Experimental and Resistance Characterization Study of Yransparent L−tube for Graded Tailing Backfill Slurry

-

摘要:

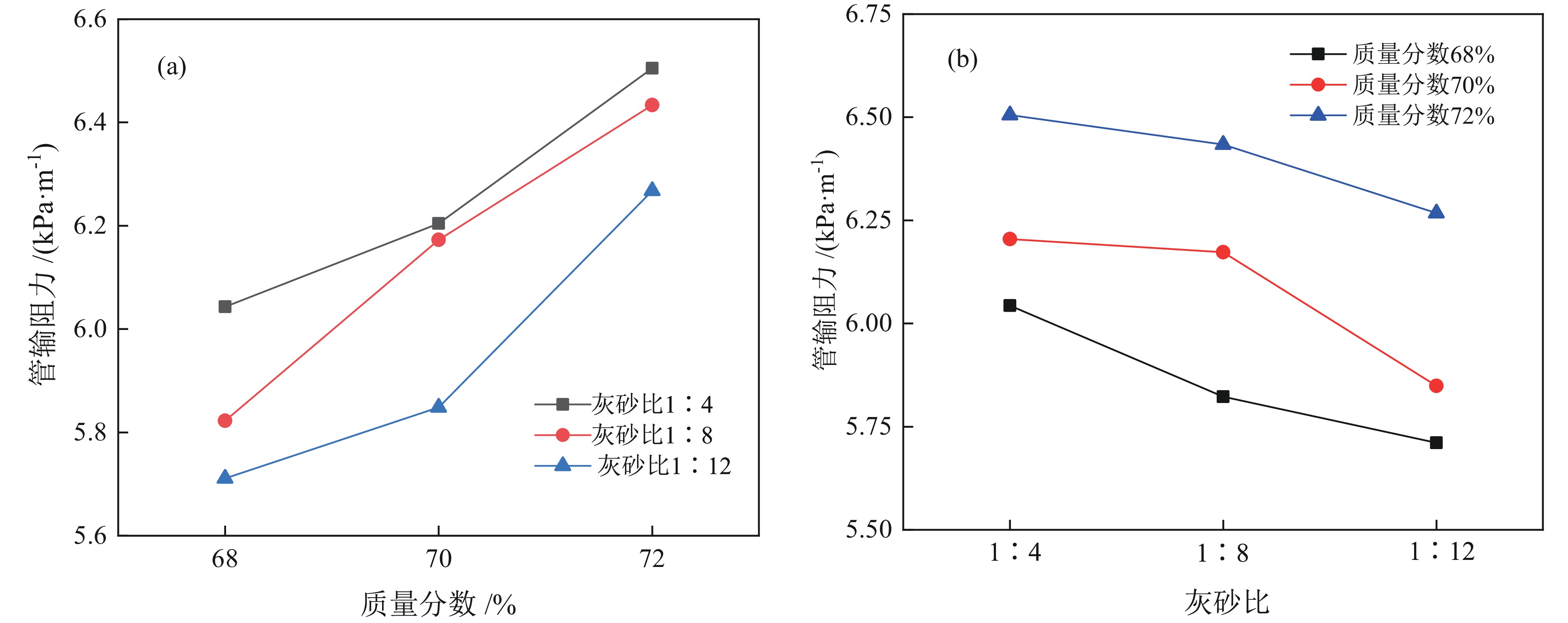

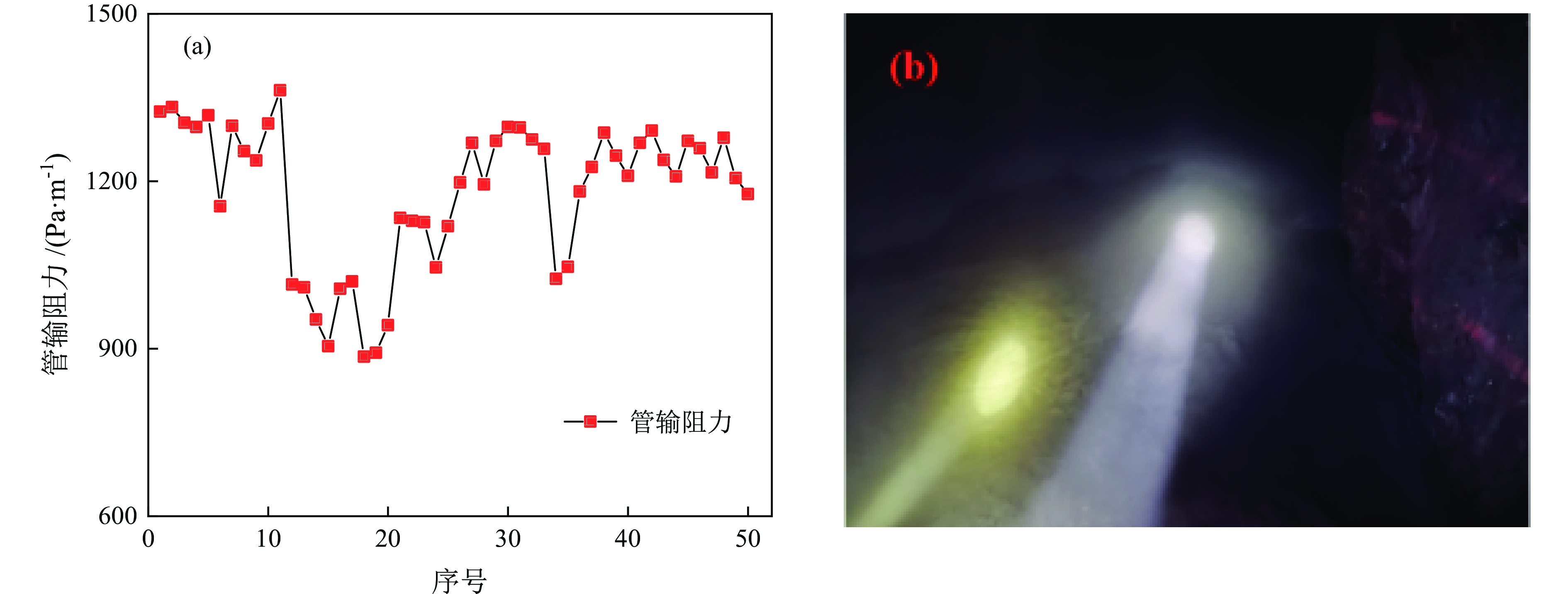

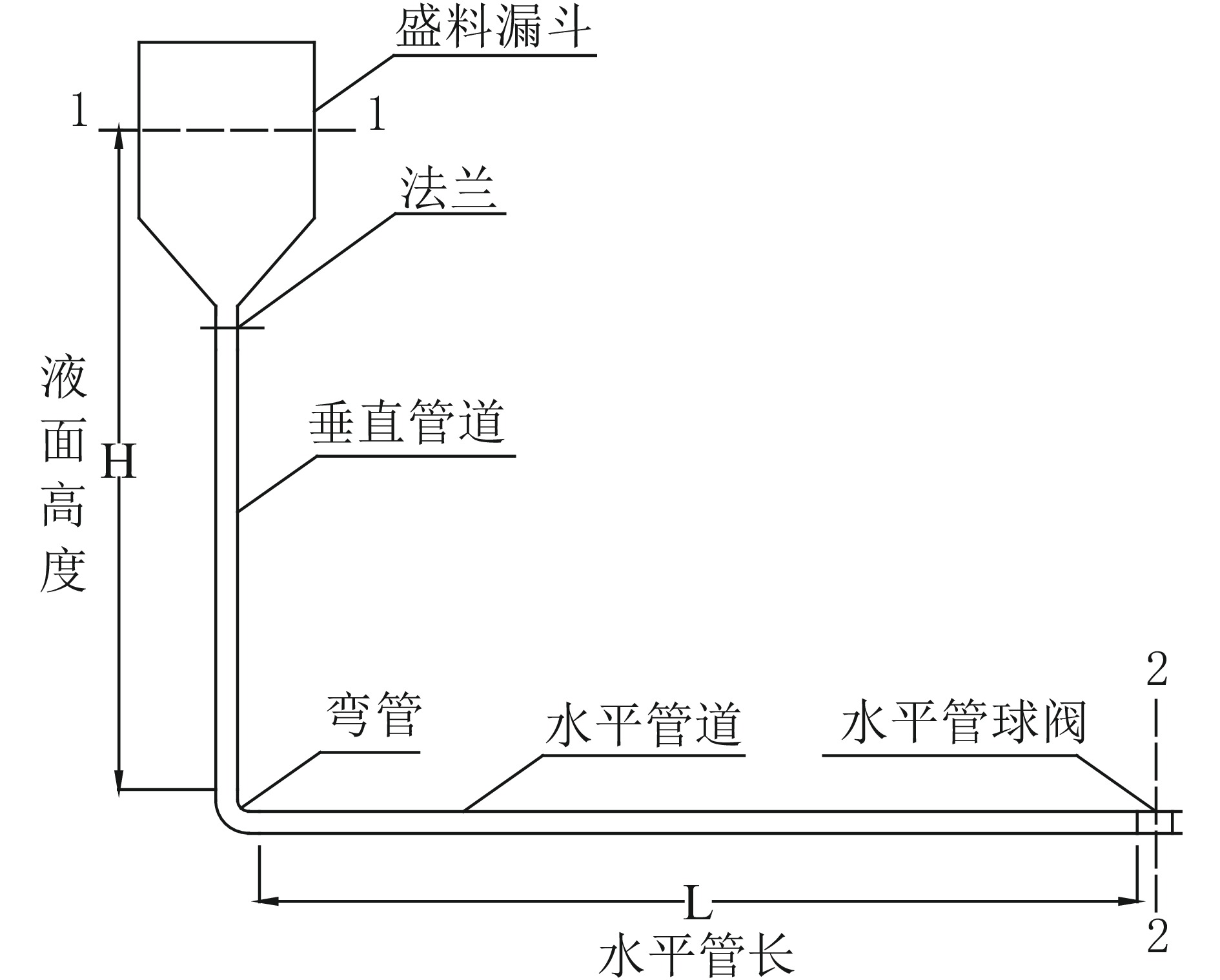

管道输送阻力是充填料浆管道输送的一个重要参数,目前普遍采用基于宾汉流变模型推导的白金汉公式进行计算,而管壁滑移效应的影响在该公式中被忽略,导致管道输送阻力的计算产生一定的偏差。因此本文基于L管输送实验,提出了考虑管壁滑移效应影响的充填料浆输送阻力计算方法,采用全面实验设计方案,研究了料浆质量分数、灰砂比和管壁滑移效应对于充填料浆管输阻力的影响。结果表明:管输阻力与质量分数、灰砂比呈正相关,与管壁滑移效应呈负相关。管壁滑移效应通过滑移贡献率来量化,该系数受质量分数的影响较明显,随着质量分数增大逐渐减弱,在质量分数较小时,受灰砂比的影响不明显。通过回归分析,构建了基于管径、流速、质量分数、灰砂比四变量,考虑管壁滑移效应的充填料浆管输阻力数学模型,并进行了工程实践验证。

Abstract:Pipe transport resistance is an important parameter of backfill slurry for pipeline transport, and the Buckingham formula based on Bingham's rheological model is commonly used for calculation, and the influence of pipe wall slip effect is ignored in the formula, leads to produce certain deviation pipeline resistance calculation. So this paper proposes a method for calculating the rheological parameters of filling slurry and transport resistance considering the influence of pipe wall slip effect based on the transparent L−pipe conveying experiments, and adopts a comprehensive experimental design scheme to study the effect of slurry mass fraction, cement−tailing ratio on pipe wall slip effect and backfill slurry pipe transport resistance. Using a comprehensive experimental design scheme, the influence of slurry mass fraction and gray−to−sand ratio on the wall slip effect and filling slurry conveying resistance was investigated. The results show that pipe transport resistance is positively correlated with mass fraction and lime sand ratio, and negatively correlated with pipe wall slip effect. The slippage effect is quantified by the slippage contribution degree, which is significantly affected by the mass fraction and gradually decreases with the increase of the mass fraction. When the mass fraction is small, the influence of the lime sand ratio is not obvious. Through regression analysis, a mathematical model of backfill slurry pipe transport resistance was constructed based on the four variables of pipe diameter, flow rate, mass fraction, and cement−tailing ratio, taking into account the wall−slip effect, which is convenient for guiding the engineering practice.

-

Key words:

- backfill slurry /

- l tube experiment /

- pipeline resistance /

- wall slip /

- resistance model

-

-

表 1 充填料浆的管输阻力

Table 1. Parameters for different rocks tested

流速/(m·s−1) 质量

分数/%灰砂比 屈服

应力/ Pa塑性黏度

/(Pa·s)管输阻力

/(kPa·m−1)1.809 68 1∶4 6.339 0.248 6.043 1.950 68 1∶8 5.966 0.218 5.822 2.044 68 1∶12 5.323 0.207 5.711 1.540 70 1∶4 12.027 0.251 6.205 1.623 70 1∶8 12.905 0.235 6.173 1.816 70 1∶12 12.505 0.192 5.848 1.561 72 1∶4 25.056 0.215 6.525 1.365 72 1∶8 24.761 0.199 6.434 1.491 72 1∶12 23.851 0.180 6.268 -

[1] 吴爱祥, 王勇, 张敏哲, 等. 金属矿山地下开采关键技术新进展与展望[J]. 金属矿山, 2021(1): 1−13.

WU A X, WANG Y, ZHAG M Z et al. New development and prospect of key technology in underground mining of metal mines[J]. Metal Mine, 2021(1): 1−13.

[2] CHOUDHARY BHANWAR SINGH, KUMAR SANTOSH. Underground void filling by cemented mill tailings[J]. International Journal of Mining Science and Technology, 2013, 23(6): 893−900. doi: 10.1016/j.ijmst.2013.11.003

[3] 吴爱祥, 杨莹, 程海勇, 等. 中国膏体技术发展现状与趋势[J]. 工程科学学报, 2018, 40(5): 517−525.

WU A X, YANG Y, CHENG H Y, et al. Status and prospects of paste technology in China[J]. Chinese Journal of Engineering, 2018, 40(5): 517−525.

[4] 李公成, 王洪江, 吴爱祥, 等. 基于倾斜管实验的膏体自流输送规律[J]. 中国有色金属学报, 2014, 24(12): 3162−3164+3166−3169.

LI G C, WANG H J, WU A X, et al. Flow transport of paste based on inclined tube experiment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3162−3164+3166−3169.

[5] 李守强, 郭利杰, 郑旭, 等. 膏体充填料浆管道自流输送分析及管线布置[J]. 中国矿业, 2021, 30(8): 149−153.

LI S Q, GUO L J, ZHENG X, et al. Analysis and pipeline layout of free flow transportation of paste filling slurry pipeline[J]. China Mining Magazine, 2021, 30(8): 149−153.

[6] 吴爱祥, 王洪江. 金属矿膏体充填理论与技术[M]. 北京: 科学出版社, 2015.

WU A X, WANG H J. Theory and technology of metal paste backfill [M]. Beijing: Science Press, 2015.

[7] 王建栋, 吴爱祥, 王贻明, 等. 粗骨料膏体抗离析性能评价模型与实验研究[J]. 中国矿业大学学报, 2016, 45(5): 866−872.

WANG J D, WU A X, WANG Y M, et al. Evaluation model and experimental study on anti−segregation performance of coarse aggregate paste[J]. Journal of China University of Mining and Technology, 2016, 45(5): 866−872.

[8] CHEN D D, JIANG X G, LV S, et al. Rheological properties and stability of lignite washery tailing suspensions[J]. Fuel, 2015: 214−221.

[9] KALYON DM. Apparent slip and viscoplasticity of concentrated suspensions[J]. Journal of Rheology, 2005, 49(3): 621−640. doi: 10.1122/1.1879043

[10] 吕馥言. 基于壁面滑移效应的浓密膏体管道输送减阻增程研究[D].中国矿业大学(北京),2018.

LV F Y, Drag-reduction of pipeline transport of dense paste based on wall slip phenomonon[D] China University of Mining and Technology (Beijing), 2018.

[11] 齐兆军, 宋泽普, 寇云鹏, 等. 某矿山全尾砂似膏体料浆L管试验研究[J]. 中国矿业, 2018, 27(10): 161−164.

QI Z J, SONG Z P, GUAN Y P, et, al. Experimental study on crude tailings paste−like slurry by L−pipe in a mine[J]. China Mining Magazine, 2018, 27(10): 161−164.

[12] 杜加法, 刘晓光, 王京生, 等. 基于L管实验的全尾砂膏体流变特性研究[J]. 金属矿山, 2020(8): 20−24.

DU J F, LIU X G, WANG J S, et, al. Rheological properties of unclassified tailings paste slurry based on L−tube pipeline Test[J]. Metal Mine, 2020(8): 20−24.

[13] 刘晓辉, 吴爱祥, 姚建, 等. 膏体尾矿管内滑移流动阻力特性及其近似计算方法[J]. 中国有色金属学报, 2019, 29(10): 2403−2410.

LIU X H, WU A X, YAO J, et al. Paste tailings tube slip flow resistance characteristics and its approximate calculation method[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(10): 2403−2410.

[14] 吴爱祥, 程海勇, 王贻明, 等. 考虑管壁滑移效应膏体管道的输送阻力特性[J]. 中国有色金属学报, 2016, 26(1): 180−187.

WU A X, CHENG H Y, WANG Y M, et al. Transport resistance characteristics of paste pipelines considering wall slip effect[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 180−187.

[15] 甘德清, 闫泽鹏, 薛振林, 等. 考虑壁面滑移效应的充填料浆管道输送阻力研究[J]. 金属矿山, 2020(9): 26−32.

GAN D Q, YAN Z P, XUE Z L, et al. Research on conveying resistance of filling slurry pipeline considering wall slip effect[J]. Metal Mine, 2020(9): 26−32.

[16] 王少勇, 吴爱祥, 阮竹恩, 等. 基于环管实验的膏体流变特性及影响因素[J]. 中南大学学报(自然科学版), 2018, 49(10): 2519−2525.

WANG S Y, WU A X, RUAN Z E, et al. Rheological properties and influencing factors of paste based on loop tube experiment[J]. Journal of Central South University (Natural Science), 2018, 49(10): 2519−2525.

[17] 郑伯坤, 姚维, 黄腾龙, 等. 基于环管试验的改性全尾砂充填料浆输送性能[J]. 中国有色金属学报, 2021, 31(2): 520−529.

ZHANG B K, YAO W, HUANG T L, et al. Conveying performance of modified full tailing filler slurry based on loop test[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 520−529.

[18] 陈琴瑞, 王洪江, 吴爱祥, 等. 用L管测定膏体料浆水力坡度试验研究[J]. 武汉理工大学学报, 2011, 33(1): 108−112.

CHEN Q R, WANG H J, WU A X, et al. Experimental study on hydraulic slope determination of paste with L−tube[J]. Journal of Wuhan University of Technology, 2011, 33(1): 108−112.

[19] 王洪江, 李公成, 吴爱祥, 等. 不同粗骨料的膏体流变性能研究[J]. 矿业研究与开发, 2014, 34(7): 59−62.

WANG H J, LI G C, WU A X, et al. Research on rheological properties of paste with different coarse aggregates[J]. Mining Research and Development, 2014, 34(7): 59−62.

[20] 董培鑫, 杨志强, 高谦, 等. 混合充填集料粒径与级配对料浆流动性影响[J]. 矿业研究与开发, 2018, 38(3): 53−59.

DONG P X, YANG Z Q, GAO Q, et al. Effect of particle size and grade of mixed filling aggregate on slurry fluidity[J]. Mining Research and Development, 2018, 38(3): 53−59.

[21] 卞继伟, 张钦礼, 王浩. 基于L管试验的似膏体管流水力坡度模型[J]. 中国矿业大学学报, 2019, 48(1): 23−28.

BIAN J W, ZHANG Q L, WANG H. Pipeline hydraulic gradient model of paste−like based on L−pipe experiments[J]. Journal of China University of Mining & Technology, 2019, 48(1): 23−28.

[22] ULKU YILMAZER, DILHAN M KALYON. Slip effects in capillary and parallel disk torsional flows of highly filled suspensions[J]. Journal of Rheology, 1998, 33(8): 1197−1212.

[23] 甘德清, 薛振林, 闫泽鹏, 等. 多场耦合条件下充填料浆管输壁面滑移特性[J]. 金属矿山, 2023(02): 30−37.

GAN D Q, XUE Z L, YAN Z P, et al. Wall Slip Characteristics of High Concentration Filling Slurry under Multi-field Coupling[J]. Metal Mine, 2023(02): 30−37.

[24] 王小林, 王洪江, 吴爱祥, 等. 全尾砂膏体管道输送壁面滑移减阻模型[J]. 中国有色金属学报, 2020, 30(9): 2201−2205.

WANG X L, WANG H J, WU A X, et al. Wall slip reduction model of all−tailing paste pipeline[J]. The Chinese Journal of Nonferrous Metals, 20, 30(9): 2201−2205.

[25] 张磊, 王洪江, 李公成, 等. 膏体管道壁面滑移特性研究进展及趋势[J]. 金属矿山, 2015(10): 1−5.

ZHANG L, WANG H J, LI G C, et al. Research progress and trend of wall slip characteristics of paste pipeline[J]. Metal Mine, 2015(10): 1−5.

[26] 陈立. 高含沙水流流变参数的试验研究[J]. 武汉水利电力学院学报, 1992(4): 384−392.

CHEN L. Experimental study on rheological parameters of water flow with high sediment content[J]. Journal of Wuhan University of Hydraulic Engineering and Electric Power, 1992(4): 384−392.

[27] 刘晓辉, 吴爱祥, 王洪江, 等. 膏体流变参数影响机制及计算模型[J]. 工程科学学报, 2017, 39(2): 190−195.

LIU X H, WU A X, WANG H J, et al. Mechanism and calculation model of rheological parameters of paste[J]. Chinese Journal of Engineering Science, 2017, 39(2): 190−195.

-

下载:

下载: