Preparation of Porous Ceramic Materials from High-Sulfur Copper Tailings and Its Pore Structure Properties

-

摘要:

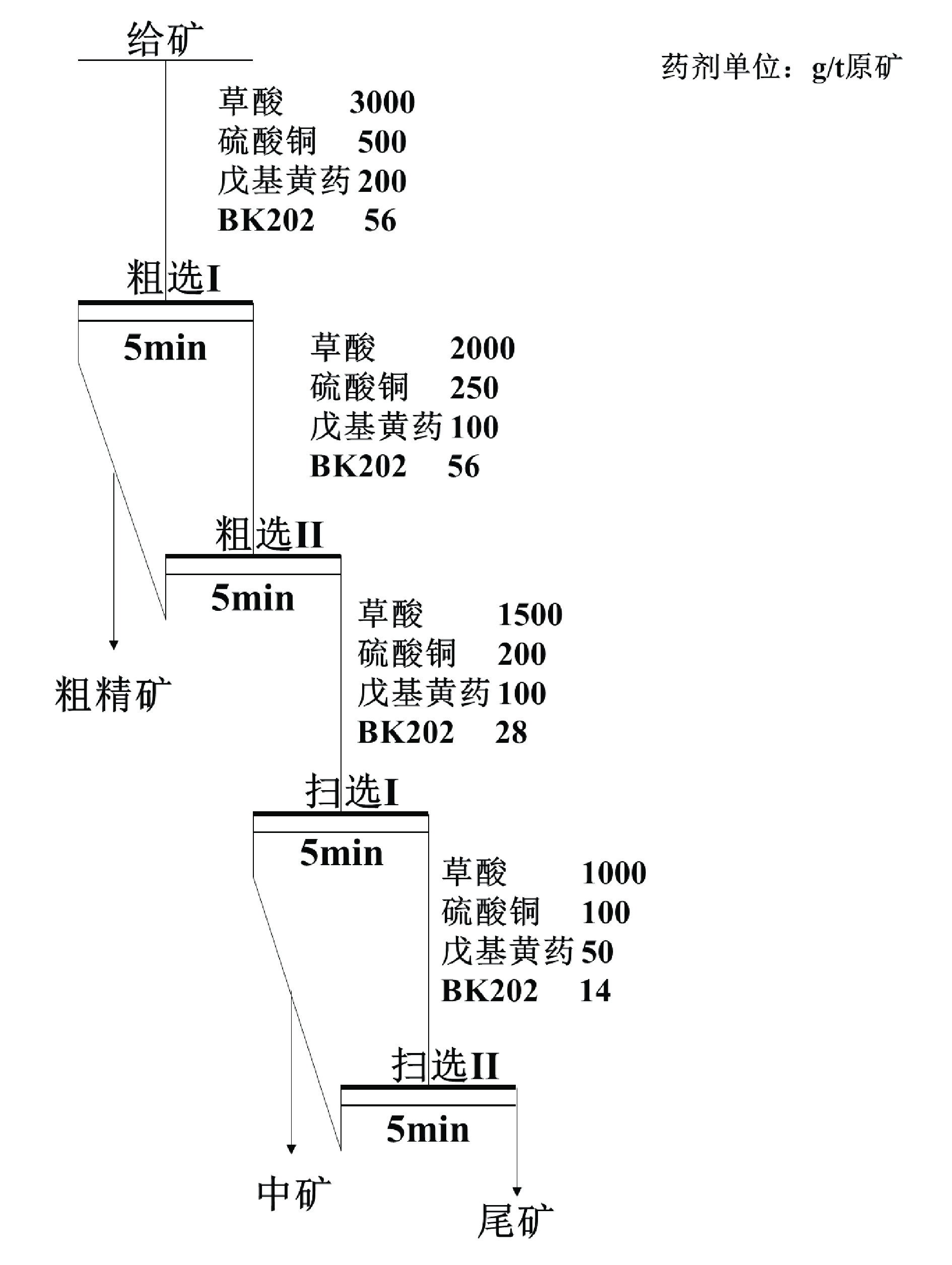

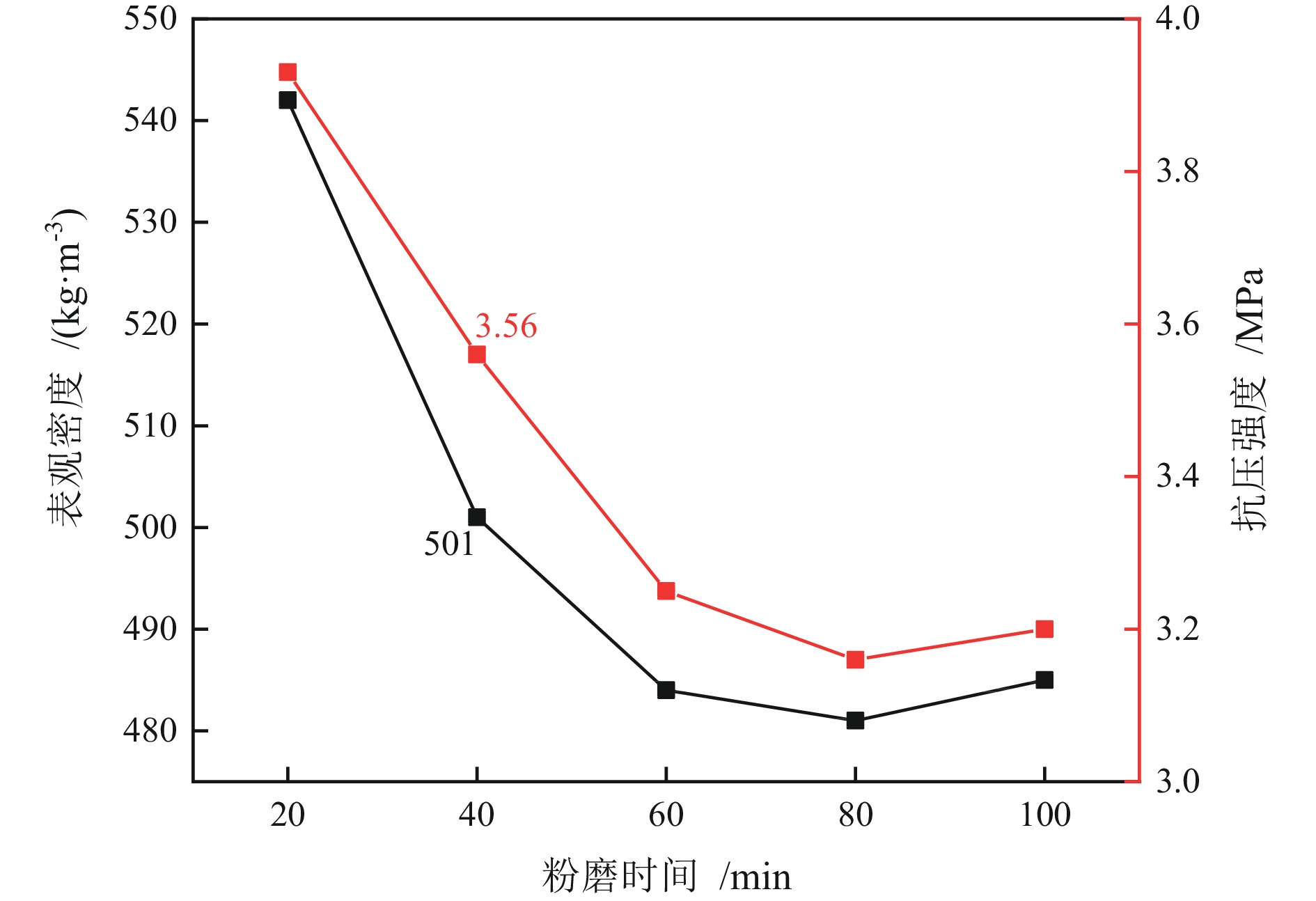

以高硫铜尾矿为主要原料制备多孔保温陶瓷材料。首先对尾矿进行浮选和磁选脱硫,将尾矿中的总硫含量从6.40%降低至0.69%,然后通过条件实验研究了原料配比、粉磨时间、发泡剂用量对多孔陶瓷材料表观密度和抗压强度的影响。当脱硫铜尾矿用量为60%、钾长石用量为20%、钠长石用量为15%、硅微粉用量为5%、发泡剂SiC用量为0.3%、粉磨时间为40 min时,多孔陶瓷性能最佳,表观密度为412 kg/m3,抗压强度为2.94 MPa,采用工业CT对多孔陶瓷材料的孔结构进行分析,多孔陶瓷的总孔隙率为56.93%,其中闭合孔隙率高达56.51%,平均喉道长度为1357.1 μm,有较高的封闭性,为多孔陶瓷提供了优良的保温隔热性能。

Abstract:The porous ceramics was preparated using high-sulfur copper-tailings as the main raw material. Firstly, flotation and magnetic separation desulfurization were carried out on the tailings to reduce the total sulfur content from 6.40% to 0.69%. The effects of raw material ratio, grinding time, and foaming agent dosage on the apparent density and compressive strength of porous ceramic materials were studied through conditional experiments. When the amount of desulfurization copper tailings was 60%, the amount of potassium feldspar was 20%, the amount of sodium feldspar was 15%, the amount of silicon micro powder was 5%, the amount of foaming agent SiC was 0.3%, and the grinding time was 40 minutes, the performance of porous ceramics was the best. The apparent density was 412 kg/m3, and the compressive strength was 2.94 MPa. The pore structure of porous ceramics was analyzed using industrial CT, and the total porosity of porous ceramics was 56.93%, with a closed porosity of up to 56.51%, The average throat length was 1 357.1 μ m. It has high sealing performance, providing excellent insulation and thermal insulation performance for porous ceramics.

-

Key words:

- high-sulfur copper tailings /

- porous ceramics /

- insulation ceramics /

- pore structure

-

-

表 1 主要原料的X射线荧光光谱分析

Table 1. X−ray fluorescence spectrum analysis of copper tailings

/% 化学成分 SiO2 Al2O3 CaO MgO K2O Na2O Fe2O3 SO3 Loss 铜尾矿 34.30 6.33 21.06 5.84 0.96 0.57 18.21 11.61 0.84 钾长石 77.50 11.98 0.61 1.52 0.36 7.15 0.32 0.02 0.45 钠长石 71.28 11.56 2.03 0.47 3.58 9 0.22 0.01 0.36 硅微粉 98.85 − − − − − − − − 表 2 浮选脱硫实验结果

Table 2. Test results of flotation desulfurization

/% 实验方案 产品名称 产率 硫品位 硫回收率 方案1

草酸+硫酸铜粗精矿 23.01 22.59 81.22 中矿 5.47 6.92 5.91 尾矿 71.52 1.15 12.85 给矿 100.00 6.40 100.00 方案2

硫化钠+硫酸铜粗精矿 22.14 22.39 77.46 中矿 6.63 6.82 7.07 尾矿 71.23 1.39 15.47 给矿 100.00 6.40 100.00 方案3

硫酸+硫代硫酸钠+

水玻璃粗精矿 19.82 24.37 75.47 中矿 2.44 10.56 4.03 尾矿 77.74 1.69 20.53 给矿 100.00 6.40 100.00 表 3 发泡陶瓷的适宜化学成分组成

Table 3. Suitable chemical composition of foamed ceramics

/% SiO2 Al2O3 Na2O+K2O CaO+MgO 50~70 >10 3~8 大于1.5 表 4 原料配比实验结果

Table 4. Test Results of Raw Material Proportion

组号 脱硫

尾矿/%钾长石/

%钠长石/

%硅微粉/

%表观

密度/(kg·m−3)抗压

强度/MPa1 80 5 10 5 684 3.14 2 70 10 10 5 636 3.22 3 70 15 15 5 614 2.95 4 60 20 15 5 542 3.93 5 50 20 20 10 545 3.91 表 5 多孔陶瓷孔隙分布数据表

Table 5. Pore Distribution Data Sheet of Porous Ceramics

项目 总孔

隙率/%连通

孔隙率/%闭合

孔隙率/%最大孔隙半径/μm 平均孔隙半径/μm 最大喉道半径/μm 数值 56.93 0.42 56.51 2074.4 490.8 438.3 项目 平均喉道半径/μm 最大喉道长度/μm 平均喉道长度/μm 平均喉道体积/μm3 最大

配位数平均

配位数数值 98.8 3380.8 1357.1 5.51*107 15 2.98 -

[1] 郭万进, 吴明海, 王阳, 等. 我国铜矿尾矿资源化利用技术现状及进展[J]. 矿产综合利用, 2023(5): 127−134.

GUO W J, WU M H, WANG Y, et al. Present situation and progress of copper mine tailings resource utilization technology in China[J]. Comprehensive utilization of minerals, 2023(5): 127−134.

[2] 袁鹏. 安徽某地铜尾矿资源的综合利用研究[J]. 矿业工程, 2023, 21(2): 61−65.

YUAN P. Study on Comprehensive Utilization of Copper Tailings in Anhui Province[J]. Mining Engineering, 2023, 21(2): 61−65.

[3] 施麟芸, 匡敬忠, 刘松柏, 等. 铜尾矿建材化应用研究现状及矿物组成影响作用规律[J]. 硅酸盐通报, 2022, 41(10): 3511−3524.

SHI L Y, KUANG J Z, LIU S B, et al. Research status of copper tailings as building materials and the influence of mineral composition[J]. Silicate Bulletin, 2022, 41(10): 3511−3524.

[4] 赵庆朝, 李伟光, 李勇, 等. 斑岩型铜尾矿制备连通孔陶瓷透水材料的试验研究[J]. 矿产保护与利用, 2022, 42(2): 152−156.

ZHAO Q C, LI W G, LI Y, et al. Experimental study on preparation of porous ceramic materials from porphyry copper tailings[J]. Conservation and Utilization of Mineral resources, 2022, 42(2): 152−156.

[5] ZHANG S Q, WANG H Y, LI K Q, et al. Effect of Gold Tailing Addition on the Mechanical Properties and Microstructure of Foam Ceramics[J]. Processes, 2023, 11(3): 844−844. doi: 10.3390/pr11030844

[6] LIU T, TANG Y, HAN L, et al. Recycling of harmful waste lead−zinc mine tailings and fly ash for preparation of inorganic porous ceramics[J]. Ceramics International, 2016, 43(6): 4910−4918.

[7] 赵威, 韩硕, 陈明堃. 钼尾矿基发泡陶瓷墙材的制备及其性能研究[J]. 商洛学院学报, 2021, 35(6): 1−5+12.

ZHAO W, HAN S, CHEN M K. A study on preparation and performance of molybdenum tailings−based foamed ceramic wall materials[J]. Journal of Shangluo University, 2021, 35(6): 1−5+12.

[8] 关昀鹤, 郑丽君, 罗旭东, 等. 铁尾矿制备碳化硅多孔陶瓷材料及其性能研究[J/OL]. 耐火材料: 1−7[2024−03−26]. http://kns.cnki.net/kcms/detail/41.1136.TF.20240103.1719.002.html.

GUAN Y H, ZHENG L J, LUO X D, et al. Preparation of porous silicon carbide ceramics from iron tailings and its properties [J/OL]. Refractory materials: 1−7[2024−03−26]. http://kns.cnki.net/kcms/detail/41.1136.TF.20240103.1719.002.html.

[9] 杨洁. 川西锂辉石浮选尾矿制备陶瓷材料及其性能研究[D]. 绵阳: 西南科技大学, 2022.

YANG J. Preparation and properties of ceramic materials from spodumene flotation tailings in western Sichuan [D]. Mianyang: Southwest University of Science and Technology, 2022.

[10] 李伟光, 宋厚彬, 刘海营, 等. 蒙古国某斑岩型铜尾矿制备轻质多孔陶瓷正交实验研究[J]. 矿产保护与利用, 2023, 43(4): 101−106.

LI W G, SONG H B, LIU H Y, et al. Orthogonal experimental study on preparation of light porous ceramics from a porphyry copper tailings in Mongolia[J]. Conservation and Utilization of Mineral resources, 2023, 43(4): 101−106.

[11] 孙海侠, 李元星, 李琼, 等. 多孔陶瓷在环境治理中的应用研究[J]. 陶瓷, 2021(6): 27−30.

SUN H X, LI Y X, LI Q, et al. Application of porous ceramics in environmental treatment[J]. Ceramics, 2021(6): 27−30.

[12] 刘媛媛, 肖慧, 李寿德. 铁尾矿烧结多孔保温材料气孔形成的机理研究[J]. 新型建筑材料, 2010, 37(04): 47−49+58.

LIU Y Y, XIAO H, LI S D. Study on bubble formation mechanism for thermal insulation porous materials of iron tailings[J] New Building Materials, 2010, 37(04): 47−49+58.

[13] 刘晓倩, 周洋, 刘旭峰等. 碳热还原法制备铁尾矿多孔陶瓷的结构与性能[J]. 矿产保护与利用, 2020, 40(3): 56−63.

LIU X Q, ZHOU Y, LIU X F, et al. Structure and properties of iron tailings porous ceramics prepared by carbothermal reduction method[J]. Conservation and Utilization of Mineral resources, 2020, 40(3): 56−63.

[14] 吴浩. 节能利废高温发泡陶瓷的制备与性能研究[D]. 武汉: 武汉理工大学, 2020.

WU H. Preparation and properties of energy−saving and waste−recycling high−temperature foamed ceramics [D]. Wuhan: Wuhan University of Technology, 2020.

-

下载:

下载: