An experimental study of the California bearing ratio of basalt fiber reinforced loess

-

摘要:

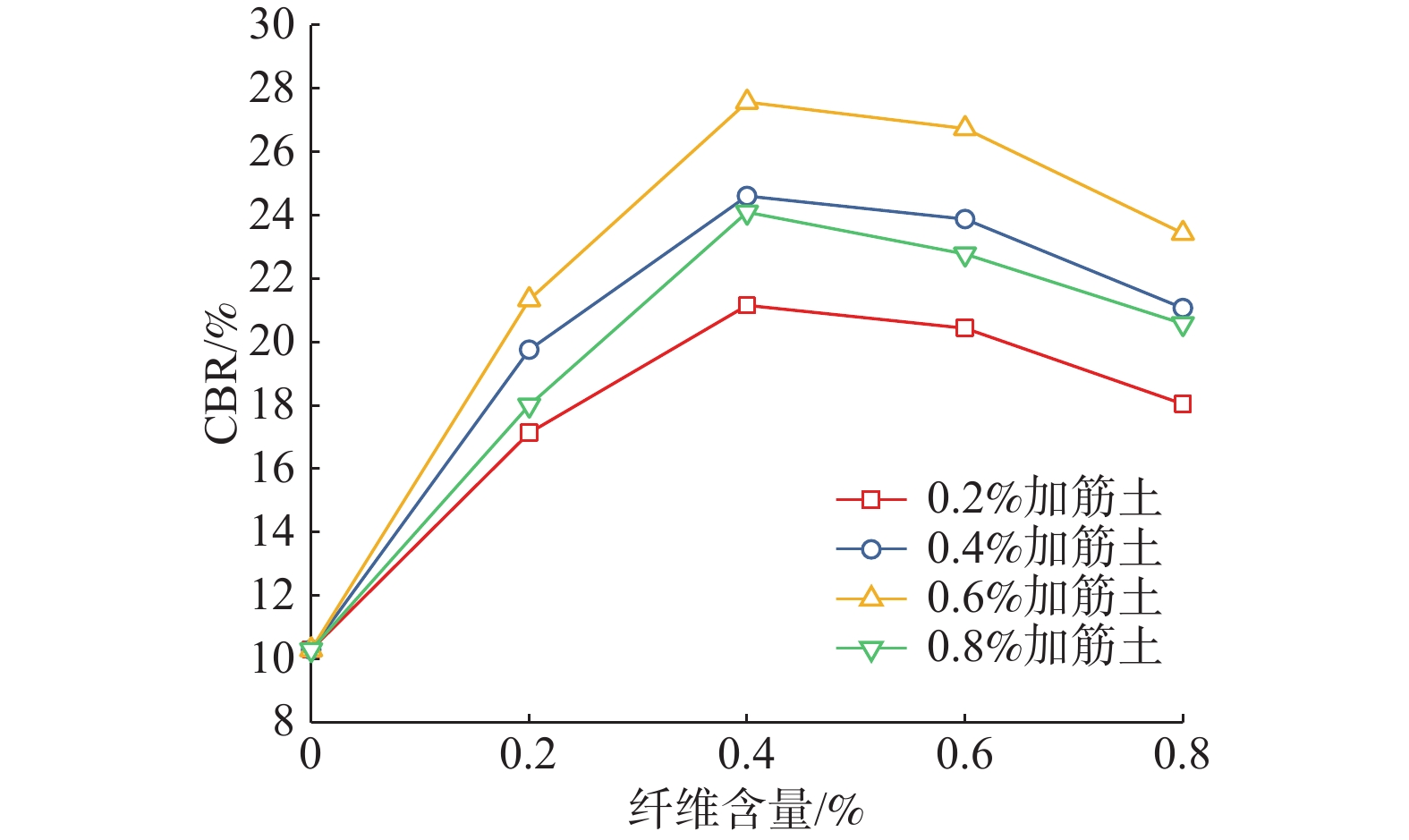

为研究纤维加筋黄土CBR值影响因素及纤维增强土体机理,以短切玄武岩纤维为筋材,通过改变土体含水率、纤维长度、纤维含量、击实次数、浸水时间等条件进行加州承载比试验,探究初始含水率、纤维参数及试验方法对加筋土局部抗剪强度的影响规律。结果表明:纤维加筋土CBR值随含水率的增加呈现先增大后减小的趋势,存在“施工最优含水率”且相比击实试验最优含水率高1%~3%左右;纤维加筋土CBR值高于黄土CBR值,确定纤维长度20 mm,纤维含量0.4%为最优配比;击实次数从30击增加到98击,黄土CBR值提高273%,纤维加入后CBR值提高327%,加筋作用使土体通过提高击实功来提升强度的效果更加显著;浸水对试样CBR值影响较大,浸水时间对试样CBR值影响较小,且纤维的加入使试样对浸水时间的敏感度进一步降低,加筋土浸水2 d后强度降低54%,浸水4 d后强度降低58%。

Abstract:In order to study the factors affecting the CBR value of the fiber-reinforced loess and the mechanism of the fiber-reinforced soil, chopped basalt fiber was used as the reinforcement material, and the CBR test was performed by changing the moisture content, fiber length, fiber content, compaction times and soaking time. The experiment explored the influence of initial moisture content, fiber parameters and test methods on the local shear strength of the reinforced soil. The results show that the CBR value of the fiber-reinforced loess has a tendency of increasing first and then decreasing with increasing moisture content. There is an "optimal moisture content for construction" and it is about 1% greater than the optimal moisture content of the compaction test. The CBR value of the reinforced soil is higher than the CBR value of loess. It is found that the fiber length of 20 mm and the fiber content of 0.4% are the optimal ratio. The compaction times increase from 30 to 98, the CBR value increases by 273%, the CBR value increases by 327% after the fiber is added. Reinforcement makes the soil local shear strength more effective by increasing the compaction work. The water immersion has a greater effect on the CBR value of the sample and the soaking time has less effect on it. The sensitivity of the sample to the soaking time is further reduced by the addition of fibers. The strength is reduced by 54% after 2 days of soaking, and the strength is reduced by 58% after 4 days of soaking.

-

Key words:

- CBR value /

- moisture content /

- fiber content /

- fiber length /

- compaction times /

- soaking time

-

-

表 1 黄土的物理性质指标

Table 1. Physical properties of loess

天然密度ρ/(g·cm−3) 比重Gs 天然含水率w/% 塑限wP/% 液限wL/% 塑性指数IP 孔隙比e 1.68 2.71 17.5% 21.2 35.2 14 0.90 表 2 玄武岩纤维的物理力学参数

Table 2. Physical and mechanical parameters of basalt fiber

密度

ρ/(g·cm−3)单丝直径

D/μm抗拉强度/

MPa弹性模量/

GPa使用温度/

℃耐酸碱性 2.63 13 3000~4800 91~110 −270~650 极强 表 3 加筋土试验参数

Table 3. Test parameters of the reinforced soil samples

纤维长度/mm 纤维含量/% w=11.1% w=12.1% w=13.1% w=14.1% w=15.1% 5 0 0.2 0.4 0.6 0.8 10 0 0.2 0.4 0.6 0.8 20 0 0.2 0.4 0.6 0.8 40 0 0.2 0.4 0.6 0.8 表 4 不同击实次数、浸水时间的试验参数

Table 4. Test parameters of different compaction times and soaking times

土样 浸水时间/d 击实次数0 击实次数50 击实次数98 素土 0 2 4 加筋土 0 2 4 表 5 不同纤维长度及含量的击实试验结果

Table 5. Compaction test results of different fiber contents and lengths

纤维长度/mm 纤维含量/% 最大干密度ρdmax/(g·cm−3) wop /% 0 0 1.95 13.1 5 0.2 1.94 13.5 0.4 1.92 12.9 0.6 1.91 12.7 0.8 1.89 12.6 10 0.2 1.93 13.3 0.4 1.93 12.8 0.6 1.91 12.4 0.8 1.90 12.9 20 0.2 1.93 12.9 0.4 1.92 12.3 0.6 1.92 13.2 0.8 1.90 13.3 40 0.2 1.92 12.6 0.4 1.91 12.7 0.6 1.90 13.3 0.8 1.88 13.0 -

[1] ANAGNOSTOPOULOS C A, TZETZIS D, BERKETIS K. Shear strength behaviour of polypropylene fiber reinforced cohesive soils[J]. Geomechanics and Geoengineering,2014,9(3):241 − 251. doi: 10.1080/17486025.2013.804213

[2] 刘建龙, 侯天顺, 骆亚生. 棉纤维加筋土无侧限抗压强度试验研究[J]. 水力发电学报,2018,37(2):12 − 21. [LIU Jianlong, HOU Tianshun, LUO Yasheng. Unconfined compressive strength of synthetic cotton fibers reinforced soil[J]. Journal of Hydroelectric Engineering,2018,37(2):12 − 21. (in Chinese with English abstract)

[3] 马闫, 谢婉丽, 彭淑君, 等. 加筋方式对黄土动力特性影响三轴试验研究[J]. 水文地质工程地质,2017,44(4):50 − 56. [MA Yan, XIE Wanli, PENG Shujun, et al. Influence of the reinforce scheme on dynamic properties of the reinforced loess with dynamic triaxial test[J]. Hydrogeology & Engineering Geology,2017,44(4):50 − 56. (in Chinese with English abstract)

[4] 吴燕开, 牛斌, 桑贤松. 随机分布剑麻纤维加筋土力学性能试验研究[J]. 水文地质工程地质,2012,39(6):77 − 81. [WU Yankai, NIU Bin, SANG Xiansong. Experimental study of mechanical properties of soil randomly included with sisal fiber[J]. Hydrogeology & Engineering Geology,2012,39(6):77 − 81. (in Chinese with English abstract)

[5] 高磊, 胡国辉, 杨晨, 等. 玄武岩纤维加筋黏土的剪切强度特性[J]. 岩土工程学报,2016,38(增刊 1):231 − 237. [GAO Lei, HU Guohui, YANG Chen, et al. Shear strength characteristics of basalt fiber-reinforced clay[J]. Chinese Journal of Geotechnical Engineering,2016,38(Sup 1):231 − 237. (in Chinese with English abstract)

[6] 陈柏年, 朱凤艳, 韩勤. CBR试验内在机理研究及影响因素的分析[J]. 交通标准化,2001,29(1):28 − 30. [CHEN Bainian, ZHU Fengyan, HAN Qin. Research on the internal mechanism of CBR test and analysis of influencing factors[J]. Communications Standardization,2001,29(1):28 − 30. (in Chinese with English abstract) doi: 10.3869/j.issn.1002-4786.2001.01.010

[7] 朱志铎, 郝建新, 黄立平. CBR试验影响因素及在工程中应注意的几个问题[J]. 岩土力学,2006,27(9):1593 − 1595. [ZHU Zhiduo, HAO Jianxin, HUANG Liping. Influential factors in CBR test and several problems to be noticed in engineering[J]. Rock and Soil Mechanics,2006,27(9):1593 − 1595. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2006.09.034

[8] 袁克阔, 党进谦, 卓莉. 黄土路基CBR值影响因素研究[J]. 路基工程,2009(6):125 − 127. [YUAN Kekuo, DANG Jinqian, ZHUO Li. Study on influencing factors of CBR value of loess subgrade[J]. Subgrade Engineering,2009(6):125 − 127. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-8825.2009.06.063

[9] 李萍, 徐佳祥, 温学涛, 等. 石灰改良黄土路基的CBR试验研究[J]. 甘肃科学学报,2008,20(4):74 − 77. [LI Ping, XU Jiaxiang, WEN Xuetao, et al. CBR experiment study of loess subgrade meliorated with lime[J]. Journal of Gansu Sciences,2008,20(4):74 − 77. (in Chinese with English abstract) doi: 10.3969/j.issn.1004-0366.2008.04.021

[10] 武建民, 顾伟杰, 陈忠达. 黄土路基CBR值试验方法研究[J]. 交通标准化,2005,33(增刊 1):125 − 127. [WU Jianmin, GU Weijie, CHEN Zhongda. Study on CBR test method for loess roadbed[J]. Communications Standardization,2005,33(Sup 1):125 − 127. (in Chinese with English abstract)

[11] 杨和平, 赵鹏程, 郑健龙. 膨胀土填料改进CBR试验方法的提出与验证[J]. 岩土工程学报,2007,29(12):1751 − 1757. [YANG Heping, ZHAO Pengcheng, ZHENG Jianlong. Suggestion and verification on modified CBR test method for expansive soils fill[J]. Chinese Journal of Geotechnical Engineering,2007,29(12):1751 − 1757. (in Chinese with English abstract) doi: 10.3321/j.issn:1000-4548.2007.12.001

[12] 郑军, 阎长虹, 夏文俊, 等. CMSC型固化剂改良土的新型CBR试验研究[J]. 工程地质学报,2008,16(4):551 − 556. [ZHENG Jun, YAN Changhong, XIA Wenjun, et al. Study of new CBR test on improved soil with CMSC firming agent[J]. Journal of Engineering Geology,2008,16(4):551 − 556. (in Chinese with English abstract) doi: 10.3969/j.issn.1004-9665.2008.04.020

[13] 周运瑜, 余江滔, 陆洲导, 等. 玄武岩纤维加固震损混凝土框架节点的抗震性能[J]. 中南大学学报(自然科学版),2010,41(4):1514 − 1521. [ZHOU Yunyu, YU Jiangtao, LU Zhoudao, et al. Seismic behavior of BFRP-reinforced pre-damaged concrete beam-column joints[J]. Journal of Central South University (Science and Technology),2010,41(4):1514 − 1521. (in Chinese with English abstract)

[14] 傅珍, 黄振, 马峰. 玄武岩纤维对老化沥青混合料路用性能的影响[J]. 材料导报,2016,30(2):118 − 122. [FU Zhen, HUANG Zhen, MA Feng. Effect of basalt fiber on the road performance of aged asphalt mixture[J]. Materials Review,2016,30(2):118 − 122. (in Chinese with English abstract)

[15] 交通部公路科学研究院. 公路土工试验规程: JTG E40-2007[S]. 北京: 人民交通出版社, 2007.

Highway Research Institute of Ministry of Communications. Test methods of soils for highway engineering: JTG E40-2007[S]. Beijing: China Communications Press, 2007. (in Chinese)

[16] 张金利, 蒋正国, 杨钢. 聚丙烯纤维红黏土力学特性试验研究[J]. 岩土工程学报,2011,33(增刊 1):427 − 432. [ZHANG Jinli, JIANG Zhengguo, YANG Gang. Experimental study on mechanical behaviors of polypropylene fiber reinforced clay[J]. Chinese Journal of Geotechnical Engineering,2011,33(Sup 1):427 − 432. (in Chinese with English abstract)

[17] 张晓颖, 荣新山, 徐吉成, 等. 玄武岩纤维表面改性对生物膜附着性能的影响[J]. 材料工程,2019,47(5):129 − 136. [ZHANG Xiaoying, RONG Xinshan, XU Jicheng, et al. Effect of surface modification of basalt fiber on biofilm attachment[J]. Journal of Materials Engineering,2019,47(5):129 − 136. (in Chinese with English abstract) doi: 10.11868/j.issn.1001-4381.2018.000189

[18] 郭爱国, 孔令伟, 胡明鉴, 等. 石灰改性膨胀土施工最佳含水率确定方法探讨[J]. 岩土力学,2007,28(3):517 − 521. [GUO Aiguo, KONG Lingwei, HU Mingjian, et al. On determination of optimum water content of lime-treated expansive soil[J]. Rock and Soil Mechanics,2007,28(3):517 − 521. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-7598.2007.03.016

[19] 王德银, 唐朝生, 李建, 等. 纤维加筋非饱和黏性土的剪切强度特性[J]. 岩土工程学报,2013,35(10):1933 − 1940. [WANG Deyin, TANG Chaosheng, LI Jian, et al. Shear strength characteristics of fiber-reinforced unsaturated cohesive soils[J]. Chinese Journal of Geotechnical Engineering,2013,35(10):1933 − 1940. (in Chinese with English abstract)

[20] 唐朝生, 施斌, 顾凯. 纤维加筋土中筋/土界面相互作用的微观研究[J]. 工程地质学报,2011,19(4):610 − 614. [TANG Chaosheng, SHI Bin, GU Kai. Microstructural study on interfacial interactions between fiber reinforcement and soil[J]. Journal of Engineering Geology,2011,19(4):610 − 614. (in Chinese with English abstract) doi: 10.3969/j.issn.1004-9665.2011.04.026

[21] 田堪良, 马俊, 李永红. 黄土结构性定量化参数的探讨[J]. 岩石力学与工程学报,2011,30(增刊 1):3179 − 3184. [TIAN Kanliang, MA Jun, LI Yonghong. Discussion on quantitative parameters of loess structure[J]. Chinese Journal of Rock Mechanics and Engineering,2011,30(Sup 1):3179 − 3184. (in Chinese with English abstract)

-

下载:

下载: