Purification and Preparation of Quartz Sand for Photovoltaic Glass in Enshi of Hubei Province

-

摘要:

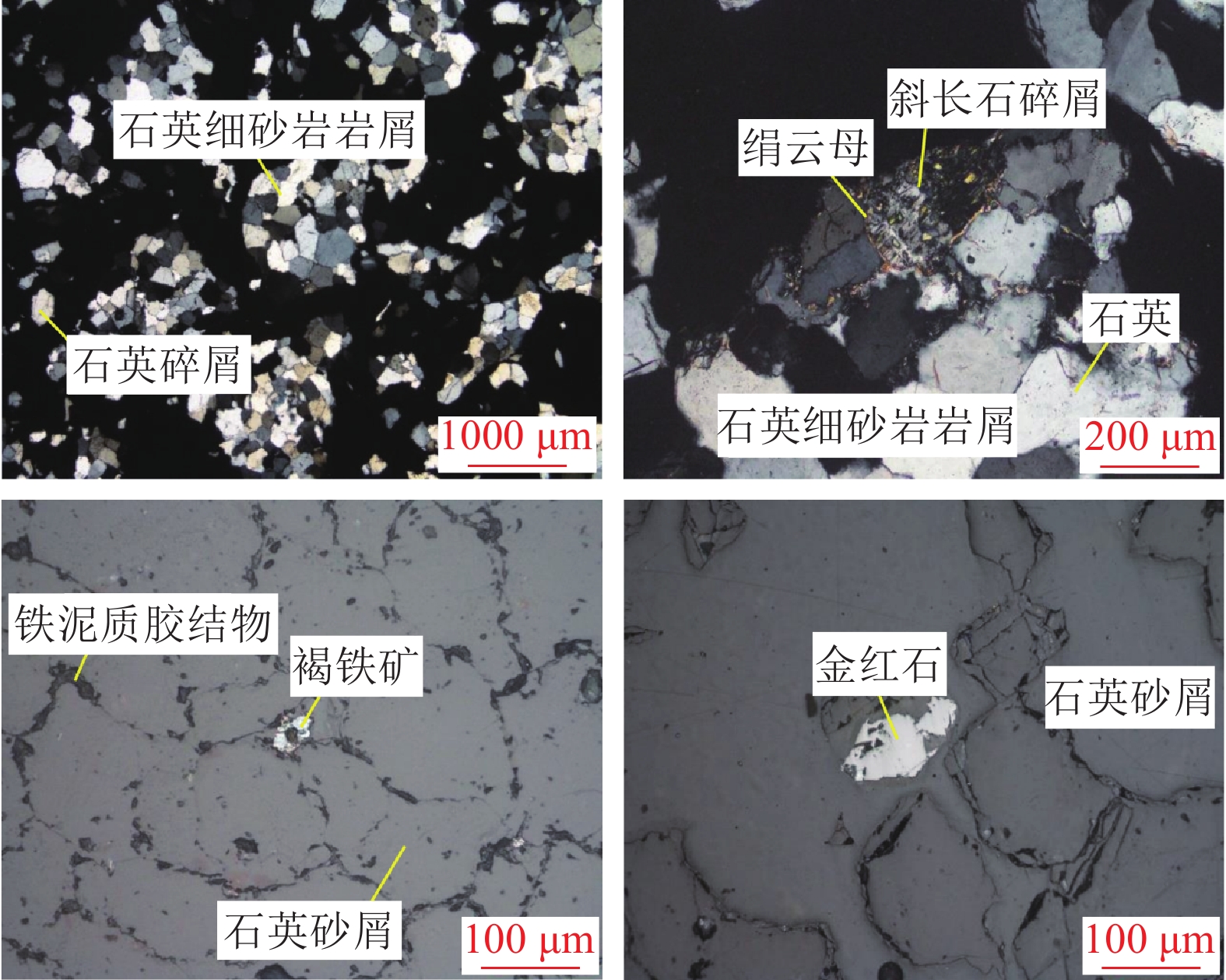

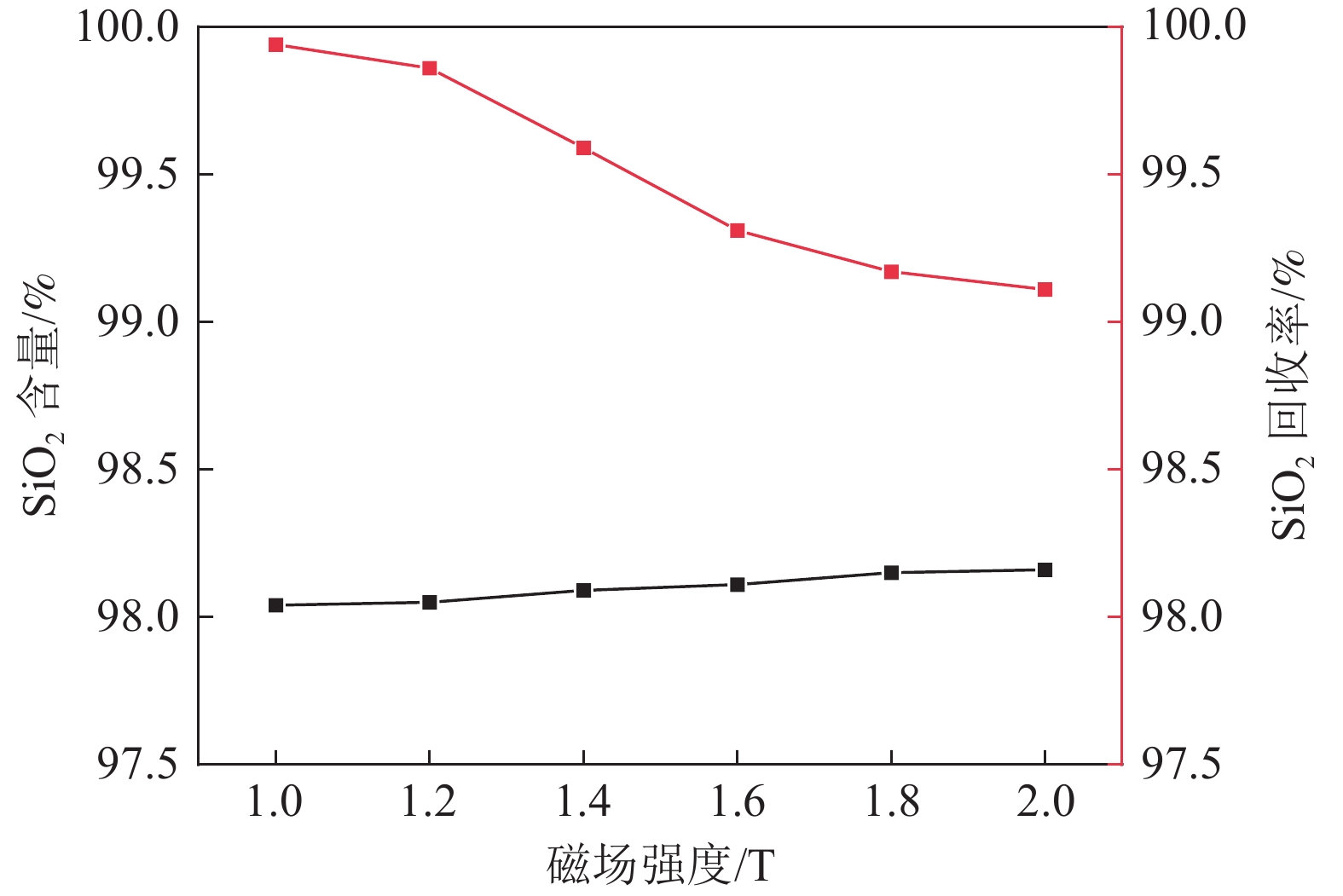

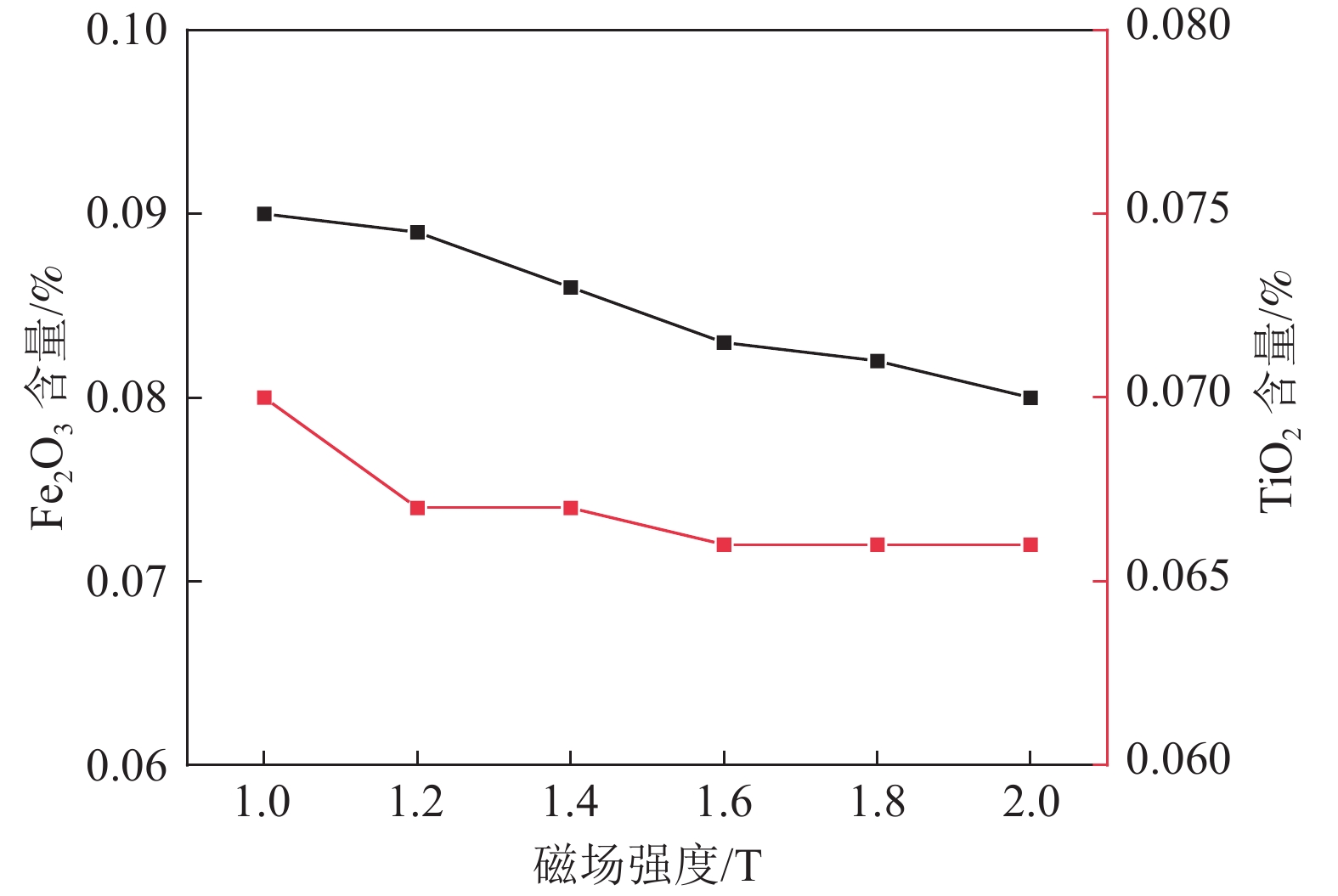

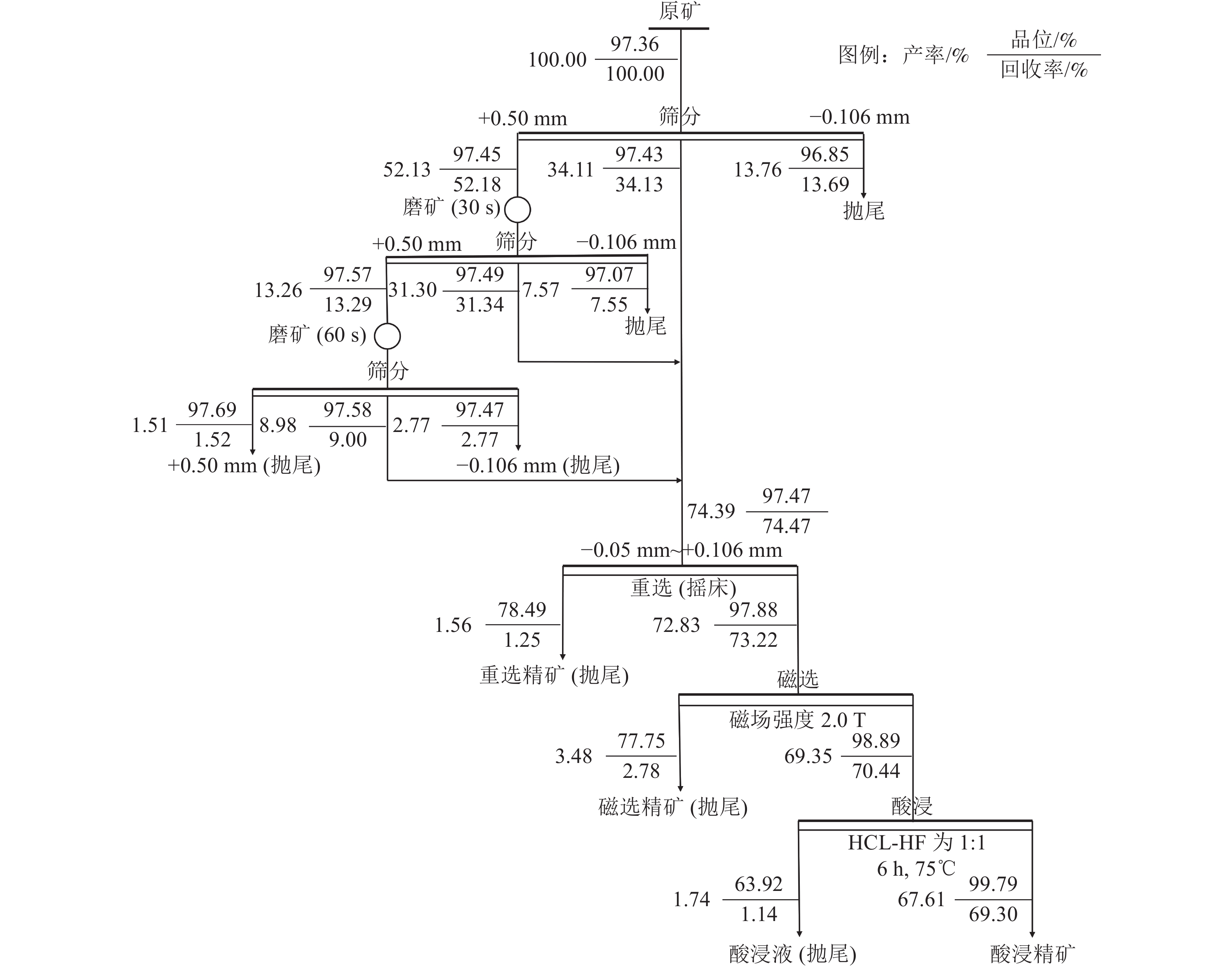

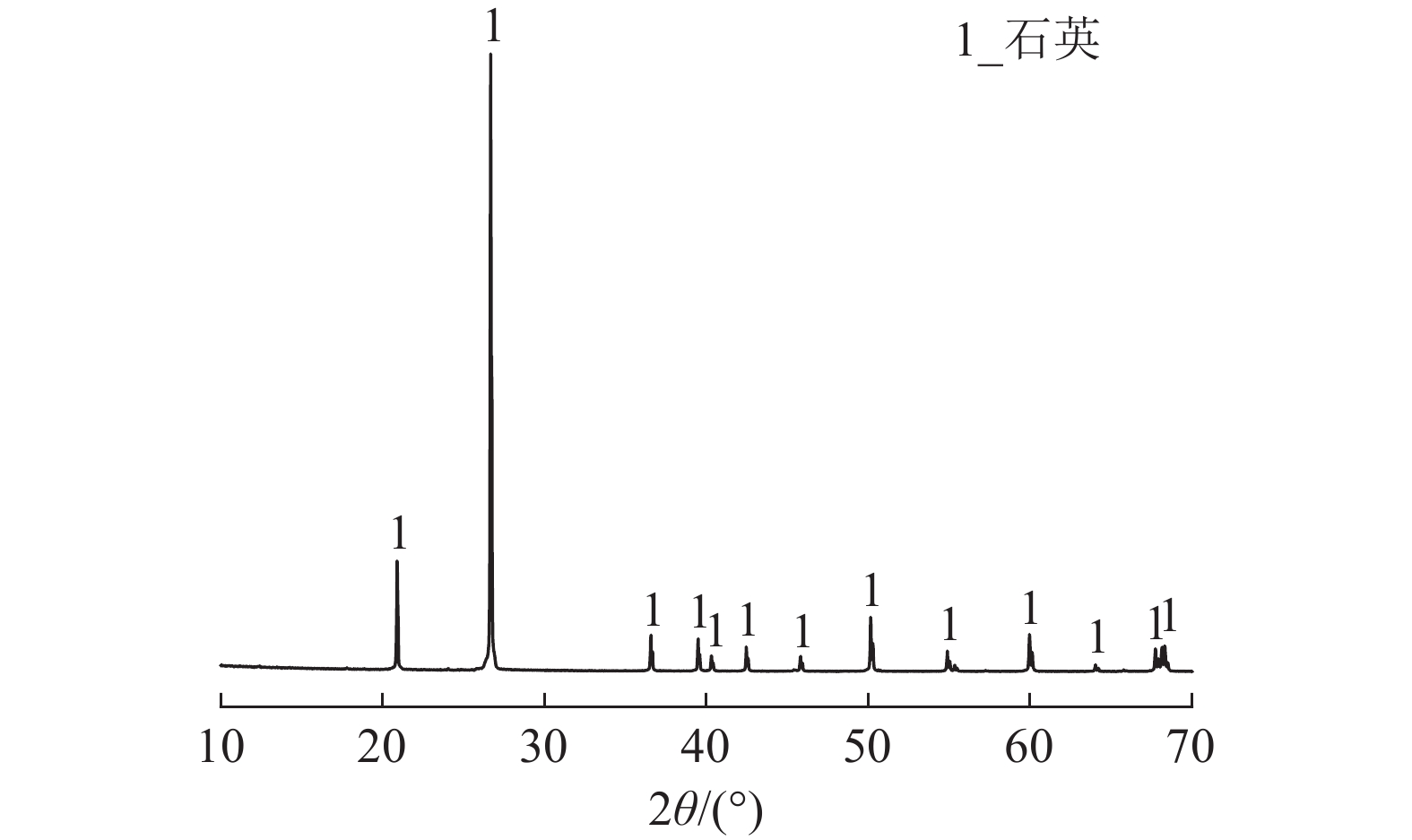

这是一篇关于矿物加工工程领域的文章。光伏玻璃用石英砂是支撑新能源行业发展必不可少的原料之一,其供应安全保障事关我国双碳政策的成功实施。本文以湖北省恩施州某大型石英砂矿为研究对象,开展了工艺矿物学与除杂提纯实验研究,发现该石英砂矿的主要杂质为斜长石、云母、褐铁矿和金红石,采用了“分级-重选-磁选-酸浸”选矿工艺流程,最终获得符合粒度要求(0.106 ~ 0.500 mm)的石英砂精矿产率为67.61 %,其SiO2含量由97.36 %提高至99.79 %,有害元素Fe2O3、TiO2与Al2O3含量则分别降低至75、80、630 g/t,石英精矿产品各项指标达到了光伏玻璃用硅质原料的生产要求,实现了该石英砂矿的有效利用。

Abstract:This is an article in the field of mining processing engineering. Quartz sand for photovoltaic glass is one of the essential raw materials to support the development of the new energy industry, and its supply security is related to the successful implementation of China's two-carbon policy. In this paper, one of the essential raw materials for development, its supply security is related to the successful implementation of China's two-carbon policy. In this paper, a large quartz sand mine in Enshi Prefecture of Hubei Province was studied, and process mineralogy and purification were carried out. It was found that the main impurities of this quartz sand mine were plagioclase, mica, limonite and rutile. The mineral processing of "fractionation-gravity separation-magnetic separation-acid leaching" was adopted, and the yields of quartz sand that met the particle size requirements (0.106 ~ 0.500 mm)were 67.61%, the content of SiO2 was increased from 97.36% to 99.79%, and the contents of harmful elements Fe2O3, TiO2 and Al2O3 were separately reduced to 75, 80 and 630 g/t. The quartz concentrates meet the production requirements of siliceous raw materials for photovoltaic glass, realizing the effective utilization of the quartz sand ore.

-

-

表 1 石英砂原矿中主要矿物及杂质含量/%

Table 1. Main useful minerals and impurities of quartz samples

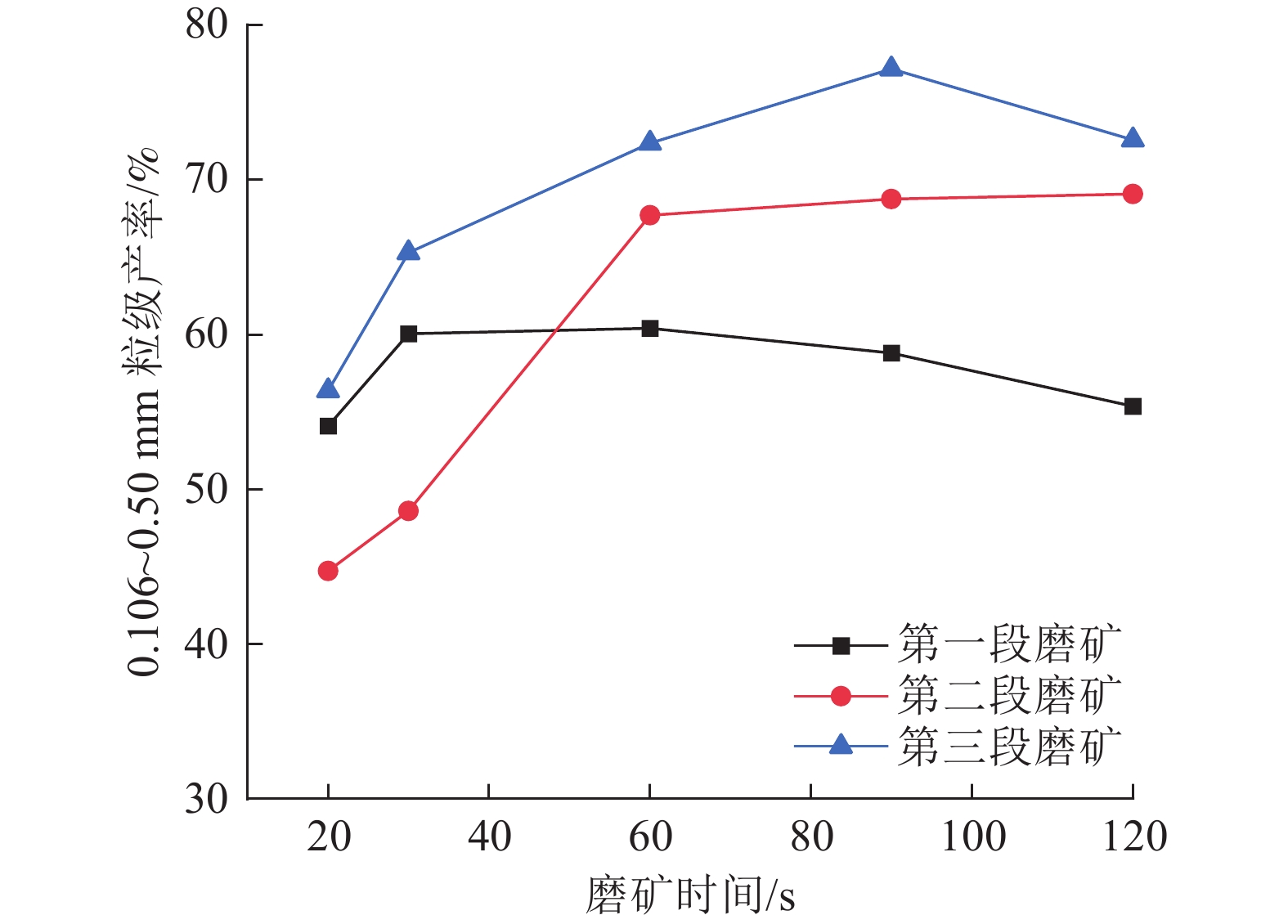

Fe2O3 Al2O3 SiO2 TiO2 CaO Cr2O3* 0.25 1.12 97.36 0.073 0.100 1.95 *单位为g/t 表 2 较佳磨矿时间的各阶段0.106 ~ 0.500 mm粒级石英产率

Table 2. Yields of 0.106 ~0.500 mm quartz for each stage of grinding under the optimum grinding time of quartz samples

作业名称 对作业产率/% 对原矿产率/% 原矿分级 34.11 34.11 一段磨矿 60.04 31.30 二段磨矿 67.72 8.98 三段磨矿 76.82 1.16 两段磨矿总产率 - 74.39 三段磨矿总产率 - 75.55 表 3 石英砂重磁联合选别实验结果

Table 3. Combined gravity separation and magnetic separation results of quartz sand

产品 产率/% Fe2O3含量/% TiO2含量/% 作业产率 原矿产率 重选尾矿 2.10 1.56 1.280 1.950 一段磁选尾矿 4.78 3.48 0.660 0.032 一段磁选精矿 95.22 69.35 0.067 0.019 给矿 100.00 74.39 0.120 0.060 表 4 石英砂盐酸酸浸正交实验结果

Table 4. Orthogonal results of quartz sand leaching tests using hydrochloric acid as the leaching reagent

实验组号 正交序列 时间A/h 温度B/℃ 液固比C 精矿含量/% Al2O3 Fe2O3 SiO2 TiO2 1 111 3.0 25 1∶1 0.29 0.0230 99.26 0.010 2 123 3.0 50 3∶1 0.42 0.0241 99.08 0.016 3 132 3.0 75 2∶1 0.42 0.0210 99.12 0.016 4 213 6.0 25 3∶1 0.22 0.0233 99.25 0.008 5 222 6.0 50 2∶1 0.36 0.0200 99.15 0.015 6 231 6.0 75 1∶1 0.33 0.0214 99.20 0.015 7 312 9.0 25 2∶1 0.29 0.0220 99.14 0.012 8 321 9.0 50 1∶1 0.25 0.0172 99.22 0.009 9 333 9.0 75 3∶1 0.38 0.0202 99.15 0.014 极差 0.05 0.07 0.09 表 5 盐酸-氢氟酸正交实验结果

Table 5. Results of hydrochloric acid-hydrofluoric acid orthogonal test

实验组号 正交序列 酸配比A(HCl 15%- HF 5%) 时间B/h 温度C/℃ 精矿含量/% Al2O3 Fe2O3 SiO2 TiO2 1 111 1∶1 3.0 25 0.140 0.0300 99.67 0.009 2 123 1∶1 6.0 75 0.063 0.0075 99.79 0.008 3 132 1∶1 9.0 50 0.068 0.0099 99.79 0.009 4 213 2∶1 3.0 75 0.066 0.0092 99.77 0.008 5 222 2∶1 6.0 50 0.092 0.0100 99.69 0.009 6 231 2∶1 9.0 25 0.130 0.0200 99.70 0.010 7 312 3∶1 3.0 50 0.130 0.0210 99.64 0.009 8 321 3∶1 6.0 25 0.160 0.0270 99.59 0.010 9 333 3∶1 9.0 70 0.071 0.0099 99.71 0.009 极差 0.10 0.04 0.10 -

[1] 杨晓勇, 孙超, 曹荆亚, 等. 高纯石英的研究进展及发展趋势[J]. 地学前缘, 2022, 29(1):231-244.YANG X Y, SUN C, CAO J Y, et al. High purity quartz: Research progress and perspective review[J]. Earth Science Frontiers, 2022, 29(1):231-244.

YANG X Y, SUN C, CAO J Y, et al. High purity quartz: Research progress and perspective review[J]. Earth Science Frontiers, 2022, 29(1):231-244.

[2] 汪灵, 李彩侠, 王艳, 等. 我国高纯石英加工技术现状与发展建议[J]. 矿物岩石, 2011, 31(4): 110-114.WANG L, LI C X, WANG Y, et al. China technologies present of high-purity quartz processing and the development propositions[J]. Mineral Petrol, 2011, 31: 110-114.

WANG L, LI C X, WANG Y, et al. China technologies present of high-purity quartz processing and the development propositions[J]. Mineral Petrol, 2011, 31: 110-114.

[3] 林敏, 徐顺秋, 刘子源, 等. 高纯石英(SiO2)评述(一): 微量、微细粒铝硅酸盐矿物的活化与分离[J]. 矿产综合利用, 2022(6): 17-20+25.LIN M, XU S Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part Ⅰ): activation and separation of trace, fine-grain alumino silicate gangue[J]. Multipurpose Utilization of Mineral Resources, 2022(6): 17-20+25.

LIN M, XU S Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part Ⅰ): activation and separation of trace, fine-grain alumino silicate gangue[J]. Multipurpose Utilization of Mineral Resources, 2022(6): 17-20+25.

[4] 肖蕲航, 李育彪, 汤启宙. 陕西某石英砂工艺矿物学及可选性实验[J]. 矿产综合利用, 2022(3):167-171.XIAO Q H, LI Y B, TANG Q Z. Study on process mineralogy and selectivity of a quartz sand in Shaanxi Province[J]. Multipurpose Utilization of Mineral Resources, 2022(3):167-171. doi: 10.3969/j.issn.1000-6532.2022.03.030

XIAO Q H, LI Y B, TANG Q Z. Study on process mineralogy and selectivity of a quartz sand in Shaanxi Province[J]. Multipurpose Utilization of Mineral Resources, 2022(3):167-171. doi: 10.3969/j.issn.1000-6532.2022.03.030

[5] 李育彪, 雷绍民, 魏桢伦, 等. 高纯石英砂制备技术与原理[M]. 北京: 科学出版社, 2023.LI Y B, LEI S M, WEI Z L, et al. Preparation technology and principle of high purity quartz sand[M]. Beijing: Science Press, 2023.

LI Y B, LEI S M, WEI Z L, et al. Preparation technology and principle of high purity quartz sand[M]. Beijing: Science Press, 2023.

[6] 林敏, 贾倩, 刘子源, 等. 高纯石英(SiO2)评述(二): 晶格杂质的活化与分离技术[J]. 矿产综合利用, 2022(6):21-25.LIN M, JIA Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part Ⅱ): activation and separation of lattice impurities[J]. Multipurpose Utilization of Mineral Resources, 2022(6):21-25. doi: 10.3969/j.issn.1000-6532.2022.06.004

LIN M, JIA Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part Ⅱ): activation and separation of lattice impurities[J]. Multipurpose Utilization of Mineral Resources, 2022(6):21-25. doi: 10.3969/j.issn.1000-6532.2022.06.004

[7] 雷绍民, 裴振宇, 钟乐乐, 等. 脉石英砂无氟反浮选热压浸出技术与机理研究[J]. 非金属矿, 2014, 37(2):40-43.LEI S M, PEI Z Y, ZHONG L L, et al. Study on the technology and mechanism of reverse flotation and hot pressing leaching with vein quartz[J]. Non-Metallic Mines, 2014, 37(2):40-43. doi: 10.3969/j.issn.1000-8098.2014.02.013

LEI S M, PEI Z Y, ZHONG L L, et al. Study on the technology and mechanism of reverse flotation and hot pressing leaching with vein quartz[J]. Non-Metallic Mines, 2014, 37(2):40-43. doi: 10.3969/j.issn.1000-8098.2014.02.013

[8] 张晋, 胡修权, 张立, 等. 某优质脉石英制备超高纯石英砂工艺实验研究[J]. 非金属矿, 2023, 46(2):65-69.ZHANG J, HU X Q, ZHANG L, et al. Experimental study on preparation of ultra-high purity quartz sand from a high quality gangue[J]. Non-Metallic Mines, 2023, 46(2):65-69. doi: 10.3969/j.issn.1000-8098.2023.02.016

ZHANG J, HU X Q, ZHANG L, et al. Experimental study on preparation of ultra-high purity quartz sand from a high quality gangue[J]. Non-Metallic Mines, 2023, 46(2):65-69. doi: 10.3969/j.issn.1000-8098.2023.02.016

[9] 陈坤, 李育彪, 王志杰, 等. 内蒙古某脉石英提纯实验研究[J]. 非金属矿, 2022, 45(1):59-62.CHEN K, LI Y B, WANG Z J, et al. Experimental study on purification of a vein quartz from Inner Mongolia[J]. Non-Metallic Mines, 2022, 45(1):59-62. doi: 10.3969/j.issn.1000-8098.2022.01.016

CHEN K, LI Y B, WANG Z J, et al. Experimental study on purification of a vein quartz from Inner Mongolia[J]. Non-Metallic Mines, 2022, 45(1):59-62. doi: 10.3969/j.issn.1000-8098.2022.01.016

[10] 张立, 胡修权, 张晋, 等. 鄂西地区某脉石英中流体包裹体特征分析[J]. 矿产综合利用, 2023(3):205-210.ZHANG L, HU X Q, ZHANG J, et al. Characteristic analysis on fluid inclusions of vein quartz in Western Hubei Province[J]. Multipurpose Utilization of Mineral Resources, 2023(3):205-210. doi: 10.3969/j.issn.1000-6532.2023.03.034

ZHANG L, HU X Q, ZHANG J, et al. Characteristic analysis on fluid inclusions of vein quartz in Western Hubei Province[J]. Multipurpose Utilization of Mineral Resources, 2023(3):205-210. doi: 10.3969/j.issn.1000-6532.2023.03.034

[11] 林敏, 徐顺秋, 刘子源, 等. 高纯石英(SiO2)评述(三): 流体包裹体的分析、活化与分离[J]. 矿产综合利用, 2022(6):26-29.LIN M, XU S Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part III): Analysis, activation and separation of fluid inclusions[J]. Multipurpose Utilization of Mineral Resources, 2022(6):26-29. doi: 10.3969/j.issn.1000-6532.2022.06.005

LIN M, XU S Q, LIU Z Y, et al. Review for high-purity quartz (SiO2) (Part III): Analysis, activation and separation of fluid inclusions[J]. Multipurpose Utilization of Mineral Resources, 2022(6):26-29. doi: 10.3969/j.issn.1000-6532.2022.06.005

[12] 张立, 胡修权, 彭兴华, 等. 高纯石英砂原料矿中流体包裹体研究[J]. 矿产综合利用, 2022(3):188-192.ZHANG L, HU X Q, PENG X H, et al. Research on fluid inclusions in vein quartz as higher purity quartz sand[J]. Multipurpose Utilization of Mineral Resources, 2022(3):188-192. doi: 10.3969/j.issn.1000-6532.2022.03.033

ZHANG L, HU X Q, PENG X H, et al. Research on fluid inclusions in vein quartz as higher purity quartz sand[J]. Multipurpose Utilization of Mineral Resources, 2022(3):188-192. doi: 10.3969/j.issn.1000-6532.2022.03.033

[13] Platias S, Vatalis K I, Charalampides G. Suitability of quartz sands for different industrial applications[J]. Procedia Economics and Finance, 2014, 14:491-498. doi: 10.1016/S2212-5671(14)00738-2

[14] ZHANG Z, LI J, LI X, et al. High efficiency iron removal from quartz sand using phosphoric acid[J]. International Journal of Mineral Processing, 2012, 114-117:30-34. doi: 10.1016/j.minpro.2012.09.001

-

下载:

下载: