Determination of 9 Major and Minor Elements in Beryllium Ore by ICP-OES with Acid Dissolution

-

摘要:

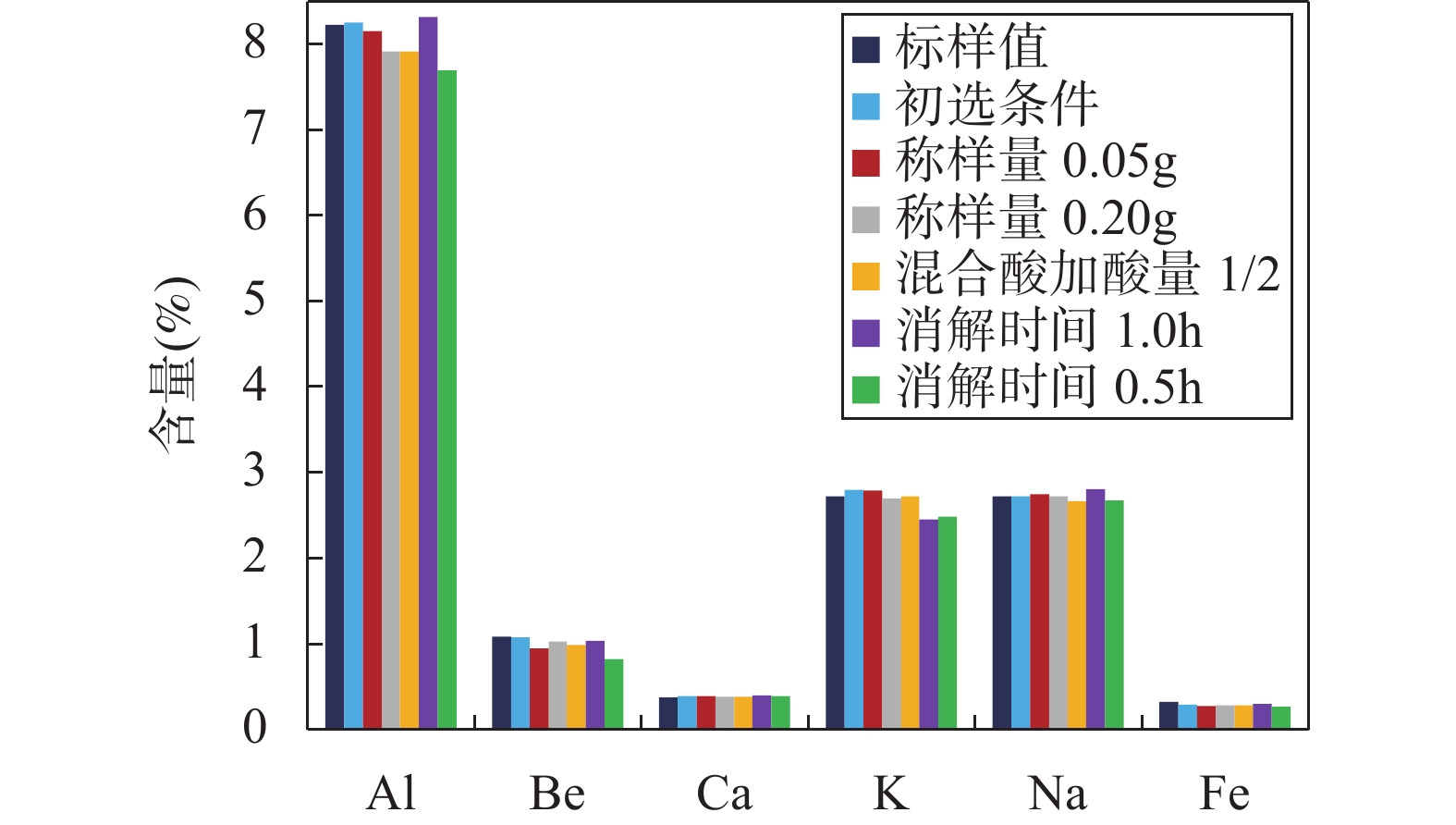

铍矿石是中国的紧缺金属矿产之一,已在多领域有广泛应用,但其组分复杂,铍含量差别较大,且常与其他金属矿物伴生,给分析测试带来诸多挑战,制约了铍矿产的勘查开发。电感耦合等离子体发射光谱法(ICP-OES)目前用于分析铍矿石仅针对单一类型样品,且存在基体干扰、分解不完全等不足,需建立适用于多种类型的铍矿石样品、仪器分析溶液基体干扰小的多元素同时测定方法。本文选用绿柱石、香花石、日光榴石样品,比较了电热板、高压密闭、微波消解、不同种类消解酸和提取酸等8种酸消解条件对铍矿石的分解效果,优化了称样量、加酸量、消解时间和仪器测定参数,建立了ICP-OES测定铍矿石中铝铍钙铁钾钠镁锂锰9种主次量元素的分析方法。结果表明,电热板消解的混合酸为硝酸-盐酸-氢氟酸-高氯酸最佳,提取酸为盐酸优于硝酸或王水,高压密闭法不能完全消解绿柱石Al、Ca、Mg元素,微波法对绿柱石Mg元素消解效果较差。通过优化现有方法的混合酸消解条件和仪器测定条件,建立的方法对精矿样品也能准确测定,仪器测定溶液的基体简单。本方法Be元素检出限0.0001%,低于铍矿石边界品位,其他元素检出限均优于现有的标准方法,主量元素精密度(RSD)均<5%,经标准物质验证,准确度满足铍矿石测定需要。该方法适用于不同类型和不同含量铍矿石样品的多元素同时分析。

-

关键词:

- 铍矿石 /

- 电感耦合等离子体发射光谱法 /

- 酸消解 /

- 仪器测定参数 /

- 多元素同时分析

Abstract:BACKGROUND Beryllium ore is one of the scarce metal minerals in China. Beryllium ore is widely used mineral resources, but it has complex components, and is always concomitant with other metallic minerals. Accurate determination of primary and secondary elements in beryllium ore is significant for its comprehensive utilization. Inductively coupled plasma-optical emission spectrometry (ICP-OES) has been used in elemental analysis of beryllium ore. However, there are some disadvantages: It is considered that beryllium concentrate is difficult to completely decompose by acid dissolution; determination of beryllium concentrate by alkali fusion has serious matrix interference; the existing research focuses on analysis of a single type of beryllium ore.

OBJECTIVES To establish a multi-element simultaneous determination method, which is suitable for various types of beryllium ore samples and has little interference with the matrix of instrumental analysis solution.

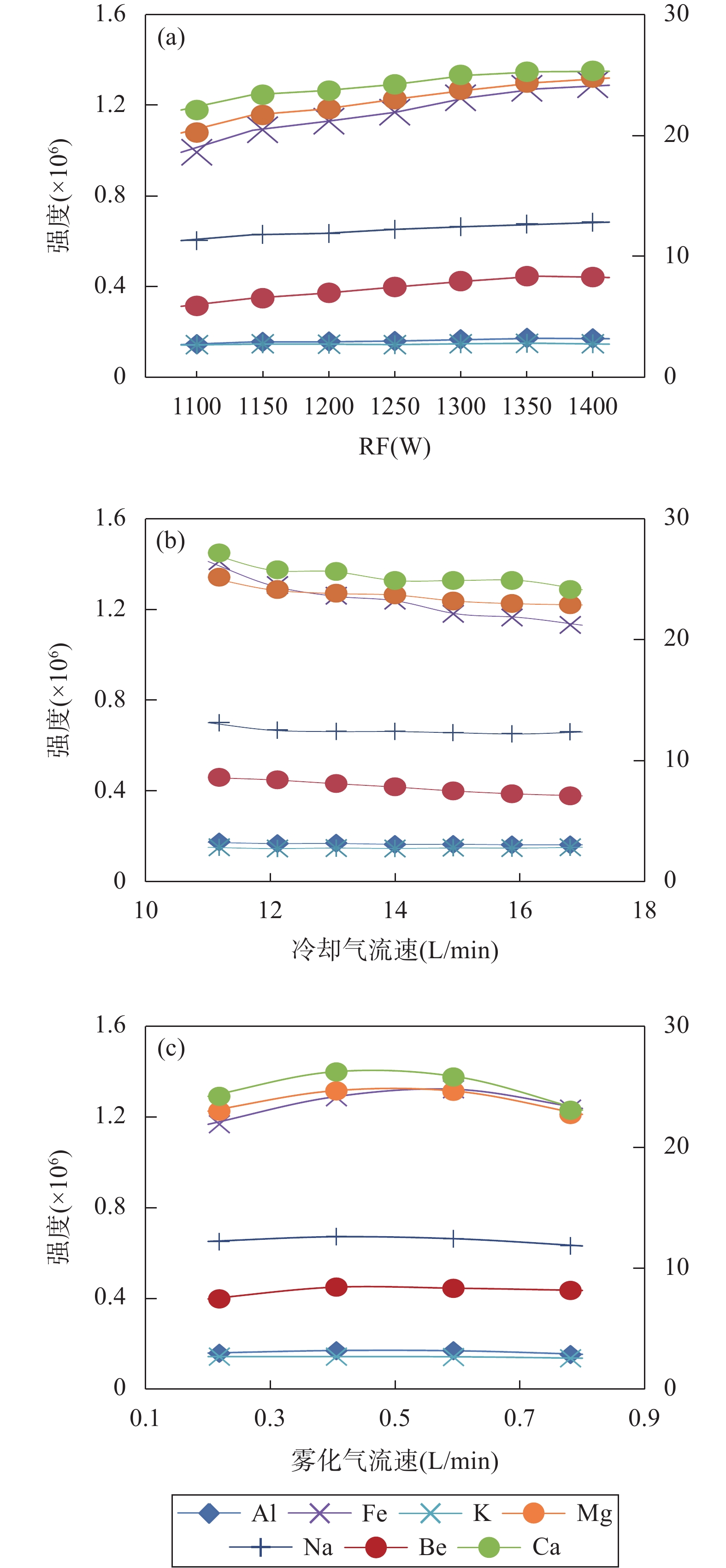

METHODS Beryl, hsianghualite and helvite samples were selected in the experiment. Digestion effect on beryllium ore under eight different acid digestion conditions were compared, such as digestion on electric heating board, high pressure sealing, microwave digestion, different kinds of acid digestion and extraction acid. The weight of the sample, the volume of the acid, the digestion time and instrument measurement were optimized. At the same time, according to beryllium ore’s mode of occurrence of elements, the best spectrum lines of each element were determined.

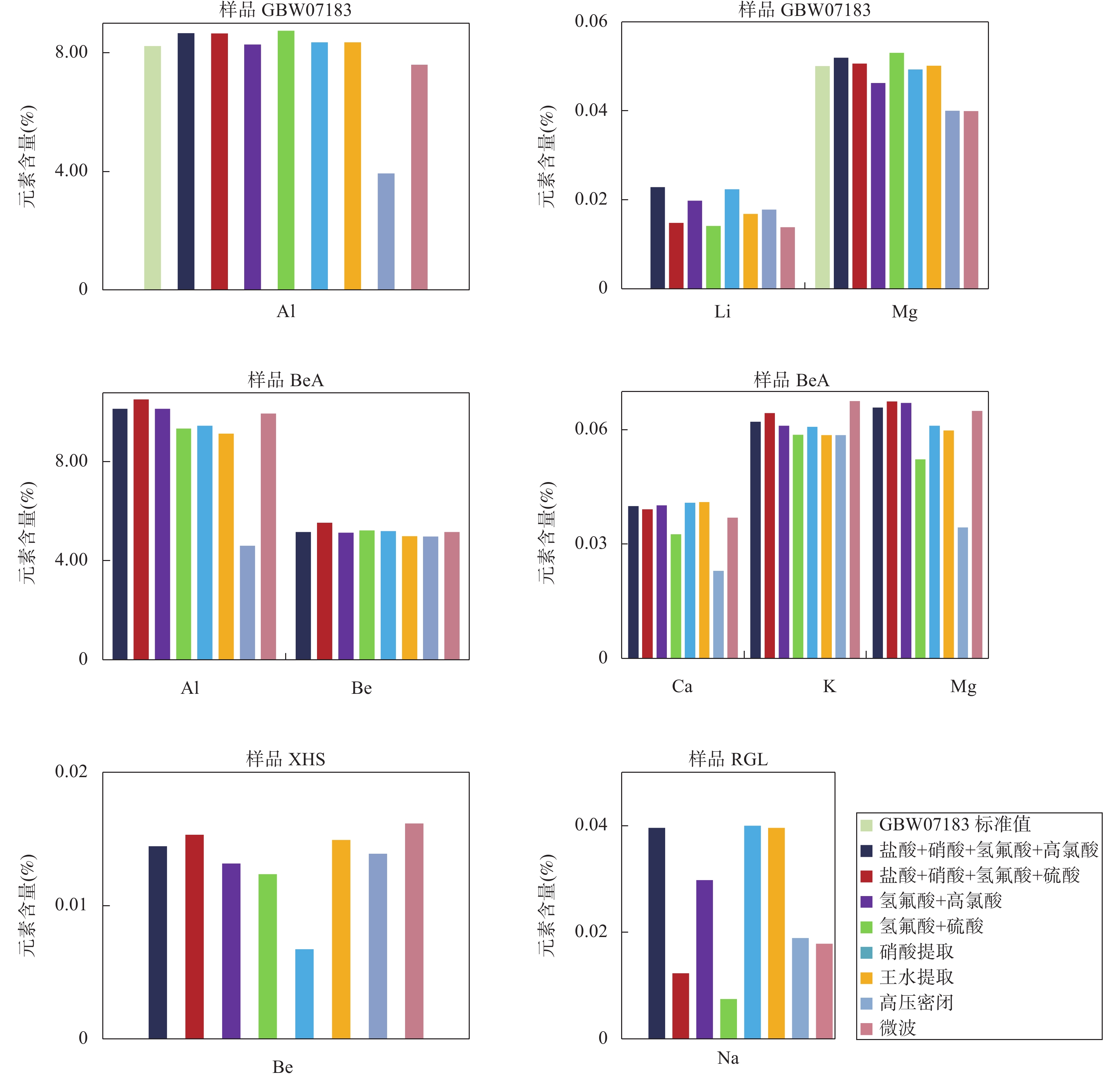

RESULTS (1) The results show that the best mixed digested acid on electric heating board is nitric acid-hydrochloric acid-hydrofluoric acid-perchloric acid. The best extracted acid is hydrochloric acid, which is better than nitric acid or aqua regia. The high-pressure sealing method cannot completely dissolve Al, Ca and Mg elements of beryl, and the microwave method has poor effect on the digestion of Mg elements of beryl. (2) The digestion conditions are determined. Weigh the sample of 0.1000g into polytetrafluoroethylene crucible, moisten the sample with a small amount of deionized water, and add 2mL nitric acid-3mL hydrochloric acid-5mL hydrofluoric acid-1mL perchloric acid; cover and place the crucible on electric heating plate; decomposing at 120℃ for 2h, then 150℃ for a further 2h; remove the lid and boil away perchloric acid at 190℃; extract with 4mL 50% hydrochloric acid and add deionized water to 25mL. The solution is determined by ICP-OES. The detection limit of Be is 0.0001%, which is lower than the boundary grade of beryllium ore. The detection limit of other elements is better than the existing standard method, and the precision RSD of each major element is <5%. By verification of standard materials, the accuracy of the method meets the needs of beryllium ore determination. The analysis accuracy and precision of three real beryllium ore samples from fields is satisfying. (3) By optimizing the conditions of mixed acid digestion and instrument determination of the existing method, the established method can also accurately determine concentrate sample, and the matrix of the solution is simple to be determined by the instrument.

CONCLUSIONS In this study, a mixed acid decomposition ICP-OES method for simultaneous determination of 9elements including Al, Be, Ca, Fe, K, Na, Mg, Li and Mn in beryllium ore has been established, which can be applied to different types and contents of beryllium ore. The established method provides necessary technical support for the research and exploration of beryllium ore.

-

-

表 1 不同酸消解方式、混合酸类型、提取酸类型的条件优化

Table 1. Condition optimization of different acid digestion modes, mixed acid types and extracting acid types.

消解方式 混合酸类型 提取酸类型 电热板消解 硝酸-盐酸-氢氟酸-高氯酸 50%盐酸 50%硝酸 50%王水 硝酸-盐酸-氢氟酸-硫酸 50%盐酸 氢氟酸-高氯酸 50%盐酸 氢氟酸-硫酸 50%盐酸 高压密闭消解 硝酸-氢氟酸 50%盐酸 微波消解 硝酸-氢氟酸 50%盐酸 表 2 ICP-OES测定元素选择的谱线

Table 2. Spectral lines selected for elements measured by ICP-OES.

待测元素 分析谱线

(nm)曲线最高点

(mg/L)标准曲线计算公式 线性相关系数

R2Al 308.215 300 y=1206x+2272 0.9996 Be 234.861 200 y=60577x+73675 0.9994 Ca 317.933 300 y=12505x+20413 0.9996 Fe 259.939 400 y=10389x+18792 0.9999 K 766.490 200 y=2466x+1564 0.9998 Na 589.592 200 y=9528x+18859 0.9990 Mg 285.213 30.0 y=17119x+2840 0.9999 Li 670.784 100 y=63464x+124949 0.9990 Mn 257.610 300 y=44063x+116324 0.9994 表 3 方法检出限、定量限和精密度

Table 3. Detection limit, quantitative limit and precision of the method.

待测元素 方法检出限

(%)定量限

(%)RSD

(%)YC

(%)Al 0.002 0.007 2.37 3.35 Be 0.0001 0.0004 3.87 6.57 Ca 0.003 0.01 3.36 8.56 Fe 0.001 0.003 4.70 8.94 K 0.001 0.003 3.46 4.98 Na 0.003 0.01 2.73 5.00 Mg 0.001 0.003 4.68 13.22 Li 0.0001 0.0003 4.09 17.74 Mn 0.006 0.02 6.48 16.57 表 4 国家一级标准物质GBW07183和GBW07150测定方法准确度结果

Table 4. Accuracy of the method by determining the first class standard materials GBW07183 and GBW07150.

待测元素 GBW07183 GBW07150 标准值

(%)测定值

(%)相对误差

(%)YB

(%)标准值

(%)测定值

(%)相对误差

(%)YB

(%)Al 8.230 8.251 0.25 2.37 7.865 7.716 −1.89 2.42 Be 1.088 1.082 −0.55 4.64 0.022 0.021 −4.55 11.04 Ca 0.372 0.383 3.13 6.10 0.416 0.428 3.00 5.94 Fe 0.329 0.320 −2.75 6.28 0.359 0.355 −0.93 6.15 K 2.723 2.756 1.20 3.54 3.404 3.406 0.07 3.29 Na 2.723 2.728 0.22 3.54 3.553 3.561 0.20 3.24 Mg 0.050 0.052 3.74 9.42 0.043 0.041 −4.98 9.70 Li / 0.011 / / / 0.0006 / / Mn 0.015 0.016 6.46 11.85 0.023 0.021 −8.13 10.95 注:“/”表示没有提供标准值。 表 5 建立的酸溶方法与碱熔结果对比

Table 5. Comparison of analytical results by acid digestion and alkali fusion.

待测元素 碱熔法测定值

(%)酸溶法测定值

(%)相对偏差

(%)YB

(%)Al 9.359 9.149 −2.24 3.18 Be 4.480 4.525 1.00 4.23 Fe 0.374 0.389 4.01 8.61 Na 0.361 0.390 8.03 8.68 表 6 绿柱石、香花石、日光榴石实际样品测定结果

Table 6. Analytical results of beryl, balsamite and heliogarnet actual samples.

待测

元素样品BeC 样品XHS 样品RGL 测定平均值

(%)RSD

(%)YC

(%)测定平均值

(%)RSD

(%)YC

(%)测定平均值

(%)RSD

(%)YC

(%)Al 8.314 2.81 3.34 9.176 0.81 3.20 0.348 0.63 8.76 Be 0.033 2.47 14.45 0.014 2.74 16.98 4.702 2.56 4.16 Ca 0.314 2.38 8.97 15.129 1.44 2.54 1.360 0.92 6.16 Fe 0.305 3.59 9.04 7.933 2.09 3.40 18.503 1.63 2.28 K 1.711 2.11 5.77 1.076 1.12 6.58 0.069 5.06 12.48 Na 2.236 1.97 5.32 0.948 0.81 6.81 0.040 0.54 13.92 Mg 0.018 0.74 16.21 0.734 1.60 7.28 0.187 2.55 10.10 Li 0.863 2.75 6.98 1.942 1.57 5.56 0.011 9.08 17.74 Mn 0.043 11.61 13.72 1.324 4.84 6.21 12.954 1.51 2.74 -

[1] 林博磊, 尹丽文, 崔荣国, 等. 全球铍资源分布及供需格局[J]. 国土资源情报, 2018(1): 13−17.

Lin B L, Yin L W, Cui R G, et al. Global beryllium resources distribution and supply and demand pattern[J]. Land and Resources Information, 2018(1): 13−17.

[2] Ashley K. Measurement of ultra-trace beryllium in occupational hygiene samples by extraction and fluorescence detection[J]. Journal of Chemical Health & Safety, 2011, 18(5): 26−33.

[3] Agrawal A, Cronin J P, Agrawal A, et al. Extraction and optical fluorescence method for the measurement of trace beryllium in soils[J]. Environmental Science & Technology, 2008, 42(6): 2066−2071.

[4] 郑莉芳, 刘新宇, 鲍帅平, 等. 稀有金属铍的性能研究进展[J]. 稀有金属, 2023, 47(2): 292−302. doi: 10.13373/j.cnki.cjrm.XY21110037

Zheng L F, Liu X Y, Bao S P, et al. Research progress on properties of rare metal beryllium[J]. Chinese Journal of Rare Metals, 2023, 47(2): 292−302. doi: 10.13373/j.cnki.cjrm.XY21110037

[5] 梁飞, 赵汀, 王登红, 等. 中国铍资源供需预测与发展战略[J]. 中国矿业, 2018, 27(11): 6−10. doi: 10.12075/j.issn.1004-4051.2018.11.011

Liang F, Zhao T, Wang D H, et al. Supply and demand forecast and development strategy of beryllium resources in China[J]. China Mining Magazine, 2018, 27(11): 6−10. doi: 10.12075/j.issn.1004-4051.2018.11.011

[6] 毛素荣, 李光明, 钟乐乐, 等. 铍的选矿研究现状和展望[J]. 有色金属(选矿部分), 2022(6): 17−24.

Mao S R, Li G M, Zhong L L, et al. Present situation and prospect of mineral processing of beryllium[J]. Nonferrous Metals (Mineral Processing Section), 2022(6): 17−24.

[7] 胡欢, 王汝成, 车旭东, 等. 关键金属元素铍的原位分析技术研究进展[J]. 岩石学报, 2022, 38(7): 1890−1900. doi: 10.18654/1000-0569/2022.07.05

Hu H, Wang R C, Che X D, et al. Research progress of in situ analysis technology of key metal element beryllium[J]. Acta Petrologica Sinica, 2022, 38(7): 1890−1900. doi: 10.18654/1000-0569/2022.07.05

[8] 贾福东, 张长青, 化志新, 等. 云南麻花坪钨铍矿床蓝柱石的鉴定特征及成分与成因分析[J]. 光谱学与光谱分析, 2020, 40(10): 3185−3192.

Jia F D, Zhang C Q, Hua Z X, et al. Identification characteristics, composition and genesis of euclase in Mahuaping tungsten-beryllium polymetallic deposit in Yunnan Province, Southwest China[J]. Spectroscopy and Spectral Analysis, 2020, 40(10): 3185−3192.

[9] 李娜, 高爱红, 王小宁. 全球铍资源供需形势及建议[J]. 中国矿业, 2019, 28(4): 69−73.

Li N, Gao A H, Wang X N. Global beryllium supply and demand trends and its enlightenment[J]. China Mining Magazine, 2019, 28(4): 69−73.

[10] 王应平, 秦红艳, 段玲敏, 等. 铬天青S差示光度法测定铍精矿、绿柱石中氧化铍量[J]. 云南化工, 2023, 50(3): 80−82.

Wang Y P, Qin H Y, Duan L M, et al. Determination of beryllium oxide in beryllium concentrate and beryl by chromazurol S differential spectrophotometry[J]. Yunnan Chemical Technology, 2023, 50(3): 80−82.

[11] Manousi N, Kabir A, Furton K G, et al. Dual lab-in-syringe flow-batch platform for automatic fabric disk sorptive extraction/back-extraction as a front end to inductively coupled plasma atomic emission spectrometry[J]. Analytical Chemistry, 2022, 94(38): 12943−12947. doi: 10.1021/acs.analchem.2c02268

[12] 贾雷, 左修源. 四酸密闭消解-电感耦合等离子体质谱(ICP-MS)法测定铀矿中的铼和钪[J]. 中国无机分析化学, 2023, 13(5): 469−474. doi: 10.3969/j.issn.2095-1035.2023.05.010

Jia L, Zuo X Y. Determination of rhenium and scandium in uranium ores by inductively coupled plasma-mass spectrometry (ICP-MS) with tetraacid confinement ablation[J]. Chinese Journal of Inorganic Analytical Chemistry, 2023, 13(5): 469−474. doi: 10.3969/j.issn.2095-1035.2023.05.010

[13] Vievard J, Amoikon T L, Coulibaly N A, et al. Extraction and quantification of pesticides and metals in palm wines by HS-SPME/GC-MS and ICP-AES/MS[J]. Food Chemistry, 2022, 393: 133352. doi: 10.1016/j.foodchem.2022.133352

[14] 龚仓, 丁洋, 陆海川, 等. 五酸溶样-电感耦合等离子体质谱法同时测定地质样品中的稀土等28种金属元素[J]. 岩矿测试, 2021, 40(3): 340−348.

Gong C, Ding Y, Lu H C, et al. Simultaneous determination of 28 elements including rare earth elements by ICP-MS with five-acid dissolution[J]. Rock and Mineral Analysis, 2021, 40(3): 340−348.

[15] 郝冬梅, 张翼明, 许涛, 等. ICP-MS法测定稀土铌钽矿中铍、铀、铌、钽、锆、铪量[J]. 稀土, 2010, 31(5): 67−69. doi: 10.3969/j.issn.1004-0277.2010.05.014

Hao D M, Zhang Y M, Xu T, et al. Determination of beryllium, uranium, niobium, tartalum, zirconium and hafnium in rare earth-niobium-tartalum mineral by ICP-MS[J]. Chinese Rare Earths, 2010, 31(5): 67−69. doi: 10.3969/j.issn.1004-0277.2010.05.014

[16] Zeng Y, Yokoyama Y, Hirabayashi S, et al. A rapid and precise method of establishing age model for coral skeletal radiocarbon to study surface oceanography using coupled X-ray photos and ICP-AES measurement[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2022, 533: 23−28.

[17] 窦向丽, 张旺强, 黑文龙, 等. 敞开酸溶-电感耦合等离子体发射光谱法测定石煤钒矿中钒铁铝磷[J]. 岩矿测试, 2022, 41(4): 673−679.

Dou X L, Zhang W Q, Hei W L, et al. Determination of vanadium, iron, aluminum and phosphorus in stone coal vanadium ore by ICP-OES with open acid dissolution[J]. Rock and Mineral Analysis, 2022, 41(4): 673−679.

[18] Erickson B. Product review: ICP-AES remains competitive[J]. Analytical Chemistry, 1998, 70(5): 211A−215A. doi: 10.1021/ac9817725

[19] 向吉锋, 孔亚君. ICP法测定铍矿中氧化铍含量[J]. 中国石油和化工标准与质量, 2014, 34(4): 21.

Xiang J F, Kong Y J. Determination of beryllium oxide in beryllium by inductively coupled plasma[J]. China Petroleum and Chemical Standard and Quality, 2014, 34(4): 21.

[20] 常学东. 测定稀有金属矿中锂、铍、铌、钽的方法选择[J]. 新疆有色金属, 2016, 39(3): 64−66.

Chang X D. Determination method selection of lithium, beryllium, niobium and tantalum in rare metal ores[J]. Xinjiang Nonferrous Metals, 2016, 39(3): 64−66.

[21] 杨萍, 陈云红. ICP-AES法测定矿石中的BeO[J]. 分析试验室, 2002, 21(5): 16−17.

Yang P, Chen Y H. Determination of BeO in ores by ICP-AES[J]. Analytical Laboratory, 2002, 21(5): 16−17.

[22] 高晶晶, 刘季花, 张辉, 等. 高压密闭消解-电感耦合等离子体质谱法测定海洋沉积物中稀土元素[J]. 岩矿测试, 2012, 31(3): 425−429.

Gao J J, Liu J H, Zhang H, et al. Determination of rare earth elements in the marine sediments by inductively coupled plasma-mass spectrometry with high-pressure closed digestion[J]. Rock and Mineral Analysis, 2012, 31(3): 425−429.

[23] 戴长文, 何小姣. 碱熔-等离子体发射光谱法测定铍矿石中铍[J]. 世界有色金属, 2020(4): 163−164.

Dai C W, He X J. Determination of beryllium in beryllium ore by alkali fusion ICP-AES[J]. World Nonferrous Metals, 2020(4): 163−164.

[24] 李志伟, 赵晓亮, 李珍, 等. 敞口酸熔-电感耦合等离子体发射光谱法测定稀有多金属矿选矿样品中的铌钽和伴生元素[J]. 岩矿测试, 2017, 36(6): 594−600.

Li Z W, Zhao X L, Li Z, et al. Determination of niobium, tantalum and associated elements in niobium-tantalum ore by inductively coupled plasma-optical emission spectrometry with open acid dissolution[J]. Rock and Mineral Analysis, 2017, 36(6): 594−600.

[25] 赵学沛. 多种酸溶矿ICP-AES测定稀有金属矿中锂铍铌钽锡[J]. 化学研究与应用, 2017, 29(11): 1714−1718.

Zhao X P. Determination of lithium, beryllium, niobium and tantalum in rare metal ores by four acid soluble ICP-AES[J]. Chemical Research and Application, 2017, 29(11): 1714−1718.

[26] 吴刚. 酸溶法、碱熔法ICP-AES/MS分析测定矿石中的稀有元素[D]. 保定: 河北大学, 2018: 21−25.

Wu G. Determination of rare elements in the minerals with acid-leaching method and alkali-fusion method by ICP-AES/MS[D]. Baoding: Hebei University, 2018: 21−25.

[27] 徐洪柳. 电感耦合等离子体原子发射光谱(ICP-AES)法测定尼日利亚铌钽锂矿石中的铌、钽、锂[J]. 中国无机分析化学, 2020, 10(3): 33−38. doi: 10.3969/j.issn.2095-1035.2020.03.007

Xu H L. Determination of niobium, tantalum and lithium in niobium-tantalum-lithium ore from nigeria by inductively coupled plasma atomic emission spectrometry[J]. Chinese Journal of Inorganic Analytical Chemistry, 2020, 10(3): 33−38. doi: 10.3969/j.issn.2095-1035.2020.03.007

[28] 《矿产资源工业要求手册》编委会. 矿产资源工业要求手册[M]. 北京: 地质出版社, 2014: 226.

The Editorial Committee of “Mineral Resources Industry Requirements Manual”. Mineral Resources Industry Requirements Manual[M]. Beijing: Geological Publishing House, 2014: 226.

[29] 《岩石矿物分析》编委会. 岩石矿物分析(第四版 第三分册)[M]. 北京: 地质出版社, 2011: 303-315.

The Editorial Committee of “Rock and Mineral Analysis”. Rock and Mineral Analysis (The 4th Edition, Volume Ⅲ) [M]. Beijing: Geological Publishing House, 2011: 303-315.

-

下载:

下载: