Research Progress on Lithium Extraction and Comprehensive Utilization from Lepidolite

-

摘要:

锂是一种重要的战略金属资源,随着电子化工行业的飞速发展,锂的需求量逐步增加。由于原生资源稀少,锂云母是提取锂产品的主要来源之一,矿石提锂清洁高效综合利用资源是该领域研究的重点。在了解锂产品的用途、附着的矿床及其锂云母的组成及结构特点的基础上,重点讨论了从锂云母中提取锂及其有价金属综合回收的几种工艺方法及提取原理,并比较了各种工艺方法的优缺点。酸法工艺技术简单、成熟,成本相对较低,但其应用受到浸出液中杂质过多的限制;碱法能够降低能耗,但在反应机理,工艺优化,设备腐蚀,试剂回收和安全控制等方面还需要做更多的工作;盐法或高压蒸汽法会消耗大量能源,但可以降低杂质含量;从锂云母中除去铝和氟可以降低锂中的杂质。未来应着力于探索低成本、高效、环保的回收工艺,从而实现锂云母中锂及有价金属的高效回收利用。

Abstract:Lithium is an important strategic metal resource. With the rapid development of the electronic chemical industry, the demand for lithium is gradually increasing. Due to the scarcity of primary resources, lepidolite is one of the main sources of lithium extraction products. The clean, efficient and comprehensive utilization of lithium extraction from ore is the focus of research in this field. Based on the understanding of the use of lithium products, the attached deposits and the composition and structural characteristics of their lepidolite, several methods and extraction principles for the comprehensive recovery of lithium and its valuable metals from lepidolite are discussed and compared. The advantages and disadvantages of various process methods are discussed. The acid process technology is simple and mature, and the cost is relatively low, but its application is limited by excessive impurities in the leaching solution; the alkaline process can reduce energy consumption, but in terms of reaction mechanism, process optimization, equipment corrosion, reagent recovery and safety control, etc. More work needs to be done; the salt method or high-pressure steam method consumes a lot of energy, but can reduce the impurity content; removing aluminum and fluorine from the lepidolite can reduce the impurities in lithium. In the future, efforts should be made to explore low-cost, high-efficiency, and environmentally friendly recycling processes to achieve efficient recycling of lithium and valuable metals in lepidolite.

-

Key words:

- Lepidolite /

- Roasting /

- Leaching /

- Comprehensive utilization /

- Clean up

-

-

[1] 吴西顺, 王登红, 黄文斌, 等. 全球锂矿及伴生铍铌钽的采选冶技术发展趋势[J]. 矿产综合利用, 2019(1):1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2019(1):1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

[2] 吴西顺, 孙艳, 王登红, 等. 国际锂矿开发技术现状、革新及展望[J]. 矿产综合利用, 2020(6):110-120. doi: 10.3969/j.issn.1000-6532.2020.06.019

WU X S, SUN Y, WANG D H, et al. International lithium mine utilization technology: current status, innovation and prospects[J]. Multipurpose Utilization of Mineral Resources, 2020(6):110-120. doi: 10.3969/j.issn.1000-6532.2020.06.019

[3] 李金龙, 何亚群, 付元鹏, 等. 废弃锂离子电池正极材料酸浸出试验研究[J]. 矿产综合利用, 2020(2):128-134. doi: 10.3969/j.issn.1000-6532.2020.02.023

LI J L, HE Y Q, FU Y P, et al. Study on leaching cathode materials of spent lithium-ion batteries[J]. Multipurpose Utilization of Mineral Resources, 2020(2):128-134. doi: 10.3969/j.issn.1000-6532.2020.02.023

[4] Wouters, J, Grepioni, et al. Novel pharmaceutical compositions through co-crystallization of racetams and Li+ salts[J]. Crystengcomm, 2013.

[5] Kostrivas A, Lippold J C. Weldability of Li-bearing aluminium alloys[J]. Metallurgical Reviews, 1999, 44(6):217-237. doi: 10.1179/095066099101528289

[6] Talens Peir L, Villalba M Ndez G, Ayres R U. Lithium: Sources, production, uses, and recovery outlook[J]. JOM (Warrendale, Pa. :1989), 2013, 65(8):986-996.

[7] Deng Hong Wang, et al. Research and exploration progress on lithium deposits in China[J]. China Geology, 2020, 31:137-152.

[8] 朱文龙, 黄万抚. 国内外锂矿物资源概况及其选矿工艺综述[J]. 现代矿业, 2010, 26(7):1-4. doi: 10.3969/j.issn.1674-6082.2010.07.001

ZHU W L, HUANG W F. Overview of lithium mineral resources at home and abroad and its beneficiation technology[J]. Modern Mining, 2010, 26(7):1-4. doi: 10.3969/j.issn.1674-6082.2010.07.001

[9] 程仁举, 李成秀, 刘星, 等. 川西某伟晶岩型锂辉石矿浮选试验研究[J]. 矿产综合利用, 2020(6):148-152. doi: 10.3969/j.issn.1000-6532.2020.06.025

CHENG R J, LI C X, LIU X, et al. Experimental research on the flotation of a pegmatite type spodumene ore in Western Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(6):148-152. doi: 10.3969/j.issn.1000-6532.2020.06.025

[10] Bulletin, 2017 M. Chinese EV boom to spur lithium capacity growth in 2018 (2017)

[11] Ogorodova L, I. Kiseleva, L. Melchakova. Thermodynamic properties of lithium micas[J]. Geochemistry International, 2010, 48(4):415-418. doi: 10.1134/S0016702910040117

[12] Hui Guo, et al. Enhanced acid treatment to extract lithium from lepidolite with a fluorine-based chemical method[J]. Hydrometallurgy 183(2019): 9-19.

[13] Kuang G, Li H, Hu S, et al. Recovery of aluminium and lithium from gypsum residue obtained in the process of lithium extraction from lepidolite[J]. Hydrometallurgy, 2015, 157:214-218. doi: 10.1016/j.hydromet.2015.08.020

[14] 冯文平, 谢晶磊, 汤建良, 等. 硫酸浸取锂云母提锂方法的研究[J]. 精细化工中间体, 2016, 46(3):66-69. doi: 10.19342/j.cnki.issn.1009-9212.2016.03.017

FENG W P, XIE J L, TANG J L, et al. Study on the method of extracting lithium from lepidolite with sulfuric acid[J]. Fine Chemical Intermediates, 2016, 46(3):66-69. doi: 10.19342/j.cnki.issn.1009-9212.2016.03.017

[15] Leemann A, Saout G L, Winnefeld F, et al. Alkali–silica reaction: the influence of calcium on silica dissolution and the formation of reaction products[J]. Journal of the American Ceramic Society, 2011, 94(4):1243-1249. doi: 10.1111/j.1551-2916.2010.04202.x

[16] 李良彬, 胡耐根, 黄学武, 等. 硫酸法锂云母提锂工艺中精硫酸锂溶液的生产方法: CN, 200610145362.5 [P]. 2008.

LI L B, HU N G, HUANG X W, et al. Production method of refined lithium sulfate solution in the process of extracting lithium from lepidolite by sulfuric acid method: CN, 200610145362.5 [P]. 2008.

[17] 赵寻, 杨静, 马鸿文, 等. 硫酸介质中锂云母分解反应动力学[J]. 中国有色金属学报, 2015, 25(9):2588-2595. doi: 10.19476/j.ysxb.1004.0609.2015.09.035

ZHAO X, YANG J, MA H W, et al. The decomposition reaction kinetics of lepidolite in sulfuric acid medium[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9):2588-2595. doi: 10.19476/j.ysxb.1004.0609.2015.09.035

[18] Vieceli N, Nogueira C A, Pereira M F C, et al. Recovery of lithium carbonate by acid digestion and hydrometallurgical processing from mechanically activated lepidolite[J]. Hydrometallurgy, 2017:S0304386X17304413.

[19] Zhang X. Energy-efficient and simultaneous extraction of lithium, rubidium and cesium from lepidolite concentrate via sulfuric acid baking and water leaching[J]. Hydrometallurgy, 2019.

[20] 裴文涛. 锂云母氟化学法多相反应器提锂新技术研究[D]. 福州: 福州大学, 2017.

PEI W T. Research on new technology of lithium extraction from lepidolite fluoride chemical multiphase reactor[D]. Fuzhou: Fuzhou University, 2017.

[21] Kumar M, Babu M N, Mankhand T R, et al. Precipitation of sodium silicofluoride (Na2SiF6) and cryolite (Na3AlF6) from HF/HCl leach liquors of alumino-silicates[J]. Hydrometallurgy, 2010, 104(2):304-307. doi: 10.1016/j.hydromet.2010.05.014

[22] Rosales G D, Pinna E G, Suarez D S, et al. Recovery process of Li, Al and Si from lepidolite by leaching with HF[J]. Minerals, 2017, 7(3):36. doi: 10.3390/min7030036

[23] Meshram P, Pandey B D, Mankhand T R. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: a comprehensive review[J]. Hydrometallurgy, 2014, 150:192-208.

[24] 李军, 朱庆山, 李洪钟. 典型含锂矿物焙烧提锂研究进展[J]. 中国科学:化学, 2017, 47(11):1273-1283.

LI J, ZHU Q S, LI H Z. Research progress on extraction of lithium by roasting typical lithium-containing minerals[J]. Science in China: Chemistry, 2017, 47(11):1273-1283.

[25] 伍习飞. 宜春锂云母提锂工艺及机理研究[D]. 长沙: 中南大学, 2012.

WU X F. Study on the technology and mechanism of lithium extraction from Yichun lepidolite[D]. Changsha: Central South University, 2012.

[26] 林高逵. 江西锂云母-石灰石烧结工艺的改进研究[J]. 稀有金属与硬质合金, 1999(2):3-5.

LIN G K. Study on improvement of Jiangxi lepidolite-limestone sintering process[J]. Rare Metals and Cemented Carbides, 1999(2):3-5.

[27] 王丁, 陈树, 刘昕昕, 等. 锂云母碱溶法提锂新工艺研究[J]. 无机盐工业, 2014, 46(9):26-28+40. doi: 10.3969/j.issn.1006-4990.2014.09.006

WANG D, CHEN S, LIU X X, et al. Research on the new technology of lithium extraction from lepidolite by alkaline solution[J]. Inorganic Salt Industry, 2014, 46(9):26-28+40. doi: 10.3969/j.issn.1006-4990.2014.09.006

[28] 苏慧, 朱兆武, 王丽娜, 齐涛. 矿石资源中锂的提取与回收研究进展[J]. 化工学报, 2019, 70(1):10-23. doi: 10.11949/j.issn.0438-1157.20180465

SU H, ZHU Z W, WANG L N, QI T. Research progress on the extraction and recovery of lithium from ore resources[J]. CIESC Journal, 2019, 70(1):10-23. doi: 10.11949/j.issn.0438-1157.20180465

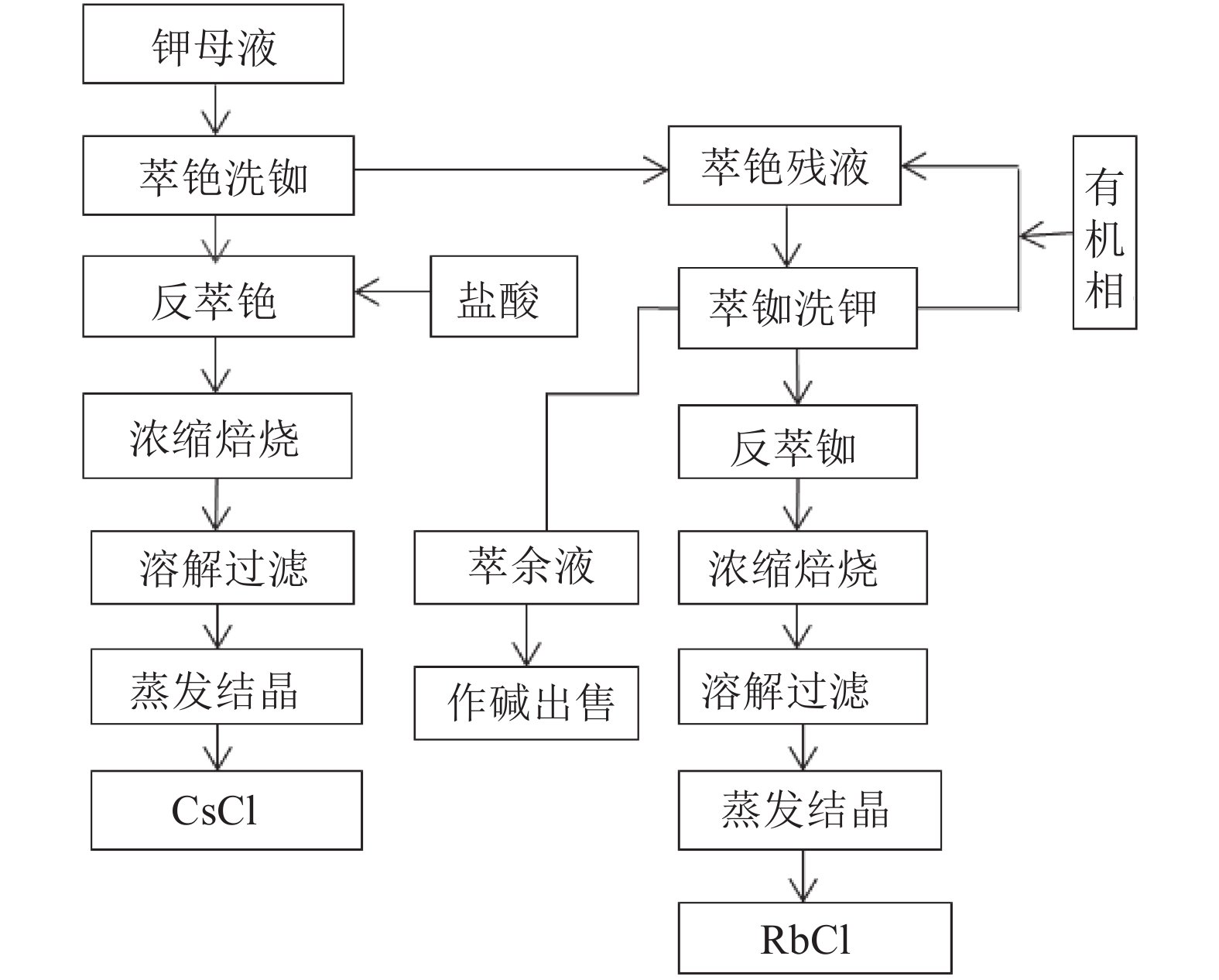

[29] 陈正炎, 胡莉茵, 程步陞. t-BAMBP萃取分离铷、铯[J]. 稀有金属, 1992(5):331-337. doi: 10.13373/j.cnki.cjrm.1992.05.004

CHEN Z Y, HU L Y, CHENG B S. Extraction and separation of rubidium and cesium with t-BAMBP[J]. Rare Metals, 1992(5):331-337. doi: 10.13373/j.cnki.cjrm.1992.05.004

[30] 雷祖伟, 钟宏. 含铷、铯锂云母矿的复合盐焙烧-浸出性能及机理[J]. 矿产综合利用, 2019(3):152-158. doi: 10.3969/j.issn.1000-6532.2019.03.033

LEI Z W, ZHONG H. Composite salt roasting - leaching performance and mechanism of lepidolite containing rubidium and cesium[J]. Multipurpose Utilization of Mineral Resources, 2019(3):152-158. doi: 10.3969/j.issn.1000-6532.2019.03.033

[31] Su H, Ju J, Zhang J, et al. Lithium recovery from lepidolite roasted with potassium compounds[J]. Minerals Engineering, 2020, 145:106087. doi: 10.1016/j.mineng.2019.106087

[32] Yan Q, Li X, Wang Z, et al. Extraction of lithium from lepidolite by sulfation roasting and water leaching[J]. International Journal of Mineral Processing, 2012, 110-111(none):1-5.

[33] Van Tri Luong, Dong Jun Kang, Jeon Woong An, et al. Iron sulphate roasting for extraction of lithium from lepidolite[J]. Hydrometallurgy, 2014.

[34] 虞宝煜, 毕玉峰. 锂云母与NaCl及NaCl-CaCl2的相互作用[J]. 稀有金属, 1994(3):231-232+235.

YU B Y, BI Y F. The interaction of lepidolite with NaCl and NaCl-CaCl2[J]. Rare Metals, 1994(3):231-232+235.

[35] 伍习飞, 尹周澜, 李新海, 等. 氯化焙烧法处理宜春锂云母矿提取锂钾的研究[J]. 矿冶工程, 2012, 32(3):95-98. doi: 10.3969/j.issn.0253-6099.2012.03.026

WU X F, YIN Z L, LI X H, et al. Study on extraction of lithium and potassium from Yichun lepidolite ore by chlorination roasting method[J]. Mining and Metallurgical Engineering, 2012, 32(3):95-98. doi: 10.3969/j.issn.0253-6099.2012.03.026

[36] Zhang X, Aldahri T, Tan X, et al. Efficient co-extraction of lithium, rubidium, cesium and potassium from lepidolite by process intensification of chlorination roasting[J]. Chemical Engineering and Processing, 2019, 147:107777.

[37] Thi, Thu, Hien-Dinh, et al. Extraction of lithium from lepidolite via iron sulphide roasting and water leaching[J]. Hydrometallurgy, 2015, 153:154-159. doi: 10.1016/j.hydromet.2015.03.002

[38] Samoilov V I, Onalbaeva Z S, Adylkanova M A, et al. Development of alkaline decomposition of lepidolite concentrate by melting with calcined soda and melt comprehensive sulfuric acid treatment[J]. Metallurgist, 2018, 62(3-4):361-368. doi: 10.1007/s11015-018-0669-z

[39] 王文祥, 黄际芬, 刘志宏. 宜春锂云母压煮溶出新工艺研究[J]. 有色金属 (冶炼部分), 2001(5):19-21.

WANG W X, HUANG J F, LIU Z H. Research on the new technology of Yichun lepidolite pressure cooking dissolution[J]. Nonferrous Metals (Extractive Metallurgy), 2001(5):19-21.

[40] 王丁, 陈树. 高压蒸汽法处理锂云母提锂工艺研究[J]. 无机盐工业, 2020, 52(2):47-49. doi: 10.11962/1006-4990.2019-0168

WANG D, CHEN S. Research on the high-pressure steam treatment of lepidolite to extract lithium[J]. Inorganic Salt Industry, 2020, 52(2):47-49. doi: 10.11962/1006-4990.2019-0168

[41] Jinlian Liu, L Y Zhou, X H Li, et al. A novel process for the selective precipitation of valuable metals from lepidolite[J]. Hydrometallurgy, 2019:29-36.

[42] Guo, Hui, Yang, et al. Fundamental research on a new process to remove Al3+ as potassium alum during lithium extraction from lepidolite[J]. Metallurgical and Materials Transactions, B. Process metallurgy and materials processing science, 2016.

-

下载:

下载: