Research Progress on Resource Treatment and Recycling of Solid Waste Containing Chromium

-

摘要:

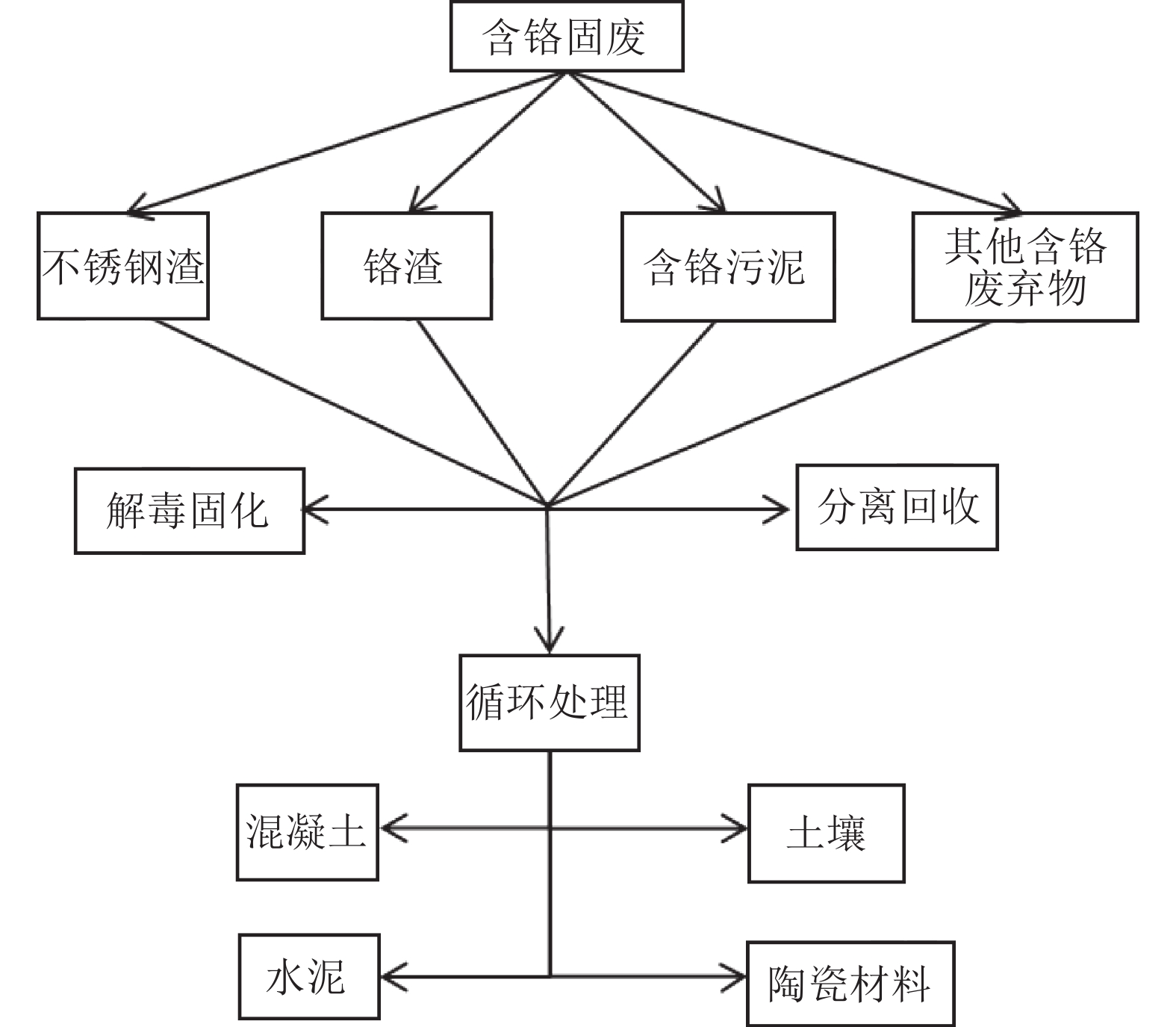

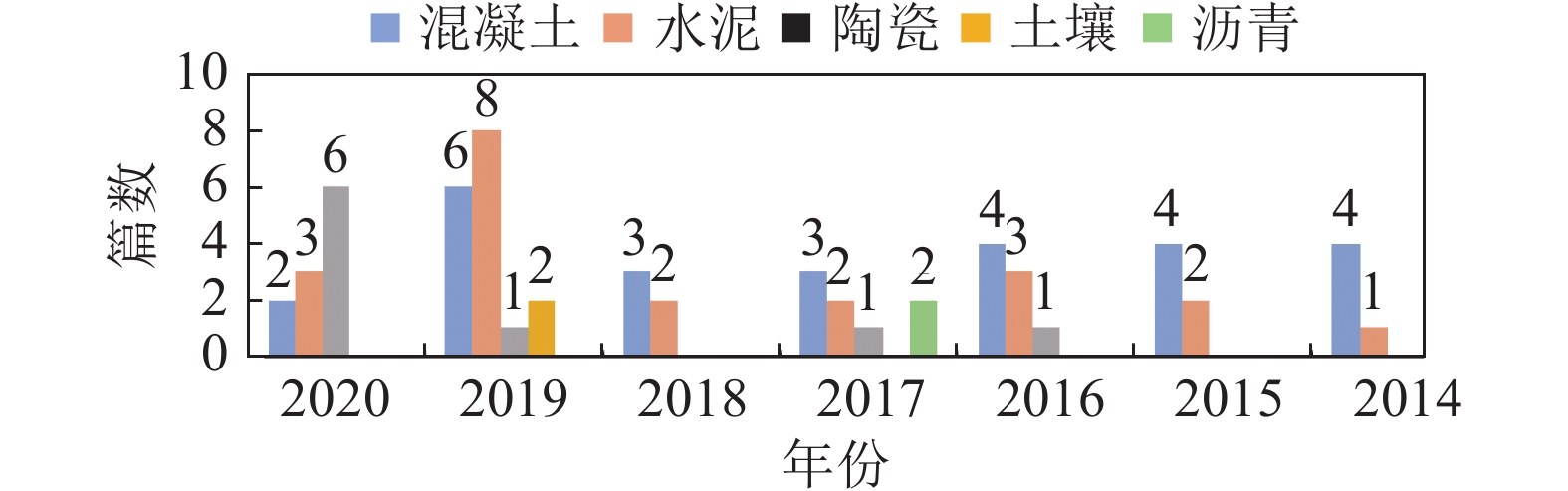

近年来,我国越来越重视生态环保,工业生产过程中的固体废弃物的处理就变得更加重要,例如不锈钢生产行业、电镀行业、铬盐生产行业等,都会产生大量的含铬固废,长期堆积不仅会占用土地资源而且还会对环境造成严重的危害。因此,开发更有效地回收、处理含铬固废的方法显得尤为重要。本文总结了我国铬矿资源的现状、预测了未来几年对于铬矿的需求量、阐述了含铬固废的现状及其危害、综述了近几年国内外对于含铬固废处理技术的新研究以及含铬固废循环利用方面的研究进展,介绍了不同处理方法的优缺点,以期在未来能够找到更好的回收、处理含铬固废的方法。

Abstract:In recent years, China has paid more and more attention to ecological and environmental protection, and the treatment of solid waste during industrial production has become more important. For example, stainless steel production industry, electroplating industry, chromium salt production industry, etc., will produce a large amount of chromium-containing solid waste. Long-term accumulation will not only occupy land resources but also cause serious harm to the environment. Therefore, it is particularly important to develop more effective methods for recycling and processing chromium-containing solid waste. This article summarizes the current situation of chromium ore resources in China, predicts the demand for chromium ore in the next few years, expounds the current situation and hazards of chromium-containing solid waste, and summarizes the new domestic and foreign chromium-containing solid waste treatment technologies in recent years. Research and progress in the recycling of chromium-containing solid waste, introducing the advantages and disadvantages of different treatment methods, in order to find a better way to recover and treat chromium-containing solid waste in the future.

-

Key words:

- Chrome ore /

- Chromium-containing solid waste /

- Stainless steel slag /

- Resource treatment /

- Recycling

-

-

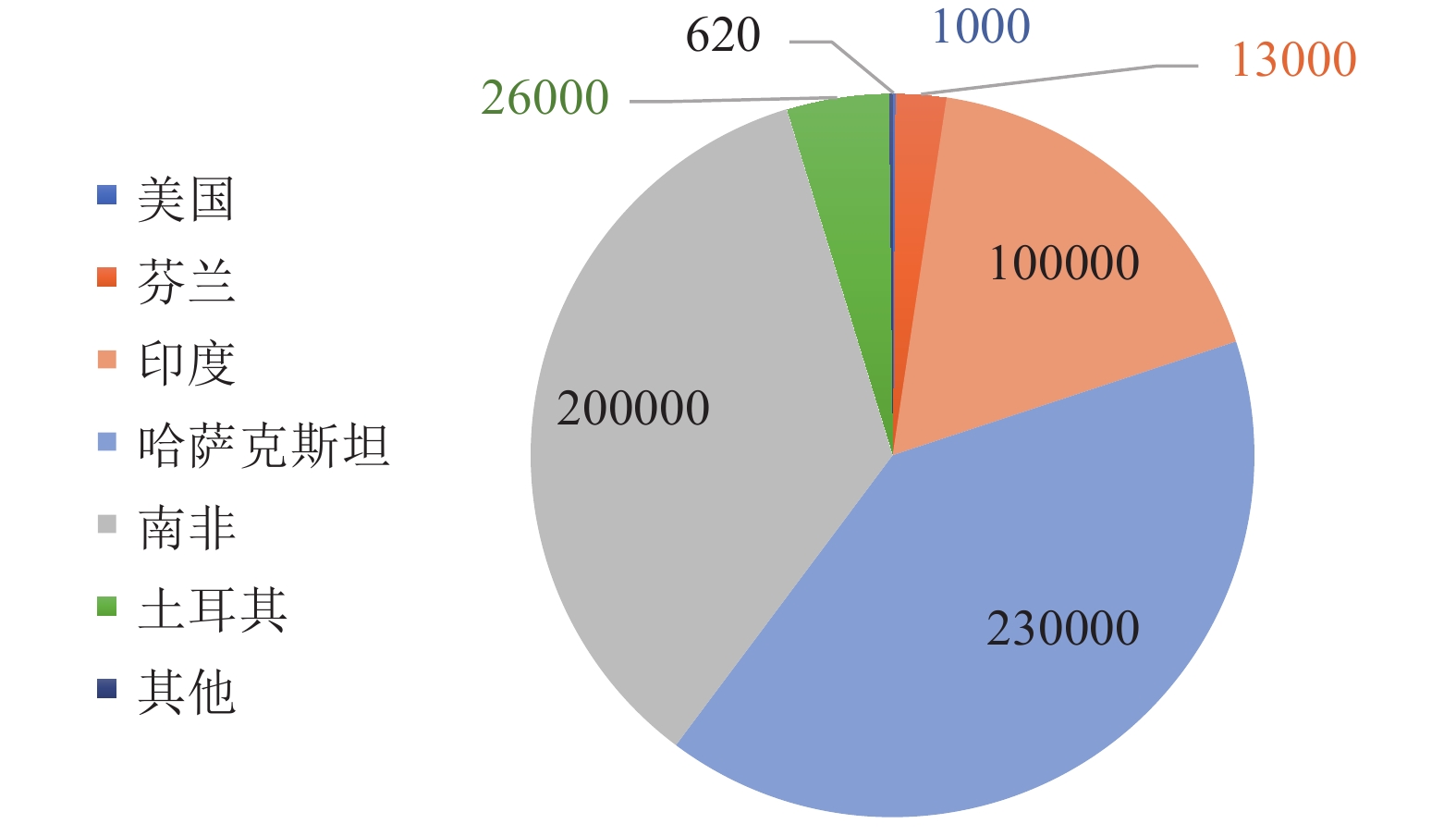

图 1 2019年世界铬矿山储量(千t)[5]

Figure 1.

图 2 2019年世界铬矿产量[5]

Figure 2.

-

[1] 邱柏欣, 顾幸勇, 董伟霞, 等. 烧成温度对铬铁渣性能影响与表征[J]. 矿产综合利用, 2020(1):188-193. doi: 10.3969/j.issn.1000-6532.2020.01.038

QIU B X, GU X Y, DONG W X, et al. Effect of firing temperatures on properties of ferrochromium slag and characterization[J]. Multipurpose Utilization of Mineral Resources, 2020(1):188-193. doi: 10.3969/j.issn.1000-6532.2020.01.038

[2] 刘宇晶. 镍铬需求将保持稳定——2020年不锈钢产业镍铬需求分析预测[J]. 中国有色金属, 2020(7):40-41. doi: 10.3969/j.issn.1673-3894.2020.07.009

LIU Y J. Nickel and chromium demand will remain stable-2020 stainless steel industry nickel and chromium demand analysis forecast[J]. China Nonferrous Metals, 2020(7):40-41. doi: 10.3969/j.issn.1673-3894.2020.07.009

[3] 操龙虎. 不锈钢渣的污染性分析及其处理方法[J]. 炼钢, 2019, 35(2):75-78.

CAO L H. Analysis of the pollution of stainless steel slag and its treatment method[J]. Steelmaking, 2019, 35(2):75-78.

[4] 刘全文, 沙景华, 闫晶晶, 等. 中国铬资源供应风险评价与对策研究[J]. 资源科学, 2018, 40(3):516-525.

LIU Q W, SHA J H, YAN J J, et al. Research on risk evaluation and countermeasures of China's chromium resources supply[J]. Resources Science, 2018, 40(3):516-525.

[5] U. S. Geological Survey. Mineral Commodity Summaries 2020[R]. Reston, VA: U. S. Geological Survey, 2020: 51.

[6] 张泽南, 张照志, 潘昭帅, 等. 全球铬矿石资源国对中国供应安全度分析[J]. 中国矿业, 2019, 28(10):69-76. doi: 10.12075/j.issn.1004-4051.2019.10.009

ZHANG Z N, ZHANG Z Z, PAN S S, et al. Analysis of the supply security of global chrome ore resource countries to China[J]. China Mining, 2019, 28(10):69-76. doi: 10.12075/j.issn.1004-4051.2019.10.009

[7] 郑明贵, 袁雪梅. 基于灰色神经网络的中国2020—2030年铬矿需求预测[J]. 资源开发与市场, 2018, 34(6):747-752. doi: 10.3969/j.issn.1005-8141.2018.06.002

ZHENG M G, YUAN X M. Forecast of China's chrome ore demand from 2020 to 2030 based on grey neural network[J]. Resources Development and Markets, 2018, 34(6):747-752. doi: 10.3969/j.issn.1005-8141.2018.06.002

[8] 李建法. 我国铬铁行业发展概况及现状[J]. 冶金管理, 2019(14):23-25.

LI J F. The development situation and status quo of my country's ferrochrome industry[J]. Metallurgical Management, 2019(14):23-25.

[9] 潘昭帅, 张照志, 王贤伟, 等. 中国再生铬资源回收利用现状及未来趋势分析[J]. 中国矿业, 2018, 27(8):17-21.

PAN Z S, ZHANG Z Z, WANG X W, et al. Analysis on the status quo and future trends of China's recycled chromium resources recycling[J]. China Mining, 2018, 27(8):17-21.

[10] LI W L, XUE X X. Emission reduction research and formation of hexavalent chromium in stainless steel smelting: Cooling rate and boron oxide addition effects[J]. Process Safety and Environmental Protection, 2018.

[11] 吕韬. 不锈钢厂含金属固废综合利用冶炼铬镍合金[A]. 《环境工程》编委会、工业建筑杂志社有限公司. 《环境工程》2019年全国学术年会论文集(下册)[C]. 《环境工程》编委会、工业建筑杂志社有限公司: 《环境工程》编辑部, 2019: 3.

LV T. Comprehensive utilization of metal-containing solid waste in stainless steel plants to smelt chromium-nickel alloys[A]. "Environmental Engineering" Editorial Board, Industrial Construction Magazine Co. , Ltd. "Environmental Engineering" 2019 National Academic Conference Proceedings (Volume 2)[C] . "Environmental Engineering" Editorial Board, Industrial Construction Magazine Co. , Ltd. : "Environmental Engineering" Editorial Office, 2019: 3.

[12] Ma G, Garbers-Craig A M. Cr (VI) containing electric furnace dusts and filter cake from a stainless steel waste treatment plant: Part 1-Characteristics and microstructure[J]. Ironmaking & Steelmaking, 2006, 33(3):229-237.

[13] ZHANG H, XIN H. An overview for the utilization of wastes from stainless steel industries[J]. Resources Conservation & Recycling, 2011, 55(8):745-754.

[14] 张雁江, 李锋锋, 郑晓华, 等. 电镀污泥的材料化处理技术综述[J]. 电镀与涂饰, 2013, 32(12):49-51. doi: 10.3969/j.issn.1004-227X.2013.12.013

ZHANG Y J, LI F F, ZHENG X H, et al. Summary of materialized treatment technology of electroplating sludge[J]. Plating and Finishing, 2013, 32(12):49-51. doi: 10.3969/j.issn.1004-227X.2013.12.013

[15] Kristen P Nickens, Steven R Patierno, Susan Ceryak. Chromium genotoxicity: a double-edged sword[J]. Chemico-Biological Interactions, 2010, 188(2):276-288.

[16] 李小明, 贾李锋, 邹冲, 等. 不锈钢酸洗污泥资源化利用技术进展及趋势[J]. 钢铁, 2019, 54(10):1-11. doi: 10.13228/j.boyuan.issn0449-749x.20190039

LI X M, JIA L F, ZOU C, et al. Progress and trend of resource utilization technology of stainless steel pickling sludge[J]. Iron and Steel, 2019, 54(10):1-11. doi: 10.13228/j.boyuan.issn0449-749x.20190039

[17] 马建明. 我国黑色金属矿产资源形势回顾与展望[J]. 国土资源情报, 2019(12):64-69.

MA J M. Review and prospect of my country’s ferrous metal mineral resources situation[J]. Land Resources Information, 2019(12):64-69.

[18] 胡晓娇, 白艳萍, 张生萍, 等. 危险废物铬渣和碱渣联合处置技术应用[J]. 广东化工, 2019, 46(9):187-188. doi: 10.3969/j.issn.1007-1865.2019.09.087

HU X J, BAI Y P, ZHANG S P, et al. Application of combined disposal technology of hazardous waste chromium residue and alkali residue[J]. Guangdong Chemical Industry, 2019, 46(9):187-188. doi: 10.3969/j.issn.1007-1865.2019.09.087

[19] 李彩霞. 钒铬渣制备氢氧化铬的研究[J]. 铁合金, 2018, 49(6):15-17+37. doi: 10.16122/j.cnki.issn1001-1943.2018.06.005

LI C X. Study on the preparation of chromium hydroxide from vanadium chromium slag[J]. Iron Alloys, 2018, 49(6):15-17+37. doi: 10.16122/j.cnki.issn1001-1943.2018.06.005

[20] 吴俊, 秦险峰, 全学军, 等. 铬铁矿无钙焙烧渣中铬盐水洗回收及还原解毒工艺研究[J]. 无机盐工业, 2019, 51(2):56-61.

WU J, QIN X F, QUAN X J, et al. Study on the recovery and detoxification process of chromium brine in calcium-free roasting slag of chromite[J]. Inorganic Salt Industry, 2019, 51(2):56-61.

[21] 张焕然, 王俊娥. 电镀污泥资源化利用及处置技术进展[J]. 矿产保护与利用, 2016(3):73-78. doi: 10.13779/j.cnki.issn1001-0076.2016.03.015

ZHANG H R, WANG J E. Progress in resource utilization and disposal technology of electroplating sludge[J]. Mineral Resources Conservation and Utilization, 2016(3):73-78. doi: 10.13779/j.cnki.issn1001-0076.2016.03.015

[22] 张垒, 刘尚超, 张道权, 等. 烧结炼铁协同处置含铬污泥的应用研究[J]. 烧结球团, 2018, 43(5):61-64.

ZHANG L, LIU S C, ZHANG D Q, et al. Study on the application of co-processing of chromium-containing sludge in sintering ironmaking[J]. Sinter Pellet, 2018, 43(5):61-64.

[23] Wang G, Lin M, Diao J, etal. Correction to Novel Strategy for Green Comprehensive Utilization of Vanadium Slag with High-Content Chromium[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(1):723-723.

[24] 易龙生, 刘苗, 赵立华, 等. 电镀污泥氨浸渣中铬的回收[J]. 环境污染与防治, 2020, 42(3):334-338.

YI L S, LIU M, ZHAO L H, et al. Recovery of chromium from electroplating sludge ammonia leaching residue[J]. Environmental Pollution and Control, 2020, 42(3):334-338.

[25] Preston Devasia, K. A. Natarajan. Bacterial leaching. 2004, 9(8): 27-34.

[26] 汪正洁, 杨健, 潘德安, 等. 不锈钢渣资源化利用技术研究现状[J]. 钢铁研究学报, 2015, 27(2):1-6.

WANG Z J, YANG J, PAN D A, et al. Research status of stainless steel slag resource utilization technology[J]. Journal of Iron and Steel Research, 2015, 27(2):1-6.

[27] 吕岩, 杨利彬, 杨勇, 等. 一种不锈钢渣中铬的在线解毒处理方法[P]. CN109628688A, 2019-04-16.

LV Y, YANG L B, YANG Y, et al. An online detoxification method for chromium in stainless steel slag[P]. CN109628688A, 2019-04-16.

[28] Liu M, Ma G, Zhang X, et al. Preparation of black ceramic tiles using waste copper slag and stainless steel slag of electric arc furnace[J]. Materials, 2020, 13(3).

[29] Lin Y, Yan B J, Fabritius Timo, et al. Immobilization of chromium in stainless steel slag using low zinc electric arc furnace dusts[J]. Metallurgical and Materials Transactions, 2020, 51(2).

[30] Beretta G, Daghio M, Tofalos A E, et al. Microbial assisted hexavalent chromium removal in bioelectrochemical Systems[J]. Water, 2020, 12(2).

[31] Foquan Gu, Yuanbo Zhang, Zhiwei Peng, et al. Selective recovery of chromium from ferronickel slag via alkaline roasting followed by water leaching[J]. Journal of Hazardous Materials, 2019:374.

[32] 王会刚, 彭犇, 岳昌盛, 等. 钢渣改性研究进展及展望[J]. 环境工程, 2020, 38(5):133-137+106. doi: 10.13205/j.hjgc.202005023

WANG H G, PENG B, YUE C S, et al. Research progress and prospects of steel slag modification[J]. Environmental Engineering, 2020, 38(5):133-137+106. doi: 10.13205/j.hjgc.202005023

[33] Julia Rosales, Francisco Agrela, José Antonio Entrenas, et al. Potential of stainless steel slag waste in manufacturing self-compacting concrete[J]. Materials, 2020, 13:2049.

[34] Zhang Y X, Liu S L, OuYang S L, et al. Transformation of unstable heavy metals in solid waste into stable state by the preparation of glass-ceramics[J]. Materials Chemistry and Physics, 2020.

-

下载:

下载: