Wheat straw anticorrosion analysis based on pore area ratio and the effect of straw on the shear strength of silty soil

-

摘要:

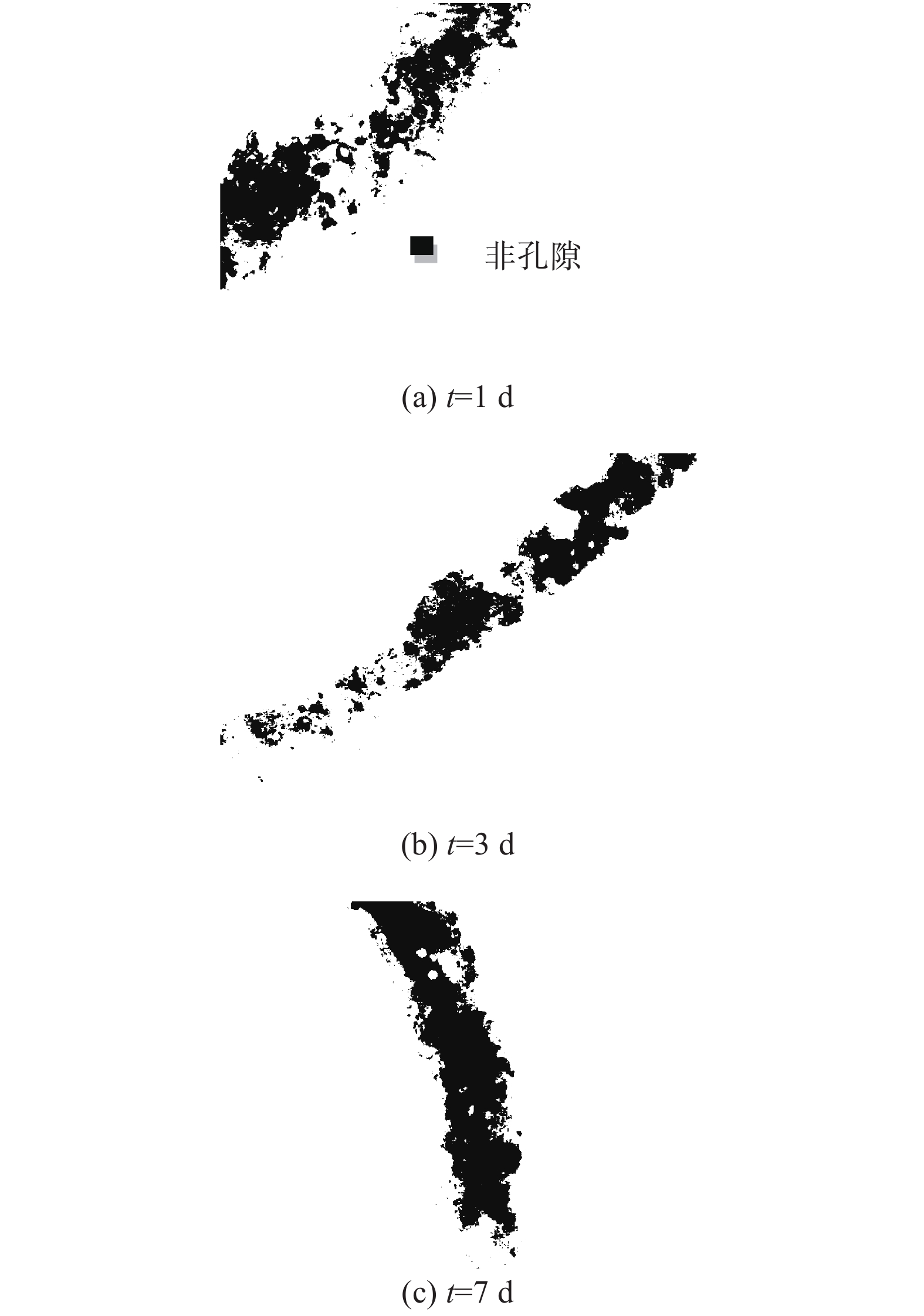

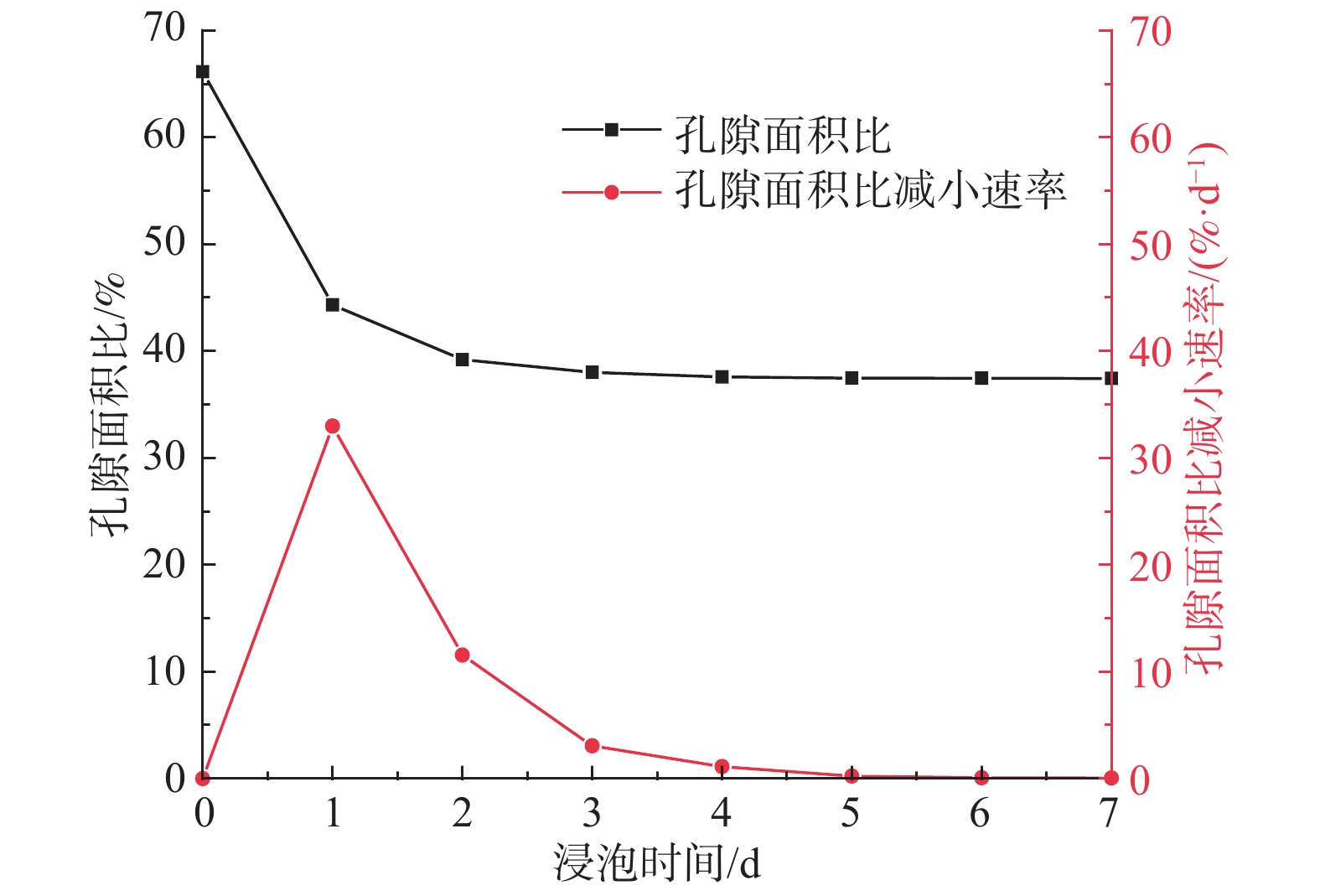

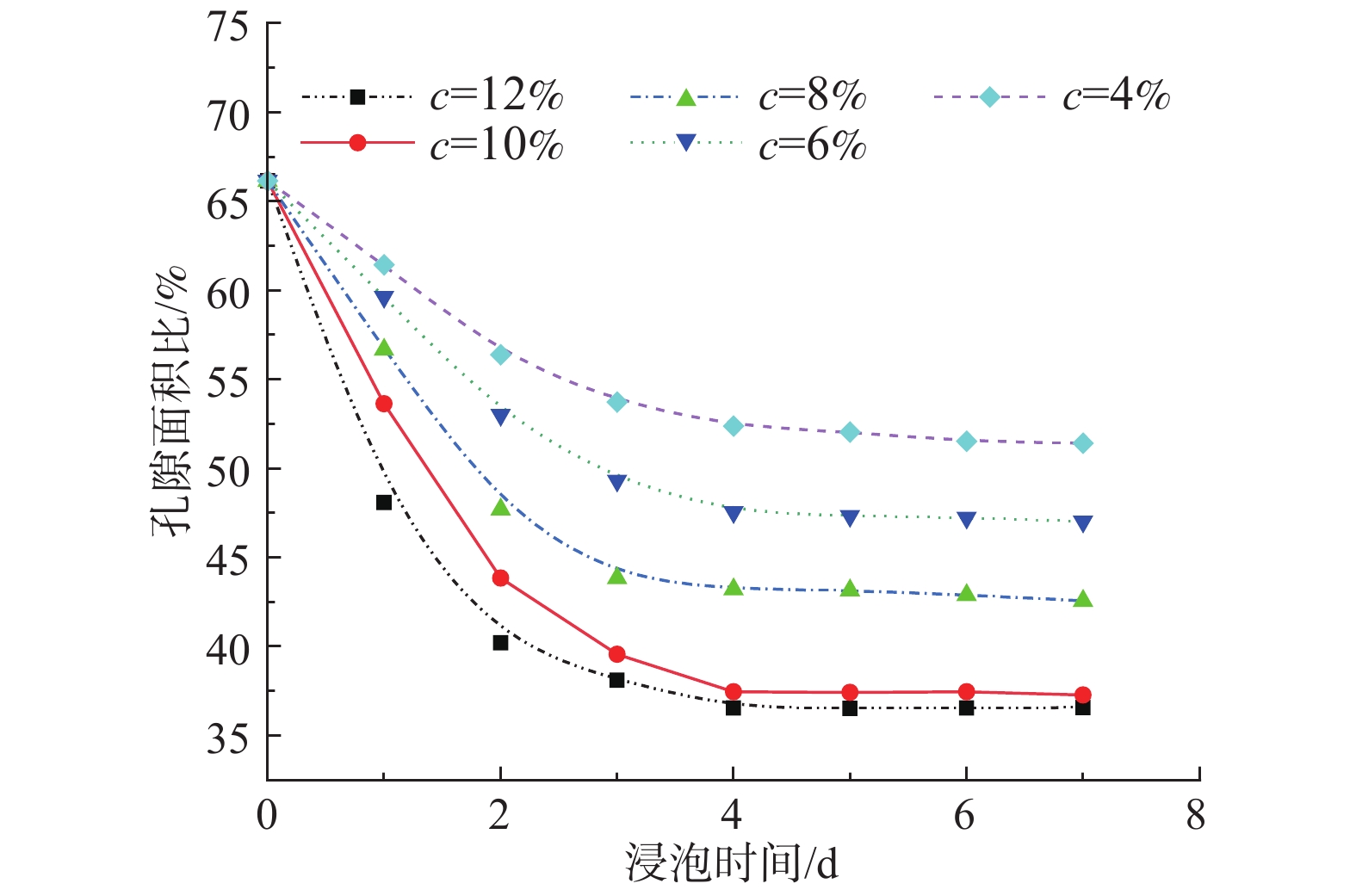

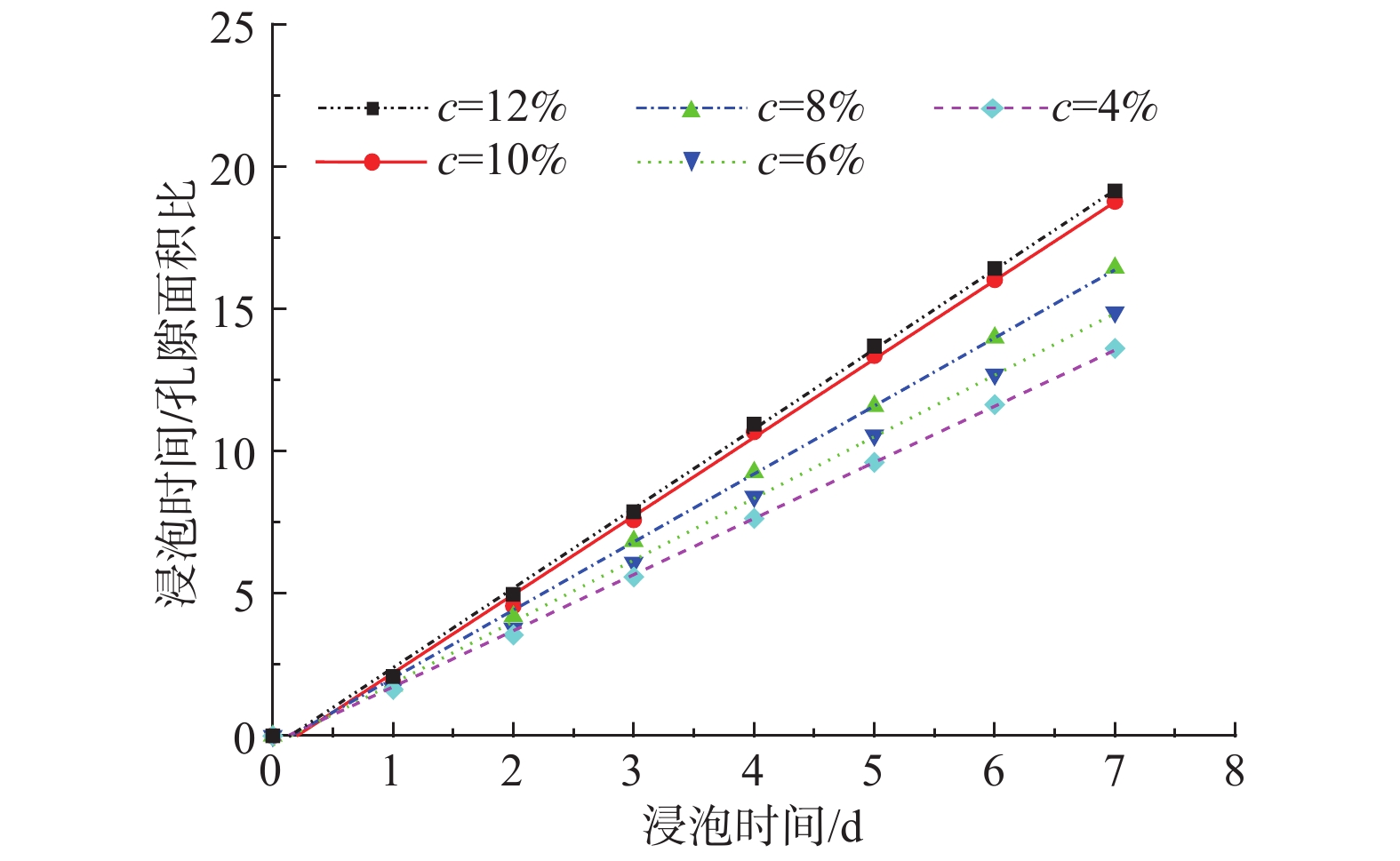

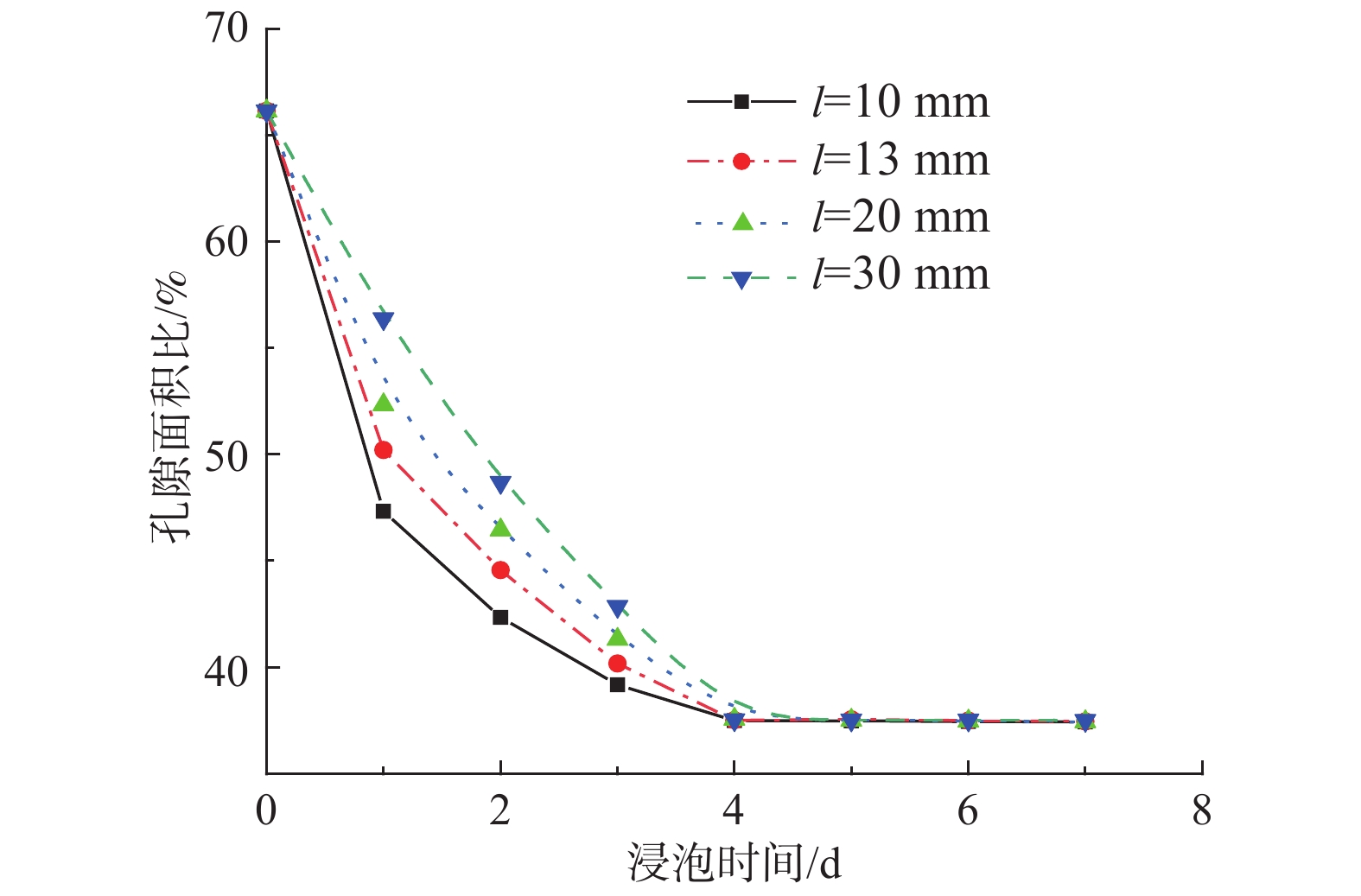

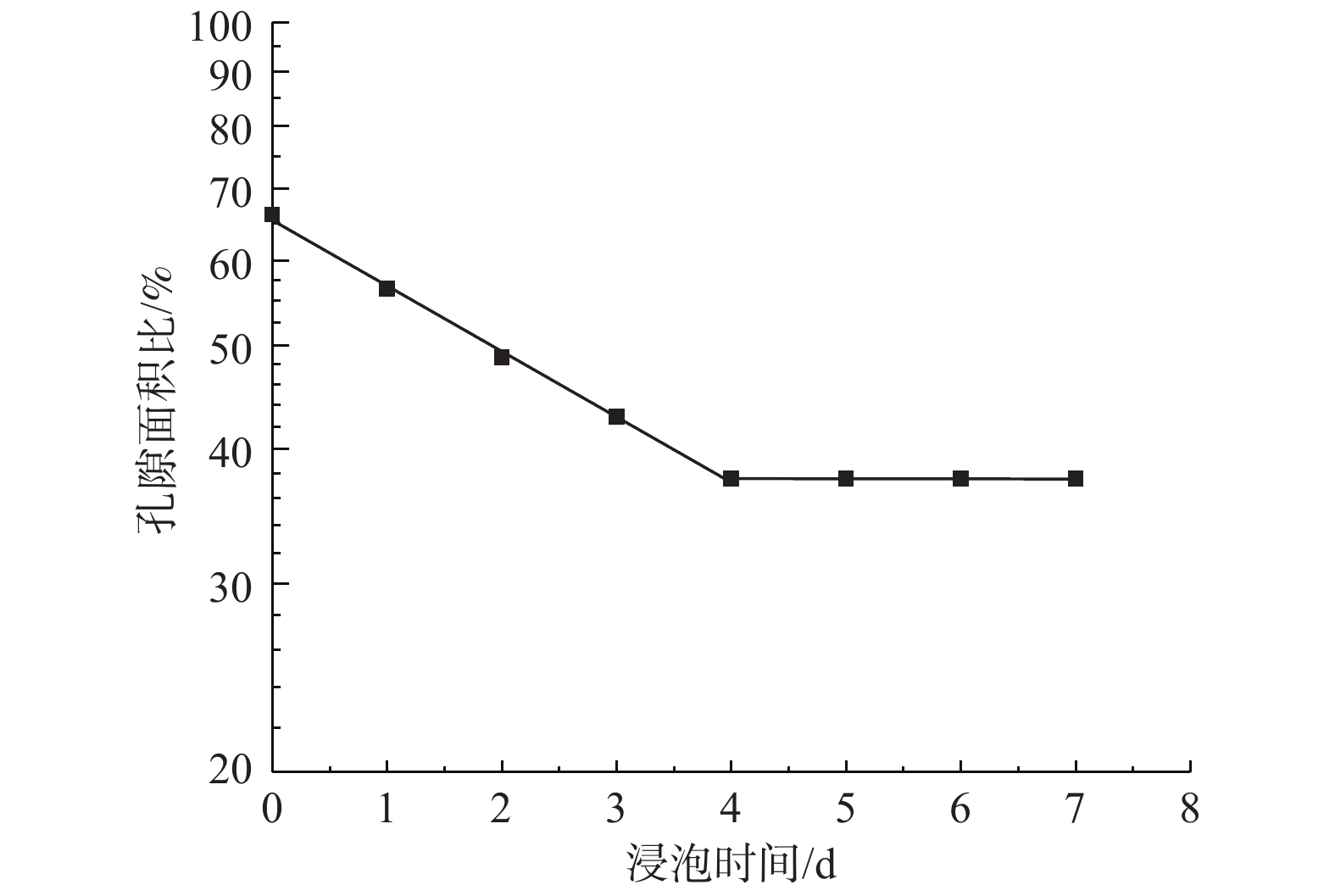

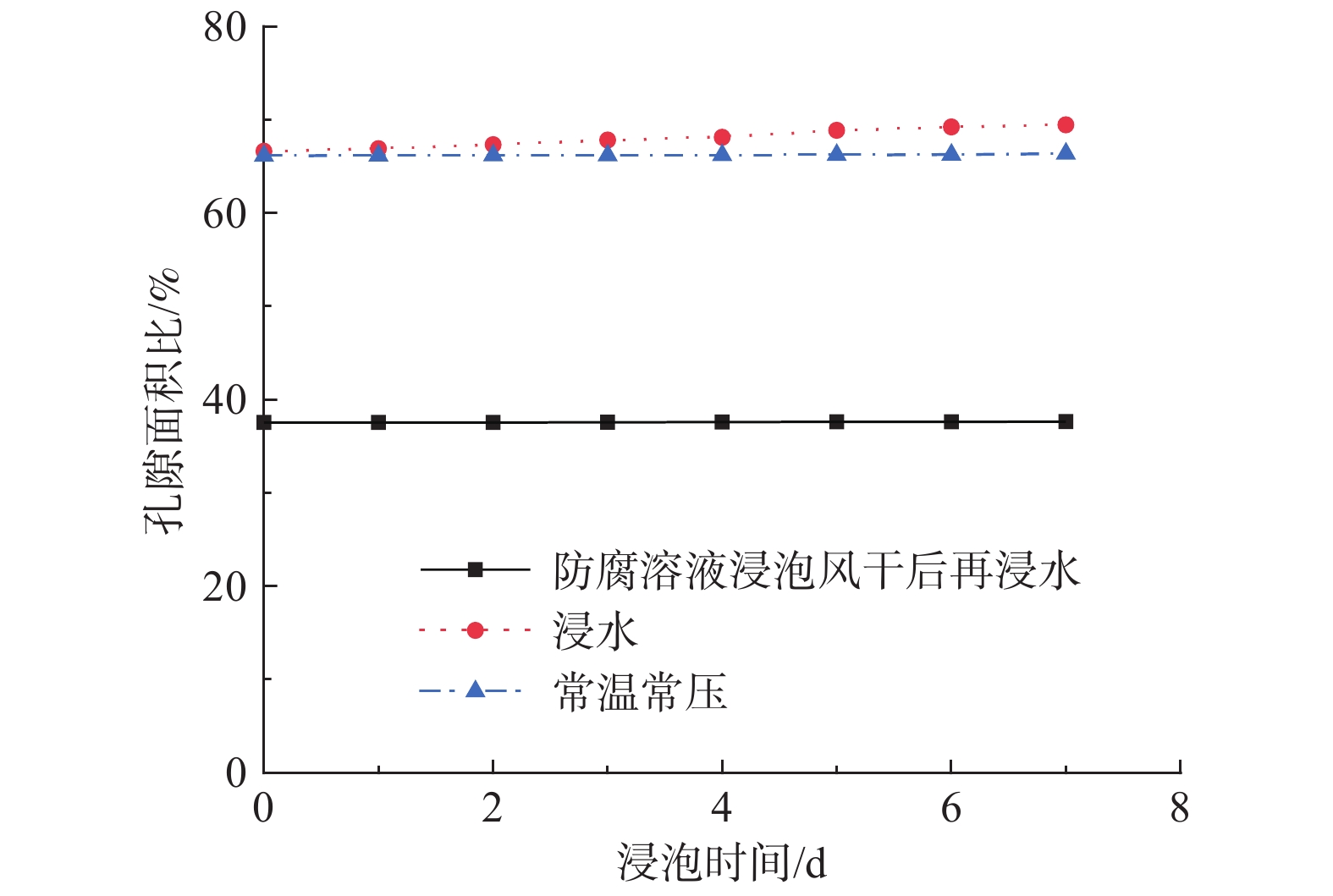

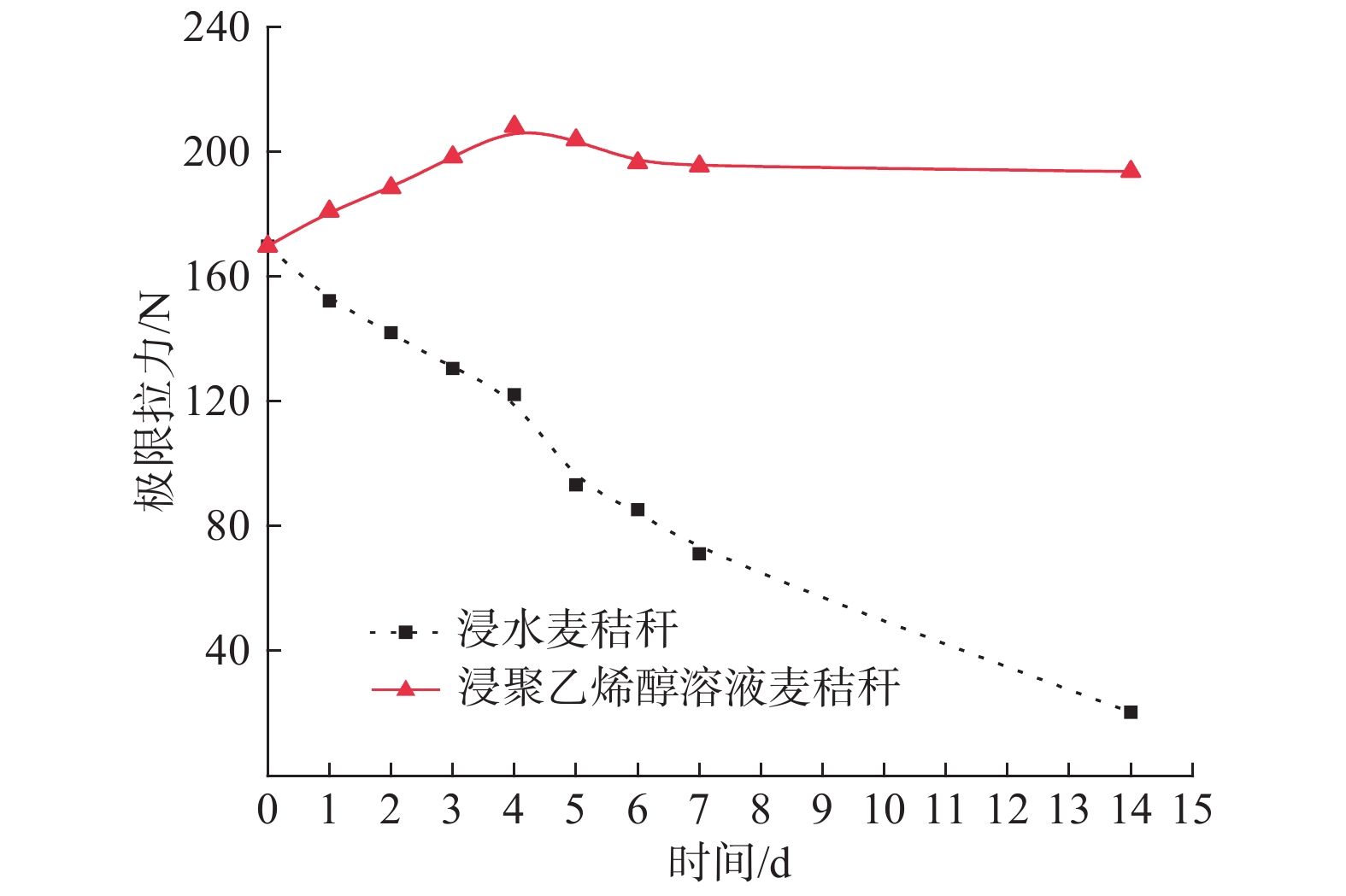

粉土性能不良,需改良后才能在高速公路路基中使用;麦秸秆环保可再生,掺入粉土会起到加筋作用,但自身易被水腐蚀,需防腐后才能使用。本文从孔隙面积比出发,分析聚乙烯醇对秸秆的防腐机理和防腐效果,通过抗拉强度试验分析防腐对秸秆抗拉强度的影响;通过直剪试验分析秸秆对粉土抗剪强度的影响。结果表明:聚乙烯醇通过自身防腐性能的发挥、填充麦秸秆孔隙减小吸水通路、在秸秆表面形成保护膜阻隔水分进入来实现防腐,孔隙面积比越小防腐效果越好;试验范围内,麦秸秆的防腐最佳浸泡时间为4 d,防腐剂最佳溶液浓度为10%,此时秸秆孔隙面积比最小,且防腐耗时最短,或经济最优。麦秸秆长度对孔隙面积比的影响主要在4 d内,与最终孔隙面积比关系不大。防腐麦秸秆抗拉强度提高。秸秆加筋土的黏聚力随秸秆掺量、麦秸秆长度的增加先增大后减小,最优掺量范围为0.4%~0.6%,最优秸秆长度为15 mm;内摩擦角随着秸秆掺量的增加略有增加,但增幅很小,不同长度下无明显规律。

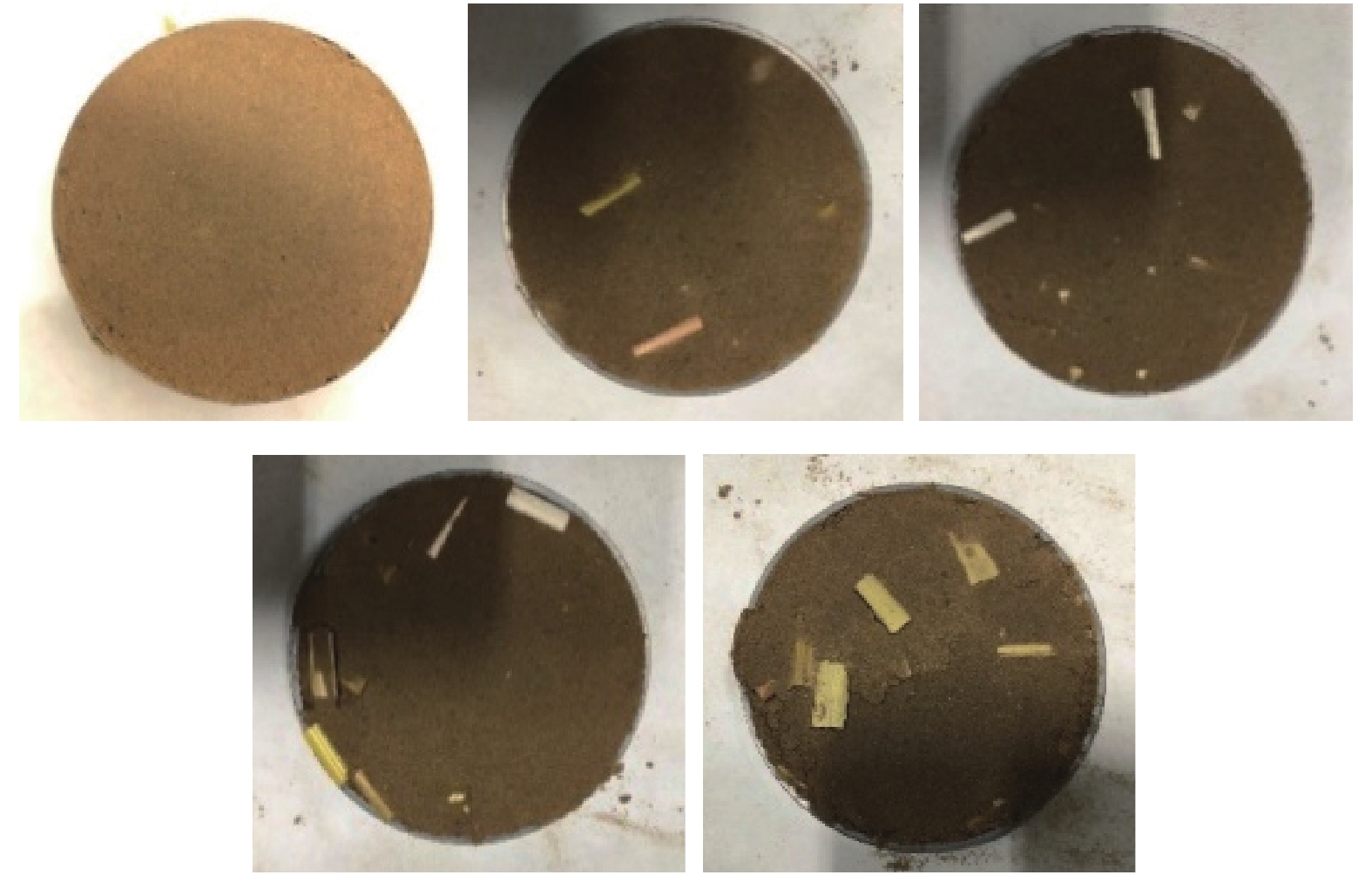

Abstract:Silty soil is of poor performance and is needed to improve before it can be used in highway subgrades. Wheat straw is environmentally friendly and renewable. When mixed with silty soil, wheat straw can play a reinforcing role, but it is easily corroded by water and can be used after corrosion protection. Based on the pore area ratio, this paper analyzes the anticorrosion mechanism and anticorrosion effect of polyvinyl alcohol on straw, the effect of anticorrosion on the tensile strength through the tensile strength test and the effect of straw on the shear strength of silty soil through the direct shear test. The results show that polyvinyl alcohol exerts its own anti-corrosion performance, fills the straw pores to reduce water absorption channels, and forms a protective film on the straw surface to block water from entering to achieve anti-corrosion. The smaller the pore area ratio, the better the anti-corrosion effect. The best soaking time for straw preservative is 4 days, and the best solution concentration for preservatives is 10%. At this time, the straw pore area ratio is the smallest, and the time for preserving is the shortest or economically optimal. The effect of the length of wheat straw on the pore area ratio is mainly within 4 days, and is not related to the final pore area ratio. The tensile strength of the anticorrosive wheat straw is increased. The cohesion of straw reinforced soil increases first and then decreases with the increase of straw content and wheat straw length. The optimal content range from 0.4% to 0.6%, and the optimal straw length is 15 mm. The internal friction angle increases slightly with the increasing straw content, but the increase is very small, and there is no obvious pattern under different lengths.

-

Key words:

- wheat straw /

- pore area ratio /

- binary method /

- anticorrosion mechanism /

- antiseptic effect /

- shear strength

-

-

表 1 颗粒粒径组成

Table 1. Particle size composition

粒径/mm 5~2 2~0.5 0.5~0.25 0.25~0.075 0.075~0.005 ≤0.005 含量/% 1.74 1.86 1.21 2.12 92.88 0.19 表 2 基于材料和时间因素的麦秸秆孔隙面积比测定

Table 2. Wheat straw pore area ratio determination based on material and time factors

麦秸秆长度l/mm 浸泡麦秸秆质量m/g 取用麦秸秆根数n 防腐剂溶液浓度c/% 溶液体积v/mL 浸泡时间t/d 20 10 5 4,6,8,10,12 900 1,2,3,4,5,6,7 10,15,20,30 10 5 试验测得的最佳浓度 900 1,2,3,4,5,6,7 说明:为减小误差,对浸泡聚乙烯醇溶液中的麦秸秆,在规定浸泡天数后每次均取出5根,在40 ℃的温度下烘干10 h去除少量水分的影响后,对5根分别进行孔隙面积比测定并取均值,以下秸秆孔隙面积比的测定也采用了同样的方法。 表 3 不同浓度下公式(1)拟合后的参数值

Table 3. Parameter values at different concentrations

浓度参数 4% 6% 8% 10% 12% a −0.2427 −0.32263 −0.35864 −0.54855 −0.39861 b 1.97152 2.16722 2.39111 2.75855 2.79711 R2 0.99935 0.99895 0.99891 0.99794 0.9989 表 4 不同长度下0~4 d范围内的曲线拟合参数

Table 4. Curve fitting parameters in the range of 0 to 4 days under different lengths

长度参数/mm 10 15 20 30 p 4.08234 4.11608 4.14074 4.18001 q −0.13241 −0.13569 −0.13679 −0.14072 R2 0.84911 0.92447 0.96535 0.99782 -

[1] 张笑峰, 张艳美, 刘锦程, 等. 纤维与粉煤灰改良粉土的正交试验分析[J]. 水利与建筑工程学报,2019,17(1):36 − 40. [ZHANG Xiaofeng, ZHANG Yanmei, LIU Jincheng, et al. Orthogonal test analysis of improved silt with fiber and fly ash[J]. Journal of Water Resources Architectural Engineering,2019,17(1):36 − 40. (in Chinese with English abstract)

[2] 肖军华. 循环荷载下路基压实粉土的临界应力与应变水平[J]. 水文地质工程地质,2010,37(5):61 − 66. [XIAO Junhua. The threshold stress and strain levels of compacted silt under repeated loadings[J]. Hydrogeology & Engineering Geology,2010,37(5):61 − 66. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-3665.2010.05.011

[3] 谭毓清, 彭成, 田宗坤. 石灰改良路基填料的动力特性试验研究[J]. 南华大学学报(自然科学版),2020,34(1):81 − 87. [TAN Yuqing, PENG Cheng, TIAN Zongkun. Experimental study of dynamic characteristics of lime modified roadbed filler[J]. Journal of University of South China (Science and Technology),2020,34(1):81 − 87. (in Chinese with English abstract)

[4] 潘望文. 水泥改良黏性土的循环动力特性[J]. 湖南理工学院学报(自然科学版),2020,33(1):38 − 43. [PAN Wangwen. Dynamic characteristics of cement-improved cohesive soil under cyclic loading[J]. Journal of Hunan Institute of Science and Technology (Natural Sciences),2020,33(1):38 − 43. (in Chinese with English abstract)

[5] 张沛云, 马学宁. 水泥改良黄土路基动力稳定性评价参数试验研究[J]. 水文地质工程地质,2019,46(2):141 − 147. [ZHANG Peiyun, MA Xuening. An experimental study of the evaluation parameters of dynamic stability of the cement-improved loess subgrade[J]. Hydrogeology & Engineering Geology,2019,46(2):141 − 147. (in Chinese with English abstract)

[6] 李国勋, 张艳美, 马丁, 等. 纤维对纳米二氧化硅石灰改良粉土力学性质的影响[J]. 土木与环境工程学报(中英文),2020(2):37 − 44. [LI Guoxun, ZHANG Yanmei, MA D, et al. Mechanical properties of nano-silica and lime stabilized silt reinforced by fiber[J]. Journal of Civil and Environmental Engineering,2020(2):37 − 44. (in Chinese with English abstract)

[7] KHATTAK M J, ALRASHIDI M. Durability and mechanistic characteristics of fiber reinforced soil-cement mixtures[J]. International Journal of Pavement Engineering,2006,7(1):53 − 62. doi: 10.1080/10298430500489207

[8] YETIMOGLU T, SALBAS O. A study on shear strength of sands reinforced with randomly distributed discrete fibers[J]. Geotextiles and Geomembranes,2003,21(2):103 − 110. doi: 10.1016/S0266-1144(03)00003-7

[9] KUMAR A, WALIA B S, MOHAN J. Compressive strength of fiber reinforced highly compressible clay[J]. Construction and Building Materials,2006,20(10):1063 − 1068. doi: 10.1016/j.conbuildmat.2005.02.027

[10] 陈轮, 李广信. 纤维加筋粘性土的抗拉和抗裂性能研究[J]. 地基处理,1992(2):25 − 31. [CHEN Lun, LI Guangxin. Research on tensile and crack resistance of fiber reinforced clay[J]. Ground Improvement,1992(2):25 − 31. (in Chinese)

[11] 唐朝生, 施斌, 刘春, 等. 影响黏性土表面干缩裂缝结构形态的因素及定量分析[J]. 水利学报,2007,38(10):1186 − 1193. [TANG Chaocheng, SHI Bin, LIU Chun, et al. Factors affecting the surface cracking in clay due to drying shrinkage[J]. Journal of Hydraulic Engineering,2007,38(10):1186 − 1193. (in Chinese with English abstract) doi: 10.3321/j.issn:0559-9350.2007.10.006

[12] 李广信, 陈轮, 郑继勤, 等. 纤维加筋粘性土的试验研究[J]. 水利学报,1995,26(6):31 − 36. [LI Guangxin, CHEN Lun, ZHENG Jiqin, et al. Experimental study on fiber-reinforced cohesive soil[J]. Journal of Hydraulic Engineering,1995,26(6):31 − 36. (in Chinese with English abstract) doi: 10.3321/j.issn:0559-9350.1995.06.005

[13] 郝建斌, 魏兴梅, 姚婕, 等. 麦秸秆加筋土的强度特性及细观结构分析[J]. 同济大学学报(自然科学版), 2019, 47(6):764 − 768.

HAO Jianbin, WEI Xingmei, YAO Jie, et al. Strength characteristics and mesostructure of wheat straw reinforced soil[J]. Journal of Tongji University (Natural Science), 2019, 47(6):764 − 768. (in Chinese with English abstract)

[14] 刘阳. 麦秸秆加筋土强度特性及应用试验研究[D]. 西安: 长安大学, 2019.

LIU Yang. Research on the strength characteristics and application of wheat straw reinforced soil[D]. Xi’an: Chang’an University, 2019.

[15] 沙琳川, 王桂尧, 张永杰, 等. 含水率与加筋率对加筋土抗剪强度的影响规律研究[J]. 水文地质工程地质,2018,45(2):51 − 58. [SHA Linchuan, WANG Guiyao, ZHANG Yongjie, et al. A study of influence of water content and reinforcement ratio on the shear strength of reinforced soil[J]. Hydrogeology & Engineering Geology,2018,45(2):51 − 58. (in Chinese with English abstract)

[16] 王桂尧, 沙琳川, 曹文贵, 等. 加筋率对稻秸秆加筋土开裂特性的试验研究[J]. 水文地质工程地质, 2017, 44(5): 52 − 58.

WANG Guiyao, SHA Linchuan, CAO Wengui, et al. An experiment study of cracking properties of rice straw reinforced soil with different ratios[J]. Hydrogeology & Engineering Geology, 2017, 44(5): 52 − 58. (in Chinese with English abstract)

[17] 白汉营, 高宇豪, 陈学军, 等. 纳米石墨粉红黏土改良机理试验研究[J]. 水文地质工程地质, 2018, 45(3): 86 − 92.

BAI Hanying, GAO Yuhao, CHEN Xuejun, et al. An experimental study of the improving mechanical properties of the nano graphite powder red clay[J]. Hydrogeology & Engineering Geology, 2018, 45(3): 86 − 92. (in Chinese with English abstract)

[18] 张齐齐, 王家鼎, 刘博榕, 等. 水泥改良土微观结构定量研究[J]. 水文地质工程地质,2015,42(3):92 − 96. [ZHANG Qiqi, WANG Jiading, LIU Borong, et al. Quantitative research on microstructure of modified soil with cement[J]. Hydrogeology & Engineering Geology,2015,42(3):92 − 96. (in Chinese with English abstract)

[19] 刘红光, 罗斌, 申士杰, 等. 秸秆建材的研究与发展现状概述[J]. 林业机械与木工设备,2019,47(5):4 − 12. [LIU Hongguang, LUO Bin, SHEN Shijie, et al. Review of research and development of straw building materials[J]. Forestry Machinery & Woodworking Equipment,2019,47(5):4 − 12. (in Chinese with English abstract) doi: 10.3969/j.issn.2095-2953.2019.05.001

[20] 张继元. 简述生土建筑历史演变与建筑生态发展视域下引发创作的相关思考[J]. 居舍,2018(29):168. [ZHANG Jiyuan. A brief description of the historical evolution of the raw soil architecture and the related thinking of creation from the perspective of the development of architectural ecology[J]. Residence,2018(29):168. (in Chinese)

[21] 张虎元, 赵天宇, 王旭东. 中国古代土工建造方法[J]. 敦煌研究,2008(5):81 − 90. [ZHANG Huyuan, ZHAO Tianyu, WANG Xudong. Ancient Chinese geotechnical construction method[J]. Dunhuang Research,2008(5):81 − 90. (in Chinese) doi: 10.3969/j.issn.1000-4106.2008.05.015

[22] 张剑辉. 关中地区传统民居生土建造技术研究[D]. 西安: 长安大学, 2017.

ZHANG Jianhui. Research on Construction Technology of Raw Soil for Traditional Residential Buildings in Guanzhong Area[D]. Xi’an: Chang’an University, 2017.

[23] 赵宜芊. 传统生土营建经验与土质特性的关联性研究[D]. 西安: 西安建筑科技大学, 2018.

ZHAO Yiqian. Research on the correlation between traditional raw soil construction experience and soil characteristics [D]. Xi’an: Xi’an University of Architecture and Technology, 2018.

[24] 彭丽云, 王剑烨. 玉米秸秆防腐及其粉土加筋效果研究[J]. 工程地质学报,2017,25(1):132 − 138. [PENG Liyun, WANG Jianye. Experimental study on anti-corrosion of corn straw and its effect in silt improvement[J]. Journal of Engineering Geology,2017,25(1):132 − 138. (in Chinese with English abstract)

[25] 张毅, 汪明礼. 聚乙烯醇及其应用[J]. 黄山学院学报, 2004, 6(3): 71 − 74.

ZHANG Yi, WANG Mingli. Polyvinyl alcohol and its application[J]. Journal of Huangshan University, 2004, 6(3): 71 − 74.(in Chinese)

[26] 王天华, 杨菲, 于凤琴, 等. 聚乙烯醇(PVA)市场分析与展望[J]. 山东化工,2016,45(2):49 − 50. [WANG Tianhua, YANG Fei, YU Fengqin, et al. Analysis and Prospect of Polyvinyl Alcohol (PVA) Market[J]. Shandong Chemical Industry,2016,45(2):49 − 50. (in Chinese) doi: 10.3969/j.issn.1008-021X.2016.02.015

[27] 吴春林. 聚乙烯醇薄膜的特性及应用[J]. 维纶通讯,2006(4):10 − 12. [WU Chunlin. Characteristics and applications of polyvinyl alcohol film[J]. Vinylon Communications,2006(4):10 − 12. (in Chinese)

-

下载:

下载: