Comparative Experimental Study of Multi−stage Ball Distribution to Improve the Efficiency of Semi−autogenous Grinding

-

摘要:

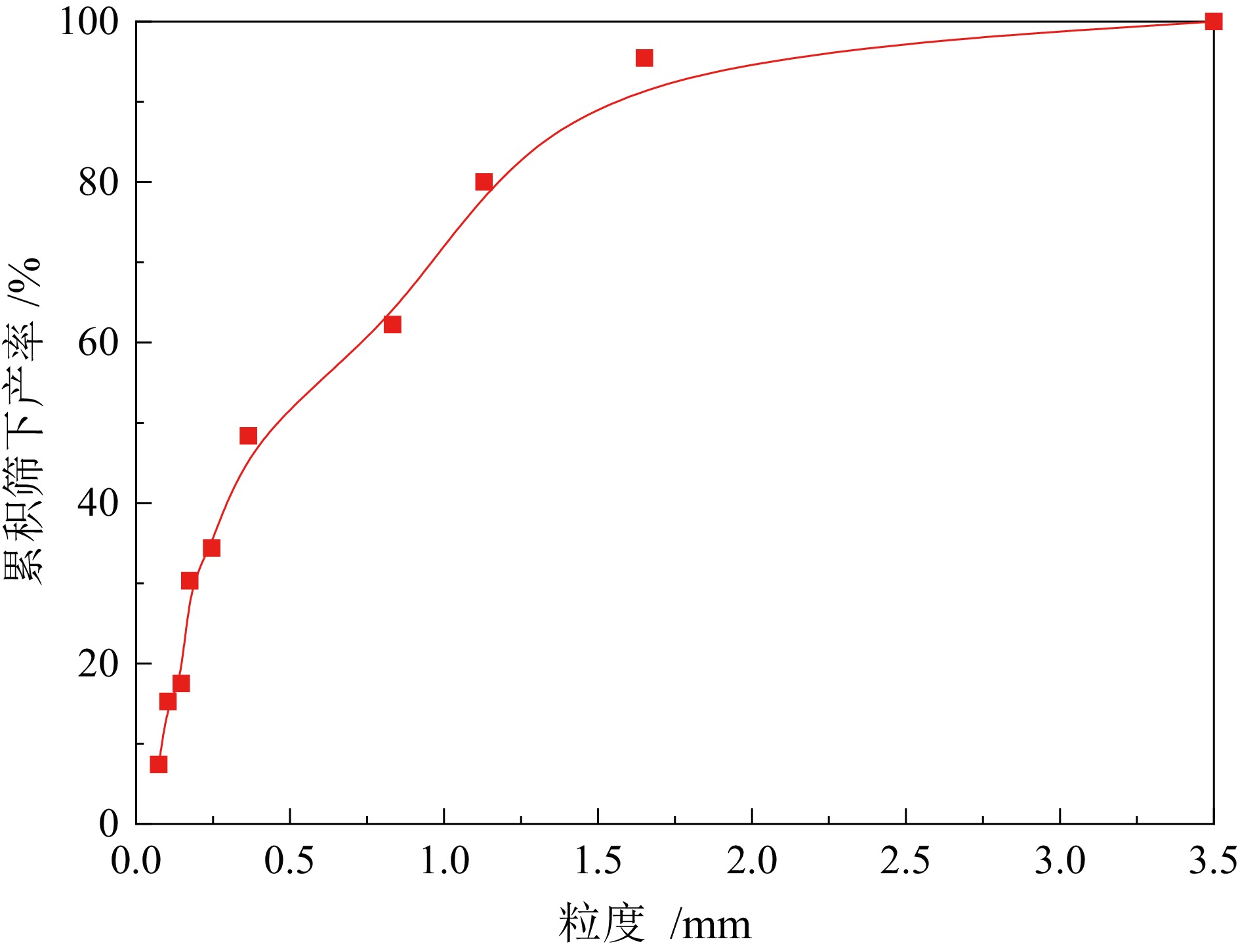

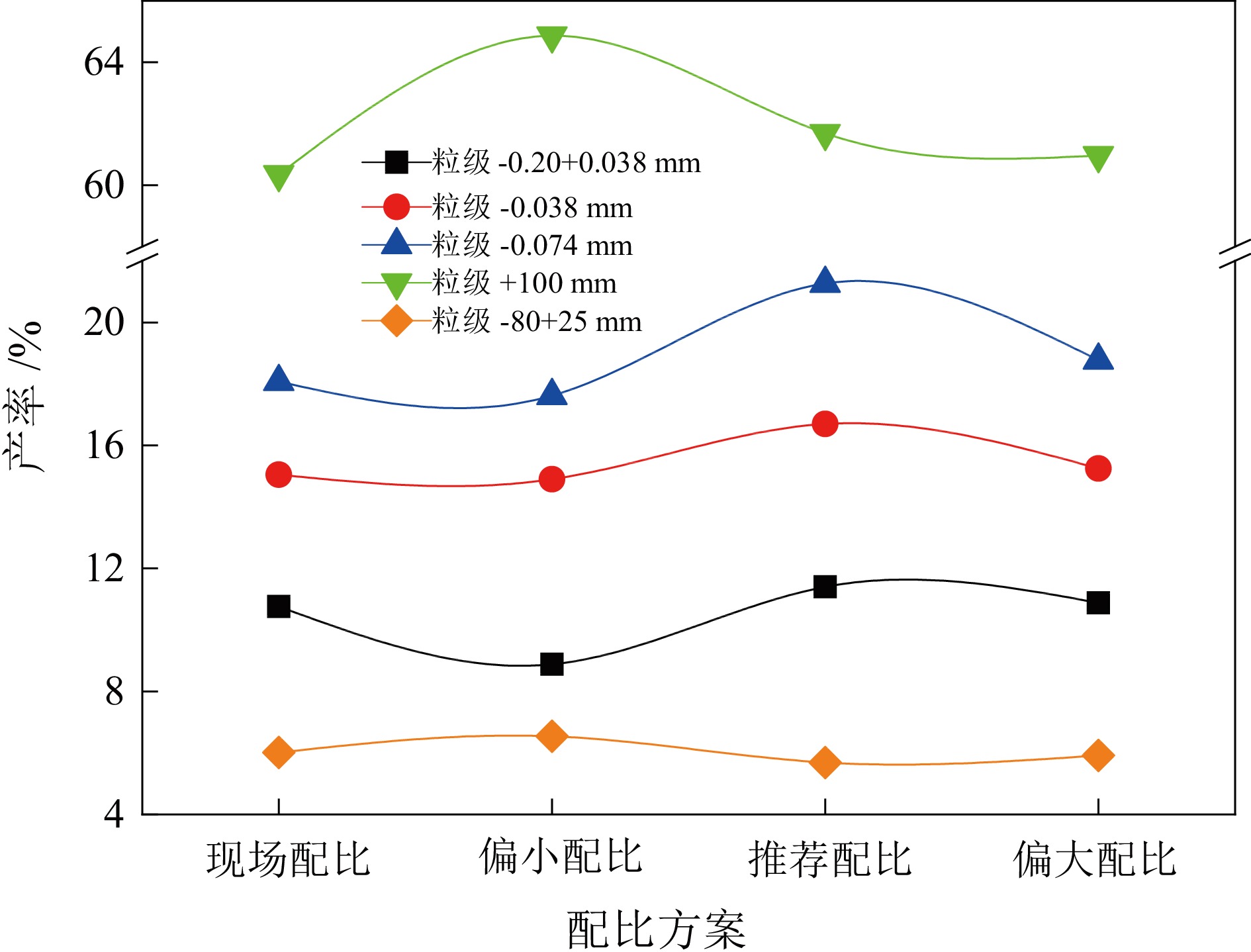

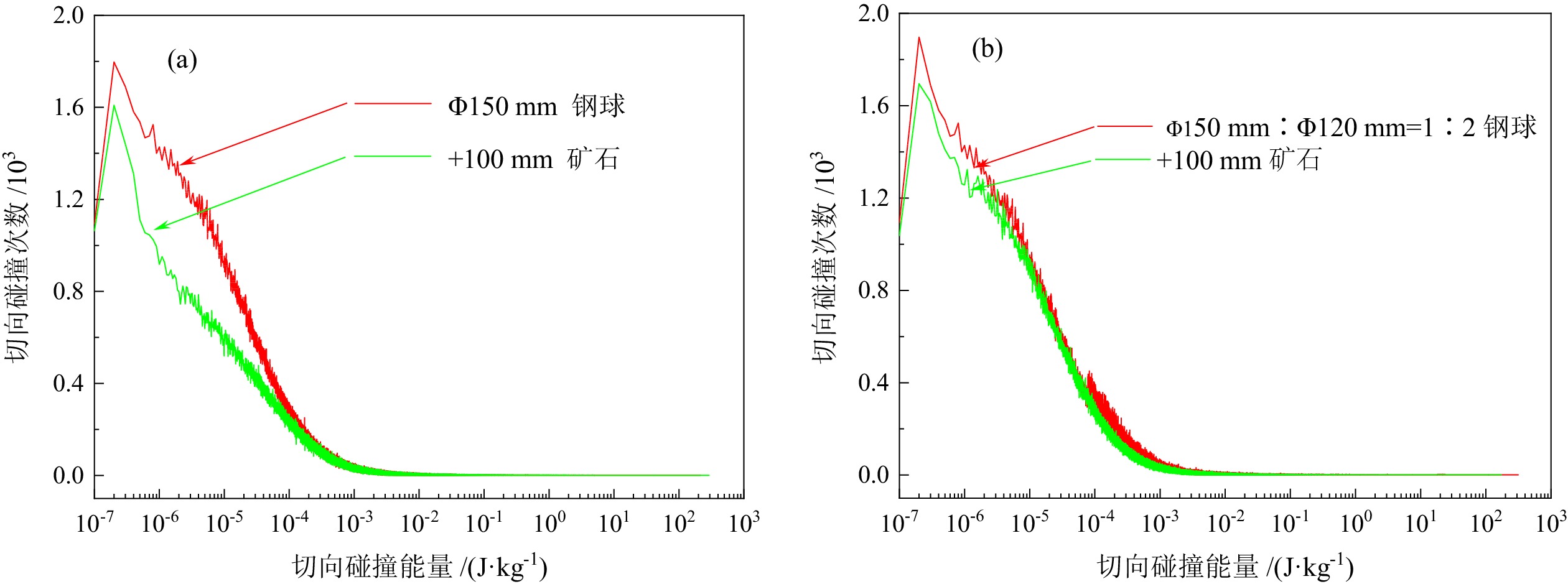

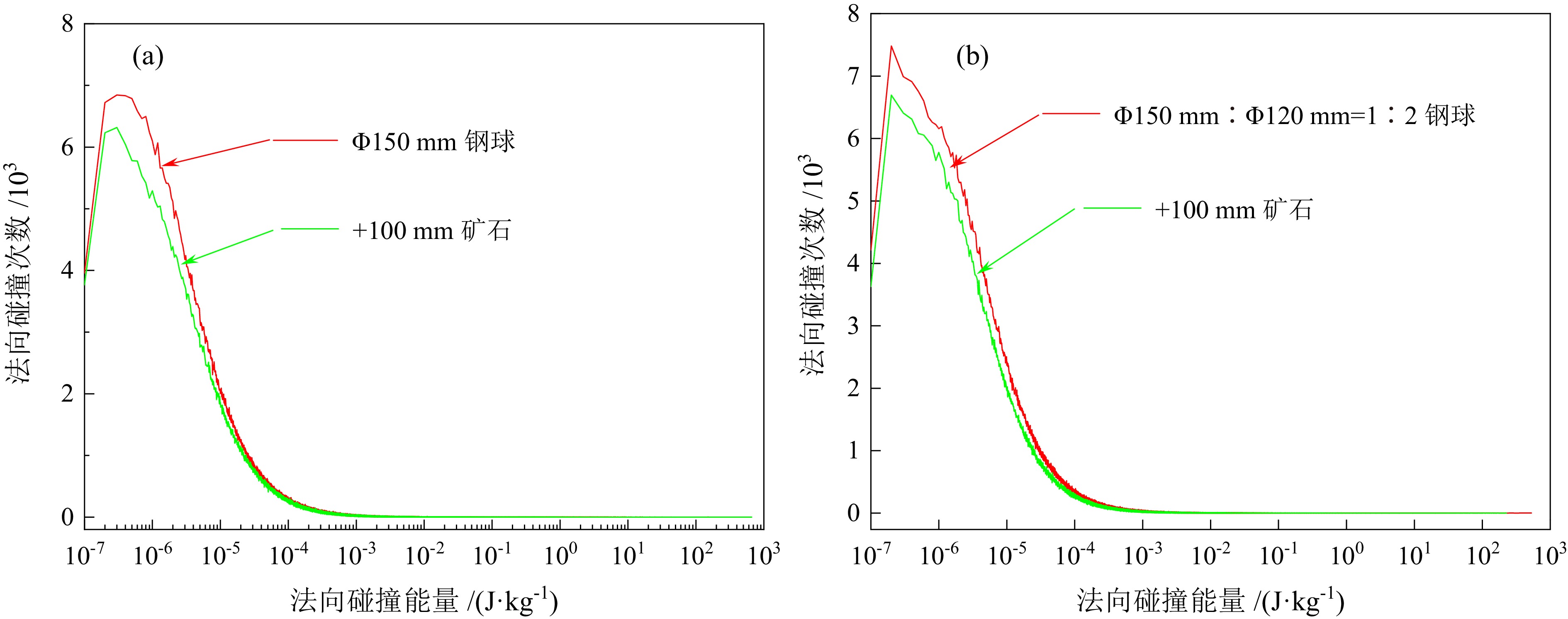

为解决四川攀枝花某铁矿选厂半自磨机中单一Φ150 mm钢球介质尺寸与给矿粒度及矿石力学性质不匹配、钢球尺寸单一导致磨机能耗高、效率低等问题,采用邦德球磨功指数实验及Azzaroni公式确定150 mm最大球径,通过D×L 450 mm×450 mm的小型磨机磨矿实验验证m(Ф150 mm)∶m(Ф120 mm)=1∶2的推荐钢球级配磨矿效果最好,进一步使用离散元(DEM)模拟仿真实验从碰撞能量的角度分析推荐钢球级配与单一Φ150 mm钢球尺寸现场钢球级配的能量利用率差异,最终确认推荐钢球级配效果最好。研究结果表明:推荐钢球级配比现场钢球级配顽石产率降低了0.32百分点,γ−0.074 mm产率提高了3.20百分点;离散元(DEM)模拟仿真实验结果表明:推荐钢球级配较现场钢球级配的切向碰撞能量利用率提高了2.98百分点,法向碰撞能量利用率提高了1.90百分点,对衬板的碰撞能量降低了306.9 J。从而验证了多级配球可有效提高半自磨机能量利用率。

Abstract:A single Φ150 mm steel ball media size in a semi−autogenous grinding ball mill in an iron ore plant in Panzhihua, Sichuan does not match the feed size and the mechanical properties of the ore, and the single steel ball size leads to high mill energy consumption and low efficiency.The maximum ball diameter of 150 mm was determined by using Bond Gong ball mill index test and Azzaroni formula, and the recommended steel ball grading of m(Ф150 mm)∶m(Ф120 mm)=1∶2 was verified to be the best by grinding test in a small mill with D×L 450×450 mm. The recommended steel ball gradation was finally confirmed to be the best. In this study, the results of laboratory grinding tests showed that the recommended steel ball grading reduced the stubborn yield by 0.32 percentage points and increased the yield of γ-0.074 mm by 3.20 percentage points compared with the on-site steel ball grading; the results of discrete element (DEM) simulation experiments showed that the recommended steel ball grading increased the tangential collision energy utilization by 2.98 percentage points and the normal collision energy utilization by 1.90 percentage points compared with the on−site steel ball grading. The results of discrete element (DEM) simulation experiments show that the recommended ball gradation has improved the tangential collision energy utilization by 2.98 percentage points, the normal collision energy utilization by 1.90 percentage points, and the collision energy to the liner plate by 306.9 J. Thus, it is verified that multi−stage ball gradation can improve the energy utilization of semi−autogenous grinding ball mill.

-

-

表 1 堆积密度测定结果

Table 1. Results of Bulk density measurement

/(g·cm−3) 第一次称重 第二次称重 第三次称重 平均值 2.13 2.15 2.17 2.15 表 2 球磨功指数相关测定结果

Table 2. Measurement results related to ball milling power index

实验筛孔

P1 /µm可磨度

Gbp/(g·r−1)产品粒度

P80/µm入磨粒度

F80/µm150 2.5 113 1951 表 3 半自磨的磨矿方案

Table 3. Grinding solution for semi-autogenous grinding

方案 级配内容 平均球径 现场级配 Ф150 mm 150 mm 偏小级配 Ф130 mm 130 mm 推荐级配 m(Ф150 mm)∶m(Ф120 mm)=1∶2 130 mm 偏大级配 m(Ф150 mm)∶m(Ф140 mm)=1∶1 145 mm 表 4 接触模型中使用的弹簧刚度和阻尼系数

Table 4. Spring stiffness and damping coefficients used in the contact model

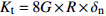

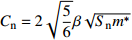

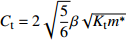

名称 法线方向(n) 切向(t) 弹簧刚度常数(K)

阻尼系数(C)

阻尼力(  )

)

表 5 参数含义

Table 5. Meaning of parameters

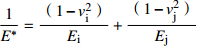

名称 表达式 备注 杨氏模量(E*)

Ei、vi、Ej、vj分别是杨氏模量、泊松比 当量半径(R*)

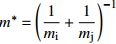

Ri、Rj表示接触球体半径 当量质量(m*)

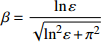

阻尼系数(β)

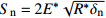

ε是恢复系数 法向刚度(Sn)

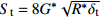

δn为重叠量 切向刚度(St)

G*为当量剪切模量 表 6 半自磨(SAG)机模拟中使用的各项参数

Table 6. Parameters used in the simulation of the semi-self-grinding (SAG) machine

参数 磨机直径 /m 磨机长度 /m 钢球充填率 /% 最大钢球直径 /mm 总充填率 /% 磨机临界转速 /(r·min−1) 衬板组数 /组 数值 9.15 5.03 14 150 32 14.04 40 表 7 材料参数

Table 7. Material parameters

材料 泊松比 弹性模量/Pa 密度/(kg·m−3) 矿石 0.26 1.27E+10 3640 钢球 0.30 8.00E+10 7800 衬板 0.30 8.00E+10 7800 表 8 接触参数

Table 8. Contact parameters

颗粒模型 恢复系数 静摩擦系数 滚动摩擦系数 钢球−钢球 0.50 0.70 0.15 钢球−矿石 0.70 0.20 0.01 矿石−矿石 0.41 0.50 0.25 表 9 半自磨机的模拟钢球级配方案

Table 9. Simulation scheme for semi-autogenous mills

方案 级配内容 平均球径 现场级配 Ф150 mm 150 mm 推荐级配 m(Ф150 mm)∶m(Ф120 mm)=1∶2 130 mm 表 10 顽石切向碰撞能量利用率

Table 10. Energy utilization of hard rock in tangential collision

方案 切向总能量 /J 介质−衬板 /J 介质−顽石 /J 能量利用率 /% 现场级配 1191316 1097.8 306193.7 25.73 推荐级配 1293076 878.8 371008.3 28.71 表 11 顽石法向碰撞能量利用率

Table 11. Naughty stone method to collision energy utilization

方案 法向总能量 /J 介质−衬板 /J 介质−顽石 /J 能量利用率 /% 现场级配 300150.1 1844.5 157788.9 52.57 推荐级配 328639.3 1537.6 178779.8 54.47 -

[1] 母福生. 破碎及磨矿技术在国内外的技术发展和行业展望(一)[J]. 矿山机械, 2011(11): 58−65. doi: 10.16816/j.cnki.ksjx.2011.11.016

MU F S. Technical development and industry outlook of crushing and grinding technology at home and abroad (I)[J]. Mining Machinery, 2011(11): 58−65. doi: 10.16816/j.cnki.ksjx.2011.11.016

[2] BARRERA D, CERRILLO L, GONGORA F, et al. Design of a wear estimator for liners in SAG mills using ANFIS modeling[C]//IEEE International Conference on Automation/Congress of the Chilean Association of Automatic Control. IEEE, 2021. DOI:10. 1109/ICAACCA51523. 2021. 9465187.

[3] A A R H, B M M, C H Z, et al. On dry SAG mills end liners: Physical modeling, DEM−based characterization and industrial outcomes of a new design[J]. Minerals Engineering, 2019, 141: 105835. doi: 10.1016/j.mineng.2019.105835

[4] 许鸿国, 曾军龙, 李杨, 等. 顽石处理对半自磨机产能的影响[J]. 中国钼业, 2021, 45(3): 31−34. doi: 10.13384/j.cnki.cmi.1006-2602.2021.03.008

XU H G, ZENG J L, LI Y, et al. Effect of recalcitrant treatment on the capacity of semi−autogenous mills[J]. China Molybdenum Industry, 2021, 45(3): 31−34. doi: 10.13384/j.cnki.cmi.1006-2602.2021.03.008

[5] 肖贤煌. 基于统计力学原理的半自磨机衬板结构优化设计[D]. 赣州: 江西理工大学, 2017.

XIAO X H. Optimization design of semi−autogenous mill liner structure based on statistical mechanics principle[D]. Ganzhou: Jiangxi University of Technology, 2017.

[6] 徐汉龙. 简用拉苏莫夫公式的方法及效果分析[C]//中国硅酸盐学会科普工作委员会, 建筑材料工业技术情报研究所, 建筑材料工业技术监督研究中心, 等. 2013国内外水泥粉磨新技术交流大会暨展览会论文集. 中国新闻联合出版社(China News United Publisher), 2013: 5.

XU H L. Method and effect analysis of simple use of Rasumov's formula[C]//Science Popularization Working Committee of China Silicate Society, Institute of Technical Information of Building Materials Industry, Research Center for Technical Supervision of Building Materials Industry, International Cement and Concrete Network. Proceedings of the 2013 Domestic and International Conference and Exhibition on the Exchange of New Technology of Cement Grinding. China News United Publisher, 2013: 5.

[7] 李启衡. 碎矿与磨矿[M[. 北京: 冶金工业出版社, 1980: 131-150.

LI Q H. Ore crushing and grinding [M[. Beijing: Metallurgical Industry Press, 1980: 131-150.

[8] 段希祥. 球磨机钢球尺寸的理论计算研究[J]. 中国科学(A辑 数学 物理学 天文学 技术科学), 1989(8): 856−863.

DUAN X X. Theoretical calculation of ball mill ball size[J]. Science in China (Series A Mathematics, Physics, Astronomy and Technical Sciences), 1989(8): 856−863.

[9] 宗路, 李旭, 蔡改贫, 等. 基于响应曲面法的半自磨机磨矿能耗研究[J]. 化工矿物与加工, 2018, 47(4): 18−21+53. doi: 10.16283/j.cnki.hgkwyjg.2018.04.006

ZONG L, LI X, CAI G P, et al. Research on grinding energy consumption of semi−autogenous mill based on response surface method[J]. Chemical Minerals and Processing, 2018, 47(4): 18−21+53. doi: 10.16283/j.cnki.hgkwyjg.2018.04.006

[10] 尹自信. 球磨机铁矿石颗粒破碎及粒度分布行为研究[D]. 徐州: 中国矿业大学, 2020.

YIN Z X. Research on particle crushing and particle size distribution behavior of iron ore in ball mill[D]. Xuzhou: China University of Mining and Technology, 2020.

[11] PENG Y X, NI X, ZHU Z C, et al. Friction and wear of liner and grinding ball in iron ore ball mill[J]. Tribology International, 2017: 506–517. DOI:10.1016/j. triboint. 2017. 06. 017.

[12] 王二锋, 张亮, 张颖新, 等. 河北某铁矿邦德球磨功指数的测定[J]. 河南科技, 2019(7): 102−106. doi: 10.3969/j.issn.1003-5168.2019.07.041

WANG E F, ZHANG L, ZHANG Y X, et al. Determination of Bond ball milling power index in an iron ore mine in Hebei[J]. Henan Science and Technology, 2019(7): 102−106. doi: 10.3969/j.issn.1003-5168.2019.07.041

[13] 全国信息与文献标准化技术委员会. 文献著录: 第4部分非书资料: GB/T 26567-2011[S]. 北京: 中国标准出版社, 2010: 3.

National Information and Documentation Standardization Technical Committee. Documentation: Part 4 Non−book materials: GB/T 26567-2011)[S]. Beijing: China Standard Press, 2010: 3.

[14] 黄国智, 方启学, 任翔, 等. 全自磨半自磨磨矿技术[M]. 北京: 冶金工业出版社, 2018: 226-230.

HUANG G Z, FANG Q X, REN X, et al. Fully autogenous semiautogenous grinding technology[M]. Beijing: Metallurgical Industry Press, 2018: 226-230.

[15] 武煜凯, 肖庆飞, 高志勇. 多级配球降低半自磨中顽石积累及改善磨矿效果试验[J]. 稀有金属, 2022(5): 46. doi: 10.13373/j.cnki.cjrm.XY20120018

WU Y K, XIAO Q F, GAO Z Y. Reduction of recalcitrant accumulation and improvement of grinding effect in semi−autogenous grinding by multi−stage ball allocation[J]. Rare Metals, 2022(5): 46. doi: 10.13373/j.cnki.cjrm.XY20120018

[16] MINDLIN R D. Compliance of elastic bodies in contact[J]. Journal of Applied Mechanics, 1949, 16: 259−268. doi: 10.1007/978-1-4613-8865-4_24

[17] MAIO F, RENZO A D. Modelling particle contacts in distinct element simulations: linear and non−linear approach[J]. Chemical Engineering Research & Design, 2005, 83(11): 1287−1297.

[18] CLEARY P W. Predicting charge motion, power draw, segregation and wear in ball mills using discrete element methods[J]. Minerals Engineering, 1998. DOI:10.1016/S0892-6875(98)00093-4.

[19] CLEARY P W, MORRISON R D. Comminution mechanisms, particle shape evolution and collision energy partitioning in tumbling mills[J]. Minerals Engineering, 2016, 86: 75−95. doi: 10.1016/j.mineng.2015.12.006

[20] CAPECE M, BILGILI E, R DAVé. Insight into first−order breakage kinetics using a particle-scale breakagerate constant[J]. Chemical Engineering Science, 2014, 117(1): 318−330.

-

下载:

下载: