New Technology for Efficient Resource Utilization of Red Mud from Bayer Process

-

摘要:

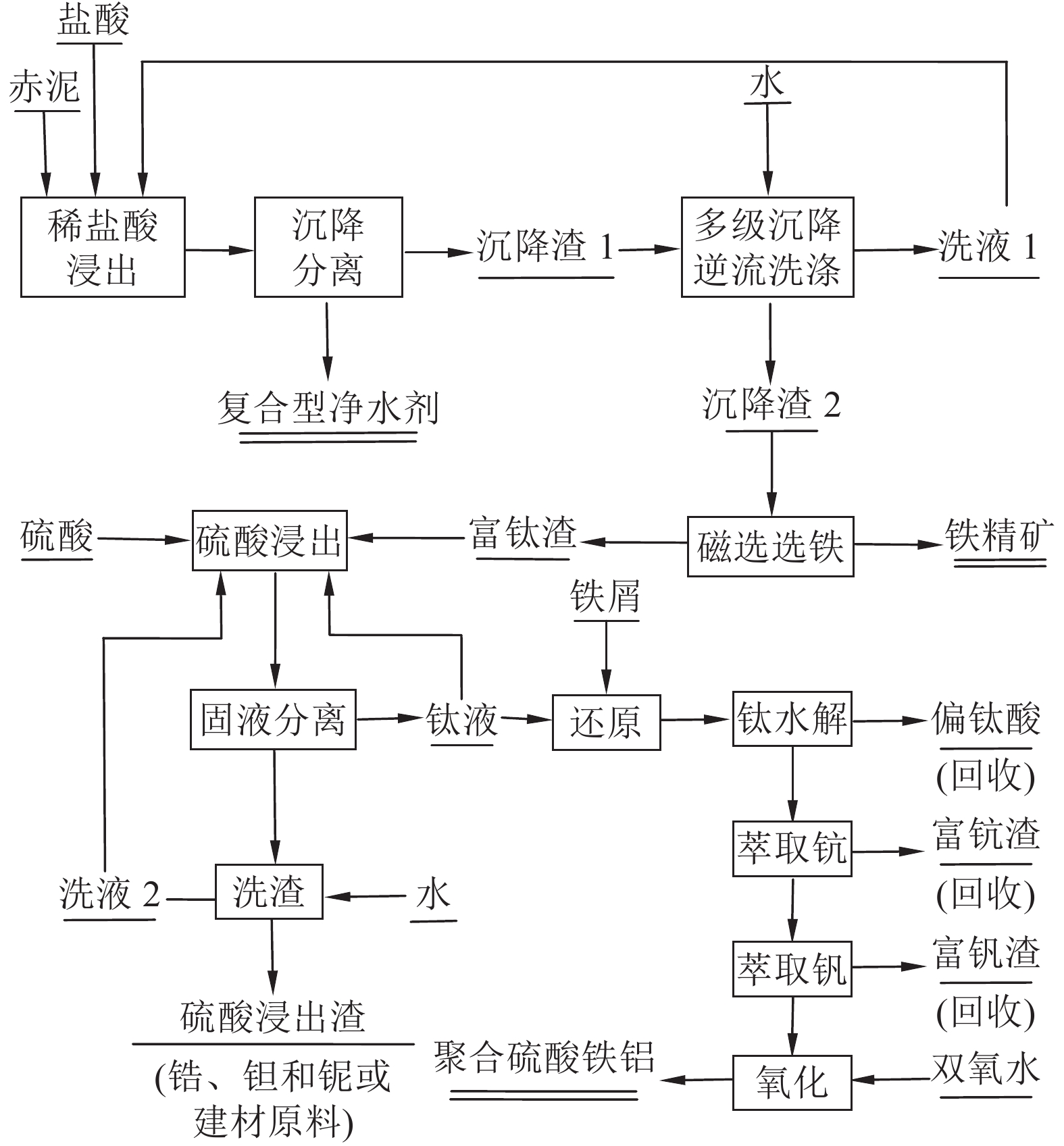

介绍了拜尔法赤泥的组成成分、性质、利用现状及高效资源化利用新技术。赤泥主要含铁、铝、硅、钙、钠、钛、氧和少量或微量钪、钒、锆、钽、铌等稀有金属,其成分复杂,矿物粒度细,物理分选困难;以往采用的赤泥冶化处理技术又因其回收元素的品位偏低和其含硅、钙过高而难以产生效益,大规模利用赤泥的工业技术至今在国内外仍没有取得突破性进展。为此,作者开发了一种新技术:赤泥用稀盐酸浸出,所得矿浆经沉降分离后得到复合型净水剂产品和浸出渣,浸出渣经磁选得到铁精矿产品和富钛渣,富钛渣用硫酸循环浸出,得到富钛液和硫酸浸出渣,从富钛液中回收钛、钪、钒,余液用于生产聚合硫酸铁铝,硫酸浸出渣可作为提取锆、钽、铌原料,或作为建材原料。本法工艺简单,能耗低,原辅材料便宜易得,产品市埸需求量大,具有显著的社会、经济和环保效益。

Abstract:The composition, properties, present utilization situation and new technology of high efficient utilization of red mud from Bayer process are introduced. The red mud mainly contains Fe, Al, Si, Ca, Na, Ti, O and a few rare metals such as Sc, V, Zr, Ta and Nb, etc. Because of the low grade of the recovered elements and the high content of silicon and calcium, it is difficult to produce benefit in the past red mud metallurgical treatment technology. Therefore, the author developed a new technology: Leach red mud with dilute hydrochloric acid, then the pulp is seperated by sedimentation to obtain a compound water purifying agent product and Leach residue, and the leach residue is magnetically separated to obtain iron concentrate product and titanium-rich slag, the titanium-rich slag is recirculated leached with sulfuric acid to obtain the titanium-rich liquid and the sulfuric acid leached slag. The titanium, scandium and vanadium are recovered from the titanium-rich liquid. The method has the advantages of simple process, low energy consumption, cheap raw and auxiliary materials, large market demand and remarkable social, economic and environmental benefits.

-

-

[1] 梁柳青. 广西不同产地赤泥化学成分及物相对比分析[J]. 化工技术与开发, 2012(6):39-40. doi: 10.3969/j.issn.1671-9905.2012.06.011

LIANG L Q. Contrastive analysis of phase and percentage of red mud in different places of Guangxi[J]. Technology & Development of Chemical Industry, 2012(6):39-40. doi: 10.3969/j.issn.1671-9905.2012.06.011

[2] 梁冬云, 洪秋阳. 某拜尔法赤泥选铁尾矿工艺矿物学研究[J]. 金属矿山, 2011(12):151-153.

LIANG D Y, HONG Q Y. Process mineralogy of tailings of separating iron from red mud of Bayer process[J]. Metal Mine, 2011(12):151-153.

[3] 刘世丰, 刘世鸿, 曾建民. 热处理赤泥的物相及粒径和比表面积[J]. 矿产综合利用, 2020(5):169-178. doi: 10.3969/j.issn.1000-6532.2020.05.027

LIU S F, LIU S H, ZENG J M, et al. Phase, particle size and specific surface area of heat-treated red mud[J]. Multipurpose Utilization of Mineral Resources, 2020(5):169-178. doi: 10.3969/j.issn.1000-6532.2020.05.027

[4] 滕春英, 周康根, 宁凌峰, 等. 盐酸分级浸出赤泥中有价金属元素[J]. 环境工程学报, 2018, 12(1):310-315. doi: 10.12030/j.cjee.201703078

TENG C Y, ZHOU K G, NING L F, et al. Stepwise leaching of valuable metals from red mud using hydrochloric acid[J]. Chinese Journal of Environmental Engineering, 2018, 12(1):310-315. doi: 10.12030/j.cjee.201703078

[5] 李建伟, 马炎, 马挺, 等. 赤泥制备免烧砖的研究现状及技术要点探讨[J]. 矿产综合利用, 2019(3):7-10. doi: 10.3969/j.issn.1000-6532.2019.03.002

LI J W, MA Y, MA T, et al. Research status and technical points of preparation of unburned brick by the red mud[J]. Multipurpose Utilization of Mineral Resources, 2019(3):7-10. doi: 10.3969/j.issn.1000-6532.2019.03.002

[6] 薛真, 薛彦辉, 王力, 等. 拜耳法赤泥中铝铁的盐酸浸出过程研究[J]. 矿产综合利用, 2018(6):139-143.

XUE Z, XUE Y H, WANG L, et al. Study on leaching of aluminum and iron from Bayer red mud with hydrochloric acid[J]. Multipurpose Utilization of Mineral Resources, 2018(6):139-143.

[7] 韩东战, 尹中林. 赤泥提钛的研究现状[J. 矿产综合利用, 2017 ( 3) : 31-37.

HAN G Z, YIN Z L. Current research situation of recovering titanium from red mud[J]. Multipurpose Utilization of Mineral Resources, 2017 ( 3) : 31-37.

[8] 池丕华, 赵孟珊, 刘丹丹, 等. 赤泥硫酸浸出液中钪的萃取试验研究[J]. 黄金, 2016, 37(2):56-58. doi: 10.11792/hj201602013

CHI P H, ZHAO M S, LIU D D, et al. Experimental study on the extraction of scandium from the sulfuric acid leach solution of red mud[J]. Gold, 2016, 37(2):56-58. doi: 10.11792/hj201602013

[9] 柯胜男, 侯斌, 刘锦卉, 等. 赤泥硫酸熟化浸出液中镓的萃取试验[J]. 科学技术与工程, 2016, 16(26):203-206. doi: 10.3969/j.issn.1671-1815.2016.26.032

KE S N, HOU B, LIU J H, et al. Experimental study on the extraction of gallium from red mud by sulfuric acid curing[J]. Science Technology and Engineering, 2016, 16(26):203-206. doi: 10.3969/j.issn.1671-1815.2016.26.032

[10] 谢营邦, 詹海鸿, 何航军, 等. 广西平果铝赤泥资源化利用扩大试验[J]. 有色金属(冶炼部分), 2014(9):30-33.

XIE Y B, ZHAN H H, HE H J, et al. Pilot-plan test of resource utilization of red mud in Guangxi Pingguo Aluminum[J]. Non-ferrous Metals (Extractive Metallurgy), 2014(9):30-33.

[11] 郭庆, 陈书文, 张军红, 等. 微波强化赤泥制备Fe-Al基絮凝剂工艺研究[J]. 矿产综合利用, 2019(4):117-121. doi: 10.3969/j.issn.1000-6532.2019.04.025

GUO Q, CHEN S W, ZHANG J H, et al. Study on preparation of Fe/Al-base flocculant from red mud by microwave[J]. Multipurpose Utilization of Mineral Resources, 2019(4):117-121. doi: 10.3969/j.issn.1000-6532.2019.04.025

[12] 张孟存. 聚合硅酸硫酸铝铁的研制及其絮凝性能[J]. 水处理技术, 2008, 34(9):61-64. doi: 10.16796/j.cnki.1000-3770.2008.09.018

ZHANG M C. Preparation of polysilicate aluminum ferric sulfate and its flocculating effect[J]. Technology of Water Treatment, 2008, 34(9):61-64. doi: 10.16796/j.cnki.1000-3770.2008.09.018

[13] 郑立柱, 王妮娜, 杜敏娟, 等. 聚合硅酸铝铁的制备及其在废水处理中的应用综述[J]. 化工技术与开发, 2011, 40(9):57-59. doi: 10.3969/j.issn.1671-9905.2011.09.018

ZHENG L Z, WANG N N, DU M J, et al. Preparation of polysilicate aluminium ferric and its application in wastewater treatment[J]. Technology & Development of Chemical Industry, 2011, 40(9):57-59. doi: 10.3969/j.issn.1671-9905.2011.09.018

[14] 何耀. 一种赤泥高效资源化利用方法: CN112011691A[P]. 2020-12-01.

HE Y. An efficient resource utilization method of red mud: CN112011691A[P]. 2020-12-01.

[15] 何耀. 赤泥浸出洗渣槽及其使用方法: CN112143900A[P]. 2020-12-29.

HE Y. Red mud soaked out the slag washing tank and its use method: CN112143900A[P]. 2020-12-29.

-

下载:

下载: