An empirical method for calculating the roughness coefficient of structural plane with line-plane combination

-

摘要:

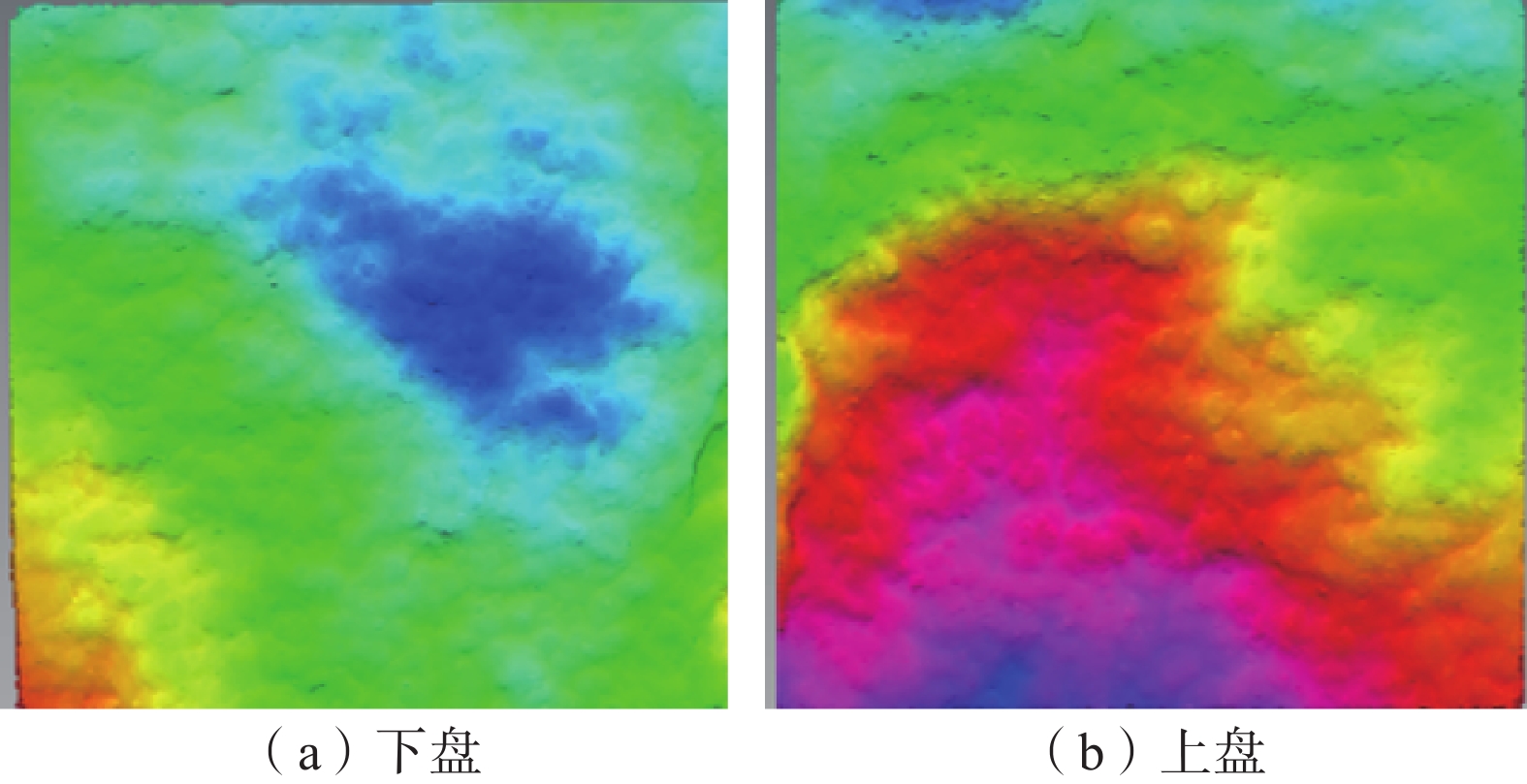

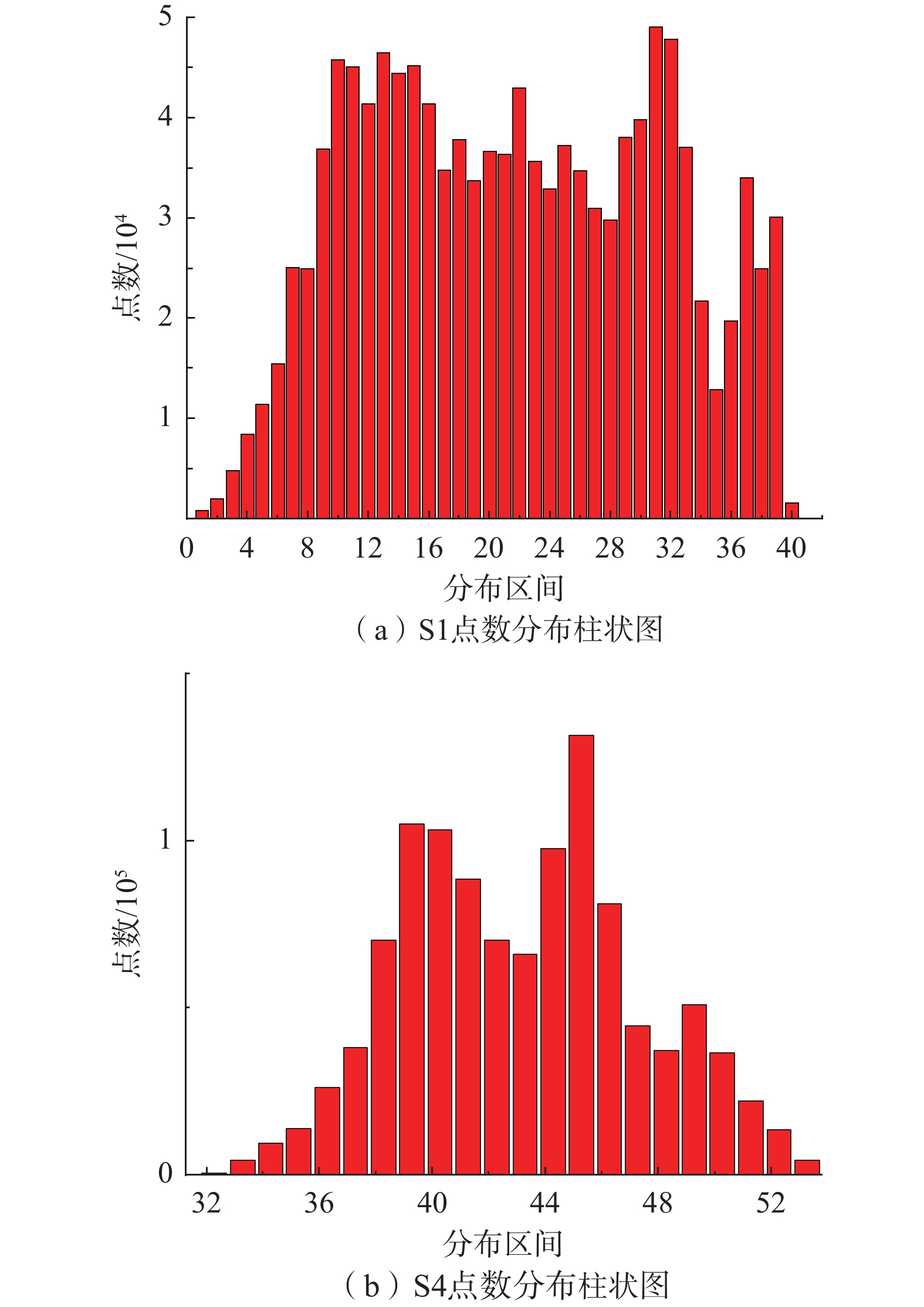

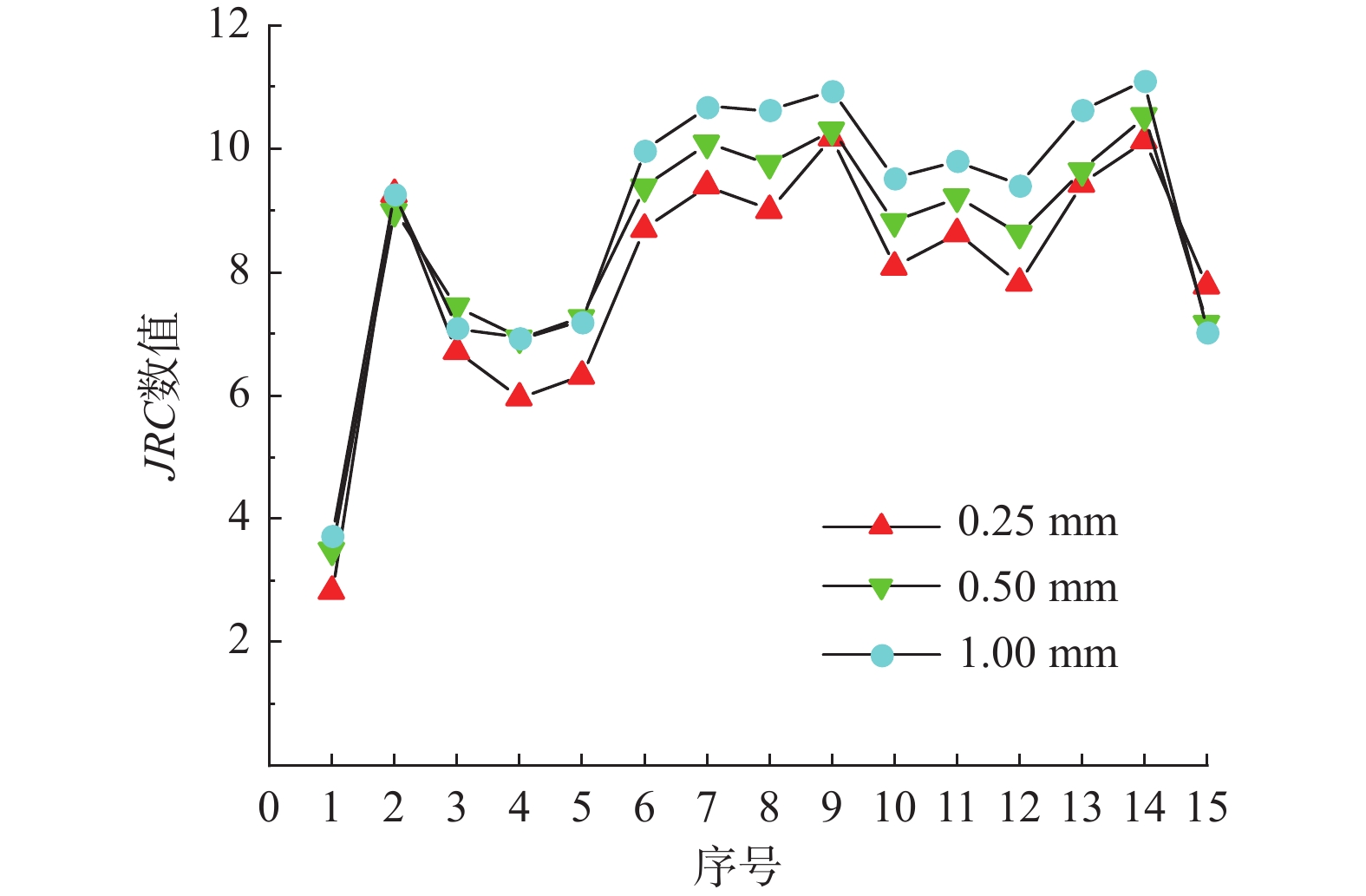

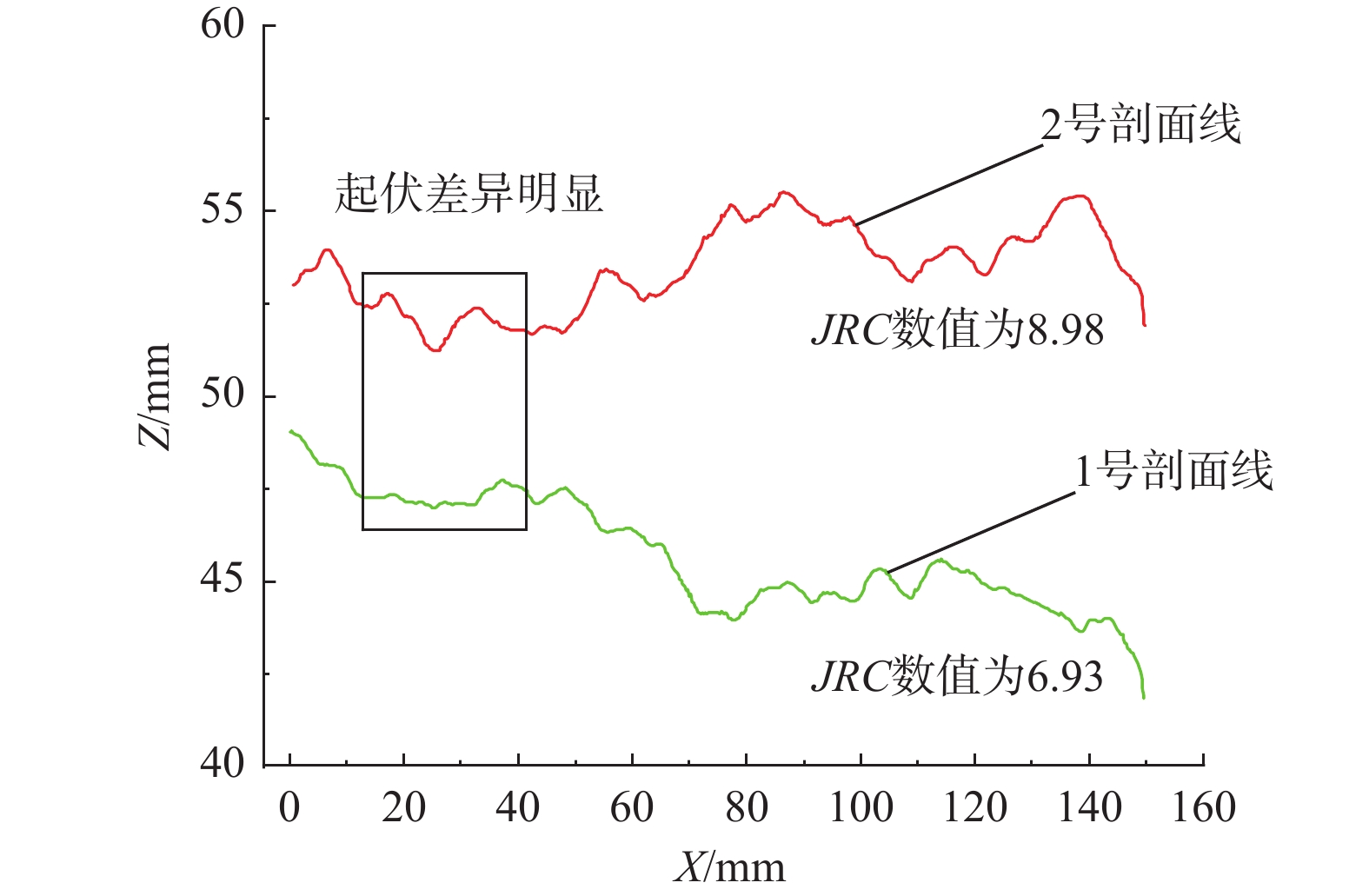

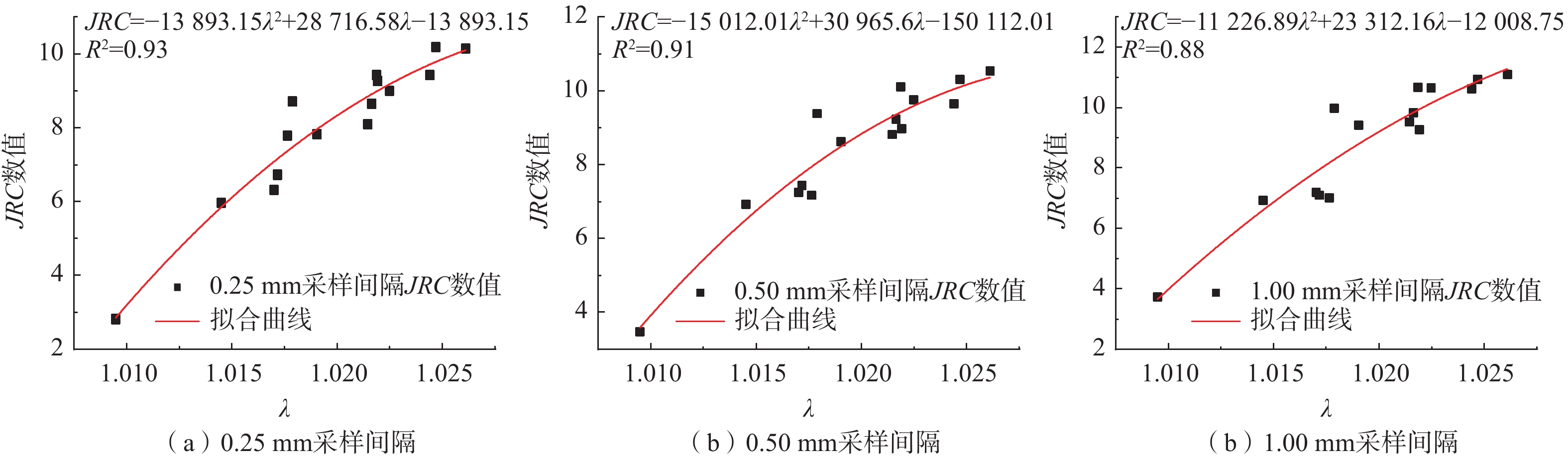

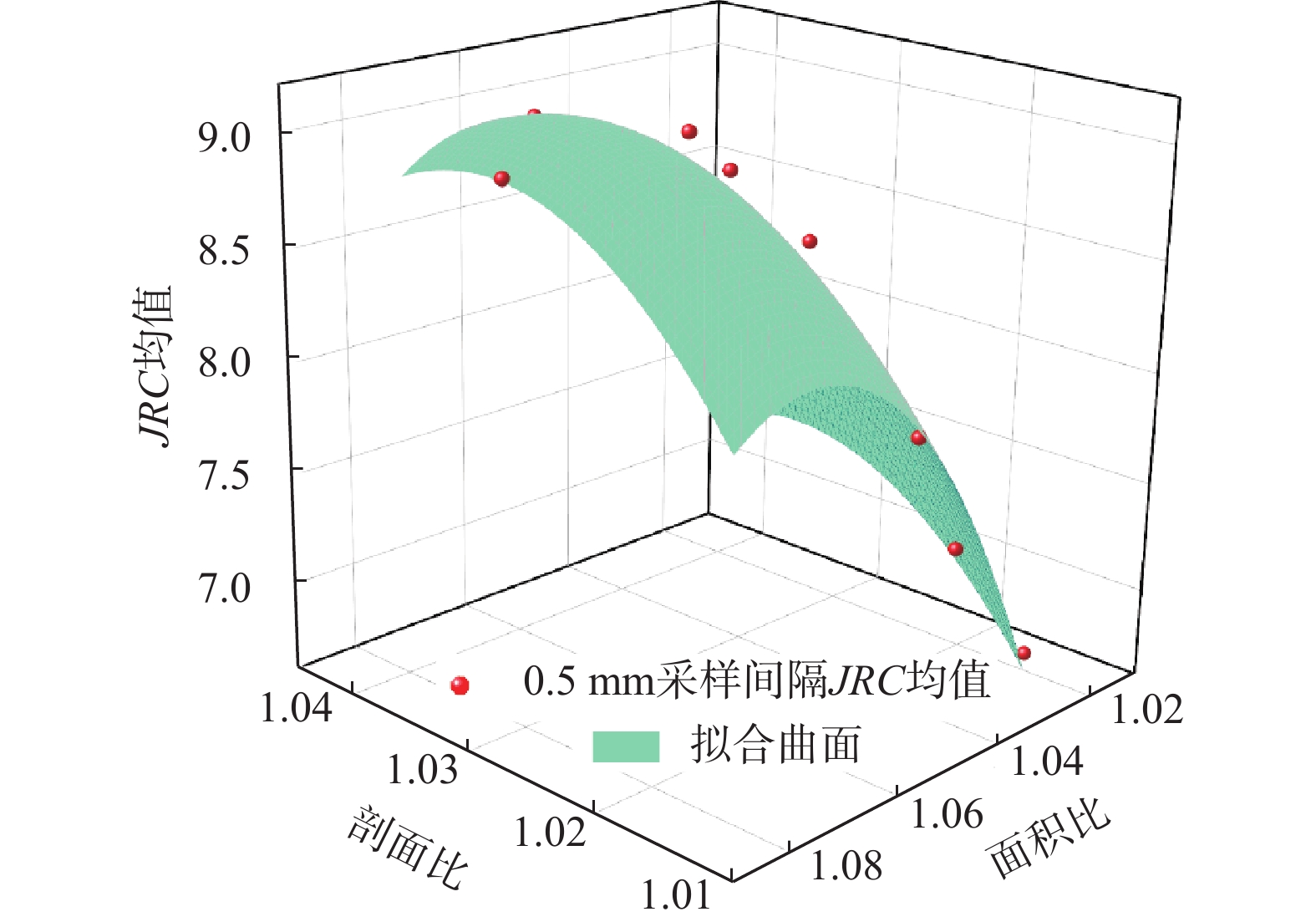

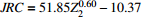

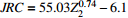

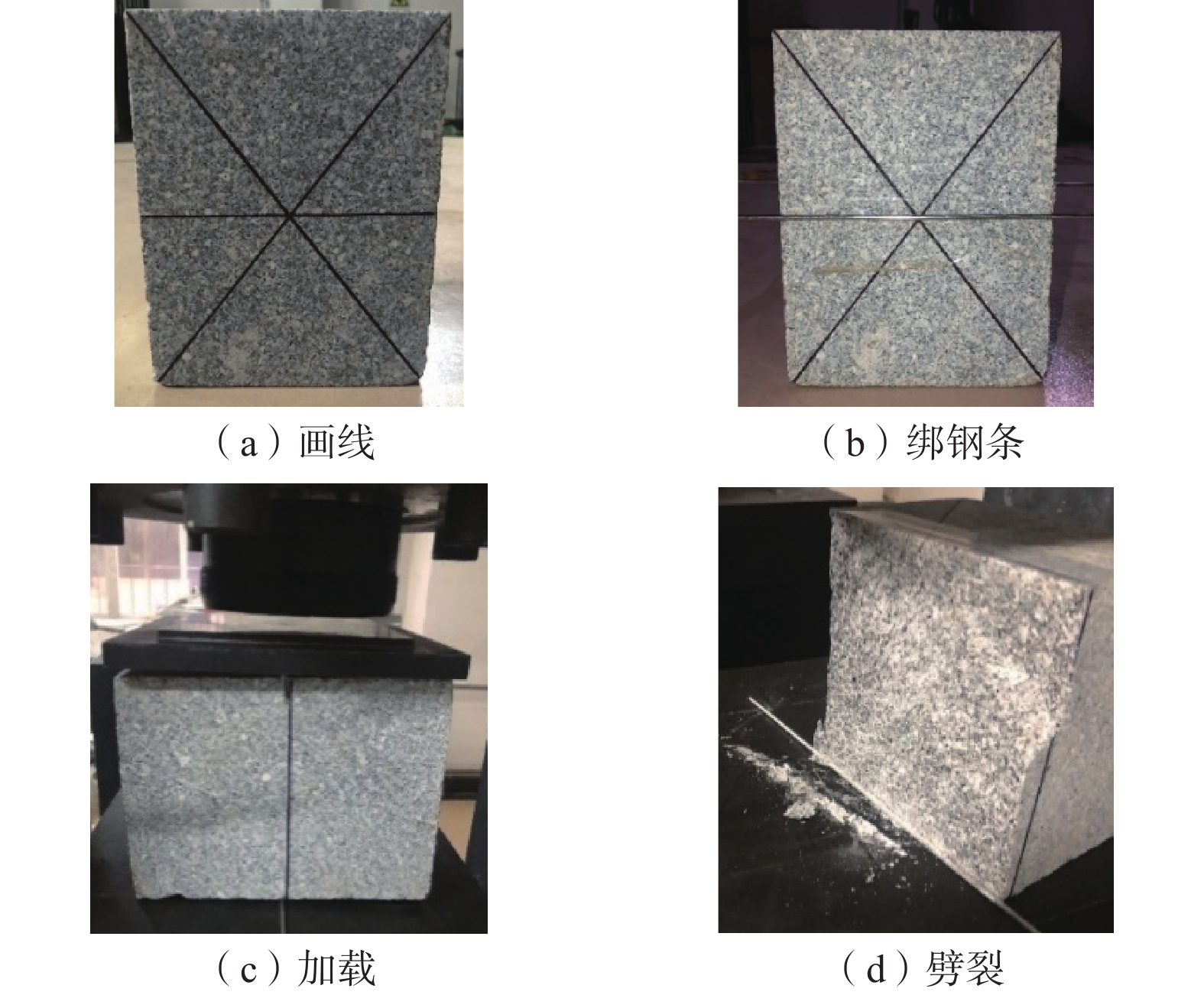

岩体结构面的剪切力学特性主要取决于其表面粗糙特征,结构面粗糙系数是表征该粗糙特征的主要方法。目前对结构面粗糙系数的研究局限于单一维度,多角度且定量化计算结构面粗糙系数能避免单一维度分析导致计算精度不准的局限性。采用立方体花岗岩,通过巴西劈裂的方式制备含结构面的试样;利用高精度三维扫描仪对试样结构面进行扫描,得到结构面的点云数据,同时借助逆向软件对点云数据进行三维重构。研究了点云数据Z方向上的分布频率,剖面线剖面比与节理粗糙系数(JRC)值的关系,结构面面积比与JRC均值的关系。研究表明:点云数据Z方向上的分布频率可以作为初步评估结构面粗糙度的手段;剖面线剖面比与JRC数值、结构面面积比与JRC均值有二次函数的关系。通过数值分析建立了结构面JRC均值与剖面比、面积比的二元函数关系,并得到结构面JRC均值的经验计算公式。本次研究为结构面粗糙度提供了一种“点-线-面”逐渐深入的多角度评估思路,得到的经验公式为计算结构面JRC均值提供了一种新的计算方法。

Abstract:The shear mechanical properties of structural plane are mainly determined by the surface roughness, and the roughness coefficient is the main method to characterize the roughness. At present, the research on the roughness coefficient is limited to a single dimension. Multi-angle and quantitative calculation of the roughness coefficient of structural plane can avoid the limitation of inaccurate calculation caused by single dimension analysis. Cubic granite blocks with structural plane are prepared by Brazilian splitting. High-precision 3D scanner is used to scan the prepared structural interview samples and obtain the point cloud data of the structural planes. At the same time, three-dimensional reconstruction of point cloud data is carried out by reverse software. The distribution frequency in the Z direction of the point cloud data, the relationship between the section ratio and joint roughness coefficient (JRC) values of the section line, and the relationship between the structural plane area ratio and the mean JRC values are studied. The results show that the distribution frequency in the Z direction of point cloud data can be used as a preliminary method to evaluate the roughness of structural surface. The relationships between section ratio and JRC value as well as area ratio of structural plane and mean JRC are both quadratic function. By numerical analysis, the binary function relation between the mean JRC of the structural planes and the section ratio and area ratio is established, and the empirical formula of the mean JRC of the structural plane is obtained. This study provides a "point-line-plane" idea to evaluate the roughness of discontinuities. The obtained empirical formula provides a new method for calculating the mean value of JRC of the structural plane.

-

Key words:

- profile ratio /

- area ratio /

- structural plane /

- joint roughness coefficient /

- calculation method

-

-

表 2 点云数据统计表

Table 2. Statistical table of point cloud data

编号 点数 最大值/mm 最小值/mm 高差/mm 均值/mm S1 1218937 40.058 0.981 39.077 22.050 S2 1111054 30.640 12.765 17.875 22.820 S3 1088516 32.568 8.304 24.264 20.708 S4 1114106 53.192 31.284 21.908 42.682 S5 1066901 26.803 14.064 12.739 20.668 S6 1064899 30.471 12.020 18.451 20.787 S7 1112041 30.997 9.428 21.569 20.359 S8 1074548 35.688 5.524 30.164 23.831 S9 1034419 27.192 0.079 27.113 18.420 S10 1038317 18.051 1.212 16.839 11.554 表 3 S4试样剖面比统计表

Table 3. Statistical table of profile ratio of sample S4

序号 基准长度/mm 实际长度/mm 剖面比 序号 基准长度/mm 实际长度/mm 剖面比 1 147.946 2 149.348 7 1.009 5 9 150.276 6 153.983 7 1.024 7 2 149.152 1 152.422 0 1.021 9 10 150.074 5 153.291 8 1.021 4 3 149.209 1 151.769 9 1.017 2 11 150.276 8 153.530 2 1.021 7 4 149.416 3 151.581 7 1.014 4 12 150.171 1 153.031 4 1.019 0 5 150.135 4 152.689 3 1.017 0 13 150.042 8 153.703 8 1.024 4 6 149.924 5 152.605 1 1.017 9 14 150.210 1 154.129 6 1.026 1 7 149.966 1 153.246 1 1.021 9 15 147.501 0 150.102 4 1.017 6 8 150.082 6 153.455 6 1.022 5 表 4 试样面积比

Table 4. Area ratios of samples

编号 基准面积/mm2 真实面积/mm2 面积比 S1 22 350 24 116.034 1 1.079 0 S2 22 350 23 423.588 8 1.048 0 S3 22 350 23 201.424 4 1.038 1 S4 21 025 22 435.221 3 1.067 1 S5 22 200 22 641.000 0 1.019 9 S6 21 316 22 213.150 6 1.042 1 S7 21 609 22 986.338 9 1.063 7 S8 22 201 22 808.410 4 1.027 4 S9 21 756 22 973.348 3 1.056 0 S10 22 052 23 216.181 8 1.052 8 表 5 试样数据统计

Table 5. Statistical data of the tested samples

序号 平均剖面比 面积比 JRC均值 S1 1.032 2 1.079 0 8.93 S2 1.029 8 1.048 0 8.62 S3 1.026 0 1.038 1 8.51 S4 1.029 5 1.067 1 8.78 S5 1.015 0 1.019 9 6.68 S6 1.016 0 1.042 1 7.86 S7 1.024 9 1.063 7 9.14 S8 1.018 0 1.027 4 7.18 S9 1.040 5 1.056 0 8.95 S10 1.026 3 1.052 8 8.90 -

[1] 穆成林,裴向军,裴钻,等. 基于岩体结构特征和未确知测度评价模型的岩质开挖边坡稳定性研究[J]. 水文地质工程地质,2019,46(4):150 − 158. [MU Chenglin,PEI Xiangjun,PEI Zuan,et al. A study of the stability of rock excavated slope based on rockmass structure and unascertained measure evaluation models[J]. Hydrogeology & Engineering Geology,2019,46(4):150 − 158. (in Chinese with English abstract)

[2] BARTON N,CHOUBEY V. The shear strength of rock joints in theory and practice[J]. Rock Mechanics,1977,10:1 − 54.

[3] 张恩铭,程谦恭,林棋文,等. 岩体结构对岩质滑坡运动过程和堆积特征的影响研究[J]. 水文地质工程地质,2022,49(3):125 − 135. [ZHANG Enming,CHENG Qiangong,LIN Qiwen, et al. A Study of the influence of rock mass structure on the propagation processes and deposit characteristics of rockslides[J]. Hydrogeology & Engineering Geology,2022,49(3):125 − 135. doi: 10.16030/j.cnki.issn.1000-3665.202107001

[4] 肖维民,刘伟超,朱占元. 基于正反向直剪试验的岩石节理JRC值计算研究[J]. 岩石力学与工程学报,2021,40(增刊 2):3098 − 3106. [XIAO Weimin,LIU Weichao,ZHU Zhanyuan. Study on calculation of rock joint JRC value based on forward and reverse direct shear tests[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(Sup 2):3098 − 3106. (in Chinese with English abstract)

[5] 陈世江,常建平,姬长兴,等. 两统计参数评估结构面粗糙度探讨及试验验证[J]. 岩石力学与工程学报,2021,40(3):476 − 489. [CHEN Shijiang,CHANG Jianping,JI Changxing,et al. A two-parameter evaluation method of joint roughness and its experimental verification[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(3):476 − 489. (in Chinese with English abstract)

[6] YU Xianbin,VAYSSADE B. Joint profiles and their roughness parameters[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1991,28(4):333 − 336.

[7] TATONE B S A,GRASSELLI G. A new 2D discontinuity roughness parameter and its correlation with JRC[J]. International Journal of Rock Mechanics and Mining Sciences,2010,47(8):1391 − 1400. doi: 10.1016/j.ijrmms.2010.06.006

[8] 孙辅庭,佘成学,万利台. Barton标准剖面JRC与独立于离散间距的统计参数关系研究[J]. 岩石力学与工程学报,2014,33(增刊 2):3539 − 3544. [SUN Futing,SHE Chengxue,WAN Litai. Research on relationship between JRC of Barton’s standard profiles and statistic parameters independent of sampling interval[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(Sup 2):3539 − 3544. (in Chinese with English abstract)

[9] 班力壬,戚承志,燕发源,等. 岩石节理粗糙度新指标及新的JRC确定方法[J]. 煤炭学报,2019,44(4):1059 − 1065. [BAN Liren,QI Chengzhi,YAN Fayuan,et al. A new method for determining the JRC with new roughness parameters[J]. Journal of China Coal Society,2019,44(4):1059 − 1065. (in Chinese with English abstract)

[10] GRASSELLI G,EGGER P. Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters[J]. International Journal of Rock Mechanics and Mining Sciences,2003,40(1):25 − 40. doi: 10.1016/S1365-1609(02)00101-6

[11] 陈曦,曾亚武. 基于Grasselli模型的一个新的岩石节理三维粗糙度指标[J]. 岩土力学,2021,42(3):700 − 712. [CHEN Xi,ZENG Yawu. A new three-dimensional roughness metric based on Grasselli’s model[J]. Rock and Soil Mechanics,2021,42(3):700 − 712. (in Chinese with English abstract)

[12] TANG Huiming,GE Yunfeng,WANG Liangqing,et al. Study on estimation method of rock mass discontinuity shear strength based on three-dimensional laser scanning and image technique[J]. Journal of Earth Science,2012,23(6):908 − 913. doi: 10.1007/s12583-012-0301-2

[13] 蔡毅,唐辉明,葛云峰,等. 岩体结构面三维粗糙度评价的新方法[J]. 岩石力学与工程学报,2017,36(5):1101 − 1110. [CAI Yi,TANG Huiming,GE Yunfeng,et al. A new method for evaluating the roughness of three-dimensional discontinuity surface of rock[J]. Chinese Journal of Rock Mechanics and Engineering,2017,36(5):1101 − 1110. (in Chinese with English abstract)

[14] 宋磊博,江权,李元辉,等. 不同采样间隔下结构面形貌特征和各向异性特征的统计参数稳定性研究[J]. 岩土力学,2017,38(4):1121 − 1132. [SONG Leibo,JIANG Quan,LI Yuanhui,et al. Stability of statistical parameters of discontinuities morphology and anisotropy characteristics based on different sampling intervals[J]. Rock and Soil Mechanics,2017,38(4):1121 − 1132. (in Chinese with English abstract) doi: 10.16285/j.rsm.2017.04.025

[15] 陈冲,陈胜宏. 结构面轮廓不等间距采样、向量表征粗糙度[J]. 岩石力学与工程学报,2021,40(增刊 1):2798 − 2805. [CHEN Chong,CHEN Shenghong. Unequal interval sampling,vector representation and roughness of joint profile[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(Sup 1):2798 − 2805. (in Chinese with English abstract)

[16] 王昌硕,王亮清,葛云峰,等. 基于统计参数的二维节理粗糙度系数非线性确定方法[J]. 岩土力学,2017,38(2):565 − 573. [WANG Changshuo,WANG Liangqing,GE Yunfeng,et al. A nonlinear method for determining two-dimensional joint roughness coefficient based on statistical parameters[J]. Rock and Soil Mechanics,2017,38(2):565 − 573. (in Chinese with English abstract)

[17] 陈曦,曾亚武. 粗糙节理的改进形貌表征方法及采样点距效应[J]. 浙江大学学报(工学版),2021,55(11):2161 − 2169. [CHEN Xi,ZENG Yawu. Improved morphology characterization method and sampling effect of rough rock joint[J]. Journal of Zhejiang University (Engineering Science),2021,55(11):2161 − 2169. (in Chinese with English abstract)

[18] 汤庆浩,张常亮,张国伟,等. 基于标准结构面粗糙度曲线的JRC量化算法[J]. 岩石力学与工程学报,2021,40(7):1402 − 1410. [TANG Qinghao,ZHANG Changliang,ZHANG Guowei,et al. Quantization algorithm of joint roughness coefficient based on standard joint roughness curves[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(7):1402 − 1410. (in Chinese with English abstract)

[19] 李化,黄润秋. 岩石结构面粗糙度系数JRC定量确定方法研究[J]. 岩石力学与工程学报,2014,33(增刊 2):3489 − 3497. [LI Hua,HUANG Runqiu. Method of quantitative determination of joint roughness coefficient[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(Sup 2):3489 − 3497. (in Chinese with English abstract)

[20] BELEM T,HOMAND-ETIENNE F,SOULEY M. Quantitative parameters for rock joint surface roughness[J]. Rock Mechanics and Rock Engineering,2000,33(4):217 − 242. doi: 10.1007/s006030070001

-

下载:

下载: