Determination of Tungsten, Molybdenum and 5 Associated Elements in Tungsten-Molybdenum Ore by Inductively Coupled Plasma-Optical Emission Spectrometry with Direct Sintering

-

摘要:

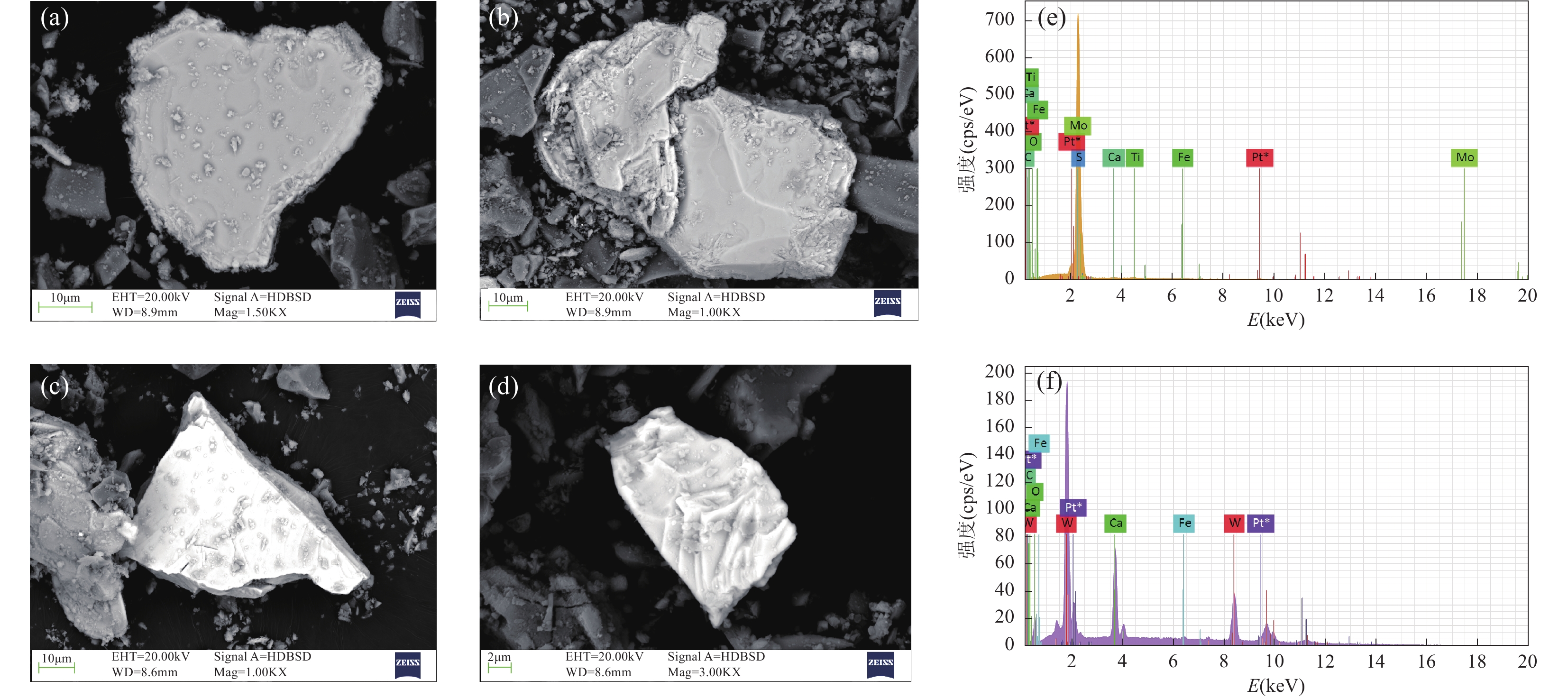

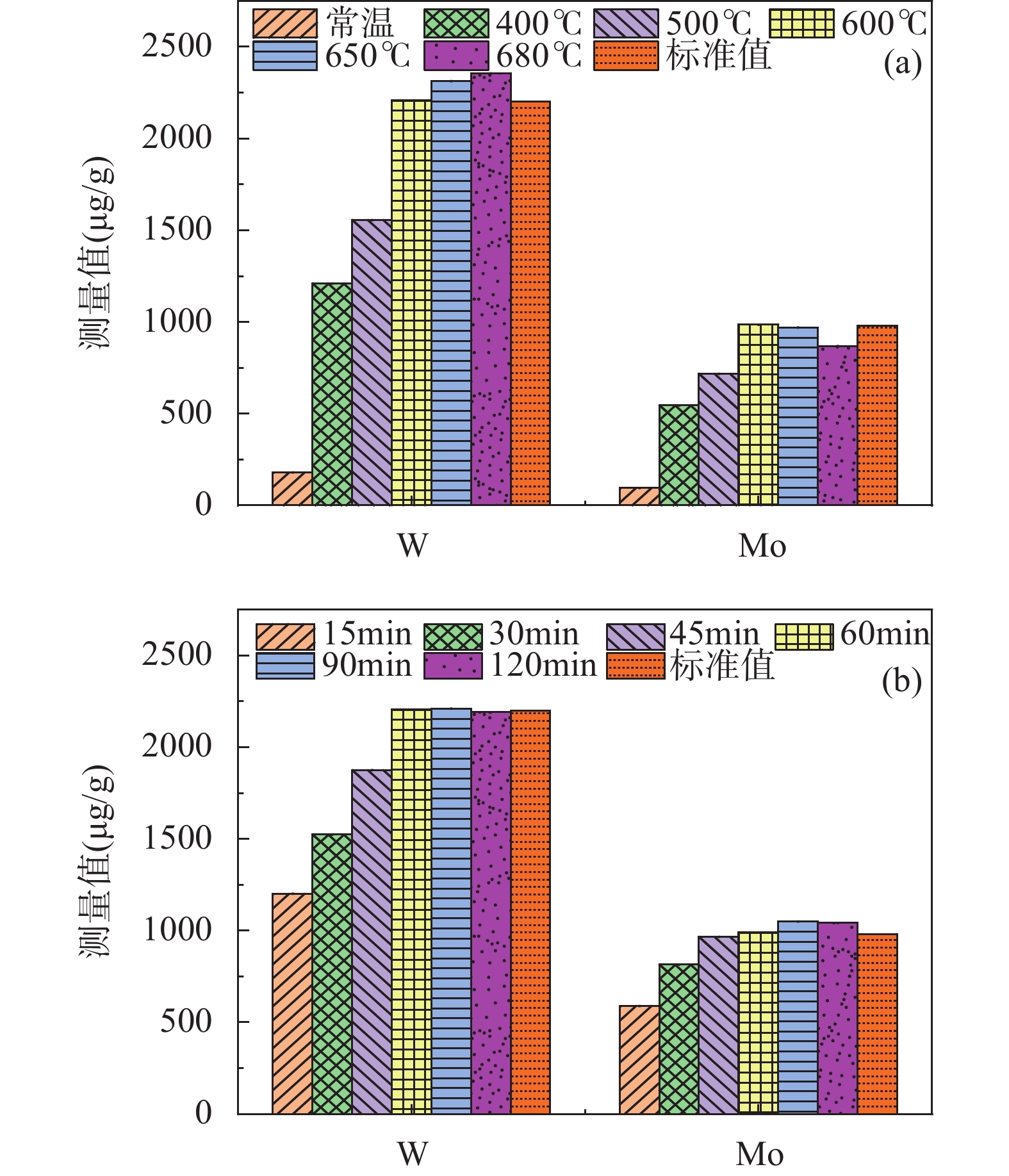

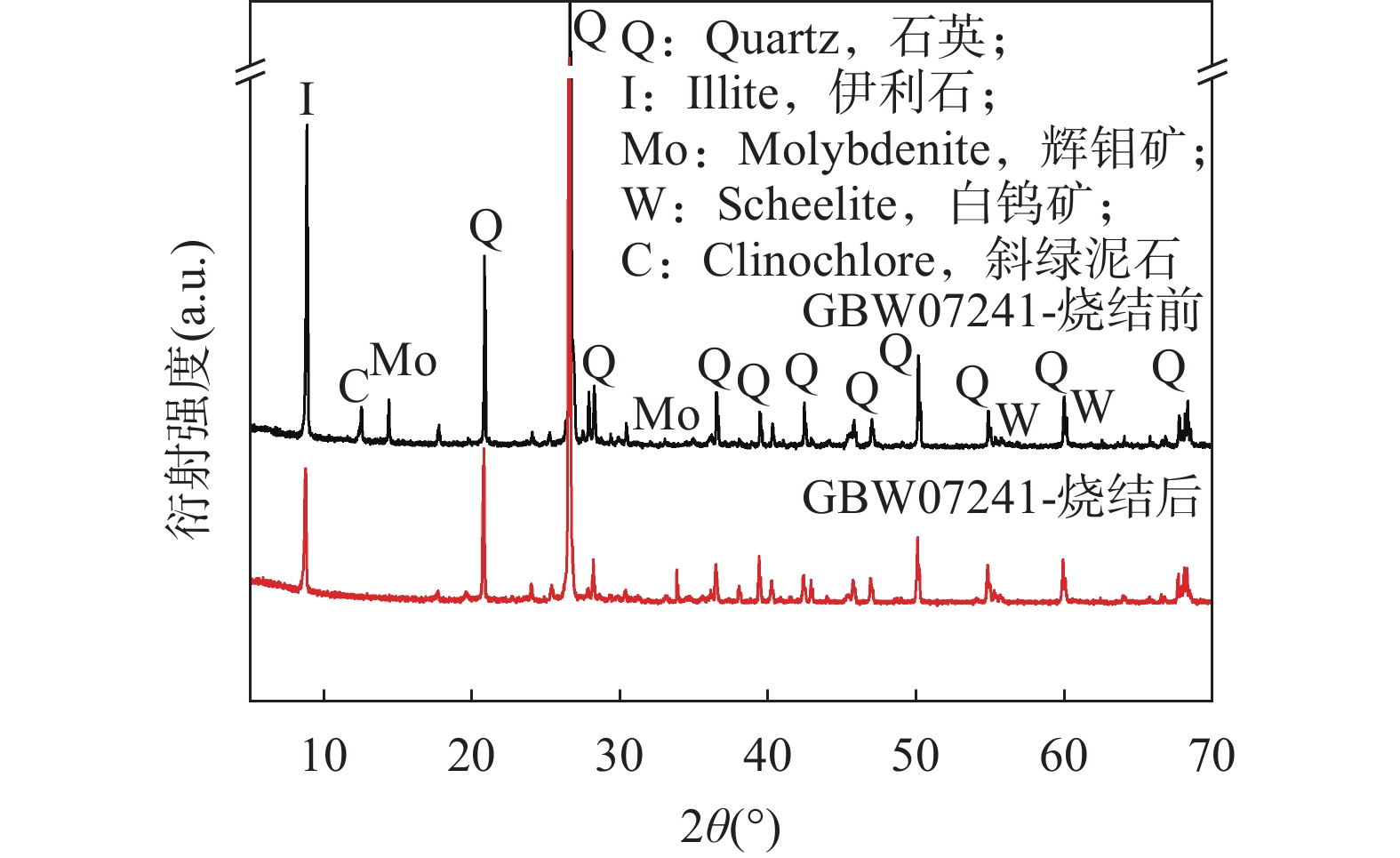

钨钼矿石一般由多种矿物组成,组分较为复杂,不溶于盐酸、硝酸和王水,常采用碱熔和混合酸酸溶法进行样品消解。然而,碱熔法带来的基体效应严重影响仪器测试的准确性和检出限,而酸溶法对钨钼等难溶元素溶出效率较低,并且需要使用氢氟酸和王水等多种无机强酸进行长时间且操作过程复杂的前处理流程,同时还会造成分析测试仪器损害的问题。因此,开发一种操作简单且高效定量分析钨钼矿石中钨钼及其伴生元素的方法十分必要。本文在碱熔和酸溶的基础上,探索并建立了一种由直接烧结、盐酸-磷酸-柠檬酸络合提取与电感耦合等离子体发射光谱仪(ICP-OES)联用的方法,同时准确定量分析钨钼矿石中钨钼铜铅锌钙铁7种元素。与传统碱熔法相比,通过高温直接烧结让样品中含目标元素的矿物转化为酸可溶态,随后在盐酸-磷酸-柠檬酸混合酸体系的络合作用下,将目标元素转移至溶液中,从而实现快速准确定量测定。最佳实验条件为:600℃烧结1h、5mL磷酸-盐酸(体积比1∶20)提取、5mL 10g/L柠檬酸络合,过滤后上机测定。采用钨矿标准物质(GBW07240和GBW07241)和钼矿标准物质(GBW07238和GBW07239)以及两种实际钨钼矿石样品对本方法进行验证,结果表明7种目标元素测定含量均在标准值范围内,相对误差和相对标准偏差(RSD)均在10%以内。本研究发现,高温直接烧结与盐酸-磷酸-柠檬酸混合酸体系络合提取联用的样品前处理方法,可有效地避免传统碱熔和混合酸酸溶法的缺点,具有更为环保和低能耗的优点,同时可有效地降低化学分析实验室样品分析测试过程中酸气污染物的排放,可为战略性钨钼矿床资源开发和综合利用提供基础支撑。

-

关键词:

- 直接烧结 /

- 电感耦合等离子体发射光谱法 /

- 钨钼矿石 /

- 钨 /

- 钼

Abstract:BACKGROUND Tungsten-molybdenum ore is generally composed of a variety of minerals with complex composition. It is insoluble in hydrochloric acid, nitric acid and aqua regia, and the alkali melting and mixed acid dissolution method was often selected for sample digestion. However, the matrix effect cause by the alkali melting method seriously affects the accuracy and detection limit of instrument testing; the acid dissolution method has low dissolution efficiency for tungsten, molybdenum and other insoluble elements, and requires a long time and a complex pretreatment process by using a variety of inorganic strong acids such as hydrofluoric acid and aqua regia, which can also cause damage to the analytical and testing instruments.

OBJECTIVES To develop a simple and efficient method for quantitative analysis of tungsten and molybdenum and its associated elements in tungsten-molybdenum ore.

METHODS Based on alkaline melting and acid dissolution, a method was established by inductively coupled plasma-optical emission spectrometry (ICP-OES) with direct sintering and complex extraction of hydrochloric acid-phosphoric acid-citric acid. Seven elements (tungsten, molybdenum, copper, lead, zinc, calcium, and iron) were analyzed in tungsten-molybdenum ore. The tungsten ore standard substances (GBW07240 and GBW07241), molybdenum ore standard substances (GBW07238 and GBW07239) and two actual tungsten-molybdenum ore samples were used to verify the method.

RESULTS Compared with the traditional alkali melting method, the minerals containing the target elements in the samples were converted to acid soluble state by direct high-temperature sintering, and the target elements were transferred to the solution under the complexation of the mixed acid system of hydrochloric acid, phosphoric acid and citric acid, so as to achieve rapid and accurate quantitative determination. The optimal experimental conditions were: sintering at 600°C for 1h, extraction with 5mL mixed acid composed of phosphoric acid and hydrochloric acid (V/V=1:20), complexation with 5mL of citric acid with a concentration of 10g/L, and determination after filtration. The results showed that the contents of the seven target elements were within the standard value range, and the relative error and relative standard deviation (RSD) were within 10%.

CONCLUSIONS The sample pretreatment method combined with direct high-temperature sintering and complex extraction of hydrochloric acid-phosphoric acid-citric acid can be used to effectively avoid the shortcomings of traditional alkali melting and mixed acid dissolution method, and has the advantages of environmental protection and low energy consumption. At the same time, it can effectively reduce the emission of acid gas pollutants in the sample analysis and testing process and has a good application prospect. The results provide basic support for the development and comprehensive utilization of strategic tungsten-molybdenum deposit resources.

-

-

表 1 不同酸度对GBW07238钨钼测定结果的影响

Table 1. Effect of different acidity on the determination of tungsten and molybdenum in GBW07238.

待测元素 标准值

(%)盐酸不同用量下的测定值(%) 盐酸

2.5mL盐酸

5mL盐酸

12.5mL盐酸

25mLW 0.36±0.3 0.34 0.36 0.32 0.30 Mo 1.51±0.3 1.41 1.52 1.45 1.40 表 2 不同柠檬酸(10g/L)添加量对GBW07238钨钼测定结果的影响

Table 2. Effect of different addition amount of citric acid on the determination of W and Mo in GBW07238.

待测元素 标准值

(%)柠檬酸不同用量下的测定值(%) 柠檬酸

1mL柠檬酸

2mL柠檬酸

5mL柠檬酸

10mLW 0.36±0.3 0.30 0.33 0.37 0.42 Mo 1.51±0.3 1.49 1.50 1.51 1.47 表 3 柠檬酸对GBW07238钨钼测量稳定性的影响

Table 3. Effect of citric acid on the measurement stability ofW and Mo in GBW07238.

放置天数

(d)不加柠檬酸 加5mL柠檬酸 W含量

测定值

(%)Mo含量

测定值

(%)W含量

测定值

(%)Mo含量

测定值

(%)0 0.29 1.47 0.37 1.52 1 0.27 1.45 0.36 1.51 2 0.25 1.43 0.37 1.50 4 0.24 1.40 0.36 1.49 7 0.22 1.38 0.37 1.49 表 4 元素测量波长和方法检出限

Table 4. Measured wavelengths of elements and detection limits of the method.

元素 测量波长

(nm)方法检出限

(%)元素 测量波长

(nm)方法检出限

(%)W 224.876 0.0014 Zn 213.856 0.0023 Mo 202.030 0.0017 CaO 317.933 0.0045 Cu 324.754 0.0024 TFe2O3 259.900 0.0067 Pb 220.353 0.0027 表 5 方法准确度和精密度(n=11)

Table 5. Accuracy and precision tests of the method (n=11).

标准物质编号 参数 W Mo Cu Pb Zn CaO TFe2O3 GBW07238 标准值(%) 0.36* 1.51* 93.6 18.7 65.5 31.44* 21.34* 测定值(%)

RSD(%)0.35*

1.211.52*

0.7592.1

2.32/

/63.4

4.5331.02*

3.4420.15*

4.09相对误差(%) 2.78 0.66 1.60 / 3.21 1.34 5.58 GBW07239 标准值(%) 0.10* 0.11* 48.6 26.1 120 23.03* 14.66* 测定值(%) 0.10* 0.11* 52.5 / 125 21.56* 14.59* RSD(%) 1.47 0.82 3.78 / 1.16 3.88 4.67 相对误差(%) 0.00 0.00 7.43 / 4.17 6.38 0.48 GBW07240 标准值(%) 150 4.2 790 0.29* 0.26* 37.33* 7.79* 测定值(%) 161 / 805 0.28* 0.27* 37.56* 7.76* RSD(%) 7.62 / 0.91 0.56 0.48 0.98 1.17 相对误差(%) 7.33 / 1.90 3.45 3.85 0.62 0.39 GBW07241 标准值(%) 2200 980 960 81.2 103 4.17* 5.6* 测定值(%) 2109 966 972 82.5 99.9 4.03* 5.4* RSD(%) 1.23 0.65 1.45 2.67 1.95 2.14 3.55 相对误差(%) 4.14 1.43 1.25 1.60 3.01 3.36 3.57 注:带“*”的数据单位为%,其余数据单位均为μg/g。 表 6 钨钼矿石中钨钼等元素三种测定方法综合对比

Table 6. Comprehensive comparison of the three methods for determination of W and Mo in tungsten-molybdenum ore.

表 7 实际样品不同方法分析结果对比

Table 7. Comparison of analytical results determined by different methods for actual samples.

-

[1] Wang X, Qin W Q, Jiao F, et al. Review on development of low-grade scheelite recovery from molybdenum tailings in Luanchuan, China: A case study of Luoyang Yulu Mining Company[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(3): 2318−2338.

[2] Hussain A, Noor H Y, Afsar U, et al. Acid recovery from molybdenum metallurgical wastewater via selective electrodialysis and nanofiltration[J]. Separation and Purification Technology, 2022, 295: 121318. doi: 10.1016/j.seppur.2022.121318

[3] 王登红. 关键矿产的研究意义、矿种厘定、资源属性、找矿进展、存在问题及主攻方向[J]. 地质学报, 2019, 93(6): 1189−1209. doi: 10.3969/j.issn.0001-5717.2019.06.003

Wang D H. Study on critical mineral resources: Significance of research, determination of types, attributes of resources, progress of prospecting, problems of utilization, and direction of exploitation[J]. Acta Geologica Sinica, 2019, 93(6): 1189−1209. doi: 10.3969/j.issn.0001-5717.2019.06.003

[4] 王川, 郭义蓉. 熔融制样-X射线荧光光谱法测定锡矿和钨钼矿中16种组分[J]. 理化检验(化学分册), 2020, 56(7): 765−770.

Wang C, Guo Y R. XRFS determination of 16 components in tin ore and tungsten molybdenum ore with fused sample preparation[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2020, 56(7): 765−770.

[5] 王风, 程相恩, 陈传伟. 电感耦合等离子体原子发射光谱法测定钼矿石中的钨钼[J]. 冶金分析, 2014, 34(6): 53−56. doi: 10.13228/j.issn.1000-7571.2014.06.011

Wang F, Cheng X E, Chen C W. Determination of tungsten and molybdenum in molybdenum ores by inductively coupled plasma-atomic emission spectrometry[J]. Metallurgical Analysis, 2014, 34(6): 53−56. doi: 10.13228/j.issn.1000-7571.2014.06.011

[6] 李纯浪, 白家源, 杨绍辉, 等. ICP-OES连续测定硫化矿石中锌、铜、锡、铁、硫、铅、钨、钼、银、镉十种元素[J]. 世界有色金属, 2019(20): 293−295. doi: 10.3969/j.issn.1002-5065.2019.20.169

Li C L, Bai J Y, Yang S H, et al. Continuous determination of zinc, copper, tin, iron, sulfur, lead, tungsten, molybdenum, silver and cadmium in sulfide ores by ICP-OES[J]. World Nonferrous Metals, 2019(20): 293−295. doi: 10.3969/j.issn.1002-5065.2019.20.169

[7] 黄朝文, 莫凯敏. 碱熔-电感耦合等离子体质谱法测定钨矿石和钼矿石中的钨钼[J]. 当代化工研究, 2023(11): 76−78. doi: 10.20087/j.cnki.1672-8114.2023.11.023

Huang C W, Mo K M. Determination of tungsten and molybdenum in tungsten ore and molybdenum ores by inductively coupled plasma-mass spectrometry with alkali fusion[J]. Modern Chemical Research, 2023(11): 76−78. doi: 10.20087/j.cnki.1672-8114.2023.11.023

[8] 杨小莉, 杨小丽, 李小丹, 等. 敞开酸溶-电感耦合等离子体质谱法同时测定钨矿石和锡矿石中14种微量元素[J]. 岩矿测试, 2014, 33(3): 321−326. doi: 10.3969/j.issn.0254-5357.2014.03.006

Yang X L, Yang X L, Li X D, et al. Simultaneous determination of 14 trace elements in and tin ore with open acid digestion by inductively coupled plasma-mass spectrometry[J]. Rock and Mineral Analysis, 2014, 33(3): 321−326. doi: 10.3969/j.issn.0254-5357.2014.03.006

[9] 王蕾, 张保科, 马生凤, 等. 封闭压力酸溶-电感耦合等离子体光谱法测定钨矿石中的钨[J]. 岩矿测试, 2014, 33(5): 661−664. doi: 10.3969/j.issn.0254-5357.2014.05.008

Wang L, Zhang B K, Ma S F, et al. Determination of wolfram in tungsten ore by pressurized acid digestion-inductively coupled plasma-atomic emission spectrometry[J]. Rock and Mineral Analysis, 2014, 33(5): 661−664. doi: 10.3969/j.issn.0254-5357.2014.05.008

[10] 李延超, 梁静, 李来平, 等. 电感耦合等离子体发射光谱法同时测定钨锡矿中6种元素[J]. 中国钨业, 2019, 34(4): 70−74. doi: 10.3969/j.issn.1009-0622.2019.04.013

Li Y C, Liang J, Li L P, et al. Simultaneous determination of 6 elements in tungsten and tin ores by inductively coupled plasma emission spectrometry[J]. China Tungsten Industry, 2019, 34(4): 70−74. doi: 10.3969/j.issn.1009-0622.2019.04.013

[11] 鲁忍. 微波消解-电感耦合等离子体原子发射光谱法测定钨矿石中钨[J]. 化学分析计量, 2020, 29(6): 105-108.

Lu R. Determination of tungsten in tungsten ore by inductively coupled plasma atomic emission spectrometry with microwave digestion[J]. Chemical Analysis and Meterage, 2019, 29(6): 105−108.

[12] 颜忠国, 杨洁懿, 刘文艳. 示波极谱法钨钼连续测定[J]. 冶金与材料, 2021, 41(6): 57, 59.

Yan Z G, Yang J Y, Liu W Y. Continuous determination of tungsten and molybdenum by oscillopolarography[J]. Metallurgy and Materials, 2021, 41(6): 57, 59.

[13] 姜云军, 李星, 姜海伦, 等. 碱熔-离子交换树脂分离-电感耦合等离子体原子发射光谱法测定钨钼矿石中的钨、钼、硼、硫和磷[J]. 理化检验(化学分册), 2018, 54(9): 1030−1034.

Jiang Y J, Li X, Jiang H L, et al. Determination of tungsten, molybdenum, boron, sulfur and phosphorus in tungsten and molybdenum ore by inductively coupled plasma atomic emission spectrometry combined with alkali fusion separation using ion exchange resin[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2018, 54(9): 1030−1034.

[14] 王力强, 王家松, 魏双, 等. 偏硼酸锂熔融-电感耦合等离子体发射光谱法测定钨钼矿石中钨钼及11种伴生元素[J]. 岩矿测试, 2021, 40(5): 688−697. doi: 10.15898/j.cnki.11-2131/td.202103190040

Wang L Q, Wang J S, Wei S, et al. Determination of W, Mo and 11 other elements in tungsten-molybdenum ores by inductively coupled plasma-optical emission spectrometry with Lithium metaborate fusion[J]. Rock and Mineral Testing, 2021, 40(5): 688−697. doi: 10.15898/j.cnki.11-2131/td.202103190040

[15] 秦海娜, 尚世超, 倪高波, 等. 硫酸磷酸溶解-电感耦合等离子体发射光谱法测定钨矿石中的钨钼铜[J]. 分析仪器, 2023(2): 57−61. doi: 10.3969/j.issn.1001-232x.2023.02.010

Qin H N, Shang S C, Ni G B, et al. Determination of tungsten, molybdenum and copper in tungsten ore by sulfuric acid and phosphoric acid solution-inductively coupled plasma emission spectrometry[J]. Analytical Instrumention, 2023(2): 57−61. doi: 10.3969/j.issn.1001-232x.2023.02.010

[16] 党铭铭, 杨萍, 雷勇, 等. 电感耦合等离子体发射光谱技术测定多金属伴生矿中钨钼铋两种消解方法的对比[J]. 岩矿测试, 2021, 40(4): 603−611. doi: 10.15898/j.cnki.11-2131/td.202103050032

Dang M M, Yang P, Lei Y, et al. Comparison of two different sample digestion methods for determination of tungsten, molybdenum, and bismuth in polymetallic ore by inductively coupled plasma-optical emission spectrometry[J]. Rock and Mineral Analysis, 2021, 40(4): 603−611. doi: 10.15898/j.cnki.11-2131/td.202103050032

[17] 杨萍, 党铭铭, 郭永艳, 等. 五酸消解-电感耦合等离子体原子发射光谱法测定矽卡岩型多金属钨矿中钨、钼、铋的含量[J]. 理化检验(化学分册), 2022, 58(7): 773−776.

Yang P, Dang M M, Guo Y Y, et al. Determination of W, Mo and Bi in skarn-type polymetallic tungsten ore by ICP-AES with penta acid digestion[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2022, 58(7): 773−776.

[18] 曹俊飞, 王婷, 李剑, 等. 微波消解-电感耦合等离子体质谱法测定钨钼矿中多种微量稀土元素[J]. 岩矿测试, 2023, 42(4): 861−873. doi: 10.15898/j.ykcs.202210190200

Cao J F, Wang T, Li J, et al. Determination of trace rare earth elements content in tungsten-molybdenum ore by inductively coupled plasma mass spectrometry with microwave digestion system[J]. Rock and Mineral Analysis, 2023, 42(4): 861−873. doi: 10.15898/j.ykcs.202210190200

[19] 赵志飞, 储溱, 向兆, 等. 电感耦合等离子体质谱法同时测定矿石中钨钼铜[J]. 冶金分析, 2012, 32(3): 20−24. doi: 10.3969/j.issn.1000-7571.2012.03.004

Zhao Z F, Chu Q, Xiang Z, et al. Simultaneous determination of tungsten, molybdenum and copper in ores by inductively coupled plasma-mass spectrometry[J]. Metallurgical Analysis, 2012, 32(3): 20−24. doi: 10.3969/j.issn.1000-7571.2012.03.004

[20] 杨林, 邹国庆, 周武权, 等. 碱熔-电感耦合等离子体发射光谱(ICP-OES)法测定钨锡矿石中钨锡钼铜铅锌硫砷[J/OL]. 中国无机分析化学. [2023-07-25].https://kns.cnki.net/kcms2/detail/11.6005.o6.20230724.1021.002.html.

Yang L, Zou G G, Zhou W Q, et al. Determination of W, Sn, Mo, Cu, Pb Zn, S, As in Tungsten-tin ore by inductively coupled plasma optical emission Spectrometry with alkali fusion[J/OL]. Inorganic Analytical Chemistry in China. [2023-07-25].https://kns.cnki.net/kcms2/detail/11.6005.o6.20230724.1021.002.html.

[21] 张征莲, 施意华, 唐碧玉, 等. 电感耦合等离子体质谱(ICP-MS)法测定炭质页岩中的钨钼钪[J]. 中国无机分析化学, 2021, 11(4): 39−44. doi: 10.3969/j.issn.2095-1035.2021.04.008

Zhang Z L, Shi Y H, Tang B Y, et al. Determination of tungsten, molybdenum and scandium in carbon shale by inductively coupled plasma mass spectrometry[J]. Chinese Journal of Inorganic Analytical Chemistry, 2021, 11(4): 39−44. doi: 10.3969/j.issn.2095-1035.2021.04.008

[22] 张邦胜, 肖连生, 张启修. 沉淀法分离钨钼的研究进展[J]. 江西有色金属, 2001(2): 26−29. doi: 10.3969/j.issn.1674-9669.2001.02.008

Zhang B S, Xiao L S, Zhang Q X. Progress in W/Mo separation by precipitation[J]. Jiangxi Nonferrous Metals, 2001(2): 26−29. doi: 10.3969/j.issn.1674-9669.2001.02.008

[23] 张聪, 王清良, 周龙, 等. 难溶含铀碱渣氧化焙烧酸浸试验研究[J]. 矿冶工程, 2022, 42(4): 116−119.

Zhang C, Wang Q L, Zhou L, et al. Experimental study on treating refractory alkaline uranium-containing residue by oxidative roasting and acid leaching[J]. Mining and Metallurgical Engineering, 2022, 42(4): 116−119.

[24] Zhu Y, Guo B, Zuo W R, et al. Effect of sintering temperature on structure and properties of porous ceramics from tungsten ore tailings[J]. Materials Chemistry and Physics, 2022, 287: 126315. doi: 10.1016/j.matchemphys.2022.126315

[25] 杨炳红, 符招弟, 傅饶, 等. 复杂钼矿石中钼的化学物相分析[J]. 冶金分析, 2020, 40(4): 23−28. doi: 10.13228/j.boyuan.issn1000-7571.010828

Yang B H, Fu Z D, Fu R, et al. Chemical phase analysis of molybdenum in complex molybdenum ore[J]. Metallurgical Analysis, 2020, 40(4): 23−28. doi: 10.13228/j.boyuan.issn1000-7571.010828

[26] 韩跃新, 靳建平, 李慧, 等. 基于XRD和SEM的含碳微细粒金矿氧化焙烧机理研究[J]. 光谱学与光谱分析, 2018, 38(5): 1592−1598.

Han Y X, Jin J P, Li H, et al. Study on the mechanism of oxidation roasting of carbonaceous fine-grained gold ores based on XRD and SEM[J]. Spectroscopy and Spectral Analysis, 2018, 38(5): 1592−1598.

[27] 王鑫尧, 杨洪英, 康建, 等. 复杂钼钨矿石溶浸试验[J]. 有色金属(冶炼部分), 2023(5): 75−80.

Wang X Y, Yang H Y, Kan J, et al. Leaching experiment of low-grade complex molybdenum tungsten ore[J]. Nonferrous Metals (Extractive Metallurgy), 2023(5): 75−80.

[28] 姜丽帅, 韩百岁, 冷红光, 等. 辉钼矿湿法冶金研究进展[J]. 中国冶金, 2023, 33(2): 22−30,37. doi: 10.13228/j.boyuan.issn1006-9356.20220702

Jiang L S, Han B S, Leng H G, et al. Research progress of hydrometallurgy of molybdenite[J]. China Metallurgy, 2023, 33(2): 22−30,37. doi: 10.13228/j.boyuan.issn1006-9356.20220702

[29] Liu R Z, Zhao Z W, Li Y L. Acid leaching-extraction-circulation process based on Mo(Ⅵ) coordination with H3PO4 to efficiently extract molybdenum from different components of molybdenum calcine[J]. Separation and Purification Technology, 2023, 322: 124269. doi: 10.1016/j.seppur.2023.124269

[30] Xiao X B, Zhang G Q, Guan W J, et al. A novel method for preparing tungsten and molybdenum peroxy complex solution and its application to tungsten-molybdenum separation[J]. Hydrometallurgy, 2023, 215: 105974. doi: 10.1016/j.hydromet.2022.105974

[31] Fu J H, Han H S, Wei Z, et al. Selective separation of scheelite from calcite using tartaric acid and Pb-BHA complexes[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 622: 126657. doi: 10.1016/j.colsurfa.2021.126657

-

下载:

下载: