Preparation of Standard Materials for Composition Analysis of Stone Coal Vanadium Ore

-

摘要:

石煤钒矿资源的开发和合理利用需要对其成分进行准确的分析测试和质量控制。目前,国内外尚未有石煤钒矿成分分析的标准物质,现有钒成分分析标准物质无论是其五氧化二钒含量,还是定值成分都无法满足我国对石煤钒矿勘查、开发和研究需要。本文对采自湖北省崇阳县小源冲钒矿、湖南省芷江县牛牯坪钒矿、湖南省古丈县岩头寨钒矿和湖南省凤凰县黑冲钒矿等4个大型石煤钒矿区样品开展了标准物质研制工作,研制了4个石煤钒矿成分分析标准物质(GBW07875、GBW07876、GBW07877、GBW07878)。将矿层样品、顶底板岩石和人工剥离高品位样品,经过颚式初碎、对辊中碎、粗粒过筛混匀、配矿混匀、盘式细磨、细粒过筛、灭活混匀等加工处理,经初检合格后,装瓶和编号。随机抽取的4×35瓶样品进行均匀性检验,F实测值均小于F0.05(34,70)=1.60,且相对标准偏差(RSD)在0.31%~7.48%之间,表明样品的均匀性好。对随机抽取样品进行长期稳定性检验和短期稳定性检验,结果没有发现统计学意义的明显差异,表明样品的稳定性良好。通过9家实验室参加协作定值研究,定值成分包括V2O5、C和SiO2等共16种成分,其中4个石煤钒矿成分分析标准物质中的V2O5的质量分数分别为0.63%、0.86%、1.55%、3.99%,涵盖边界品位0.50%、工业品位0.70%、富矿品位≥1%,碳含量分别为2.40%、3.46%、5.60%、7.27%。本批次4个标准物质的研制成功,可为石煤钒矿的科学利用和研究提供参考和借鉴。

Abstract:BACKGROUND The development and rational utilization of stone coal vanadium ore resources require accurate analysis of its components and quality control. At present, there is no standard material for composition analysis of vanadium ore in the world, and the existing standard material cannot meet the needs of exploration, development and research of vanadium ore in China, either in the content of vanadium pentoxide or in the certified values of other elements.

OBJECTIVES To prepare standard materials for composition analysis of stone coal vanadium ore.

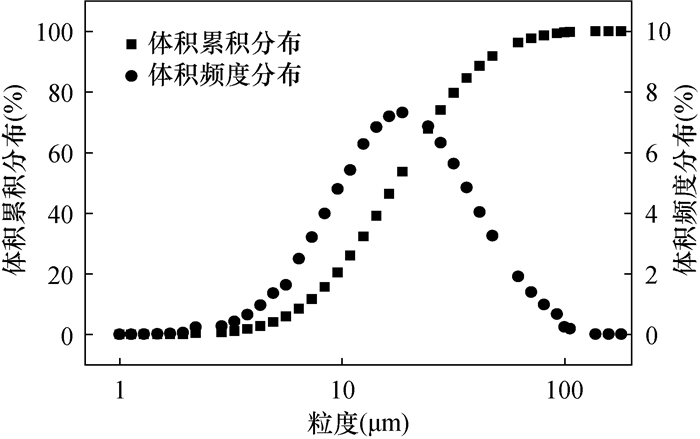

METHODS Ore samples, roof and floor rocks and artificially stripped high-grade samples were collected from four large stone coal vanadium districts, including Xiaoyuanchong vanadium mine in Chongyang County, Hubei Province, the Niuguuping in Zhijiang County, Hunan Province, the Yantouzhai in Guzhang County, Hunan Province, and the Heichong in Fenghuang County, Hunan Province. The samples were subjected to jaw-type primary crushing, roller crushing, coarse-grain sieving and mixing, ore blending and mixing, disc fine grinding, fine-grain sieving, and inactivation. After passing the initial inspection, samples were bottled and numbered.

RESULTS For the uniformity test of randomly selected 4×35 bottles, the measured values of F were all less than F0.05(34, 70)=1.60, and the relative standard deviation was between 0.31% and 7.48%, indicating good uniformity of the samples. Long-term and short-term stability tests were carried out on randomly selected samples, and no statistically significant difference was found, indicating good stability of the samples. Nine laboratories participated in the collaborative certified value research, which included 16 components such as V2O5, C and SiO2. Mass fractions of V2O5 in the four stone coal vanadium ore standard materials were 0.63%, 0.86%, 1.55%, 3.99%, covering cut-off grade of 0.50%, industrial grade of 0.70%, and rich-ore grade of ≥ 1%. Carbon contents of four standard materials were 2.40%, 3.46%, 5.60% and 7.27%, respectively.

CONCLUSIONS The successful development of 4 standard substances (GBW07875, GBW07876, GBW07877, GBW07878) in this batch can provide reference for scientific utilization and research of stone coal vanadium ore.

-

Key words:

- stone coal vanadium ore /

- reference materials /

- component analysis /

- certified values

-

-

表 1 候选物的采集与制备

Table 1. Collection and preparation of candidates

候选物编号 矿区名称 候选物样品采集与制备 标准物质样品配制与制备 样品

编号描述 粒度

(mm)质量

(kg)五氧化二钒

含量(%)分取质量

(kg)总质量

(kg)粒度

(mm)五氧化二钒

含量(%)分装数

(瓶)GV-1 HB-XYC Y-1 矿层样 1.0 175 0.70 180 240 0.097 0.62 1599 Y-2 顶底板样 1.0 160 0.35 60 GV-2 HN-NGP Y-3 矿层样 1.0 260 0.91 210 240 0.097 0.87 1391 Y-4 顶底板样 1.0 90 0.52 30 GV-3 HN-YTZ Y-5 矿层样 1.0 195 1.01 165 245 0.097 1.55 1511 Y-6 顶底板样 1.0 95 0.50 15 Y-7 富矿样 1.0 75 3.16 65 GV-4 HN-HC Y-8 人工剥离

富矿样1.0 325 3.98 240 240 0.097 4.01 1646 表 2 候选物均匀性检验结果统计分析

Table 2. Statistical analysis of homogeneity test for the candidates

候选物

编号统计项目 成分含量 V2O5 SiO2 Al2O3 Fe2O3 P S C GV-1 $\bar x $ (%)0.64 81.05 7.20 1.35 0.071 0.24 2.39 RSD(%) 3.57 0.31 1.10 1.57 2.79 6.49 4.28 F实测值 1.41 0.81 1.28 0.86 0.63 1.19 1.04 GV-2 $\bar x $ (%)0.86 77.41 7.58 1.66 0.096 0.328 3.50 RSD(%) 2.46 0.43 1.65 2.04 2.86 5.89 7.48 F实测值 0.98 0.68 0.72 0.77 1.16 1.20 0.70 GV-3 $\bar x $ (%)1.55 76.89 5.36 1.97 0.17 0.46 5.62 RSD(%) 1.70 0.28 1.83 1.68 3.29 2.78 3.02 F实测值 0.82 1.06 0.85 1.59 1.24 0.79 0.76 GV-4 $\bar x $ (%)3.97 63.87 8.48 2.00 0.26 0.53 7.31 RSD(%) 1.43 0.28 1.58 2.54 1.37 5.67 5.33 F实测值 0.65 0.76 0.65 0.70 1.10 1.10 0.88 候选物

编号统计项目 成分含量 Cu Pb Zn Ni Cd Mo As Ag U x(×10-6) 65.8 23.5 45.8 30.1 1.38 63.8 29.7 4.39 36.2 GV-1 RSD(%) 2.02 5.67 3.25 1.64 3.35 2.34 5.38 2.23 3.38 F实测值 1.24 0.87 0.43 0.77 1.02 0.77 1.10 0.65 1.19 x(×10-6) 91.1 25.7 86.5 42.7 2.66 67.0 53.8 6.62 30.2 GV-2 RSD(%) 1.51 6.26 3.69 3.01 1.88 2.81 4.35 2.42 3.08 F实测值 1.00 0.58 0.69 0.65 1.36 1.58 1.01 0.73 1.27 x(×10-6) 187.2 44.2 130.7 56.4 8.03 49.0 71.7 11.98 39.5 GV-3 RSD(%) 2.13 5.68 1.70 1.87 2.22 2.65 3.71 2.99 3.37 F实测值 0.82 0.94 0.96 1.18 0.87 0.98 1.03 0.72 0.91 $\bar x $ (×10-6)335.2 69.31 331.3 107.8 38.18 103.8 130.1 12.63 58.98 GV-4 RSD(%) 1.95 4.26 1.48 1.61 2.60 2.39 3.84 1.96 3.19 F实测值 1.58 1.29 1.18 1.10 0.71 1.19 1.30 1.53 0.62 表 3 候选物稳定性检验结果统计分析

Table 3. Statistical analysis of stability test for the candidates

样品编号 统计项目 成分含量 V2O5 SiO2 Al2O3 Fe2O3 P S C GV-1 $\bar x $ (%)0.63 80.83 7.18 1.36 0.070 0.26 2.58 RSD(%) 0.52 0.13 0.59 2.30 1.34 2.54 0.71 b1 -0.00020 0.0013 0.0057 0.0029 0.00014 -0.00014 -0.0013 t0.05×s(b1) 0.0012 0.041 0.012 0.011 0.00024 0.0025 0.0065 GV-2 $\bar x $ (%)0.86 77.74 7.58 1.68 0.10 0.34 3.68 RSD(%) 0.75 0.090 1.22 1.97 1.57 2.49 2.32 b1 0.00049 -0.0042 0.0076 0.0027 0.000010 0.00021 0.00062 t0.05×s(b1) 0.0023 0.025 0.032 0.012 0.00058 0.0032 0.033 GV-3 $\bar x $ (%)1.56 76.77 5.36 1.95 0.17 0.47 5.73 RSD(%) 0.78 0.18 0.56 1.51 1.45 2.92 0.39 b1 0.0011 -0.007 0.0028 0.0029 0.00029 0.0000 -0.0036 t0.05×s(b1) 0.0041 0.051 0.010 0.010 0.0008 0.0053 0.0052 GV-4 $\bar x $ (%)4.03 63.71 8.54 2.03 0.26 0.55 7.30 RSD(%) 0.23 0.22 0.12 0.59 0.88 2.51 0.25 b1 0.00088 -0.014 -0.00009 0.0011 0.00017 -0.00029 0.00073 t0.05×s(b1) 0.0032 0.047 0.0040 0.0041 0.00080 0.0052 0.0069 样品编号 统计项目 成分含量 Cu Pb Zn Ni Cd Mo As Ag U GV-1 $\bar x $ (×10-6)67.80 26.48 45.37 29.70 1.43 62.86 33.45 4.54 37.39 RSD(%) 0.44 4.73 3.97 2.57 6.00 2.34 2.03 1.82 0.80 b1 0.016 -0.075 -0.14 0.060 -0.0095 0.13 -0.11 -0.0044 0.017 t0.05×s(b1) 0.11 0.46 0.64 0.27 0.028 0.51 0.16 0.030 0.11 GV-2 $\bar x $ (×10-6)93.25 28.11 88.39 41.65 2.76 66.46 58.51 6.85 31.13 RSD(%) 1.61 2.00 3.25 2.35 3.08 1.89 3.11 1.61 0.39 b1 0.12 -0.060 -0.31 0.077 -0.0076 0.098 -0.30 0.0014 -0.0060 t0.05×s(b1) 0.53 0.18 0.94 0.34 0.029 0.44 0.41 0.042 0.045 GV-3 $\bar x $ (×10-6)192.4 43.07 127.2 55.92 8.36 48.17 75.00 12.18 40.35 RSD(%) 1.43 2.61 2.39 2.47 0.91 2.11 3.64 0.37 0.51 b1 0.20 0.067 -0.31 0.12 -0.0045 0.081 -0.39 0.0032 -0.016 t0.05×s(b1) 0.98 0.41 1.00 0.48 0.028 0.36 0.75 0.016 0.07 GV-4 $\bar x $ (×10-6)336.5 68.41 331.2 107.6 39.92 102.3 132.7 13.00 58.56 RSD(%) 1.34 2.23 2.05 1.37 1.72 0.89 3.85 1.01 0.54 b1 0.49 0.18 -0.62 0.12 -0.051 0.066 -0.58 0.00077 -0.023 t0.05×s(b1) 1.46 0.48 2.31 0.51 0.24 0.32 1.63 0.050 0.11 注:表中 $\bar x $ 为成分测定的平均值,s为标准偏差,b1为回归系数。表 4 石煤钒矿成分分析标准物质各成分定值方法

Table 4. Determination methods of each parameter of standard materials for composition analysis of stone coal vanadium ore

成分 数据组数 分析测试方法 成分 数据组数 分析测试方法 V2O5 9 VOL,COL,ICP-OES SiO2 9 GR,ICP-OES,XRF Al2O3 9 VOL,ICP-OES,XRF Fe2O3 9 VOL,COL,ICP-OES,XRF,FAAS P 9 COL,ICP-OES,XRF S 9 VOL,HCS C 9 GC,VOL,HCS Cu 9 ICP-OES,ICP-MS,XRF Pb 9 ICP-OES,ICP-MS Zn 9 ICP-OES,ICP-MS Ni 9 ICP-OES,ICP-MS,XRF Cd 9 ICP-MS Mo 9 ICP-OES,ICP-MS,POL,COL As 9 AFS Ag 9 FAAS U 9 ICP-MS 注:VOL—容量法;COL—分光光度法;ICP-OES—电感耦合等离子体发射光谱法;GR—重量法;XRF—X射线荧光光谱法;FAAS—火焰原子吸收光谱法;GC—元素分析仪法;HCS—高频燃烧-红外吸收光谱法;ICP-MS—电感耦合等离子体质谱法;POL—极谱法;AFS—原子荧光光谱法。 表 5 石煤钒矿成分分析标准物质的标准值和不确定度

Table 5. Standard values and uncertainties of standard materials for composition analysis of stone coal vanadium ore

成分 质量分数(×10-2) GV-1 GV-2 GV-3 GV-4 V2O5* 0.62±0.03 0.86±0.03 1.55±0.03 3.99±0.08 SiO2* 80.72±0.19 77.71±0.29 76.75±0.24 63.84±0.34 Al2O3* 7.00±0.16 7.52±0.21 5.37±0.13 8.49±0.13 Fe2O3* 1.31±0.07 1.66±0.08 1.93±0.07 2.00±0.05 P 0.067±0.002 0.094±0.004 0.16±0.01 0.25±0.01 S 0.26±0.02 0.34±0.03 0.49±0.03 0.58±0.04 C 2.40±0.10 3.46±0.20 5.60±0.13 7.27±0.24 成分 质量分数(×10-6) GV-1 GV-2 GV-3 GV-4 Cu 70±3 93±4 185±8 333±14 Pb 29±4 27±3 43±3 71±8 Zn 49±5 88±7 129±7 334±15 Ni 30±2 41±3 55±3 104±4 Cd 1.4±0.2 2.6±0.2 8.3±0.3 39±2 Mo 63±4 67±4 48±3 100±4 As 32±3 54±4 71±6 125±11 Ag 4.5±0.3 6.5±0.4 11.6±0.7 12.7±0.7 U 40±2 33±2 43±3 61±4 注:“*”表示总量(以氧化物计)。 表 6 国家一级标准物质实测结果与标准值对比

Table 6. Comparison of certified results and certified results of national standard materials

标准物质编号 成分 计量单位 标准值 实测值 标准物质编号 成分 计量单位 标准值 实测值 GBW07226 V2O5 10-2 0.572±0.009 0.562 GBW07103 SiO2 10-2 72.83±0.10 72.79 GBW07103 Al2O3 10-2 13.40±0.07 13.41 GBW07108 Fe2O3 10-2 2.52±0.07 2.48 GBW07105 P 10-2 0.413±0.013 0.411 GBW07233 S 10-2 0.72±0.03 0.73 GBW07108 C 10-2 9.0±0.2 8.92 GBW07406 Cu 10-6 390±14 389 GBW07318 Pb 10-6 66±6 66.5 GBW07311 Zn 10-6 373±14 365 GBW07105 Ni 10-6 140±7 141 GBW07162 Cd 10-6 32±2 32.2 GBW07164 Mo 10-6 137±17 146 GBW07164 As 10-6 260±30 251 GBW07237 Ag 10-6 13.5±0.8 13.2 GBW04108 U 10-6 79(s=0.0002) 81 -

[1] 戴子林, 张恩普. 从石煤钒矿中浸钒技术的研究现状[J]. 矿冶工程, 2015, 35(6): 85-88. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201506025.htm

Dai Z L, Zhang E P. Technical status of leaching vanadium from stone coal vanadium ore[J]. Mining and Metallurgical Engineering, 2015, 35(6): 85-88. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201506025.htm

[2] 张卫国, 侯恩科, 杨建业, 等. 石煤中钒-钼-硒等伴生元素研究[J]. 稀有金属, 2019, 43(10): 1092-1101. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201910012.htm

Zhang W G, Hou E K, Yang J Y, et al. Study on vanadium-molybdenum-selenium and other associated elements in stone coal[J]. Chinese Journal of Rare Metals, 2019, 43(10): 1092-1101. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201910012.htm

[3] 崔文婧. 我国钒矿资源开发利用现状及建议[J]. 合作经济与科技, 2019(6): 54-56. https://www.cnki.com.cn/Article/CJFDTOTAL-HZJJ201911020.htm

Cui W J. Development and utilization status and suggestions of vanadium ore resources in China[J]. Cooperation of Economy and Technology, 2019(6): 54-56. https://www.cnki.com.cn/Article/CJFDTOTAL-HZJJ201911020.htm

[4] 吴先文, 江振寅, 吴志雄. 鄂东南石煤钒矿地质特征及找矿标志[J]. 中国煤炭地质, 2013, 25(4): 10-13. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMT201304004.htm

Wu X W, Jiang Z Y, Wu Z X. Geological characteristics and prospecting indicators of stone-like coal vanadium ore in southeastern Hubei[J]. Coal Geology of China, 2013, 25(4): 10-13. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMT201304004.htm

[5] 陈明辉, 胡祥昭, 卢兵, 等. 湘西北岩头寨钒矿成矿地质特征及成因[J]. 矿产勘查, 2014(5): 751-761. https://www.cnki.com.cn/Article/CJFDTOTAL-YSJS201405009.htm

Chen M H, Hu X Z, Lu B, et al. Metallogenic characteristics and genesis of the Yantouzhai vanadinum deposit in the northwesten Hunan[J]. Mineral Exploration, 2014(5): 751-761. https://www.cnki.com.cn/Article/CJFDTOTAL-YSJS201405009.htm

[6] 邓旭升, 李明琴, 张梅江. 贵州三穗八弓钒矿床岩、矿石特征及其成因初探[J]. 贵州大学学报(自然科学版), 2014, 31(3): 41-44. https://www.cnki.com.cn/Article/CJFDTOTAL-GZDI201403012.htm

Deng X S, Li M Q, Zhang M J. Characteristics of rock and ore and preliminary analysis of genesis in Bagong V deposit in Sansui of Guizhou Province[J]. Journal of Guizhou University (Natural Sciences), 2014, 31(3): 41-44. https://www.cnki.com.cn/Article/CJFDTOTAL-GZDI201403012.htm

[7] 游先军, 田宗平, 李力, 等. 从湘西黑色页岩中提取钒的工艺研究[J]. 湿法冶金, 2008, 27(1): 31-34. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ200801013.htm

You X J, Tian Z P, Li L, et al. Process research on extracting of vanadium from black shales[J]. Hydrometallurgy of China, 2008, 27(1): 31-34. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ200801013.htm

[8] 邢学永, 万洪强, 宁顺明, 等. 某石煤钒矿的选矿与提钒试验研究[J]. 有色金属(选矿部分), 2016(3): 43-47. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201603010.htm

Xing X Y, Wan H Q, Ning S M, et al. Experimental research on mineral processing and vanadium extraction from a stone coal vanadium ore[J]. Nonferrous Metals (Mineral Processing Section), 2016(3): 43-47. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201603010.htm

[9] 田宗平, 曹健, 秦毅. 石煤钒矿硫酸浸出制备五氧化二钒的试验研究[J]. 无机盐工业, 2014, 10(6): 31-33. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG201412007.htm

Tian Z P, Cao J, Qin Y. Experimental study on preparation of vanadium pentoxide from stone coal vanadium ore by sulfuric acid leaching[J]. Inorganic Chemicals Industry, 2014, 10(6): 31-33. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG201412007.htm

[10] 康健, 林璠, 刘爽, 等. 湖北省某石煤钒矿的提钒工艺[J]. 矿产综合利用, 2015(2): 29-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201502006.htm

Kang J, Lin P, Liu S, et al. Vanadium extraction process of a stone coal vanadium ore in Hubei Province[J]. Multipurpose Utilization of Mineral Resources, 2015(2): 29-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201502006.htm

[11] 刘佳鹏, 孙伟, 王丽, 等. 陕西某石煤钒矿的新型选矿工艺研究[J]. 有色金属(选矿部分), 2015(2): 58-63. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201502014.htm

Liu J P, Sun W, Wang L, et al. Study on a new beneficiation technology of a vanadium-bearing stone coal ore in Shaanxi[J]. Nonferrous Metals (Mineral Processing Section), 2015(2): 58-63. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201502014.htm

[12] 刘大学, 厉彦江, 常耀超, 等. 石煤钒矿直接硫酸浸出工艺扩大试验[J]. 矿冶, 2013, 22(4): 60-66. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ201304025.htm

Liu D X, Li Y J, Chang Y C, et al. Pilt test on extraction action of vanadium from stone coal by direct sulfuricacid leaching[J]. Mining & Metallurgy, 2013, 22(4): 60-66. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ201304025.htm

[13] 孙伟, 辜小川, 刘润清, 等. 某炭质石煤钒矿中钒的赋存状态及其浮选研究[J]. 矿冶工程, 2013(6): 34-37. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201306009.htm

Sun W, Gu X C, Liu R Q, et al. Occurrence state of vanadium minerals in carbonaceous stone coal and corresponding beneficiation technology[J]. Mining and Metallurgical Engineering, 2013(6): 34-37. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201306009.htm

[14] 尹飞, 邹维, 揭晓武, 等. 高硅质石煤钒矿浸出机理研究[J]. 有色金属(冶炼部分), 2016(9): 21-23. https://www.cnki.com.cn/Article/CJFDTOTAL-METE201609006.htm

Yin F, Zou W, Jie X W, et al. Study on vanadium leaching mechanism from high siliceous stone coal vanadium ore[J]. Nonferrous Metals (Extractive Metallurgy), 2016(9): 21-23. https://www.cnki.com.cn/Article/CJFDTOTAL-METE201609006.htm

[15] 胡艺博, 叶国华, 左琪, 等. 石煤钒矿酸浸液提钒萃取剂的研究进展与前景[J]. 矿产综合利用, 2020(1): 10-15.

Hu Y B, Ye G H, Zuo Q, et al. Research progress and prospect of extractants for vanadium from acid leaching solution of stone coal vanadium ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1): 10-15.

[16] 谢元林. 钒在钢中的合金化作用及应用[J]. 特钢技术, 2015(1): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-TGJS201501002.htm

Xie Y L. Effect of vanadium on alloying and its applications[J]. Special Steel Technology, 2015(1): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-TGJS201501002.htm

[17] 陈宇宁, 张守海, 蹇锡高. 钒电池用两性离子交换膜的研究进展[J]. 膜科学与技术, 2020, 40(3): 151-159. https://www.cnki.com.cn/Article/CJFDTOTAL-MKXY202003028.htm

Chen Y N, Zhang S H, Jian X G. Recent progress on amphoteric in exchange membranes for vanadium redox flow battery applications[J]. Membrane Science and Technology, 2020, 40(3): 151-159. https://www.cnki.com.cn/Article/CJFDTOTAL-MKXY202003028.htm

[18] 洪飞, 刘耀华, 吕振生, 等. 钛铁矿化学成分标准物质研制[J]. 岩矿测试, 2014, 33(1): 67-73. http://www.ykcs.ac.cn/article/id/82cf00b1-ad39-479b-b13c-db18e56b96b4

Hong F, Liu Y H, Lv Z S, et al. Certified reference materials preparation of ilmenite chemical composition[J]. Rock and Mineral Analysis, 2014, 33(1): 67-73. http://www.ykcs.ac.cn/article/id/82cf00b1-ad39-479b-b13c-db18e56b96b4

[19] 刘妹, 顾铁新, 潘含江, 等. 泛滥平原沉积物标准物质研制[J]. 岩矿测试, 2018, 37(5): 558-571. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201801080002

Liu M, Gu T X, Pan H J, et al. Preparation of seven certified reference materials of floodplain sediments[J]. Rock and Mineral Analysis, 2018, 37(5): 558-571. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201801080002

[20] 赵晓亮, 李志伟, 王烨, 等. 铌钽精矿标准物质研制[J]. 岩矿测试, 2018, 37(6): 90-97. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201711230185

Zhao X L, Li Z W, Wang Y, et al. Preparation and certification of niobium-tantalum concentrate reference materials[J]. Rock and Mineral Analysis, 2018, 37(6): 90-97. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201711230185

[21] 曾美云, 刘金, 邵鑫, 等. 磷矿石化学成分分析标准物质研制[J]. 岩矿测试, 2017, 36(6): 633-640. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201705170082

Zeng M Y, Liu J, Shao X, et al. Preparation of phosphate ore reference materials for chemical composition analysis[J]. Rock and Mineral Analysis, 2017, 36(6): 633-640. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201705170082

[22] 全国标准物质管理委员会. 标准物质目录[M]. 北京: 中国质检出版社, 中国标准出版社, 2017.

National Administrative Committee for Certified Reference Materials. List of standard substances[M]. Beijing: Quality Inspection of China Press, Standards Press of China, 2017.

[23] 田宗平, 易晓明, 曹健, 等. 黑色岩系(石煤)钒矿矿物特征研究与应用[J]. 中国冶金, 2016, 26(2): 13-17. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201602004.htm

Tian Z P, Yi X M, Cao J, et al. Black rock series (stone coal) vanadium ore mineral characteristics research and application[J]. China Metallurgy, 2016, 26(2): 13-17. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201602004.htm

[24] 田宗平, 易晓明, 秦毅, 等. 黑色岩系(石煤)钒矿标准物质候选物的采集与制备[J]. 湿法冶金, 2016, 35(3): 255-259. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201603019.htm

Tian Z P, Yi X M, Qin Y, et al. Collection and preparation of black rock (stone coal) vanadium ore standard material candidate[J]. Hydrometallurgy of China, 2016, 35(3): 255-259. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201603019.htm

[25] 王毅民, 高玉淑, 王晓红, 等. 中国海大陆架沉积物超细标准物质系列研制[J]. 分析化学, 2009, 37(11): 1700-1705. https://www.cnki.com.cn/Article/CJFDTOTAL-FXHX200911041.htm

Wang Y M, Gao Y S, Wang X H, et al. Preparation of five China sea and continental shelf sediment reference materials with ultra fine particle size[J]. Chinese Journal of Analytical Chemistry, 2009, 37(11): 1700-1705. https://www.cnki.com.cn/Article/CJFDTOTAL-FXHX200911041.htm

[26] 杨理勤. 常量金标准物质标准值的不确定度评定方法[J]. 黄金, 2015, 36(9): 80-82. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ201509029.htm

Yang L Q. Discussion about the assessment method of the uncertainty degree of certified values from ore gold reference materials[J]. Gold, 2015, 36(9): 80-82. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ201509029.htm

[27] 田宗平, 李力, 曹健. 石煤钒矿中五氧化二钒的测定与基准校验[J]. 中国材料科技与设备, 2014, 10(6): 31-33.

Tian Z P, Li L, Cao J. Stone coal vanadium ore vanadium pentoxide capacity analysis the benchmark preparation and validation[J]. Chinese Materials Science Technology & Equipment, 2014, 10(6): 31-33.

[28] 田宗平, 曹健, 李力, 等. 石煤中五氧化二钒的磷钨钒酸光度法测定研究与应用[J]. 湖南有色金属, 2016, 32(5): 69-73. https://www.cnki.com.cn/Article/CJFDTOTAL-HNYJ201605020.htm

Tian Z P, Cao J, Li L, et al. Among the stone coal vanadium pentoxide spectrophotometry analysis determination of research and application[J]. Hunan Nonferrous Metals, 2016, 32(5): 69-73. https://www.cnki.com.cn/Article/CJFDTOTAL-HNYJ201605020.htm

[29] 罗琦, 曾少乾, 田宗平. 石煤钒矿中五氧化二钒容量法测定及量值溯源研究[J]. 中国锰业, 2017, 35(4): 112-116. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMM201704031.htm

Luo Q, Zeng S Q, Tian Z P. Tracing research of capacity method determination and its volume value in vanadium pentoxide of stone coal vanadium mine[J]. China's Manganese Industry, 2017, 35(4): 112-116. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMM201704031.htm

[30] 刘立平, 赵锦华, 张佑云, 等. 石煤钒矿中五氧化二钒测定方法的确认与应用[J]. 湿法冶金, 2018, 37(5): 425-430. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201805018.htm

Liu L P, Zhao J H, Zhang Y Y, et al. Confirmation and application of determination method of vanadium pentoxide in stone coal vanadium mine[J]. Hydrometallurgy of China, 2018, 37(5): 425-430. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201805018.htm

-

下载:

下载: