Investigation on Preparation of Glass-ceramics with Iron Tailings

-

摘要:

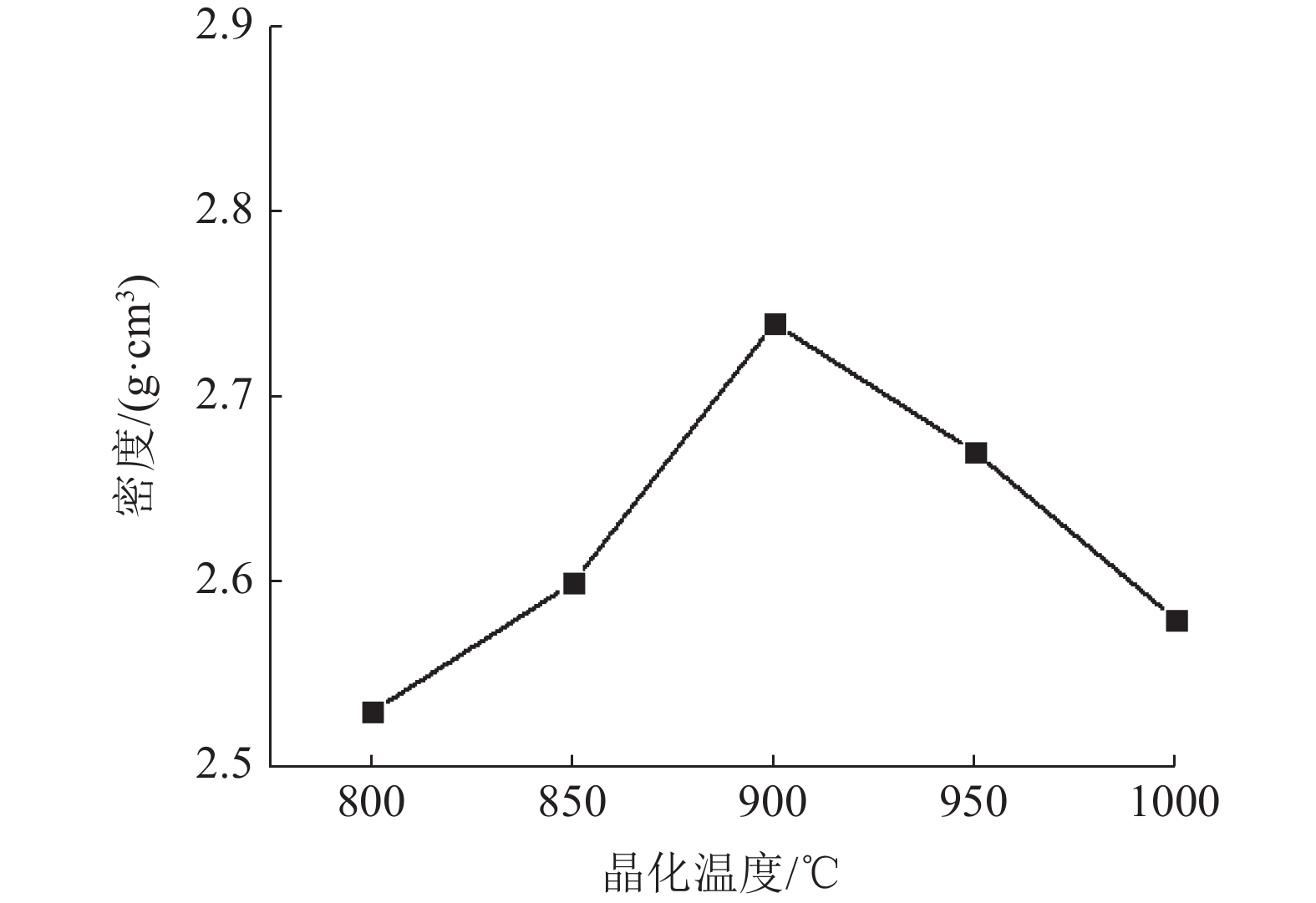

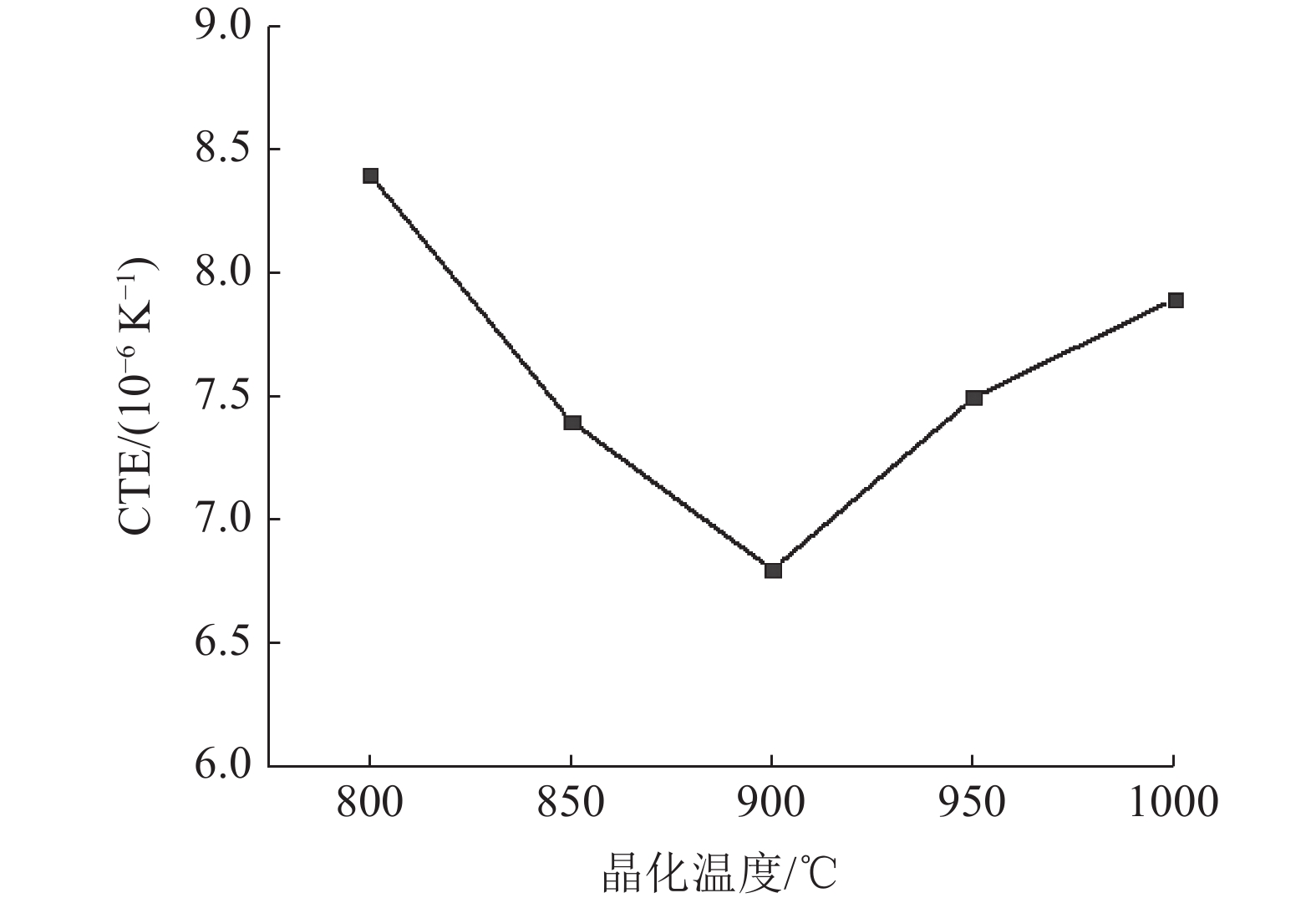

采用烧结法以商洛某尾矿库现存铁尾矿为主要原料制备微晶玻璃。对基础玻璃熔制较佳工艺进行了优化,并探究晶化温度和保温时间对微晶玻璃的抗压强度、密度以及热膨胀系数的影响。结果表明:在熔制温度1400℃,保温2 h条件下熔制的基础玻璃性能较优;在晶化温度900℃,保温2 h条件下晶化处理得到的微晶玻璃试样性能较优,其抗压强度达到158.32 MPa,密度为2.74 g/cm3,热膨胀系数为6.8×10-6 K-1。

Abstract:The glass-ceramics were prepared by sintering method from an iron tailings in Shangluo area. The optimum process parameters of melting base glass were optimized. The effects of the crystallization temperature on the compressive strength, density and thermal expansivity of glass-ceramics were investigated. The results show that optimal performance of the base glass melted can be obtained at the melting temperature of 1400℃ and melting time of 2 h. Moreover the best properties of the glass-ceramics such as compressive strength of 158.32 MPa, density of 2.74 g/cm3, thermal expansivity of 6.8×10-6K-1 could be obtained at the crystallization temperature of 900℃ and holding time of 2 h.

-

Key words:

- Iron tailings /

- Glass-ceramics /

- Compressive strength /

- Coefficient of thermal expansion

-

-

表 1 铁尾矿的化学成分/%

Table 1. Chemical composition of iron tailings

SiO2 Al2O3 CaO MgO Fe2O3 FeO K2O Na2O 其他 66.00 7.06 1.86 0.25 3.18 4.15 2.59 0.86 14.05 表 2 不同熔制温度下得到的基础玻璃特性

Table 2. Characteristics of the base glass at different melting temperatures

熔制温度 1200℃ 1300℃ 1400℃ 特性 粘稠,

有气泡流动,

少量气泡易流动,

无气泡表 3 不同熔制时间下得到的基础玻璃效果

Table 3. Characteristics of the base glass at different melting time

熔制时间 1 h 2 h 3 h 特性 粘稠,

有气泡均匀,

流动性好均匀,

流动性差 -

[1] 张景书. 商洛市尾矿资源综合利用现状及其对策[J]. 商洛学院学报, 2013, 27(4):3-7.

ZHANG J S. Present situation and countermeasures of comprehensive utilization of tailings resources in Shangluo[J]. Journal of Shangluo University, 2013, 27(4):3-7.

[2] 刘淑鹏, 张小伟. 我国金属矿山尾矿综合利用现状及对策[J]. 中国资源综合利用, 2020, 38(3):75-78.

LIU S P, ZHANG X W. Current situation and countermeasures of comprehensive utilization of metal mine tailings in China[J]. China Resources Comprehensive Utilization, 2020, 38(3):75-78.

[3] 吕绍伟, 姜屏, 钱彪, 等. 铁尾矿砂力学特性及再生利用研究进展[J]. 硅酸盐通报, 2020, 39(2):466-470.

LV S W, JIANG P, QIAN B, et al. Advances in mechanical properties and recycling of iron tailing sand[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(2):466-470.

[4] 李红霞, 李保卫, 邓磊波, 等. 微波热处理温度对尾矿微晶玻璃晶化过程及性能的影响[J]. 材料导报, 2019, 33(20): 3401-3407.

LI H X, LI B W, DENG L B, et al. Effect of microwave heat treatment temperature on crystallization process and properties of tailings glass-ceramics[J]. Materials Review, 2019, 33(20): 3401-3407.

[5] 南宁, 刘萍, 孙强强, 等. 利用铁尾矿制备微晶玻璃试验研究[J]. 当代化工, 2019, 48(10):2199-2201.

NAN N, LIU P, SUN Q Q, et al. Experimental study on preparation of glass-ceramics from iron tailings[J]. Contemporary Chemical Industry, 2019, 48(10):2199-2201.

[6] 李红霞, 李保卫, 徐鹏飞, 等. 热处理时间对透辉石系尾矿微晶玻璃析晶及其性能的影响[J]. 材料研究学报, 2020, 34(03):209-216.

LI H X, LI B W, XU P F, et al. Effect of heat treatment time on crystallization and properties of glass-ceramics of diopside tailings[J]. Journal of Materials Research, 2020, 34(03):209-216.

[7] 潘德安, 逯海洋, 刘晓敏, 等. 高硅铁尾矿制备轻质闭孔泡沫陶瓷研究[J]. 中国陶瓷, 2020, 56(3):51-58.

PAN D A, LU H Y, LIU X M, et al. Study on preparation of lightweight closed-cell foam ceramics from high silicone iron tailings[J]. China Ceramics, 2020, 56(3):51-58.

[8] 佟志芳, 范佳乐, 曾庆钋, 等. 利用金属尾矿制备泡沫微晶玻璃的研究现状及展望[J]. 有色金属科学与工程, 2020, 11(2):34-41.

TONG Z F, FAN J L, ZENG Q P, et al. Research status and prospects of foam glasses prepared from metal tailings[J]. Nonferrous Metals Science and Engineering, 2020, 11(2):34-41.

[9] 李保庆, 郭艳平, 党海峰. MgO对飞灰屏玻璃协同制备微晶玻璃析晶及性能的影响[J]. 矿产综合利用, 2020(1):135-139.

LI B Q, GUO Y P, DANG H F. Effect of MgO on crystallization and properties of glass ceramics from fly ash and waste glass[J]. Multipurpose Utilization of Mineral Resources, 2020(1):135-139.

[10] 廖力. 利用铜矿尾矿制备微晶玻璃试验研究[J]. 矿产综合利用, 2017(6):82-85.

LIAO L. Experimental study on preparation of glass-ceramics from copper tailings[J]. Multipurpose Utilization of Mineral Resources, 2017(6):82-85.

-

下载:

下载: