A Method for Estimating Micro-area Composition of Quartz-diorite Based on Quantitative Mapping of Electron Probe Microanalysis

-

摘要:

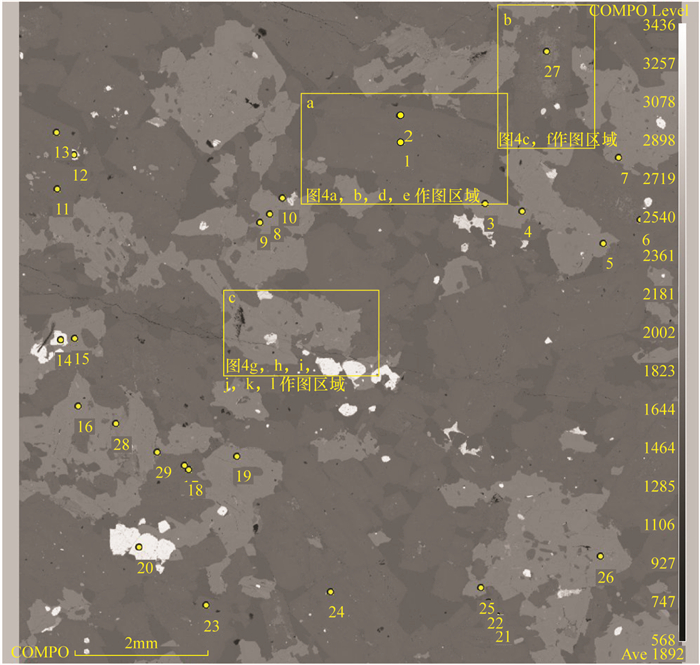

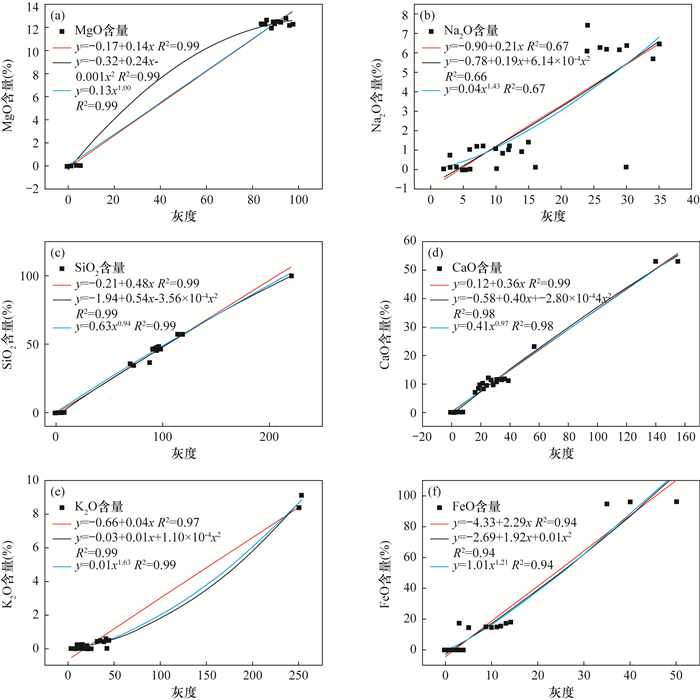

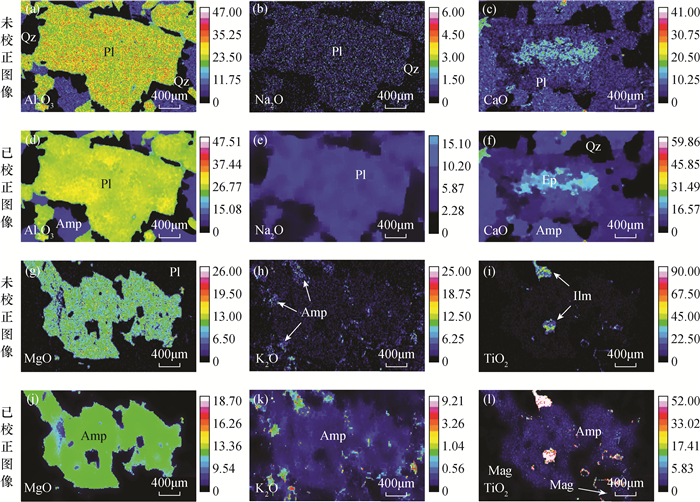

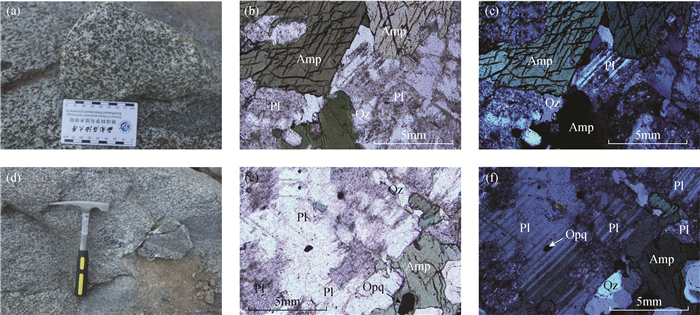

岩石的微区成分特征是精细化反演岩石演化的重要依据,而常规的电子探针面扫描分析方法无法提供面扫描区域的定量分析结果。本文使用矿物分布相对均匀的代表性岩石样品开展了岩石薄片的面扫描和矿物的定量分析。通过对常规测试的主量元素的面扫描进行图像校正,并利用ZAF校正后的点分析数据与面扫描图像的灰度值进行最小二乘法曲线拟合的方式,实现了X射线强度与质量浓度的转换。对比全岩X射线荧光光谱(XRF)测试数据,电子探针面扫描定量化方法的主量元素SiO2、CaO、FeO、Al2O3、TiO2的相对误差在10%以内,且相对标准偏差(RSD)不高于12%,具有良好的一致性;MgO和Na2O的相对误差与标准偏差略大,可通过多次测量加以改善;K2O由于缺乏富钾硅酸盐矿物的定量分析数据,导致结果不精确。研究表明,在仪器测试条件良好的情况下使用电子探针定量数据校正面扫描图像,可对矿物分布较均匀的岩石开展微区成分分析,给出估计结果,并通过多个切面的多次测量等方式,减少来自矿物形态、粒径大小、分布的影响。

Abstract:BACKGROUND The estimation of bulk composition of the micro-area of a rock is an important basis of tracing rock evolution. The conventional electron probe microanalysis (EPMA) mapping method cannot provide quantitative analysis results of the surface scanning area.

OBJECTIVES In order to estimate the composition of the micro-area by quantitative mapping of EPMA.

METHODS The mapping and point analyses were carried out to determine the composition of the micro-area of a homogeneous quartz-diorite. By performing image correction of the pixels of the mapping of the major elements, and using the point analysis data after ZAF correction and the gray value of the surface scan image to perform the least square curve fitting method, the X-ray intensity and concentration were converted.

RESULTS By comparing to X-ray fluorescence spectrometry (XRF), the relative errors of SiO2, CaO, FeO, Al2O3 and TiO2 of EPMA method were within 10%, and the relative standard deviation was less than 10%. The relative error and standard deviation of MgO and Na2O were slightly larger, which can be improved by multiple measurements. The K2O content were not accurate due to lack of K-rich silicate minerals' point analysis.

CONCLUSIONS The results show that the estimation of micro-area composition of a rock with relatively homogeneous mineral distributions can be carried out by using point analyses of EPMA to correct the mapping under good instrument conditions, and the influence of mineral morphology, particle size, and distribution can be reduced by multiple measurements on different sections.

-

-

表 1 斜长石和角闪石电子探针分析结果

Table 1. Electron probe microanalysis results of plagioclase and amphibole

成分 斜长石不同测试点位的分析结果(%) 角闪石不同测试点位的分析结果(%) 1 2 11 13 17 18 23 24 3 4 5 7 8 9 15 16 19 25 26 SiO2 57.83 56.74 56.74 56.54 56.89 57.67 57.78 57.25 45.82 47.71 47.08 46.36 47.17 46.72 46.50 45.66 46.68 47.66 45.85 TiO2 0.00 0.00 0.00 0.08 0.00 0.00 0.00 0.00 2.28 1.03 1.14 1.28 1.31 1.47 1.95 2.39 1.85 1.19 2.26 Al2O3 27.03 27.80 28.07 28.28 28.28 28.28 27.57 25.23 8.30 7.33 7.64 7.20 7.63 7.82 8.00 8.58 7.80 7.17 8.35 FeO 0.19 0.13 0.18 0.08 0.11 0.10 0.10 0.04 15.22 15.12 15.35 15.01 14.44 15.49 14.88 14.27 14.66 14.63 14.88 MnO 0.00 0.02 0.00 0.00 0.01 0.00 0.02 0.00 0.47 0.44 0.38 0.48 0.50 0.48 0.45 0.48 0.45 0.50 0.49 MgO 0.02 0.03 0.00 0.00 0.02 0.02 0.01 0.00 12.24 12.54 12.47 12.76 12.41 12.32 11.92 12.27 12.49 12.64 12.29 CaO 8.49 9.47 9.47 9.91 9.59 8.88 8.62 6.96 11.10 11.74 11.73 11.34 11.35 11.24 11.28 11.41 11.16 11.68 10.94 Na2O 6.44 6.26 6.17 5.71 6.08 6.18 6.37 7.41 1.23 0.85 0.74 1.00 1.06 1.05 1.23 1.17 1.16 0.92 1.39 K2O 0.19 0.16 0.17 0.08 0.13 0.21 0.11 0.08 0.49 0.50 0.52 0.44 0.47 0.49 0.49 0.54 0.44 0.49 0.49 总含量 100.19 100.61 100.80 100.67 101.11 101.33 100.57 96.98 97.14 97.26 97.05 95.86 96.33 97.08 96.70 96.76 96.69 96.87 96.94 O 8.02 7.99 8.00 8.03 8.00 8.02 8.02 7.98 23.00 23.00 23.00 23.00 23.00 23.00 23.00 23.00 23.00 23.00 23.00 Si 2.59 2.53 2.53 2.53 2.53 2.56 2.58 2.63 6.55 6.79 6.71 6.70 6.77 6.67 6.67 6.55 6.68 6.80 6.57 Ti 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.25 0.11 0.12 0.14 0.14 0.16 0.21 0.26 0.20 0.13 0.24 Al 1.42 1.46 1.47 1.49 1.48 1.48 1.45 1.37 1.40 1.22 1.28 1.23 1.29 1.32 1.35 1.45 1.32 1.21 1.40 Fe 0.01 0.01 0.01 0.00 0.04 0.00 0.00 0.01 1.82 1.80 1.83 1.82 1.73 1.85 1.78 1.71 1.75 1.75 1.78 Mn 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.06 0.05 0.05 0.06 0.06 0.06 0.05 0.06 0.05 0.06 0.06 Mg 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 2.60 2.66 2.65 2.75 2.65 2.62 2.55 2.62 2.67 2.69 2.62 Ca 0.41 0.45 0.45 0.48 0.46 0.42 0.41 0.34 1.70 1.80 1.80 1.76 1.74 1.72 1.73 1.75 1.71 1.79 1.69 Na 0.56 0.54 0.53 0.50 0.52 0.53 0.55 0.66 0.34 0.24 0.20 0.28 0.30 0.30 0.34 0.32 0.32 0.26 0.39 K 0.01 0.01 0.01 0.00 0.01 0.01 0.01 0.01 0.09 0.09 0.10 0.08 0.09 0.09 0.09 0.10 0.08 0.09 0.09 总阳离子数 5.00 5.00 5.00 5.00 5.04 5.00 5.00 5.01 16.81 16.75 16.75 16.81 16.77 16.78 16.77 16.83 16.79 16.77 16.83 An 41.64 45.13 45.46 48.74 46.20 43.73 42.52 34.01 Ab 57.22 53.96 53.56 50.81 53.03 55.04 56.85 65.51 Or 1.13 0.90 0.98 0.45 0.77 1.23 0.63 0.48 表 2 石英、磁铁矿、磷灰石、绿帘石和黑云母电子探针分析结果

Table 2. Electron probe microanalysis results of quartz, magnetite, apatite, epidote and biotite

成分 石英不同测试点位分析结果(%) 磁铁矿不同测试点位分析结果(%) 磷灰石不同测试点位分析结果(%) 绿帘石不同测试点位分析结果(%) 黑云母不同测试点位分析结果(%) 10 6 12 14 20 21 22 27 28 29 SiO2 99.77 0.04 0.04 0.05 0.06 0.06 0.11 36.52 35.49 34.87 TiO2 0.00 0.06 0.01 0.01 0.02 0.00 0.00 0.00 2.831 2.59 Al2O3 0.00 0.04 0.06 0.07 0.18 0.00 0.01 20.97 15.79 15.83 FeO 0.06 95.10 96.12 95.98 95.44 0.00 0.05 17.22 17.57 18.30 MnO 0.00 0.05 0.07 0.12 0.14 0.04 0.06 0.00 0.00 0.00 MgO 0.00 0.00 0.00 0.04 0.03 0.02 0.00 0.00 12.12 12.24 CaO 0.02 0.00 0.00 0.00 0.00 53.01 53.06 23.05 0.03 0.09 Na2O 0.01 0.03 0.01 0 0.04 0.09 0.14 0.00 0.08 0.09 K2O 0.00 0.01 0.00 0.00 0.00 0.00 0.01 0.00 9.14 8.36 P2O5 - - - - - 46.77 46.56 - - - 总含量 99.86 95.32 96.30 96.27 95.90 99.99 100.00 97.76 93.05 92.37 O 2.00 4.00 4.00 4.00 4.00 12.00 12.00 12.50 12.00 12.00 Si 0.997 0.002 0.002 0.003 0.003 0.004 0.008 2.92 2.73 2.73 Ti 0.000 0.002 0.000 0.000 0.001 0.000 0.000 0.00 0.15 0.15 Al 0.000 0.002 0.004 0.004 0.010 0.000 0.001 1.98 1.46 1.46 Fe 0.000 3.984 3.987 3.981 3.967 0.000 0.003 1.15 1.20 1.20 Mn 0.000 0.002 0.003 0.005 0.006 0.003 0.004 0.00 0.00 0.00 Mg 0.000 0.000 0.000 0.003 0.003 0.002 0.000 0.00 1.43 1.43 Ca 0.000 0.000 0.000 0.000 0.000 4.367 4.377 1.97 0.01 0.01 Na 0.000 0.002 0.001 0.000 0.004 0.013 0.021 0.00 0.01 0.01 K 0.000 0.001 0.000 0.000 0.000 0.000 0.001 0.00 0.83 0.83 P - - - - - 3.045 3.035 - - - 总阳离子数 1.00 4.00 4.00 4.00 3.99 7.43 7.45 9.02 7.82 7.82 表 3 面扫描定量化微区分析结果与全岩XRF分析结果对比

Table 3. Comparison between estimated results from quantified mapping and bulk XRF data

原样品号 SiO2 CaO K2O TFe2O3 Na2O MgO Al2O3 TiO2 XRF:全岩GC01-1(%) 52.12 7.20 1.50 8.72 4.28 4.75 18.16 1.16 XRF:全岩GC01-3(%) 57.09 6.72 1.15 6.98 4.19 3.38 16.95 0.99 电子探针面扫描定量化(%) 56.10 7.40 0.66 7.38 3.50 3.52 16.80 0.93 相对误差(%) 1.81 4.13 -40.18 -4.07 -12.28 -9.36 -2.91 -9.42 RSD(%) 4.77 4.92 38.24 11.85 10.70 19.41 4.31 11.62 注:相对误差=(实际值-真实值)/真实值×100;标准偏差: $ s = \sqrt {\sum {{({x_i} - x)}^2}/(n{\rm{ - }}1)} $ ;相对标准偏差(RSD)=标准偏差/平均值×100;FeO=0.9×Fe2O3。表 4 定量化面扫描与面扫描定量化处理方式的对比

Table 4. Comparison of different processing methods of quantitative mapping

-

[1] Wang H Z, Zhang H F, Zhai M G, et al. Granulite facies metamorphism and crust melting in the Huai'an terrane at~1.95Ga, North China Craton: New constraints from geology, zircon U-Pb, Lu-Hf isotope and metamorphic conditions of granulites[J]. Precambrian Research, 2016, 286: 126-151. doi: 10.1016/j.precamres.2016.09.012

[2] 孙春青, 游海涛, 刘嘉麒, 等. 火山灰全岩与原位分析差异: 以四海龙湾记录的1600年前金龙顶子火山喷发为例[J]. 地球科学, 2016, 41(1): 97-104. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX201601008.htm

Sun C Q, You H T, Liu J L, et al. Differences between whole rock and in situ analysis on Tephra: Evidence from the 1600a cal. BP eruption of Jinlongingzi Volcano[J]. Earth Science, 2016, 41(1): 97-104. https://www.cnki.com.cn/Article/CJFDTOTAL-DQKX201601008.htm

[3] Wang H Z, Laurent O, Zhang H F, et al. Recognition and significance of c. 800Ma upper amphibolite to granulite facies metamorphism in metasedimentary rocks from the NW margin of the Yangtze Block[J]. Journal of the Geological Society, 2020, 177(2): 424-441. doi: 10.1144/jgs2019-035

[4] 许乃岑, 沈加林, 张静. X射线衍射-X射线荧光光谱-电子探针等分析测试技术在玄武岩矿物鉴定中的应用[J]. 岩矿测试, 2015, 34(1): 75-81. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2015.01.010

Xu N C, Shen J L, Zhang J. Application of X-ray diffraction, X-ray fluorescence spectrometry and electron microprobe in the identification of basalt[J]. Rock and Mineral Analysis, 2015, 34(1): 75-81. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2015.01.010

[5] 周伟, 曾梦, 王健, 等. 熔融制样-X射线荧光光谱法测定稀土矿石中的主量元素和稀土元素[J]. 岩矿测试, 2018, 37(3): 298-305. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201706280113

Zhou W, Zeng M, Wang J, et al. Determination of major and rare earth elements in rare earth ores by X-ray fluorescence spectrometry with fusion sample preparation[J]. Rock and Mineral Analysis, 2018, 37(3): 298-305. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201706280113

[6] 李小莉, 吴良英, 王力强, 等. X射线荧光光谱法分析碳酸盐时两种制样方法的比较[J]. 理化检验(化学分册), 2016, 52(6): 664-668. https://www.cnki.com.cn/Article/CJFDTOTAL-LHJH201606012.htm

Li X L, Wu L Y, Wang L Q, et al. Comparative study on the 2 methods for preparation of sample discs in XRFs analysis of carbonates[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2016, 52(6): 664-668. https://www.cnki.com.cn/Article/CJFDTOTAL-LHJH201606012.htm

[7] 汪方跃, 葛粲, 宁思远, 等. 一个新的矿物面扫描分析方法开发和地质学应用[J]. 岩石学报, 2017, 33(11): 3422-3436. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB201711006.htm

Wang F Y, Ge C, Ning S Y, et al. A new approach to LA-ICP-MS mapping and application in geology[J]. Acta Petrologica Sinica, 2017, 33(11): 3422-3436. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB201711006.htm

[8] Spear F S, Wolfe O M. Evaluation of the effective bulk composition (EBC) during growth of garnet[J]. Chemical Geology, 2018, 491: 39-47. doi: 10.1016/j.chemgeo.2018.05.019

[9] 田作林, 张泽明, 董昕. 有效全岩成分的计算方法及其在变质相平衡模拟中的应用[J]. 岩石学报, 2020, 36(9): 2616-2630. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB202009003.htm

Tian Z L, Zhang Z M, Dong X. Calculation of effective bulk composition and its application in metamorphic phase equilibria modeling[J]. Acta Petrologica Sinica, 2020, 36(9): 2616-2630. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB202009003.htm

[10] 聂潇, 王宗起, 陈雷, 等. 蚀变粗面岩中再平衡结构黑云母的电子探针分析[J]. 岩矿测试, 2019, 38(5): 565-574. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201807100081

Nie X, Wang Z Q, Chen L, et al. Electron microprobe analysis of biotite with reequilibration texture in altered trachyte[J]. Rock and Mineral Analysis, 2019, 38(5): 565-574. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201807100081

[11] 秦玉娟, 余朝丰, 徐洋, 等. 应用电子探针原位微区分析技术测试硅硼钠石矿物[J]. 电子显微学报, 2016, 35(3): 217-222. doi: 10.3969/j.issn.1000-6281.2016.03.006

Qin Y J, Yu C F, Xu Y, et al. A microarea analysis technique of EPMA to probe reedmergnerite[J]. Journal of Chinese Electron Microscopy Society, 2016, 35(3): 217-222. doi: 10.3969/j.issn.1000-6281.2016.03.006

[12] Reed S J B. Electron microprobe analysis and scanning electron microscopy in geology[M]. Cambridge: Cambridge University Press, 2005: 164.

[13] Batanova V G, Sobolev A V, Magnin V. Trace element analysis by EPMA in geosciences: Detection limit, precision and accuracy[C]//IOP Conference Series: Materials Science and Engineering, 2018, 304.

[14] Ritchie N. Embracing uncertainty: Modeling the standard uncertainty in electron probe microanalysis—Part Ⅰ[J]. Microscopy and Microanalysis, 2020, 26(3): 469-483. doi: 10.1017/S1431927620001555

[15] Lanari P, Alice V, Thomas B, et al. Quantitative compositional mapping of mineral phases by electron probe micro-analyser[R]. London: Geological Society (Special Publications), 2019: 39-63.

[16] Donovan J, Allaz J, Handt A, et al. Quantitative WDS com-positional mapping using the electron microprobe[J]. The American Mineralogist, 2021, 106: 1717-1735. doi: 10.2138/am-2021-7739

[17] Yasumoto A, Yoshida K, Kuwatani T, et al. A rapid and precise quantitative electron probe chemical mapping technique and its application to an ultrahigh-pressure eclogite from the Moldanubian Zone of the Bohemian Massif (Nové Dvory, Czech Republic)[J]. American Mineralogist, 2018, 103(10): 1690-1698. doi: 10.2138/am-2018-6323CCBY

[18] Ortolano G, Visalli R, Godard G, et al. Quantitative X-ray map analyser (Q-XRMA): A new GIS-based statistical approach to mineral image analysis[J]. Computers and Geosciences, 2018, 115: 56-65. doi: 10.1016/j.cageo.2018.03.001

[19] 周剑雄, 毛水和, 陈克樵, 等. 电子探针分析[M]. 北京: 地质出版社, 1988: 499.

Zhou J X, Mao S H, Chen K Q, et al. Electron probe micro-analysis[M]. Beijing: Geological Publishing, 1998: 499.

[20] 梁细荣, 姚立, 田地. 电子探针背景扣除和谱线干扰修正方法的进展[J]. 岩矿测试, 2008, 27(1): 49-54. doi: 10.3969/j.issn.0254-5357.2008.01.013 http://www.ykcs.ac.cn/article/id/ykcs_20080118

Liang X R, Yao L, Tian D. Progress in background subtraction and spectral interference correction in electron probe microanalysis[J]. Rock and Mineral Analysis, 2008, 27(1): 49-54. doi: 10.3969/j.issn.0254-5357.2008.01.013 http://www.ykcs.ac.cn/article/id/ykcs_20080118

[21] Newbury D E, Marinenko R B, Myklebust R L, et al. Quantitative compositional mapping with the electron probe microanalyzer[M]. Springer Press, 1991: 335-369.

[22] 毕秀丽, 邱雨檬, 肖斌, 等. 基于统计特征的图像直方图均衡化检测方法[J]. 计算机学报, 2021, 44(2): 292-303. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJX202102003.htm

Bi X L, Qiu Y M, Xiao B, et al. Histogram equalization detection based on statistical features in digital image[J]. Chinese Journal of Computers, 2021, 44(2): 292-303. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJX202102003.htm

[23] Anupama S, Prajwalasimha S N, Swapna H. Image de-noising algorithm based on filtering and histogram equalizationl[C]//Proceedings of the Second International Conference on I-SMAC, 2019: 325-328.

[24] 李明辉, 郜鲜辉, 吴金金, 等. 电子探针波谱仪和能谱仪在材料分析中的应用及对比[J]. 电子显微学报, 2020, 39(2): 218-223. doi: 10.3969/j.issn.1000-6281.2020.02.018

Li M H, Gao X H, Wu J J, et al. The application and comparison of EPMA WDS and EDS in material analysis[J]. Journal of Chinese Electron Microscopy Society, 2020, 39(2): 218-223. doi: 10.3969/j.issn.1000-6281.2020.02.018

[25] Joseph D G, Charles H. High count rate electron probe microanalysis[J]. Journal of Research of the National Institute of Standards and Technology, 2002, 107(6): 503-508. doi: 10.6028/jres.107.043

[26] Chen B H, Tseng Y, Yin J L. Gaussian-adaptive bilateral filter[J]. IEEE Signal Processing Letters, 2020, 27: 1670-1674. doi: 10.1109/LSP.2020.3024990

[27] 杨赞伟, 郑亮亮, 曲宏松, 等. 联合均值滤波与泊松核双边滤波降噪算法研究[J]. 计算机仿真, 2020, 37(9): 460-463, 468. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJZ202009097.htm

Yang Z W, Zheng L L, Qu H S, et al. Image denoising research of combining mean filtering with Poisson Kernel improved bilateral filtering[J]. Computer Simulation, 2020, 37(2): 460-463, 468. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJZ202009097.htm

[28] Kikongi P, Salvas J, Gosselin R. Curve-fitting regression: Improving light element quantification with XRF[J]. X-Ray Spectrometry, 2017, 46(5): 347-355. doi: 10.1002/xrs.2760

[29] Willis K V, Srogi L A, Lutz T, et al. Phase composition maps integrate mineral compositions with rock textures from the micro-meter to the thin section scale[J]. Computers and Geosciences, 2017, 109: 162-177. doi: 10.1016/j.cageo.2017.08.009

[30] 张迪, 陈意, 毛骞, 等. 电子探针分析技术进展及面临的挑战[J]. 岩石学报, 2019, 35(1): 261-274. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB201901022.htm

Zhang D, Chen Y, Mao Q, et al. Progress and challenge of electron probe microanalysis technique[J]. Acta Petrologica Sinica, 2019, 35(1): 261-274. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXB201901022.htm

[31] 李德忍. 电子探针分析过程中钠不稳定机理的新解释初探[J]. 岩矿测试, 1995, 14(3): 224-226. http://www.ykcs.ac.cn/article/id/ykcs_19950350

Li D R. An explanation for the unstability of sodium determination in the electron microprobe analysis of Albite[J]. Rock and Mineral Analysis, 1995, 14(3): 224-226. http://www.ykcs.ac.cn/article/id/ykcs_19950350

[32] 张文兰, 胡欢, 谢磊, 等. Na元素的EPMA定量分析: 矿物晶体结构对Na行为的制约[J]. 高校地质学报, 2021, 27(3): 327-339. https://www.cnki.com.cn/Article/CJFDTOTAL-GXDX202103009.htm

Zhang W L, Hu H, Xie L, et al. Quantitative analysis of Na by EPMA: Constraints for the behavior of Na by the crystal structure[J]. Geological Journal of China Universities, 2021, 27(3): 327-339. https://www.cnki.com.cn/Article/CJFDTOTAL-GXDX202103009.htm

[33] 杨宗锋, 罗照华, 黄丹峰, 等. 花岗质岩石中矿物含量和粒径对代表性样品的约束[J]. 北京大学学报(自然科学版), 2010, 46(6): 951-959. https://www.cnki.com.cn/Article/CJFDTOTAL-BJDZ201006015.htm

Yang Z F, Luo Z H, Huang D F, et al. Constraints on representative samples from crystal contents and size in granitic rocks[J]. Acta Scientiarum Naturalium Universitatis Pekinensis, 2010, 46(6): 951-959. https://www.cnki.com.cn/Article/CJFDTOTAL-BJDZ201006015.htm

[34] 杨宗锋, 李解, 姜晓杰, 等. 火成岩结构的二维定量化分析方法[J]. 地学前缘, 2020, 27(5): 23-38. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202005005.htm

Yang Z F, Li J, Jiang X J, et al. Two dimensional quantitative textural analysis method for igneous rock[J]. Earth Science Frontiers, 2020, 27(5): 23-38. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY202005005.htm

[35] Hezel D C. A model for calculating the errors of 2D bulk analysis relative to the true 3D bulk composition of an object, with application to chondrules[J]. Computers and Geosciences, 2007, 33(9): 1162-1175. doi: 10.1016/j.cageo.2007.01.003

[36] Richard M P, Owen M W, David J W, et al. Quantifying geological uncertainty in metamorphic phase equilibria modelling; a Monte Carlo assessment and implications for tectonic interpretations[J]. Geoscience Frontiers, 2016, 7(4): 591-607. doi: 10.1016/j.gsf.2015.08.005

[37] McCanta M C, Dyar M D, Dobosh P A. Extracting bulk rock properties from microscale measurements: Subsampling and analytical guidelines[J]. GSA Today, 2017, 27(7): 4-9.

[38] Sharma J, Naik A, Pant N, et al. Estimation of effective bulk composition—Critical appraisal and a scanning electron microscope based approach[J]. Geological Journal, 2021, 56(6): 2950-2962. doi: 10.1002/gj.4077

[39] Hombourger C, Outrequin M. Quantitative analysis and high-resolution X-ray mapping with a field emission electron microprobe[J]. Microscopy Today, 2013, 21(3): 10-15. doi: 10.1017/S1551929513000515

[40] Takahashi H, Mcswiggen P, Nielsen C. A unique wavelength- dispersive soft X-ray emission spectrometer for electron probe X-ray microanalyzers[J]. Microscopy and Analysis, 2014, 15: 5-8.

[41] Llovet X, Moy A, Pinard P T, et al. Electron probe microanalysis: A review of recent developments and applications in materials science and engineering[J]. Progress in Materials Science, 2021, 116: 100673.

-

下载:

下载: