Determination of Rhenium in Tungsten and Molybdenum Ore by ICP-MS with Lefort Aqua Regia Microwave Digestion and 8-hydroxyquinoline Precipitation

-

摘要:

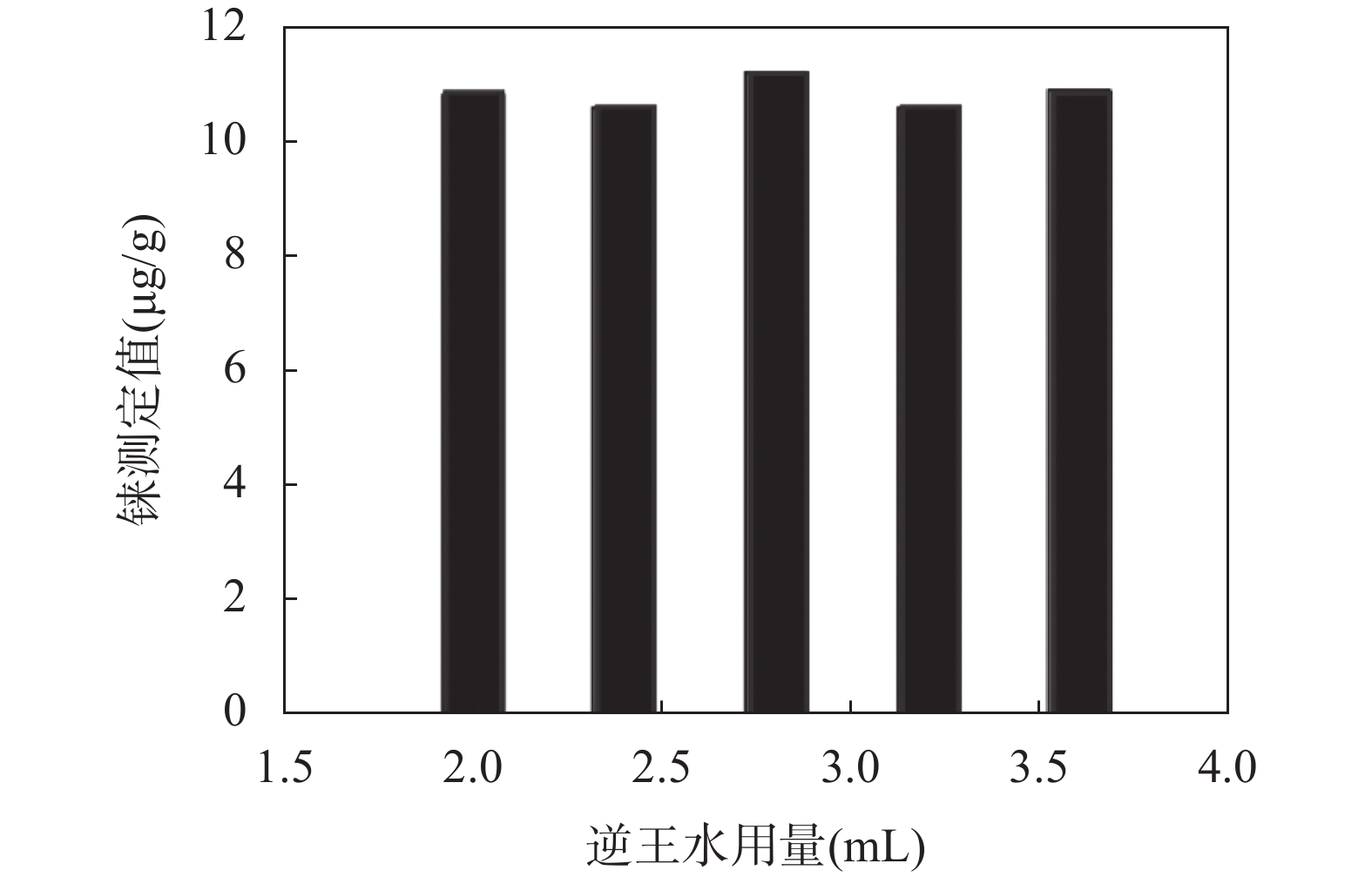

铼在地壳中的丰度低且分散,多伴生于钨钼矿中,现有方法常采用碱熔富集,流程长且繁琐,亟需开发一种简便快捷的检测方法。本文建立了逆王水微波消解钨钼矿石样品,8-羟基喹啉沉淀分离钨钼元素,与电感耦合等离子体质谱联用的检测方法。结果表明:0.0500g样品,2.80mL逆王水即可实现铼元素的全部溶出,0.20mL有机沉淀剂8-羟基喹啉(3%)在乙酸-乙酸铵缓冲体系(pH 4.5)中可选择性沉淀钼、钨元素,有效消除基体元素钼、钨(沉淀率>95%)对Re定量干扰,同时不引入新干扰元素。相比现有分离富集前处理流程更加简便快捷,前处理时间缩短为现有方法的1/4;该方法对Re的检出限为6.9ng/g,采用国家一级标准物质钼矿石(GBW07238)、钼矿石(GBW07285)、铼钼矿石(GBW07373)和钨锡铋矿石(GBW07369)对方法的准确度进行了验证,测定值与推荐值吻合,相对误差为0.71%~6.07%,RSD<5%。本方法建立的“消解-分离富集”处理流程所需时间从常规的8~12h缩短至2h左右,在准确定量矿石样品中Re的同时简化了样品前处理流程,快速的样品处理及低廉的测试成本有助于关键稀有金属矿产的开发利用。

Abstract:BACKGROUND Rhenium (Re) is a key mineral resource widely used in the aerospace field. As one of the rarest elements in the earth, Re rarely exists as an independent mineral but is dispersed in various sulfide ores. Due to its low content and dispersed distribution, the highly sensitive and accurate quantification of Re (ng/g) in complex ore is one of the challenges of modern geological analysis. In order to solve the problem of incomplete decomposition and the great interference caused by co-dissolution of high abundance matrix elements, the existing “digestion-separation” method using 8-12h for one sample is complicated, time-consuming and labor-intensive. Therefore, the development of a simple, fast and low-cost method is urgently required.

OBJECTIVES To establish an analytical method based on Lefort aqua regia microwave digestion, molybdenum and tungsten precipitation, ICP-mass spectrometry for the determination of rhenium in ore.

METHODS Lefort aqua regia microwave digestion was used to fully decompose ore, and then the organic precipitator 8-hydroxyquinoline (8-HQ) was used to selectively precipitate high-abundance matrix interference elements molybdenum (Mo) and tungsten (W) in the acid-ammonium acetate buffer system (pH 4.5). The organic precipitator 8-HQ was used to precipitate Mo and W to produce stable hydroxyquinoline molybdenum [MoO2(C9H6ON)2] and tungsten [WO2(C9H6ON)2], thereby removing the high-abundance Mo and W in the digestion solution and reducing the interference of matrix on the quantitative analysis of Re. The relevant parameters of Lefort aqua regia microwave digestion and 8-HQ precipitation were systematically studied, and the digestion and precipitation properties were deeply studied by using national certified reference materials.

RESULTS The key parameters that influence ore digestion including volume of Lefort aqua regia and temperature of microwave digestion, were determined as 2.8mL and 130℃ for step 1 and 150℃ for step 2 separately. The addition amount of 8-HQ was also determined as 0.2mL (3%, w%) by comparing precipitation rates of W, Mo and W-Mo solution (25g/mL) under different amounts, and results showed that the precipitation rate was greater than 95% in different ore digestion solutions. In the established method, the detection limit of Re was 6.9ng/g, the relative error was 0.71%-6.07%, and the RSD was less than 5%.

CONCLUTIONS The method established in this study can effectively eliminate the interference of matrix elements molybdenum and tungsten on Re quantification without introducing new interference elements. Compared with the existing “digestion-separation” process, the method is simpler and faster (shortened from 8-12h for one sample to approximately 1h) and the method has been successfully applied in molybdenum ore, rhenium molybdenum ore and tungsten-tin bismuth ore. This study proves that interfering instead of target element precipitation is feasible and provides a simple, fast and low-cost method for accurate quantification of Re in complex ore.

-

-

表 1 微波消解两段式程序升温中温度的优化

Table 1. Optimization of temperature in two-step microwave digestion program (50mg sample in 1000W microwave).

第一段温度

(℃)铼测定值

(µg/g)第二段温度

(℃)铼测定值

(µg/g)铼推荐值

(µg/g)110 10.5 140 10.5 10.9±0.7

10.9±0.7

10.9±0.7120 10.4 150 10.8 130 10.8 160 10.6 表 2 逆王水微波消解过程中W、Mo的溶出

Table 2. Dissolution of W and Mo in Lefort aqua regia microwave digestion (130℃ for 8min and 150℃ for 38 min in 1000W microwave).

标准样品编号 钨标准值

(µg/g)钨测定值

(µg/g)钨溶出率

(%)钼标准值

(%)钼测定值

(%)钼溶出率

(%)GBW07285 54.7 52.0 95.1 5.17 5.27 102.0 GBW07373 370 344 93.0 9.09 8.99 98.9 GBW07238 3600 1312 25.0 1.51 1.50 99.3 GBW07369 79600 1652 0.8 0.361 0.360 99.7 表 3 W、Mo单元素及双元素溶液在不同8-HQ添加量下的沉淀率

Table 3. Precipitation rate of W, Mo and W-Mo solution (25µg/mL) under different 8-HQ addition amount.

沉淀剂及

相应浓度沉淀剂用量

(mL)单元素沉淀率

(%)双元素沉淀率

(%)Mo W Mo W 8-HQ

(0.3%,w%)0.20 99.21 28.72 53.19 22.41 0.50 99.66 31.36 99.77 70.72 0.75 99.81 53.37 99.86 90.95 1.00 99.94 79.32 99.86 97.27 1.50 99.96 92.73 99.84 99.16 2.00 99.97 93.08 99.81 99.39 8-HQ

(3%,w%)0.20 99.99 99.54 99.83 99.32 0.50 99.97 99.80 99.85 99.56 0.75 99.99 99.96 99.85 99.57 1.00 99.96 99.96 99.86 99.76 1.50 99.97 99.97 99.77 99.73 2.00 99.99 99.97 99.81 99.79 表 4 8-HQ对实际样品中W、Mo元素的沉淀率

Table 4. Precipitation rate of W, Mo elements in real samples under 8-HQ.

标准物质

编号待测

元素沉淀前元素含量

(µg/mL)沉淀后元素含量

(µg/mL)沉淀率

(%)GBW07238 Mo 3.020 0.0224 99.26 W 0.2625 0.0035 98.67 GBW07373 Mo 18.20 0.0511 99.72 W 0.6880 0.0013 99.81 GBW07369 Mo 0.7251 0.0326 95.50 W 0.3304 0.0054 98.37 表 5 方法的精密度和准确度

Table 5. Accuracy and precision tests of the method.

标准物质

编号铼含量测定值

(μg/g)铼含量标准值

(μg/g)相对误差

(%)RSD

(%)GBW07238 0.37±0.01 (0.35) 6.07 2.6 GBW07285 32.50±0.49 31.20±3.70 4.09 1.5 GBW07373 10.80±0.20 10.90±0.70 0.85 2.0 GBW07369 0.35±0.01 0.35±0.03 0.71 4.6 注:测定值以“平均值±标准偏差”的形式表示(平行实验次数n=8)。 -

[1] 郭娟, 崔荣国, 王卉, 等. 世界铼资源供需现状及展望[J]. 国土资源情报, 2020(10): 67−74.

Guo J, Cui R G, Wang H, et al. Supply and demand situation and outlook of global rhenium resources[J]. Natural Resources Information, 2020(10): 67−74.

[2] 陈喜峰, 陈秀法, 李娜, 等. 全球铼矿资源分布特征与开发利用形势及启示[J]. 中国矿业, 2019, 28(5): 7−12. doi: 10.12075/j.issn.1004-4051.2019.05.031

Chen X F, Chen X F, Li N, et al. Distribution characteristics and development & utilization status of global rhenium resources and enlightenments[J]. China Mining Magazine, 2019, 28(5): 7−12. doi: 10.12075/j.issn.1004-4051.2019.05.031

[3] Karadjov M, Velitchkova N, Veleva O, et al. Spectral interferences in the determination of rhenium in molybdenum and copper concentrates by inductively coupled plasma optical emission spectrometry (ICP-OES)[J]. Spectrochimica Acta Part B:Atomic Spectroscopy, 2016, 119: 76−82. doi: 10.1016/j.sab.2016.03.011

[4] 赵庆令, 李清彩. 电感耦合等离子体发射光谱法测定钼矿石和铜矿石中的铼[J]. 岩矿测试, 2009, 28(6): 593−594. doi: 10.15898/j.cnki.11-2131/td.2009.06.008

Zhao Q L, Li Q C. Determination of rhenium in molybdenum and copper ores by inductively coupled plasma atomic emission specrometry[J]. Rock and Mineral Analysis, 2009, 28(6): 593−594. doi: 10.15898/j.cnki.11-2131/td.2009.06.008

[5] 王景凤. 基体分离-电感耦合等离子体原子发射光谱法测定辉钼精矿中痕量铼[J]. 冶金分析, 2023, 43(1): 62−67. doi: 10.13228/j.boyuan.issn1000-7571.011848

Wang J F. Determination of trace rhenium in molybdenite concentrate by matrix separation-inductively coupled plasma emission spectrometry[J]. Metallurgical Analysis, 2023, 43(1): 62−67. doi: 10.13228/j.boyuan.issn1000-7571.011848

[6] 贾雷, 左修源. 四酸密闭消解-电感耦合等离子体质谱(ICP-MS)法测定铀矿中的铼和钪[J]. 中国无机分析化学, 2023, 13(5): 469−474.

Jia L, Zuo X Y. Determination of rhenium and scandiumin uranium ores by inductively coupled plasma mass spectrometry (ICP-MS) with tetraacid confinement ablation[J]. Chinese Journal of Inorganic Analytical Chemistry, 2023, 13(5): 469−474.

[7] Zhen Y, Chen H, Zhang M, et al. Cadmium and cobalt ions enhanced-photochemical vapor generation for determination of trace rhenium by ICP-MS[J]. Applied Spectroscopy Reviews, 2022, 57(4): 318−337. doi: 10.1080/05704928.2021.1878368

[8] Bettinardi D J, Brown M A, Paulenova A, et al. Separation and determination of ultratrace rhenium quantities in molybdenum matrix[J]. Separation Science and Technology, 2021, 56(16): 2789−2800. doi: 10.1080/01496395.2020.1849304

[9] 李明, 蔡玉曼, 张培新. 电感耦合等离子体质谱(ICP-MS)法测定钨矿石、钼矿石中的铼[J]. 中国无机分析化学, 2019, 9(6): 29−34. doi: 10.3969/j.issn.2095-1035.2019.06.007

Li M, Cai Y M, Zhang P X. Determination of Re in tungsten ore and molybdenum ore by inductively coupled plasma mass spectrometry[J]. Chinese Journal of Inorganic Analytical Chemistry, 2019, 9(6): 29−34. doi: 10.3969/j.issn.2095-1035.2019.06.007

[10] 申玉民, 边朋沙, 李晓敬, 等. 电感耦合等离子体质谱法测定地质样品中痕量铼[J]. 冶金分析, 2018, 38(12): 7−12.

Shen Y M, Bian P S, Li X J, et al. Determination of trace rhenium in geological sample by inductively coupled plasma mass spectrometry[J]. Metallugical Analysis, 2018, 38(12): 7−12.

[11] 王妍力, 罗明标, 柯麟, 等. 氧化镁烧结-电感耦合等离子体质谱法测定砂岩型铀矿中的痕量铼[J]. 岩矿测试, 2016, 35(4): 373−377.

Wang Y L, Luo M B, Ke L, et al. Determination of trace rhenium in sandstone-type uranium deposits by inductively coupled plasma-mass spectrometry with magnesium oxide sintering[J]. Rock and Mineral Analysis, 2016, 35(4): 373−377.

[12] 张艳, 郝辉, 雒虹. 电感耦合等离子体质谱(ICP-MS)法测定矿石中的铼——三种前处理方法比较[J]. 中国无机分析化学, 2016, 6(1): 34−37. doi: 10.3969/j.issn.2095-1035.2016.01.009

Zhang Y, Hao H, Luo H. Comparison of three sample pretreatment methods in determination of rhenium in ores by ICP-MS[J]. Chinese Journal of Inorganic Analytical Chemistry, 2016, 6(1): 34−37. doi: 10.3969/j.issn.2095-1035.2016.01.009

[13] 熊英, 吴峥, 董亚妮, 等. 封闭消解-阳离子交换分离-电感耦合等离子体质谱法测定铜铅锌矿石中的铼[J]. 岩矿测试, 2015, 34(6): 623−628. doi: 10.15898/j.cnki.11-2131/td.2015.06.004

Xiong Y, Wu Z, Dong Y N, et al. Determination of rhenium in copper-lead-zinc ore by inductively coupled plasma-mass spectrometry with closed decomposition and cation exchange separation[J]. Rock and Mineral Analysis, 2015, 34(6): 623−628. doi: 10.15898/j.cnki.11-2131/td.2015.06.004

[14] 任志海, 夏照明, 李树强. 电感耦合等离子体质谱法(ICP-MS)测定钼矿石中的铼[J]. 中国无机分析化学, 2013, 3(3): 27−29.

Ren Z H, Xia Z M, Li S Q. Determination of rhenium in molybdenum ores by inductively coupled plasma mass spectrometry (ICP-MS)[J]. Chinese Journal of Inorganic Analytical Chemistry, 2013, 3(3): 27−29.

[15] 屈文俊, 杜安道. 高温密闭溶样电感耦合等离子体质谱准确测定辉钼矿铼-锇地质年龄[J]. 岩矿测试, 2003, 22(4): 254−257.

Qu W J, Du A D. Highly precise Re-Os dating of molybdenite by ICP-MS with Carius tube sample digestion[J]. Rock and Mineral Analysis, 2003, 22(4): 254−257.

[16] 李丽君, 薛静. 微波消解-电感耦合等离子体质谱法测定高岭土中10种微量元素[J]. 岩矿测试, 2022, 41(1): 22−31.

Li L J, Xue J. Determination of 10 trace elements in kaolin by ICP-MS with microwave digestion[J]. Rock and Mineral Analysis, 2022, 41(1): 22−31.

[17] 王娜, 徐铁民, 魏双, 等. 微波消解-电感耦合等离子体质谱法测定超细粒度岩石和土壤样品中的稀土元素[J]. 岩矿测试, 2020, 39(1): 68−76.

Wang N, Xu T M, Wei S, et al. Determination of rare earth elements in ultra-fine rock and soil samples by ICP-MS using microwave digestion[J]. Rock and Mineral Analysis, 2020, 39(1): 68−76.

[18] 张莉娟, 方蓬达, 王力强, 等. 微波消解-电感耦合等离子体发射光谱法测定砂岩型铀矿中的铀钍[J]. 岩矿测试, 2022, 41(5): 798−805.

Zhang L J, Fang P D, Wang L Q, et al. Determination of uraniumand thorium in sandstone uranium deposits by inductively coupled plasma-optical emission spectrometry with microwave digestion[J]. Rock and Mineral Analysis, 2022, 41(5): 798−805.

[19] 郑智慷, 曾江萍, 王家松, 等. 常压密闭微波消解-电感耦合等离子体发射光谱法测定锑矿石中的锑[J]. 岩矿测试, 2020, 39(2): 208−215.

Zheng Z K, Zeng J P, Wang J S, et al. Determination of antimony in antimony ores by inductively coupled plasma-optical emission spectrometry with microwave digestion[J]. Rock and Mineral Analysis, 2020, 39(2): 208−215.

[20] 黄靖, 王英滨, 周冠轩, 等. 微波消解-电感耦合等离子体发射光谱法测定粉煤灰中的镓[J]. 岩矿测试, 2020, 39(1): 92−98.

Huang J, Wang Y B, Zhou G X, et al. Determination of gallium in coal fly ash by inductively coupled plasma-optical emission spectrometry with microwave digestion[J]. Rock and Mineral Analysis, 2020, 39(1): 92−98.

[21] 邱朝辉, 钟宏, 曹占芳, 等. 铼的分离分析方法研究进展[J]. 稀有金属与硬质合金, 2010, 38(1): 56−59.

Qiu Z H, Zhong H, Cao Z F, et al. The latest development of rhenium separation and analysis methods[J]. Rare Metals and Cemented Carbides, 2010, 38(1): 56−59.

[22] Chen S, Wang X, Niu Y, et al. Simple and cost-effective methods for precise analysis of trace element abundances in geological materials with ICP-MS[J]. Science Bulletin, 2017, 62(4): 277−289. doi: 10.1016/j.scib.2017.01.004

[23] 李晓云, 王羽, 金婵, 等. 微波消解-高分辨电感耦合等离子体质谱法测定土壤中8种金属元素[J]. 岩矿测试, 2022, 41(3): 374−383.

Li X Y, Wang Y, Jin C, et al. Determination of 8 metal elements in soil by high-resolution inductively coupled plasma-mass spectrometry with microwave digestion[J]. Rock and Mineral Analysis, 2022, 41(3): 374−383.

-

下载:

下载: