Rapid Determination of Trace Impurity Elements in Pure Molybdenum by Inductively Coupled Plasma-Mass Spectrometry Based on the Online-Standard-Addition Method

-

摘要:

纯钼的纯度或杂质含量对材料性能有重要的影响,痕量杂质的准确测量是产品质量控制的关键。电感耦合等离子体质谱法(ICP-MS)由于具有高灵敏、多元素同时测量的优势,是测量痕量杂质的最有效方法之一;但在测量高浓度纯钼基体中的痕量杂质时,会产生较强的基体抑制效应,严重影响测量结果准确性。基体匹配法、标准加入法以及基于同位素丰度比值测量的同位素稀释质谱法(IDMS)可以有效地补偿复杂的基体效应,获得准确的测量结果;但步骤繁琐、分析效率低、分析成本高使其难以满足高通量的测量需求。本万工作集成了标准加入法的准确性及在线自动分析的高效性,基于标准加入法的原理,通过双路进样,将样品溶液与标准溶液(系列标准溶液依次自动进样)同时引入三通进行混合,然后经过雾化进入ICP-MS进行检测,从而建立了基于在线加标的ICP-MS法。该方法有效地补偿了高浓度试样的基体效应,通过样品-标准进样流量差异的校正,提高了测量结果的准确性,实现了纯钼中29种痕量杂质元素的快速准确测量,满足了纯钼中痕量杂质标准物质的准确定值要求。经考察,本工作建立的方法对29种元素的方法检出限(MDL)在0.004~0.90μg/g之间,标准加入法标准曲线的线性相关系数r基本大于0.999,除Ca、Zn由于沾污问题导致的测量准确性较差外(Ca、Zn相对偏差分别为32%、13%),27种元素的测量相对偏差在−6.8%~5.1%之间。将Cr、K测量结果与IDMS法比较,进一步验证了该方法的可靠性。结果表明,两种方法测量结果偏差在1%以内,且具有相当的精密度(本方法对于Cr、K的RSD为1.8%~3.2%,IDMS法的RSD为0.9%~1.4%),但本方法分析效率与分析成本具有明显的优势,经评估15min可完成29种元素的测量,分析效率比IDMS法可提高上百倍,能够满足高通量的样品测试需求。

Abstract:BACKGROUND Molybdenum (Mo) is widely used in aerospace, nuclear industry, integrated circuits, flat display and photovoltaic solar energy and other fields[2-4]. The purity or impurity content of high purity molybdenum has an important effect on material properties, so the accurate measurement of trace impurities is the key to quality control. In the China national standard “Molybdenum Powder” (GB/T 3461—2016), the limits of impurities such as Pb and Bi which are commonly in the range of 5 to 50mg/kg, are specified. Rapid and accurate analysis of trace or ultra-trace impurities is necessary with the development of high purity Mo requirements of high throughput analysis. The ICP-MS method has become the most powerful method for trace impurities analysis in high purity Mo, but the tedious and time-consuming matrix effect calibration strategies makes it a big challenge to achieve rapid and accurate analysis. ICP-MS has the advantages of high sensitivity, good accuracy and the possibility of simultaneous measurement of multiple elements, compared with AAS, ICP-OES, and GD-MS methods. However, the matrix effect is heavy in the analysis of high purity Mo, which seriously affects the accuracy of the measurement results. Matrix matching method, standard addition method and isotope dilution mass spectrometry (IDMS) based on isotope abundance ratio measurement can effectively compensate for the complex matrix effect, and accurate analytical results can be obtained, but the analysis processes are complicated, the efficiency is low, and the cost is high, making it difficult to meet the measurement requirements of high throughput. To meet the requirements of rapid analysis, on-line analysis based on flow injection[28] and tandem calibration[29] was used. The online matrix separation and pre-concentration process for flow injection not only eliminates the matrix effect and reduces the detection limits, but also improves the automation level, and achieves high throughput measurement[31-33]. Wang et al.[32] measured a variety of trace metal elements in seawater samples within 28.5min based on online ion exchange. An online calibration process through a new analytical methodology called tandem calibration could be achieved based on a dual sample introduction system with two nebulizers working in parallel[29] or a multiple-channel nebulizer[34], for which the special design of the nebulizer is necessary.

OBJECTIVES To develop a rapid and accurate method for the analysis of trace impurities in high purity molybdenum to meet the requirements of high throughput sample tests.

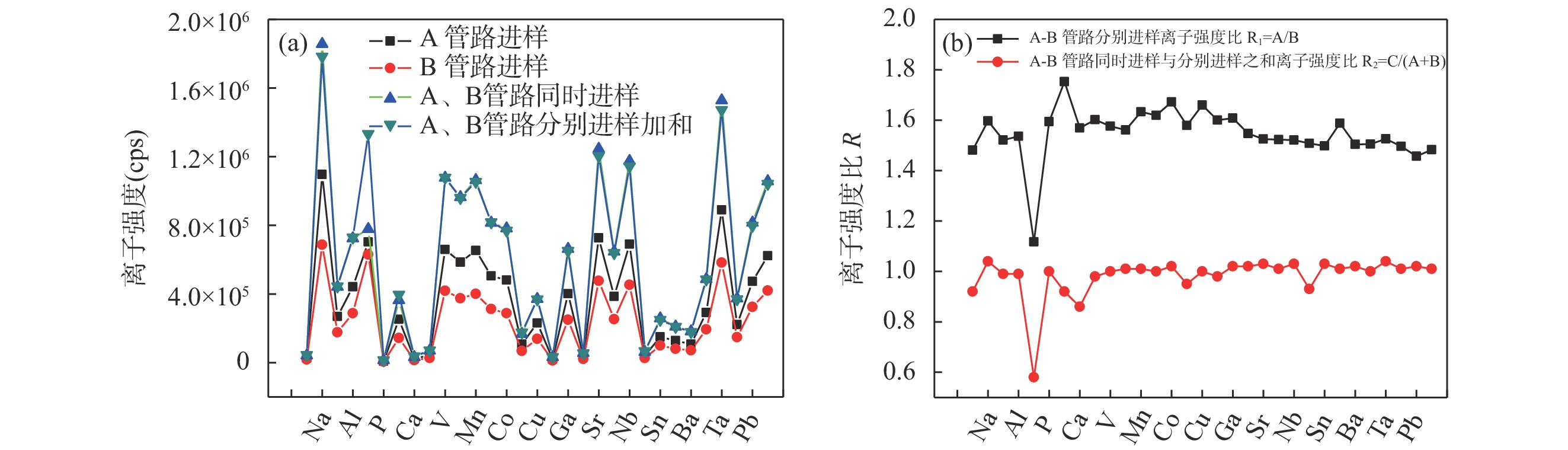

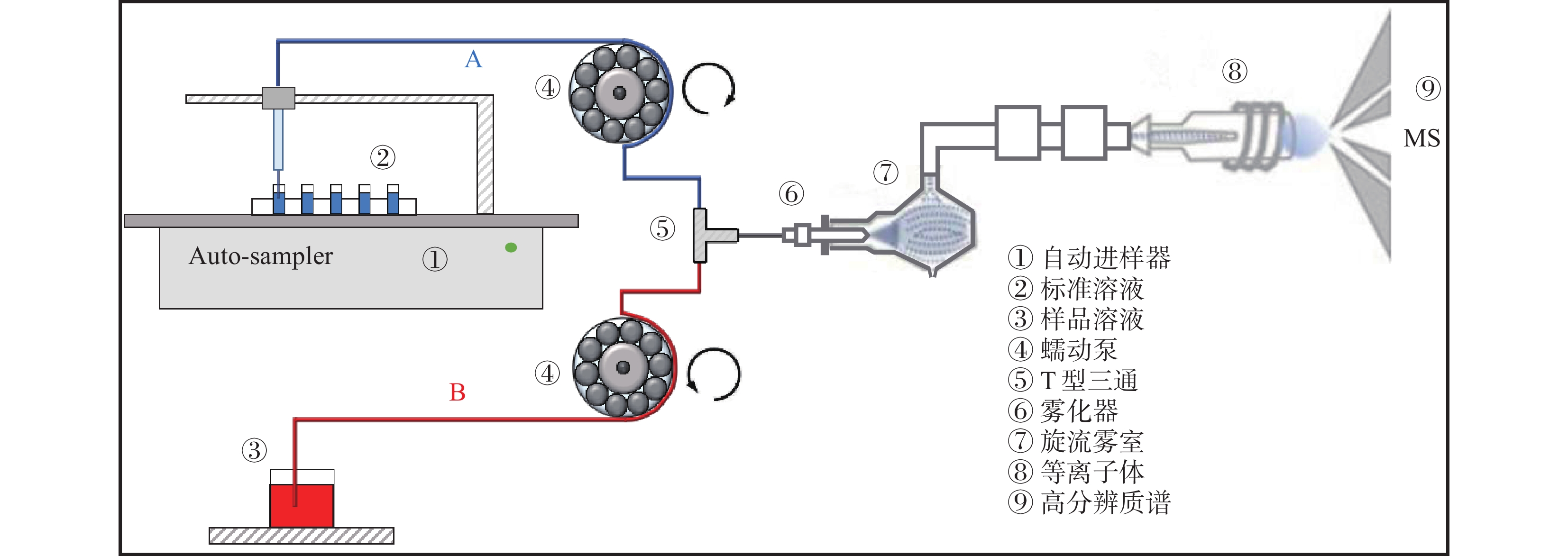

METHODS A dual-channel simultaneous sampling ICP-MS measurement method based on online-standard-addition was established by calibrating the difference in sample-standard injection flow rate. The in-house online platform was set up based on an auto-sampler and two peristatic pumps. The pure Mo reference material candidates containing homogeneous impurities with mass fraction of 0.1-200μg/g were used as samples. About 0.1g sample was digested based on the China national standard GB/T 4325.26—2013 and diluted about 1000-fold for analysis. The digested sample solution was introduced from a tube (designated as A) continuously by using a peristaltic to a T-joint in which the sample solution and a series of standard solutions from another tube (B) using an auto-sampler were mixed thoroughly. The mixed solutions were introduced through a nebulizer and rotary spray chamber, ionized in the plasma, and then introduced to mass spectrometry for analysis. For more accurate results, the difference flow rate between the sample and standard tube (the internal diameter of the sampling tube was 0.25mm and 0.38mm for the sample and standard, respectively) was calibrated by using the 20ng/mL standard solution. The ratio (R1) of intensity using A tube injection to the intensity using B tube injection was 1.54±0.06 for each element, indicating the difference of injection flow for A and B tube. The ratio of intensities for simultaneous sample injection to the sum intensities of A and B injection respectively was about 1.

RESULTS Methodological parameters for ICP-MS method based on online-standard-addition were evaluated in terms of method detection limit (MDL), linearly dependent coefficient, precision and accuracy. The limits of detection of this method based on the 3-σ criterion ranged from 0.004μg/g to 0.90μg/g for 29 elements, which meets the requirements of trace impurities analysis. The linear correlation coefficient r of the standard curve was mostly more than 0.999 at the concentration range of 0-500ng/g. The precision was evaluated by introducing the Mo digested solutions from A tube and 5ng/mL standard solution from B tube simultaneously, and the relative standard deviations (RSDs) of 6 repeated measurements were low, ranging from 0.8%-3.9% for 28 elements, in spite of the relative high RSD for Nb (6.1%). The multi-elements standard solution of GBW(E)082429, GBW(E)082430, GBW(E)082431were used for accuracy evaluation. After flow rate calibration, the relative deviation (RDs) between measured values and certified values ranged from −6.8% to 5.1% for 27 elements. For Ca and Zn, the RDs were relatively large (32% for Ca and 13% for Zn), which was probably due to the contamination. To further evaluate the method reliability, the analytical results of K and Cr were compared with those by using the IDMS method. Relative deviation of less than 1% between the two methods was found. Calibration of the difference for flow rate between the sample and standard injection. When the sample and standard is introduced from different tubes or nebulizers, the efficiency should be calibrated. The mathematical correction used was first introduced by Salin et al.[36] A dual sample introduction system based on two nebulizers working in parallel was set up by Canals et al.[29] The transport efficiencies for online standard addition were calibrated and the deviations of less than 3% for Na, K, Ba and Rb elements analysis in different matrixes were obtained. Different from the reported systems which needed to be specially designed[29,34], the online platform in this work was simple and easy to apply, because it only used a T-joint for the mixing of the sample and standard. This similar setup was found elsewhere[37-38]. In this setup, the same nebulizer was used for the sample and standard solution, and thus the same nebulization efficiency was obtained. The difference of signals between using A tube injection and B tube injection only resulted from the flow rates. In the flow process, fractionation could not occur. Therefore, the very consistent R1 factors were found for different elements, which indicated that it was not needed for the measurement of R1 factors for all elements. The merits of online-standard-addition ICP-MS method.Satisfactory limits of detection were obtained for 29 elements ranging from 0.004μg/g to 0.90μg/g, which was better than the MDL derived from the China national standard GB/T 4325.26—2013(1μg/g) and was comparable with the reported method based on ICP-MS/MS[6]. In fact, compared with the traditional standard addition method, the online method would attenuate the MDL due to the dilution of sample solution, although Schwartz et al.[37] deemed that there was no obvious difference between online and traditional methods in terms of SNR (Signal to Noise Ratio) and precision. The good precision 0.8%-3.9% for 28 elements was better than literature[37-38]. Apart from Ca and Zn, the satisfactory accuracy for 27 elements (relative deviation ranged from −6.8% to 5.1%) was obtained, which was better than the online internal standard method[39] because of the calibration of matrix effect for the standard-addition method. The comparative results of Cr and K by using the online-standard-addition method (this work) and the IDMS method showed good agreement of ±1%, which further validates the reliability of this work. It can be concluded that the accuracy and precision of this established method were comparable with the IDMS method. However, the analysis efficiency and cost showed obvious advantages, because the measurement of 29 elements could be completed in 15min, and thus the analysis efficiency was hundreds of times higher than that of the IDMS method.

CONCLUSIONS The method combined the properties of high accuracy and high throughput, and thus can achieve rapid and accurate trace impurities analysis in pure Mo.

-

-

表 1 在线加标ICP-MS法检出限、精密度、标准曲线线性方法学参数

Table 1. Methodological parameters for ICP-MS method based on online-standard-addition. The method detection limit (MDL) was evaluated based on the 3σ criterion. The precision was represented by the relative standard deviation (RSD) of 6 repeated measurements. The linearly dependent coefficient r was evaluated based on the concentration range of 0-500ng/g.

元素 检出限

(μg/g)RSD

(%,n=6)线性相关系数

r元素 检出限

(μg/g)RSD

(%,n=6)线性相关系数

rB 0.44 3.3 0.9566 Zn 0.10 2.2 0.9999 Na 0.19 1.7 0.9998 Ga 0.004 3.3 0.9998 Mg 0.17 3.9 0.9995 As 0.10 3.5 0.9997 Al 0.25 0.8 0.9999 Sr 0.013 2.0 0.9997 Si / / 0.7839 Zr 0.075 2.0 1.0000 P 0.32 1.3 0.9986 Nb 0.057 6.1 0.9999 K 0.90 3.9 0.9998 Cd # # −0.3704 Ca 0.16 3.2 0.9998 Sn 0.018 1.8 0.9986 Ti 0.12 1.1 1.0000 Sb 0.054 1.1 0.9905 V 0.018 2.6 0.9999 Ba 0.071 3.9 0.9998 Cr 0.033 2.0 0.9997 Hf 0.023 3.8 0.9990 Mn 0.046 1.7 0.9999 Ta 0.059 2.9 0.9985 Fe 0.18 1.4 0.9999 W 0.12 2.0 0.9999 Co 0.014 1.6 0.9999 Pb 0.021 3.4 0.9997 Ni 0.080 1.0 0.9998 Bi 0.012 2.7 0.9997 Cu 0.10 3.0 0.9995 注:“/”表示对于Si元素,由于空白值较高,故未列出检出限及RSD数据;“#”表示对于Cd元素,由于MoO及MoN的干扰在非基体分离条件下无法去除,故未列出检出限及RSD数据。

表 2 在线加标ICP-MS法方法验证

Table 2. Method validation for ICP-MS method based on online-standard-addition. The calibrated values were calculated based on the measured values multiplied by the intensity ratio R1. For the certified values (or nominal values), the calculated values were used based on the certified values of standard solutions and the dilution factors. The relative deviations (RDs) between the calibrated values and certified values were used to evaluate the method reliability and accuracy and calculated by using the equation: RD=(calibrate values-certified values)/certified values×100%.

元素 测量值

(ng/g)强度比值

R1*校正值

(ng/g)理论值**

(ng/g)相对偏差##

(%)B 14.1 1.48 20.9 20.6 1.8 Na 13.2 1.60 21.0 21.6 −2.5 Mg 14.4 1.52 21.9 21.6 1.3 Al 13.8 1.54 21.3 21.6 −1.5 Si 79.5 1.12 88.8 20.6 /& P 13.3 1.59 21.1 20.6 2.8 K 13.5 1.54# 20.8 21.6 −3.5 Ca 18.2 1.57 28.6 21.6 32.0 Ti 12.9 1.60 20.7 20.6 0.5 V 13.8 1.58 21.7 21.6 0.6 Cr 13.6 1.56 21.2 21.6 −1.7 Mn 13.5 1.63 22.0 21.6 2.1 Fe 13.2 1.62 21.4 21.6 −0.9 Co 12.8 1.67 21.4 21.6 −0.8 Ni 14.4 1.58 22.7 21.6 5.1 Cu 13.0 1.66 21.5 21.6 −0.4 Zn 15.2 1.60 24.3 21.6 13.0 Ga 13.5 1.61 21.8 21.6 0.9 As 14.1 1.55 21.7 21.6 0.8 Sr 13.9 1.53 21.2 21.6 −1.8 Zr 13.4 1.52 20.4 20.6 −0.9 Nb 12.9 1.52 19.6 20.6 −4.6 Cd 17.6 1.51 26.5 21.6 /& Sn 16.1 1.50 24.1 24.3 −0.7 Sb 15.7 1.59 25.0 24.3 2.8 Ba 14.0 1.50 21.0 21.6 −2.5 Hf 16.8 1.50 25.3 24.3 4.2 Ta 13.5 1.53 20.5 20.6 −0.1 W 13.3 1.50 19.9 20.6 −3.4 Pb 13.8 1.46 20.1 21.6 −6.8 Bi 14.3 1.48 21.1 21.6 −2.1 注:“*”表示R1为标准进样管(A管)与样品进样管(B管)相同浓度溶液信号强度比,为流量差异校正因子; “**”表示理论值为标准溶液稀释(500倍)后计算得出的浓度值,标准物质原浓度为10mg/kg,扩展不确定度为3(k=2); “#”表示采用其他元素的比值平均值;“&”表示对于111Cd,由于受到95Mo16O的干扰,因此采用简单酸基体溶液难以评估其可靠性,故未列出相对偏差;对于Si,由于使用氢氟酸导致测量空白严重偏高,故未列出相对偏差;“##”通过公式计算:(校正值-理论值)/理论值×100%。

表 3 在线加标-ICP-MS法与同位素稀释质谱法的测量结果比较

Table 3. Comparison of the measurement results by using ICP-MS method based on online-standard-addition and using isotope dilution mass spectrometry, respectively. The relative standard deviations (RSDs) and standard deviations (SDs) of 4 repeated measurements were listed for each element.

元素 含量测定值(μg/g) 在线加标ICP-MS法* RSD

(%)同位素稀释质谱法* RSD

(%)Si / / 24.8±1.5 6.0 K 87.4±2.8 3.2 87.7±0.8 0.9 Cr 50.1±0.9 1.8 50.4±0.7 1.4 注:“*”表示平均值±SD(n=4);“/”表示由于采用氢氟酸消解,Si空白较高,故未列出测量结果及RSD数据。

表 4 纯钼粉标准物质候选物样品中杂质元素测量结果

Table 4. Measurement results of impurity elements in high purity molybdenum powder reference material candidate sample by using ICP-MS method based on online-standard-addition. The relative standard deviations (RSDs) of 4 repeated measurements were listed.

元素 含量测定值

(μg/g)RSD

(%,n=4)元素 含量测定值

(μg/g)RSD

(%,n=4)B <1.5 / Zn <0.3 / Na 73.4 5.7 Ga 0.4 46 Mg 85.1 1.8 As 1.2 24 Al 18.1 1.3 Sr 17.8 3.4 Si / / Zr 16.4 3.0 P 83.3 1.9 Nb <0.2 / K 87.4 3.2 Cd / / Ca 18.6 7.0 Sn 171.2 2.6 Ti 99.6 2.2 Sb 150.1 2.9 V 17.7 3.4 Ba 18.2 3.0 Cr 50.1 1.8 Hf 16.7 1.4 Mn 178.4 1.5 Ta 19.4 1.7 Fe 122.5 2.8 W 18.7 5.1 Co 20.2 0.9 Pb 1.5 9.4 Ni 31.6 0.6 Bi 1.5 10 Cu 199.2 1.5 / / / -

[1] 安耿, 李晶, 刘仁智, 等. 钼溅射靶材的应用、制备及发展[J]. 中国钼业, 2011, 35(2): 45−48. doi: 10.3969/j.issn.1006-2602.2011.02.013

An G, Li J, Liu R Z, et al. The application, manufacture and developing trend of molybdenum sputtering target[J]. China Molybdenum Industry, 2011, 35(2): 45−48. doi: 10.3969/j.issn.1006-2602.2011.02.013

[2] 刘元元. 高纯镁和高纯钼的质谱纯度分析及其结果不确定度评定[D]. 北京: 钢铁研究总院, 2018.

Liu Y Y. Study on the purity analysis method by mass spectrometry and its uncertainty evaluation for magnesium & molybdenum[D]. Beijing: Central Iron & Steel Research Institute, 2018.

[3] Ye Z, Tan C, Huang X, et al. Emerging MoS2 wafer-scale technique for integrated circuits[J/OL]. Nano-micro Letters (2023-01-18)[2023-07-18]. https: //link. springer. com/article/10. 1007/s40820-022-01010-4.

[4] Santagata A, Pace M L, Bellucci A, et al. Enhanced and selective absorption of molybdenum nanostructured surfaces for concentrated solar energy applications[J]. Materials, 2022, 15(23): 8333. doi: 10.3390/ma15238333

[5] 杨帆, 王快社, 胡平, 等. 高纯钼溅射靶材的研究现状及发展趋势[J]. 热加工工艺, 2013, 42(24): 10−12. doi: 10.14158/j.cnki.1001-3814.2013.24.020

Yang F, Wang K S, Hu P, et al. Research status and development tread of high purity molybdenum sputtering target material[J]. Hot Working Technology, 2013, 42(24): 10−12. doi: 10.14158/j.cnki.1001-3814.2013.24.020

[6] 符靓, 施树云, 唐有根, 等. 高纯钼粉中超痕量杂质的质谱分析[J]. 光谱学与光谱分析, 2018, 38(8): 2588−2594.

Fu L, Shi S Y, Tang Y G, et al. Analysis of ultra-trace impurities in high purity molybdenum powder trough inductively coupled plasma tandem mass spectrometry[J]. Spectroscopy and Spectral Analysis, 2018, 38(8): 2588−2594.

[7] 夏明星, 郑欣, 王峰, 等. 钼粉制备技术及研究现状[J]. 中国钨业, 2014, 29(4): 45−48.

Xia M X, Zheng X, Wang F, et al. Preparation technology and research status of molybdenum powder[J]. China Tungsten Industry, 2014, 29(4): 45−48.

[8] Benedik L, Pilar A M, Prosen H, et al. Determination of ultra-trace levels of uranium and thorium in electrolytic copper using radiochemical neutron activation analysis[J]. Applied Radiation and Isotopes, 2021, 175: 109801. doi: 10.1016/j.apradiso.2021.109801

[9] Messaoudi M, Begaa S, Hamidatou L, et al. Determination of selenium in roasted beans coffee samples consumed in Algeria by radiochemical neutron activation analysis method[J]. Radiochimica Acta, 2018, 106(2): 141−146. doi: 10.1515/ract-2017-2782

[10] Silver B R. Atomic absorption spectroscopy reveals anomalous transfer of heavy metal across a water/1, 2-DCE interface[J]. Portugaliae Electrochimica Acta, 2021, 39: 415−420. doi: 10.4152/pea.2021390603

[11] Zhong W S, Ren T, Zhao L J. Determination of Pb (lead), Cd (cadmium), Cr (chromium), Cu (copper), and Ni (nickel) in Chinese tea with high-resolution continuum source graphite furnace atomic absorption spectrometry[J]. Journal of Food and Drug Analysis, 2016, 24(1): 46−55. doi: 10.1016/j.jfda.2015.04.010

[12] 林建奇. 双通道-原子荧光光谱和固体进样-冷原子吸收光谱测定岩石中痕量汞[J]. 岩矿测试, 2021, 40(4): 512−521. doi: 10.15898/j.cnki.11-2131/td.202006180093

Lin J Q. Determination of trace mercury in rocks by dual-channel atomic fluorescence spectrometry and solid sampling-cold atomic absorption spectrometry[J]. Rock and Mineral Analysis, 2021, 40(4): 512−521. doi: 10.15898/j.cnki.11-2131/td.202006180093

[13] Karlidağ N E, Toprak M, Demirel R, et al. Development of copper nanoflowers based dispersive solid-phase extraction method for cadmium determination in shalgam juice samples using slotted quartz tube atomic absorption spectrometry[J]. Food Chemistry, 2022, 396: 133669. doi: 10.1016/j.foodchem.2022.133669

[14] Aghahoseini M, Azimi G, Amini M K. An on-line matrix separation and preconcentration procedure for ICP-OES determination of Cd, Co, Cu, Mn and Pb traces in Zr and Zr-Nb alloys using a cation-exchange resin microcolumn[J]. Journal of Analytical Atomic Spectrometry, 2021, 36(5): 1074−1083. doi: 10.1039/D1JA00033K

[15] Dong X, Xiong Y, Wang N, et al. Determination of trace elements in high-purity quartz samples by ICP-OES and ICP-MS: A normal-pressure digestion pretreatment method for eliminating unfavorable substrate Si[J]. Analytica Chimica Acta, 2020, 1110: 11−18. doi: 10.1016/j.aca.2020.03.006

[16] Hommel C, Hassler J, Matschat R, et al. A fast and robust direct solid sampling method for the determination of 27 trace, main and minor elements in soda-lime glass based on ETV-ICP OES and using a gaseous halogenating modifier[J]. Journal of Analytical Atomic Spectrometry, 2021, 36(8): 1683−1693. doi: 10.1039/D1JA00081K

[17] Khan S R, Sharma B, Chawla P A, et al. Inductively coupled plasma optical emission spectrometry (ICP-OES): A powerful analytical technique for elemental analysis[J]. Food Analytical Methods, 2022,15(3): 666-688.

[18] 王焕文. 高纯钼成分分析用标准样品的研制[D]. 北京: 北京有色金属研究总院, 2020.

Wang H W. Manufacturing of reference material for composition analysis of high purity molybdenum[D]. Beijing: General Research Institute for Nonferrous Metals, 2020.

[19] 王焕文, 陈雄飞, 孙泽明, 等. GD-MS用高纯钼成分分析质量控制样品的研制[J]. 稀有金属, 2022, 46(1): 131−136.

Wang H W, Chen X F, Sun Z M, et al. Manufacturing of quality control samples for composition analysis of high purity molybdenum by GD-MS[J]. Chinese Journal of Rare Metals, 2022, 46(1): 131−136.

[20] 张见营, 李昕霓, 周涛, 等. 脉冲-辉光放电质谱法测量稀土合金中的关键元素[J]. 分析化学, 2018, 46(5): 757−764.

Zhang J Y, Li X N, Zhou T, et al. Measurement of key elements in rare earth alloy by pulsed glow discharge mass spectrometry[J]. Chinese Journal of Analytical Chemistry, 2018, 46(5): 757−764.

[21] Dong J, Qian R, Zhuo S, et al. Development and application of a porous cage carrier method for detecting trace elements in soils by direct current glow discharge mass spectrometry[J]. Journal of Analytical Atomic Spectrometry, 2019, 34(11): 2244−2251. doi: 10.1039/C9JA00265K

[22] 龚仓, 丁洋, 陆海川, 等. 五酸溶样-电感耦合等离子体质谱法同时测定地质样品中的稀土等28种金属元素[J]. 岩矿测试, 2021, 40(3): 340−348.

Gong C, Ding Y, Lu H C, et al. Simultaneous determination of 28 elements including rare earth elements by ICP-MS with five-acid dissolution[J]. Rock and Mineral Analysis, 2021, 40(3): 340−348.

[23] 李丽君, 薛静. 微波消解-电感耦合等离子体质谱法测定高岭土中10种微量元素[J]. 岩矿测试, 2022, 41(1): 22−31.

Li L J, Xue J. Determination of 10 trace elements in Kaolin by ICP-MS with microwave digestion[J]. Rock and Mineral Analysis, 2022, 41(1): 22−31.

[24] Cobelo-García A, Mulyani M E, Schäfer J. Ultra-trace interference-free analysis of palladium in natural waters by ICP-MS after on-line matrix separation and pre-concentration[J]. Talanta, 2021, 232: 122289. doi: 10.1016/j.talanta.2021.122289

[25] Sloop J T, Gonçalves D A, O’Brien L M, et al. Evaluation of different approaches to applying the standard additions calibration method[J]. Analytical and Bioanalytical Chemistry, 2021, 413: 1293−1302. doi: 10.1007/s00216-020-03092-8

[26] Ni Y, Bu W, Xiong K, et al. Trace impurity analysis in uranium materials by rapid separation and ICP-MS/MS measurement with matrix matched external calibration[J]. Microchemical Journal, 2021, 169: 106615. doi: 10.1016/j.microc.2021.106615

[27] 张肇瑞. 高纯钼、钛的分析方法研究[D]. 北京: 北京有色金属研究总院, 2012.

Zhang Z R. Study on trace elemental analysis of high-purity molybdenum and titanium[D]. Beijing: General Research Institute for Nonferrous Metals, 2012.

[28] Trojanowicz M, Kołacińska K. Recent advances in flow injection analysis[J]. Analyst, 2016, 141(7): 2085−2139. doi: 10.1039/C5AN02522B

[29] Aguirre M Á, Kovachev N, Almagro B, et al. Compensation for matrix effects on ICP-OES by on-line calibration methods using a new multi-nebulizer based on Flow Blurring® technology[J]. Journal of Analytical Atomic Spectrometry, 2010, 25(11): 1724−1732. doi: 10.1039/c004854b

[30] Søndergaard J, Asmund G, Larsen M M. Trace elements determination in seawater by ICP-MS with on-line pre-concentration on a Chelex-100 column using a ‘standard’instrument setup[J]. MethodsX, 2015, 2: 323−330. doi: 10.1016/j.mex.2015.06.003

[31] Hathorne E C, Haley B, Stichel T, et al. Online preconcentration ICP-MS analysis of rare earth elements in seawater[J]. Geochemistry, Geophysics, Geosystems, 2012, 13(1): 1−12.

[32] Wang W, Evans R D, Newman K, et al. Automated separation and measurement of 226Ra and trace metals in freshwater, seawater and fracking water by online ion exchange chromatography coupled with ICP-MS[J]. Microchemical Journal, 2021, 167: 106321. doi: 10.1016/j.microc.2021.106321

[33] Poehle S, Schmidt K, Koschinsky A. Determination of Ti, Zr, Nb, V, W and Mo in seawater by a new online-preconcentration method and subsequent ICP–MS analysis[J]. Deep Sea Research Part Ⅰ: Oceanographic Research Papers, 2015, 98: 83−93. doi: 10.1016/j.dsr.2014.11.014

[34] Ido K, Matsushita R, Fujii S I, et al. Multiple-channel concentric grid nebulizer for online standard addition in inductively coupled plasma optical emission spectrometry[J]. Analytical Sciences, 2020, 36(6): 717−722. doi: 10.2116/analsci.19P385

[35] Lum T S, Leung K S Y. Strategies to overcome spectral interference in ICP-MS detection[J]. Journal of Analytical Atomic Spectrometry, 2016, 31(5): 1078−1088. doi: 10.1039/C5JA00497G

[36] Hamier J, Salin E D. Tandem calibration methodology: Dual nebulizer sample introduction for inductively coupled plasma atomic emission spectrometry[J]. Journal of Analytical Atomic Spectrometry, 1998, 13(6): 497−505. doi: 10.1039/a801689e

[37] Schwartz A J, Ray S J, Hieftje G M. Automatable on-line generation of calibration curves and standard additions in solution-cathode glow discharge optical emission spectrometry[J]. Spectrochimica Acta Part B: Atomic Spectroscopy, 2015, 105: 77−83. doi: 10.1016/j.sab.2014.08.035

[38] 卫碧文, 缪俊文, 龚治湘, 等. 在线标准加入火焰原子吸收光谱法测定钮扣电池中铅和镉[J]. 理化检验(化学分册), 2006, 42(10): 815−817.

Wei B W, Miao J W, Gong Z X, et al. FAAS determination of lead and cadmium in button-shaped cell with on-line standard addition[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2006, 42(10): 815−817.

[39] 张雅丽, 孙巍, 张磊, 等. 在线内标浓度对电感耦合等离子体质谱法测定栀子金属元素的影响[J]. 药物评价研究, 2017, 40(4): 500−505.

Zhang Y L, Zhang W, Zhang L, et al. Effect of determination of metals in Cardenia jasminoides Ellis by ICP-MS from on-line internal standard solution[J]. Drug Evaluation Research, 2017, 40(4): 500−505.

[40] 张颖. 电感耦合等离子体质谱法测定高纯铼酸铵中 19 种痕量杂质元素[J]. 硬质合金, 2013(6): 337−342.

Zhang Y. Determination of 19 trace impurities in high purity ammonium rhenate by inductively coupled plasma mass spectrometry[J]. Cemented Carbide, 2013(6): 337−342.

[41] 刘跃, 林冬, 王记鲁, 等. 四种碰撞/反应模式-电感耦合等离子体串联质谱法测定土壤和水系沉积物样品中的银[J]. 岩矿测试, 2022, 41(6): 1017−1028. doi: 10.15898/j.cnki.11-2131/td.202112230206

Liu Y, Lin D, Wang J L, et al. Determination of silver in soil and stream sediments by ICP-MS/MS with four collision/reaction modes[J]. Rock and Mineral Analysis, 2022, 41(6): 1017−1028. doi: 10.15898/j.cnki.11-2131/td.202112230206

[42] Yamamoto M, Horigome K, Kuno T. Accurate and precise measurement of uranium content in uranium trioxide by gravimetry: Comparison with isotope dilution mass spectrometry and its uncertainty estimation[J]. Applied Radiation and Isotopes, 2022, 190: 110460. doi: 10.1016/j.apradiso.2022.110460

-

下载:

下载: