40(2): 143−146.

LI Z C, HUANG Y, FU X S, et al. Selection and preparation of liners for large semi−automatic mill[J]. Casting Technology, 2019, 40(2): 143−146.

[14] 唐新民. 冬瓜山铜矿半自磨机筒体衬板和钢球的研究[J]. 化工矿物与加工, 2013, 42(10): 20−25.

TANG X M. Study on cylinder liner and steel ball of semi−automatic mill in Dongguashan[J]. Chemical Minerals and Processing, 2013, 42(10): 20−25.

[15] 卢建坤. 基于离散单元法的大型球磨机介质运动分析及参数优化[D]. 洛阳: 河南科技大学机电工程学院, 2013: 49−55.

LU J K. Media motion analysis and parameter optimization of large ball mill based on discrete unit method [D]. Luoyang: College of Mechanical and Electrical Engineering, Henan University of Science and Technology, 2013: 49−55.

[16] N V BRILLIANTOV, F SPAHN, J M. HERTZSH. Model for collisions in granular gases[J]. Phys Rev E, 1996: 53, 5382.

[17] 钟文镇, 何克晶, 周照耀, 等. 粉末材料堆积的物理模型与仿真系统[J]. 物理学报, 2009, 58(S1): 21−28.

ZHONG W Z, HE K J, ZHOU Z Y, et al. Physical model and simulation system for powder material stacking[J]. Journal of Physics, 2009, 58(S1): 21−28.

[18] ZHU H P, YU A B. The effects of wall and rolling resistance on the couple stress of granular materials in vertical flow[J]. Physica A: Statistical Mechanics and its Applications, 2003: 347−360.

[19] P W CLEARY, R D MORRISON. Understanding fine ore breakage in a laboratory scale ball mill using DEM[J]. Minerals Engineering, 2011, 24: 352−366. doi: 10.1016/j.mineng.2010.12.013

[20] 田秋娟. 基于离散元方法的大型球磨机工作性能研究[D]. 长春: 吉林大学, 2011: 1−5.

TIAN Q J. Research on the working performance of large ball mill based on discrete element method [D]. Changchun: Jilin University, 2011: 1−5.

[21] P W CLEARY, D MORRISON. Comminution mechanisms, particle shape evolution and collision energy partitioning in tumbling mills[J]. Minerals Engineering, 2016, 86: 75−95. doi: 10.1016/j.mineng.2015.12.006

[22] P W CLEARY, B MOTION. Axial segregation and power consumption in a full scale two chamber cement mill[J]. Minerals Engineering, 2009, 22: 809−820. doi: 10.1016/j.mineng.2009.02.005

[23] A SATO, J KANO, F SAITO. Analysis of abrasion mechanism of grinding media in a planetary mill with DEM simulation[J]. Advanced Powder Technology, 2017, 21: 212−216.

[24] PENG Y X, LI T Q, ZHU Z C, et al. Discrete element method simulations of load behavior with mono−sized iron ore particles in a ball mill[J]. Advances in Mechanical Engineering, 2017, 9(5): 1−10.

[25] 李腾飞, 林蜀勇, 张博, 等. 不同转速率下球磨机内钢球的碰撞研究[J]. 中南大学学报(自然科学版), 2019, 50(2): 251−256.

LI T F, LIN S Y, ZHANG B, et al. Study on the collision of steel balls in ball mills at different rotation rates[J]. Journal of Central South University (Natural Science Edition), 2019, 50(2): 251−256.

[26] 张谦, 肖庆飞, 杨森, 等. 喀拉通克铜镍矿球磨机磨矿作业质量优化试验研究[J]. 矿产综合利用, 2020(4): 100−105.

ZHANG Q, XIAO Q F, YANG S, et al. Experimental study on the quality optimization of ball mill grinding operation in Karatunk copper−nickel ore[J]. Mineral Comprehensive Utilization, 2020(4): 100−105.

[27] 武煜凯, 肖庆飞, 高志勇. 多级配球降低半自磨中顽石积累及改善磨矿效果试验[J]. 稀有金属, 2022, 46(5): 673−680.

WU Y K, XIAO Q F, GAO Z Y. Experiment on multi−stage ball distribution to reduce recalcitrant stone accumulation and improve grinding effect in semi−autogenous grinding[J]. Rare Metals, 2022, 46(5): 673−680.

[28] MORRISON R D, SHI F, WHYTE R. Modelling of incremental rock breakage by impact–For use in DEM models[J]. Minerals Engineering, 2007, 20(3): 303−309. doi: 10.1016/j.mineng.2006.10.015

[29] CLEARY P W, ROB D, MORRISON R D, et al. Delaney. Incremental damage and particle size reduction in a pilot SAG mill: DEM breakage method extension and validation[J]. Minerals Engineering, 2018, 128: 56−68. doi: 10.1016/j.mineng.2018.08.021

-

下载:

下载: