Preparation of Corundum Based Composite Ceramics Using Bauxite Tailings and Vanadium−titanium Magnetite Tailings as Raw Materials

-

摘要:

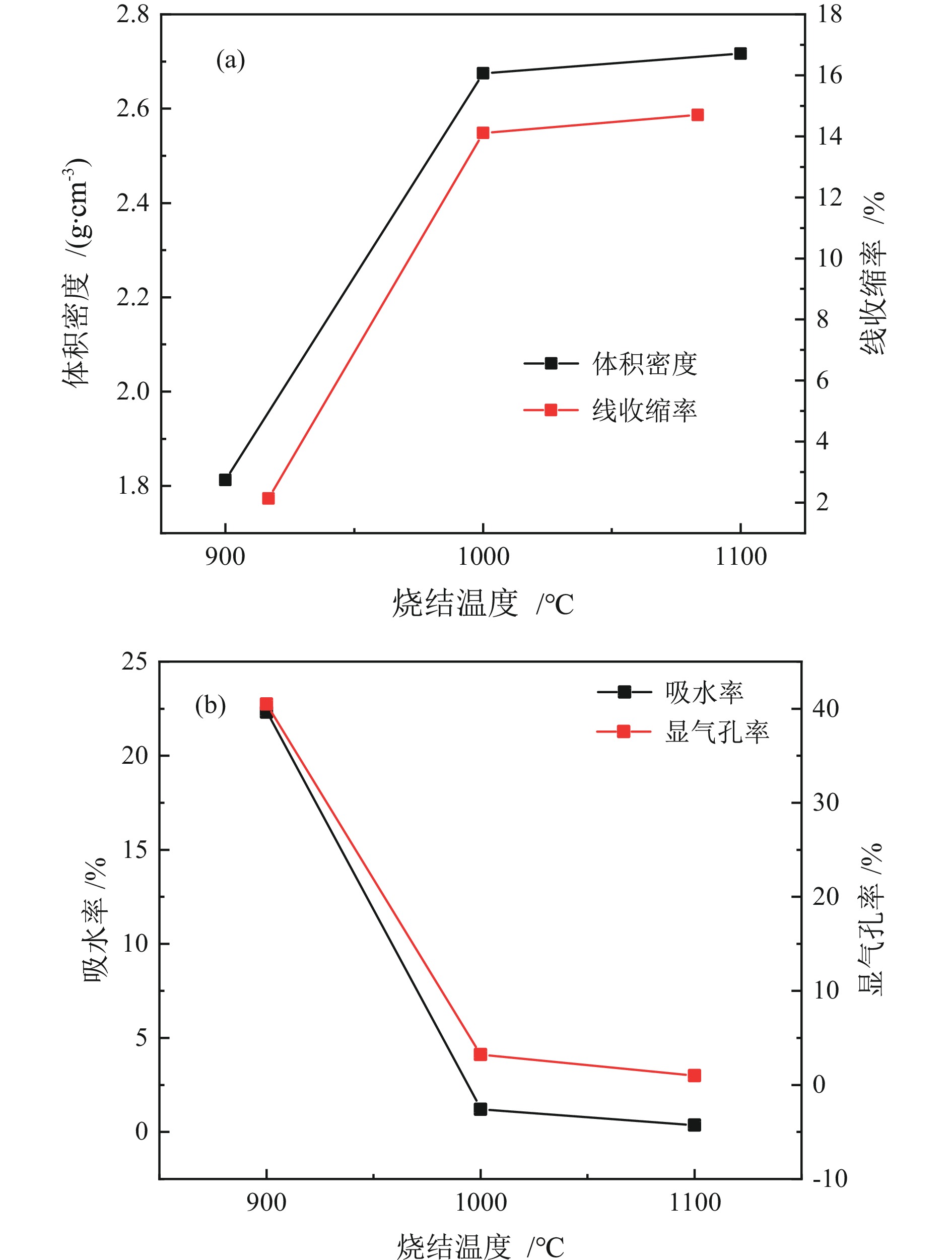

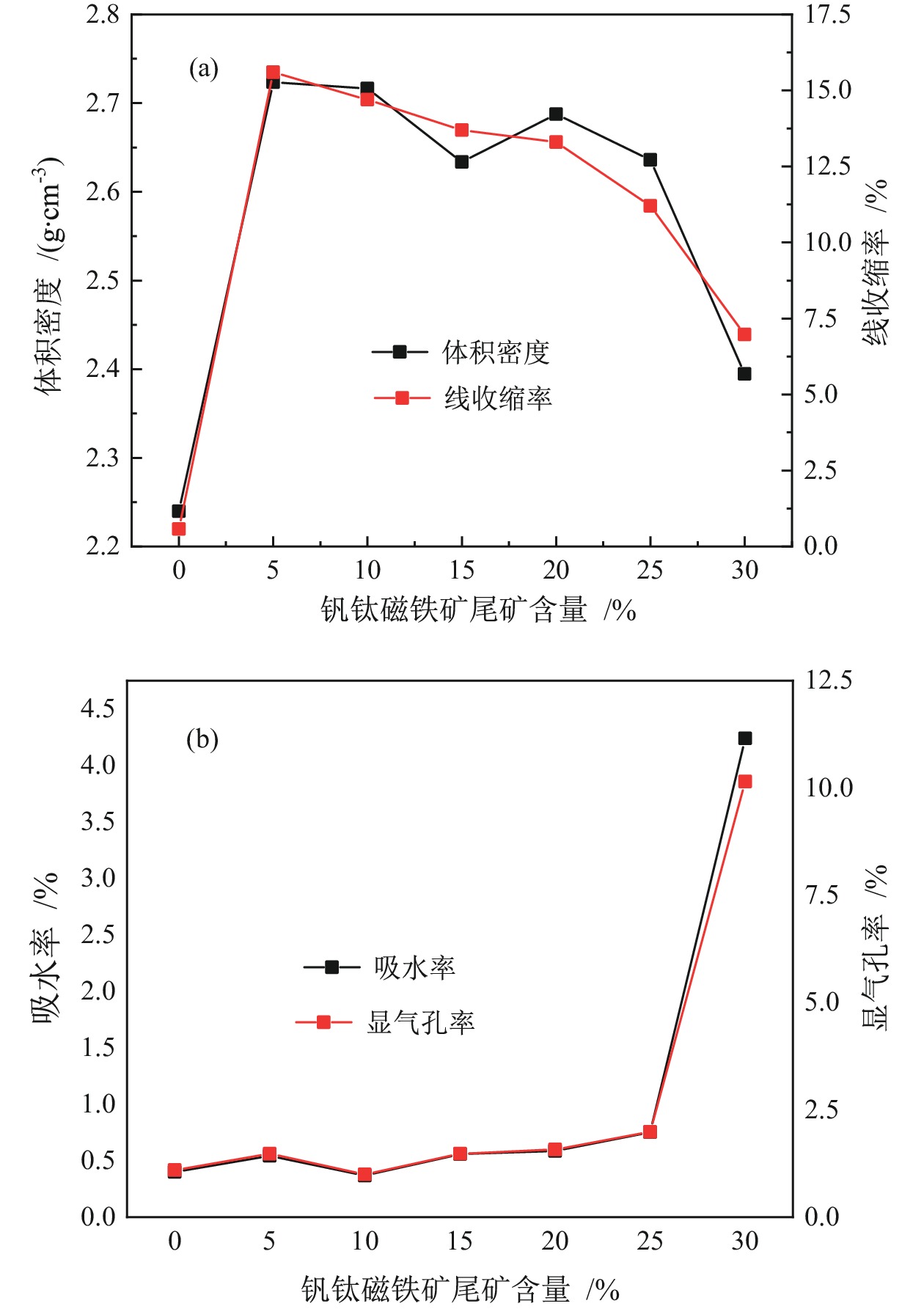

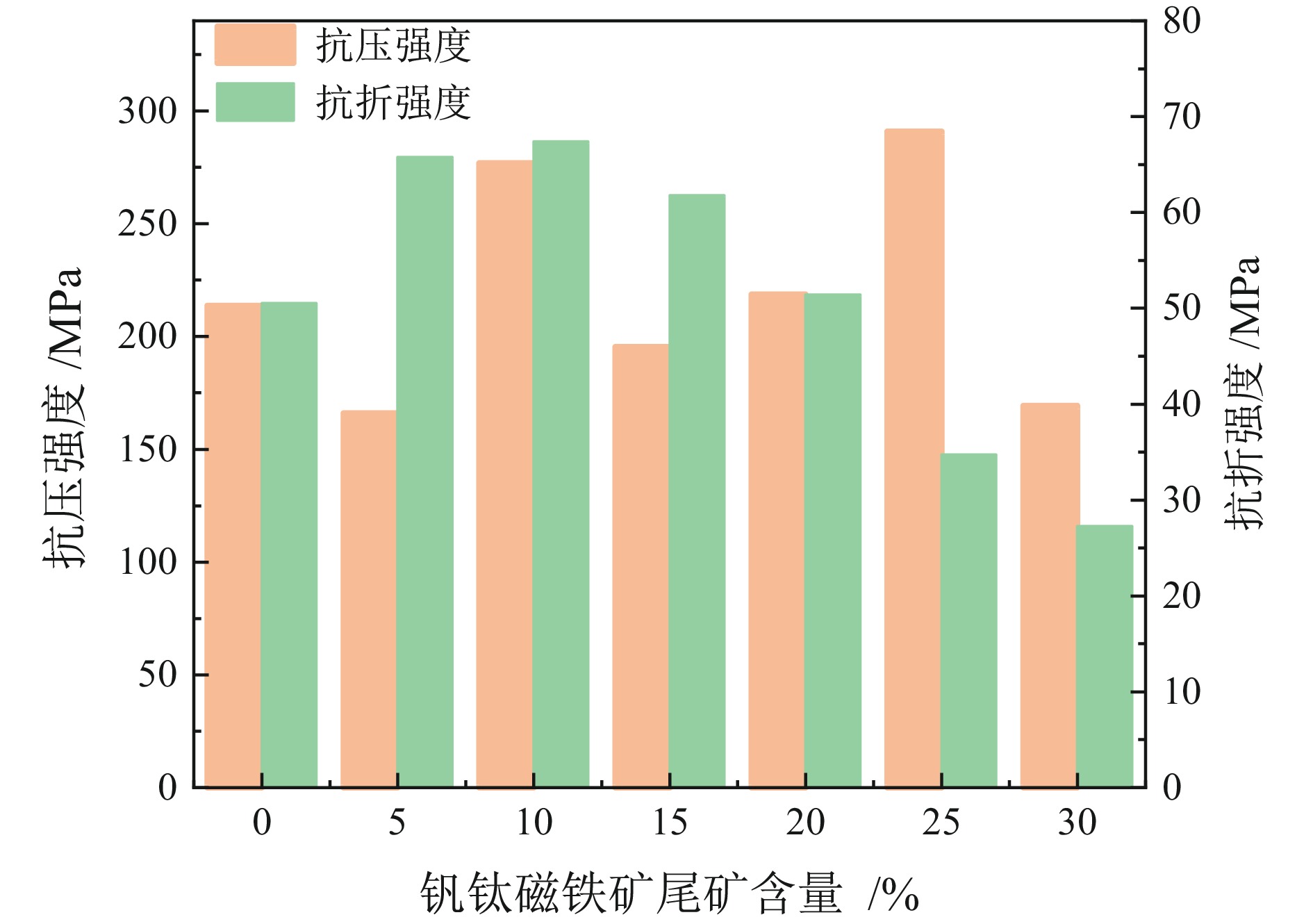

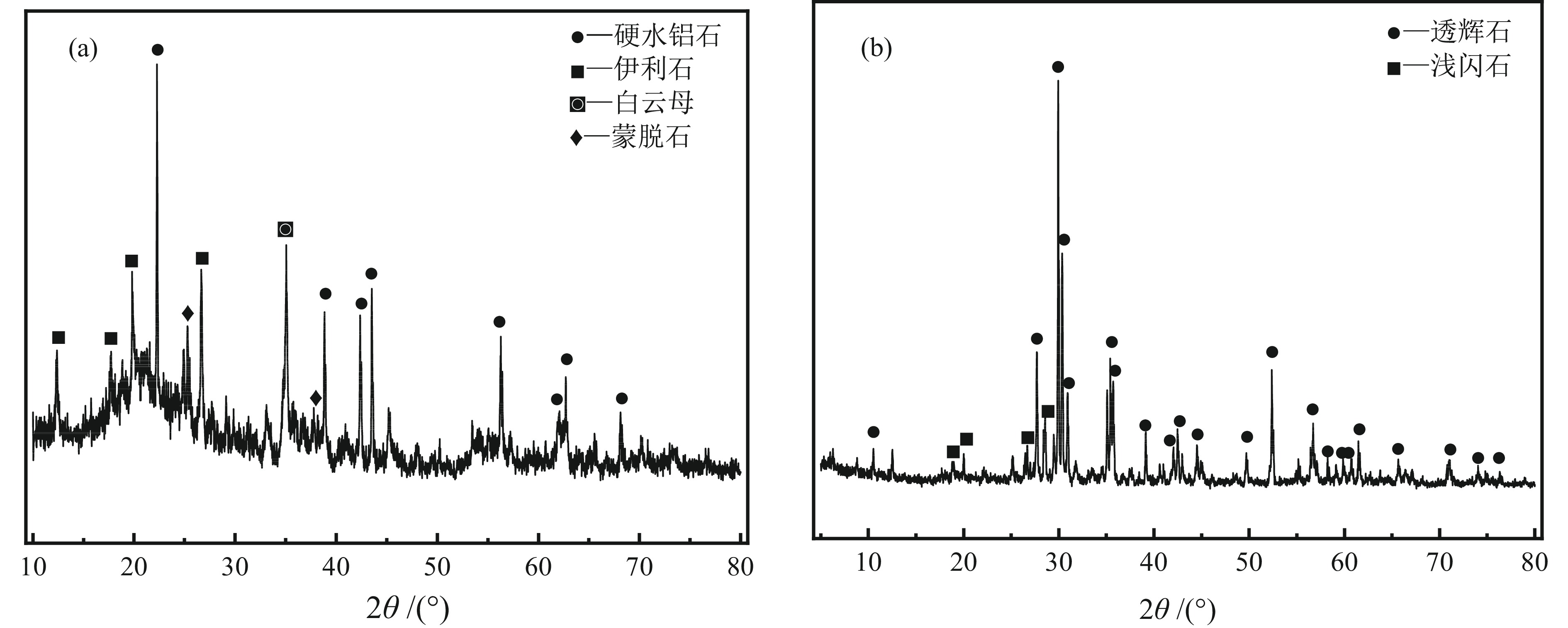

以铝土矿尾矿和钒钛磁铁矿尾矿为原料,经混料、成型和高温烧成等工艺制备了刚玉质复相陶瓷,研究了钒钛磁铁矿尾矿添加量、烧成温度等因素对制得复相陶瓷材料的物相、显微形貌及力学性能的影响规律。结果表明:当铝土矿尾矿与钒钛磁铁矿尾矿质量比为9∶1时,在1100 ℃下保温3 h制得刚玉质复相陶瓷材料的性能最优,其体积密度为2.71 g/cm3,抗压强度为276.9 MPa,抗折强度为67.3 MPa。

Abstract:The corundum based composite ceramics were prepared via a high temperature sintering process, using the bauxite tailings and vanadium−titanium magnetite tailings as raw materials. The effects of vanadium−titanium magnetite tailings addition and sintering temperature on the phase composition, morphology, and mechanical properties of the as−prepared composite ceramics were investigated in detail. The results indicated that the best performances were observed with the content ratio of 9∶1 between bauxite tailings and vanadium−titanium magnetite, after sintering at 1 100 ℃ for 3 h. The optimized volume density, compressive strength, and flexural strength were 2.71 g/cm3, 276.9 MPa, and 67.3 MPa, respectively.

-

-

表 1 实验原料主要化学成分分析结果

Table 1. Analysis results of the main chemical components of the raw materials

/% 成分 Al2O3 SiO2 Fe2O3 K2O TiO2 CaO SO3 MgO P2O5 Na2O MnO 铝土矿尾矿 44.57 35.01 11.18 3.77 3.03 0.77 0.83 0.45 0.21 0.11 / 钒钛磁铁矿尾矿 9.22 38.65 12.29 0.76 1.96 25.08 / 10.34 0.67 0.51 0.22 表 2 实验原料的质量配比

Table 2. Ratio of raw materials

/% 铝土矿尾矿 100 95 90 85 80 75 70 钒钛磁铁矿尾矿 0 5 10 15 20 25 30 -

[1] 李玲, 杨超. 利用尾矿作为建材原料的研究进展[J]. 建材发展导向, 2014, 12(16): 63−67.

LI L, YANG C. Research progress on using tailings as building materials[J]. Development Guide to Building Materials, 2014, 12(16): 63−67

[2] 邢益强, 吴晓鹏, 潘孟博, 等. 铝矾土尾矿基陶瓷透水砖的制备及其性能研究[J]. 中国陶瓷, 2021, 57(2): 46−54.

XING Y Q, WU X P, PAN M B, et al. Research on preparation and performance of bauxite tailings−based ceramic permeable brick[J]. China Ceramics, 2021, 57(2): 46−54.

[3] 韩跃新, 柳晓, 何发钰, 等. 我国铝土矿资源及其选矿技术进展[J]. 矿产保护与利用, 2019, 39(4): 151−158.

HAN Y X, LIU X, HE F Y, et al. Current situation of bauxite resource and its beneficiation technology in China[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4): 151−158.

[4] 谢武明, 楼匡宇, 张文治, 等. 铝土矿选尾矿制备烧结砖的试验研究[J]. 新型建筑材料, 2013, 40(7): 43−45. doi: 10.3969/j.issn.1001-702X.2013.07.013

XIE W M, LOU K Y, ZHANG W Z, et al. Utilization of bauxite tailings in manufacture of fired bricks[J]. New Building Materials, 2013, 40(7): 43−45. doi: 10.3969/j.issn.1001-702X.2013.07.013

[5] YALLEY PETER PAA−KOFI, ASIEDU EMMANUEL, MPAE ISAAC. Effects of bauxite tailings as partial replacement for sand in sandcrete bricks production[J]. Civil & Environmental Research, 2014, 6(11): 23−30.

[6] 勾密峰, 黄飞, 王思军, 等. 煅烧铝土矿尾矿对水泥凝结时间的影响[J]. 材料导报, 2015(18): 100−102,112.

GOU M F, HUANG F, WANG S J, et al. Effect of calcined bauxite tailings on the setting time of cement[J]. Materials Review, 2015(18): 100−102,112.

[7] 申献江, 马冬阳, 张梅, 等. 铝土矿尾矿除杂及合成刚玉−莫来石研究[J]. 耐火材料, 2017, 51(4): 256−259.

SHEN X J, MA D Y, ZHANG M, et al. Synthesis of corundum−mullite composites from impurity−removed bauxite tailings[J]. Refractories, 2017, 51(4): 256−259.

[8] YANG D, FENG N X, WANG Y N, et al. Preparation of primary Al−Si alloy from bauxite tailings by carbothermal reduction process[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 147−152. doi: 10.1016/S1003-6326(09)60112-6

[9] SHEN X J, QIU G B, YUE C S, et al. Multiple copper adsorption and regeneration by zeolite 4A synthesized from bauxite tailings[J]. Environmental Science and Pollution Research, 2017, 24(27): 21829−21835. doi: 10.1007/s11356-017-9824-5

[10] LU Q H, HU Y H. Synthesis of aluminum tripolyphosphate anticorrosive pigment from bauxite tailings[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 483−488. doi: 10.1016/S1003-6326(11)61202-8

[11] 童秋桃. 利用铝土矿浮选尾矿制备氧化铝和絮凝剂的研究[D]. 长沙: 中南大学, 2013

TONG Q T. Research on preparation of aluminum oxide and flocculant from bauxite tailing[D]. Changsha: Central South University, 2013.

[12] 刘三军, 刘永, 李向阳, 等. 用铝土矿选矿尾矿制备聚合氯化铝及污水处理试验研究[J]. 湿法冶金, 2020, 39(6): 539−542.

LIU S J, LIU Y, LI X Y, et al. Preparation of polyaluminum chloride using bauxite tailings and its application in wastewater treatment[J]. Hydrometallurgy of China, 2020, 39(6): 539−542.

[13] 刘三军, 刘永, 李向阳, 等. 铝土矿尾矿制备聚合氯化铝的浸出试验研究[J]. 衡阳:南华大学学报(自然科学版), 2020, 34(4): 54−57+65.

LIU S J, LIU Y, LI X Y, et al. Experimental study on leaching of poly aluminium chloride (PAC) from bauxite tailings[J]. Hengyang: Journal of Nanhua University(Science & Technology), 2020, 34(4): 54−57+65.

[14] RUAN W Q, GOU M F, LIAO J G. Effect of NaOH solution on performance of aerated concrete containing bauxite tailings[J]. Non−metalic Mines, 2021, 44(6): 38−41.

[15] MA D Y, WANG Z D, GUO M, et al. Feasible conversion of solid waste bauxite tailings into highly crystalline 4A zeolite with valuable application[J]. Waste Manage ment, 2014, 34(11): 2365−2372. doi: 10.1016/j.wasman.2014.07.012

[16] ZHANG M, GUO M, WANG Z D, et al. Method for preparing 4A molecular sieve from bauxite tailings: CN102976353A[P]. 2013−03− 20.

[17] 杨帆, 王淇, 闵鑫, 等. 低品位锂辉石对铝矾土尾矿制备莫来石基复相陶瓷的影响[J]. 金属矿山, 2022(9): 244−250.

YANG F, WANG Q, MIN X, et al. Influence of low grade spodumene on preparation of mulite−based compound ceramics with bauxite tailings[J]. Metal Mine, 2022(9): 244−250.

[18] 李悦. 利用铝矾土尾矿制备过滤多孔陶瓷[J]. 轻金属, 2016(3): 9−12.

LI Y. Production of porous ceramic for filtration by using bauxite tailings[J]. Light Metals, 2016(3): 9−12.

[19] 张翱, 闵鑫, 王淇, 等. 铝土矿尾矿直接烧成制备陶瓷材料及其力学性能研究[J]. 矿产保护与利用, 2022, 42(4): 121−127.

ZHANG A, MIN X, WANG Q, et al. Study on the direct firing of bauxite tailings to prepare ceramic materials and their mechanical properties[J]. Conservation and Utilization of Mineral Resources, 2022, 42(4): 121−127.

[20] REN Y P. Reaction mechanism of porous ceramics prepared from steel slag and bauxite tailings[J]. Metallurgical Engineering, 2018, 5(4): 137−144. doi: 10.12677/MEng.2018.54019

[21] 陈新义, 房明浩, 王淇, 等. 赤泥低温烧结制备长石—刚玉质复相陶瓷[J]. 矿产保护与利用, 2021, 41(6): 103−111.

CHEN X Y, FANG M H, WANG Q, et al. Low−temperature preparation of feldspar−corundum composite ceramics from red mud[J]. Conservation and Utilization of Mineral Resources, 2021, 41(6): 103−111.

[22] 李林, 姜涛, 陈超, 等. 攀西钒钛磁铁矿尾矿制备储水泡沫陶瓷的研究[J]. 矿产综合利用, 2020(6): 7−13+6.

LI L, JIANG T, CHEN C, et al. Study on preparation of water-retaining foam ceramics from vanadium titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 7−13+6.

[23] 王维清, 张杰, 朱欣宇, 等. 全尾矿基轻质发泡陶瓷的制备及正交试验研究[J]. 非金属矿, 2022, 45(1): 90−93+97.

WANG W Q, ZHANG J, ZHU X Y, et al. Orthogonal experimental study on the preparation of lightweight foamed ceramics by tailings[J]. Non−metallic Mines, 2022, 45(1): 90−93+97.

[24] 陈桃, 简胜, 谢贤, 等. 钒钛磁铁矿尾矿综合利用研究进展[J]. 矿产保护与利用, 2021, 41(2): 174−178.

CHEN T, JIAN S, XIE X, et al. Research progress on comprehensive utilization of vanadium−titanium magnetite tailings[J]. Conservation and Utilization of Mineral Resources, 2021, 41(2): 174−178.

[25] 刘长淼, 吴东印, 吕子虎, 等. 某钒钛磁铁矿尾矿中钛铁矿的选矿研究[J]. 中国矿业, 2015, 24(5): 115−117+128. doi: 10.3969/j.issn.1004-4051.2015.05.025

LIU C M, WU D Y, LV Z H, et al. Study on recovering ilmenite from V−Ti magnetite tailings[J]. China Mining Magazine, 2015, 24(5): 115−117+128. doi: 10.3969/j.issn.1004-4051.2015.05.025

[26] 宋晓敏, 王永刚. 承德双塔山某尾矿综合回收钛、铁试验[J]. 现代矿业, 2015, 31(1): 86−87+121.

SONG X M, WANG Y G. Comprehensive recovery of titanium and iron from a tailings in Shuangtashan, Chengde[J]. Modern Mining, 2015, 31(1): 86−87+121.

-

下载:

下载: