Present Situation of Comprehensive Utilization of High Iron Manganese Oxide Ore and Development in Reduction Roasting

-

摘要:

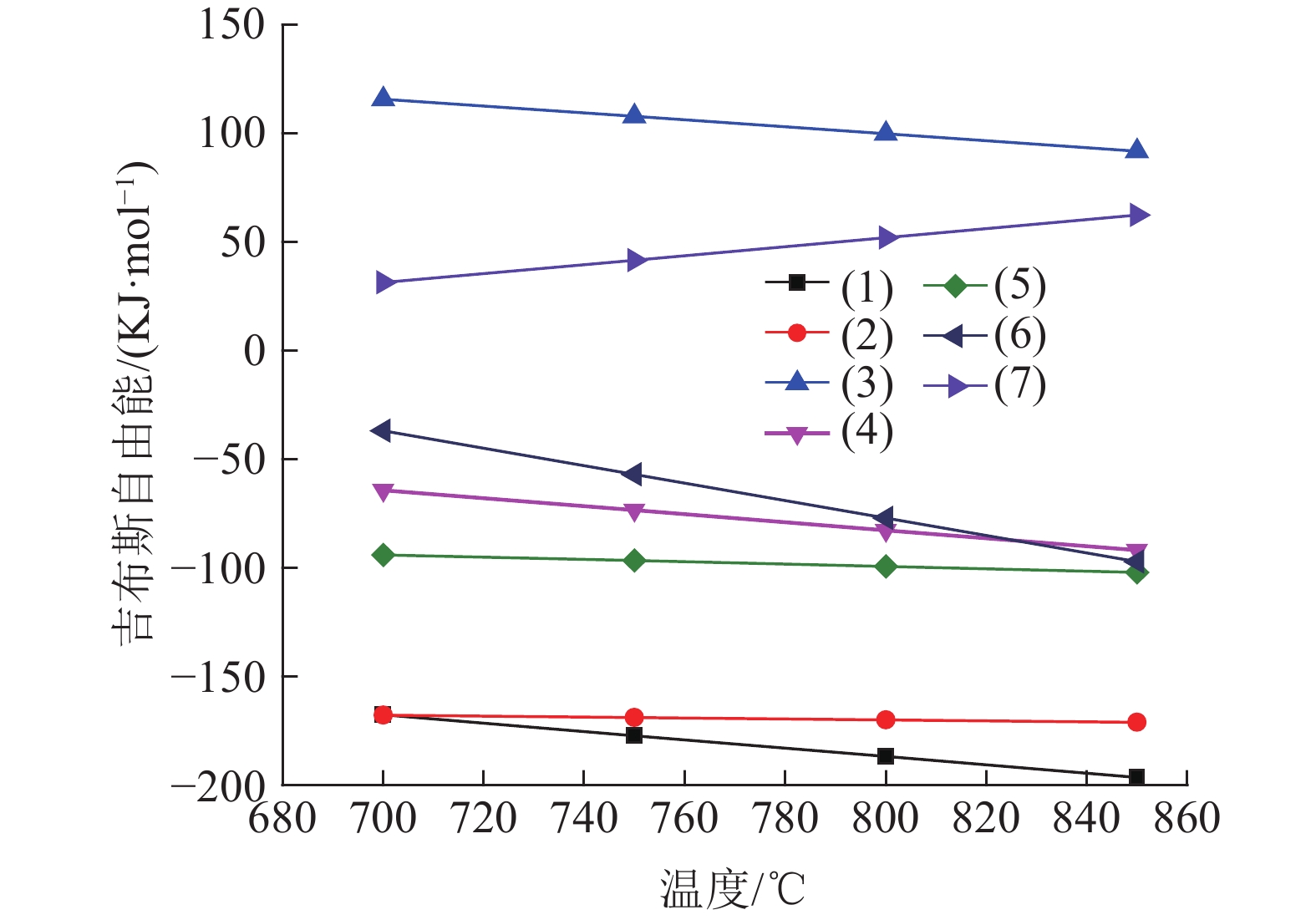

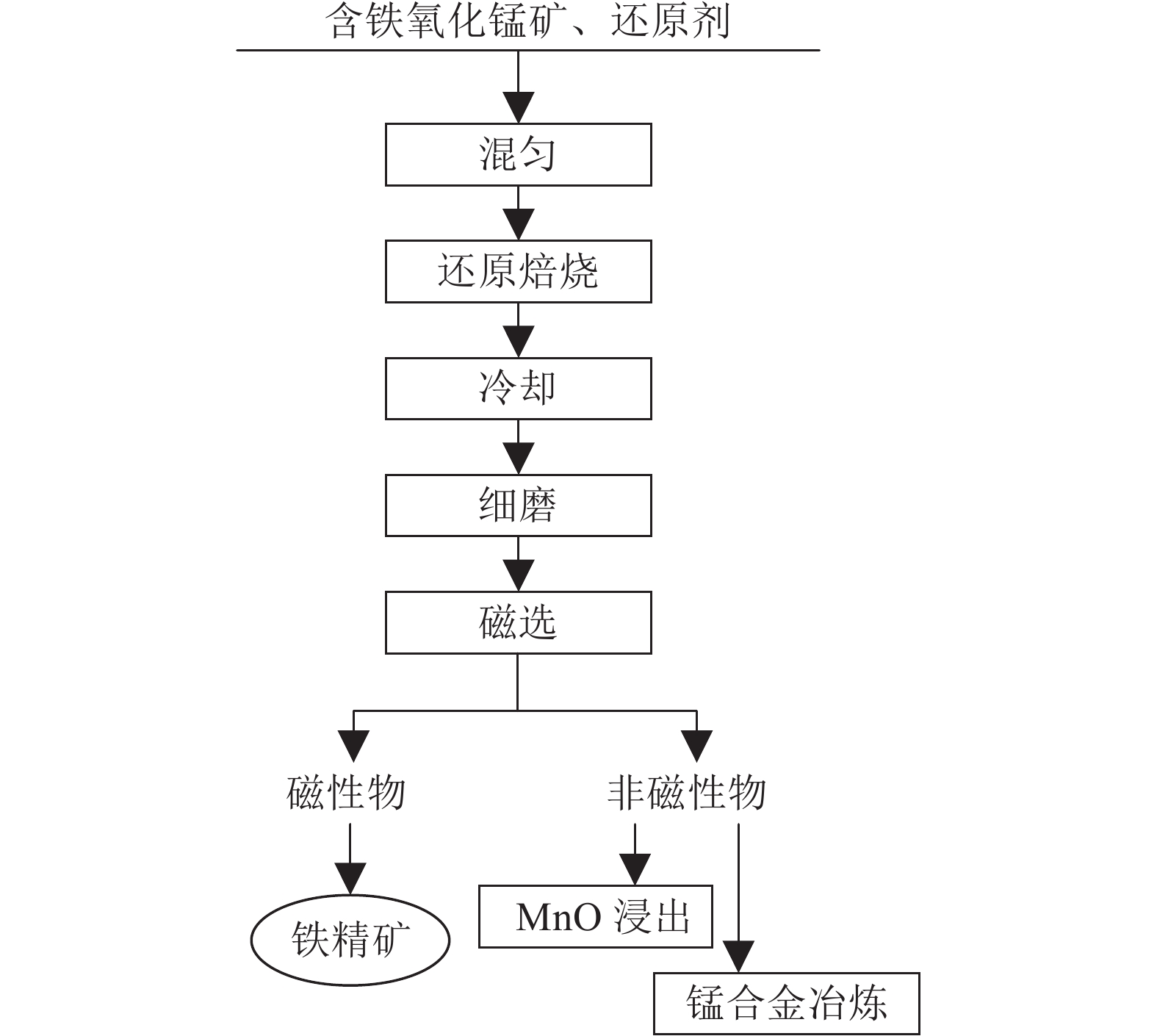

锰被广泛应用于钢铁、化工、有色冶金、电池等领域。我国氧化锰矿大多数为高铁低锰的贫矿,冶炼前大多需要选矿预处理。常用工艺有高炉冶炼法、还原焙烧—浸出法、直接还原—浸出法。其中,还原焙烧—浸出工艺可以实现铁锰矿物的选择性分离,综合资源利用率高,但焙烧过程的能耗很大。对铁锰矿物同步还原反应热力学条件与动力学过程进行研究,明确氧化铁矿物磁化还原与氧化锰预还原交互作用及同步还原规律、氧化锰和氧化铁矿矿相转变和晶型转变规律、还原过程中粘结物的矿物组成和粘结方式,为实现铁矿物和锰矿物低温还原,节约能源消耗提供理论依据。

Abstract:Manganese is widely used in steel, chemical, non-ferrous metallurgy, batteries and other fields. Most of the manganese oxide ore in China are lean ore with high iron and low manganese, and most of them need beneficiation pretreatment before smelting. Commonly used processes include blast furnace smelting method, reduction roasting-leaching method, and direct reduction-leaching method. Among them, the reduction roasting-leaching process can realize the selective separation of iron and manganese minerals, and the comprehensive resource utilization rate is high, but the energy consumption of the roasting process is large. The thermodynamic conditions and kinetics of the simultaneous reduction of iron and manganese minerals must be studied, and the interaction between the magnetization reduction of iron oxide minerals and the pre-reduction of manganese oxide and the law of simultaneous reduction, the phase transformation and crystal form transformation of manganese oxide and iron oxide ore must be clarified, the mineral composition and bonding method of the bond during the reduction process. Provide a theoretical basis for realizing the low-temperature reduction of iron minerals and manganese minerals and saving energy consumption.

-

Key words:

- Manganese oxide ore /

- Iron minerals /

- Simultaneous reduction /

- Manganese monoxide /

- Magnetite

-

-

表 1 不同氧化锰矿还原—浸出实验

Table 1. Reduction-leaching test of different manganese oxide ore

还原剂 矿种 反应条件 锰浸出率 SO2 软锰矿 硫酸浓度0.46 mol/L,浸出时间80 min,液固体积质量比4∶1,温度40 ℃,搅拌速度300 r/min ,循环浸出5次,SO2流量0.2 L/min ≥95% 硫酸亚铁 软锰矿 硫酸浓度43.10 g/L,硫酸亚铁与软锰矿的质量比1∶1.95,反应温度90 ℃,反应时间

2 h,搅拌转速400 r/min,硫酸铵加入量6.0 g≥95% 2,3,4,5,6-

五羟基己醛软锰矿 硫酸用量45 mL、反应温度95 ℃、2,3,4,5,6-五羟基己醛用量20 g,反应时间6 h 97% 稻草 软锰矿 30 g粒径为100 μm的稻草,在363 K下,用1.4 mol/L的硫酸浸出50 g,反应时间5 h 90.74% 铁屑 硬锰矿和软锰矿 -0.074 mm 80%,铁矿比1∶13,酸矿比0.6∶1,液固比3∶1,室温下浸出60 min ≥97.60% -

[1] Veerendra Singh, Tarun Chakraborty, Sunil K Tripathy. A review of low grade manganese ore upgradation processes[J]. Mineral Processing and Extractive Metallurgy Review, 2019.

[2] 洪世琨. 我国锰矿资源开采现状与可持续发展的研究[J]. 中国锰业, 2011, 29(3):13-16. HONG S K. Status of China Mn-ore in resources exploitation and the sustainable development[J]. China's Manganese Industry, 2011, 29(3):13-16. doi: 10.3969/j.issn.1002-4336.2011.03.004

[3] 张风平, 徐本军. 我国氧化锰矿石选矿工艺研究现状[J]. 湿法冶金, 2014, 33(2):79-81. ZHANG F P, XU B J. Research status of beneficiation of manganese oxide ores[J]. Hydrometallurgy of China, 2014, 33(2):79-81. doi: 10.13355/j.cnki.sfyj.2014.02.01

[4] 李勇, 罗星, 夏瑜. 广西某氧化锰矿选矿试验研究[J]. 矿产综合利用, 2020(5):64-68. LI Y, LUO X, XIA Y. Experimental research on mineral processing of a manganese oxide ore in Guangxi[J]. Multipurpose Utilization of Mineral Resources, 2020(5):64-68.

[5] Zhou F, Chen T, Yan C, et al. The flotation of low-grade manganese ore using a novel linoleate hydroxamic acid[J]. Colloids & Surfaces A Physicochemical & Engineering Aspects, 2015, 466:1-9.

[6] 武芳芳, 钟宏, 王帅. 氧化锰矿还原工艺技术研究进展[J]. 应用化工, 2012, 41(8):1443-1447. WU F F, ZHONG H, WANG S. Research progress of manganese oxide ores reduction process[J]. Applied Chemical Industry, 2012, 41(8):1443-1447. doi: 10.3969/j.issn.1671-3206.2012.08.038

[7] 李同庆. 低品位软锰矿还原工艺技术与研究进展[J]. 中国锰业, 2008, 26(2):4-17. LI T Q. Technology of low grade pyrolusite ore reduction process and recent advances[J]. China's Manganese Industry, 2008, 26(2):4-17. doi: 10.3969/j.issn.1002-4336.2008.02.002

[8] Zhuo Cheng, Guocai Zhu, Yuna Zhao. Study in reduction-roast leaching manganese from low-grade manganese dioxide ores using cornstalk as reductant[J]. Hydrometallurgy. 2009, (96): 176–179.

[9] Xike Tian, Xiaoxia Wen, Chao Yang, et al. Reductive leaching of manganese from low-grade manganese dioxide ores using corncob as reductant in sulfuric acid solution[J]. Hydrometallurgy. 2010, (100): 157-160.

[10] 贺周初, 彭爱国, 郑贤福, 等. 两矿法浸出低品位氧化锰矿的工艺研究[J]. 中国锰业, 2004, 22(2):62-64. HE Z C, PENG A G, ZHENG X F, et al. Study on technology of low grade manganese oxide ore by two ore method[J]. China's Manganese Industry, 2004, 22(2):62-64.

[11] 卢宗柳, 都安治. 两矿法浸出氧化锰矿的几个工艺问题[J]. 中国锰业, 2006, 24(1):39-42. LU Z L, DU A Z. Some technical problems on soaking methods of MnO ore[J]. China's Manganese Industry, 2006, 24(1):39-42. doi: 10.3969/j.issn.1002-4336.2006.01.011

[12] 袁明亮, 庄剑鸣. 用硫酸亚铁渣直接浸出低品位软锰矿[J]. 矿产综合利用, 1994(6):6-9. YUAN M L, ZHUANG J M. Direct leaching of low-grade pyrolusite with ferrous sulfate slag[J]. Multipurpose Utilization of Mineral Resources, 1994(6):6-9.

[13] 张田, 王海峰, 王家伟, 等. 软锰矿有机还原制备硫酸锰的实验[J]. 矿产综合利用, 2018(3):77-80. ZHANG T, WANG H F, WANG J W, et al. Experiment of preparation of manganese sulfate by organic reduction using pyrolusite[J]. Multipurpose Utilization of Mineral Resources, 2018(3):77-80. doi: 10.3969/j.issn.1000-6532.2018.03.0016

[14] 王恒峰, 刘林. 难选氧化锰矿石制取硫酸锰工艺试验研究[J]. 现代矿业, 2009, 477(1):43-46. WANG H F, LIU L. Experimental study on preparation of manganese sulfate from refractory manganese oxide ores[J]. Modern Mining, 2009, 477(1):43-46. doi: 10.3969/j.issn.1674-6082.2009.01.013

[15] 白玉兴, 张振伟, 姜润田, 等. 中贫品位软锰矿直接还原为硫酸锰工艺研究[J]. 无机盐工业, 2001(06):6-7. BAI Y X, ZHANG Z W, JIANG R T, et al. Study on the preparation of manganese sulfate by direct reduction from medium and low grade pyrolusites[J]. Inorganic Chemicals Industry, 2001(06):6-7. doi: 10.3969/j.issn.1006-4990.2001.06.002

[16] 李春, 何良惠, 李升章, 等. 软锰矿与黄铁矿共同焙烧制备硫酸锰的研究[J]. 化学世界, 2000(2):66-69. LI C, HE L H, LI S Z, et al. Study on preparation of manganese sulfate by roasting manganese dioxide ore and pyrite[J]. Chemical World, 2000(2):66-69. doi: 10.19500/j.cnki.0367-6358.2000.02.003

[17] 袁明亮, 邱冠周. 软锰矿直接还原浸出的研究[J]. 矿产综合利用, 2000(5):4-8. YUAN M L, QIU G Z. Direct reductive leaching of manganese dioxide ore[J]. Multipurpose Utilization of Mineral Resources, 2000(5):4-8. doi: 10.3969/j.issn.1000-6532.2000.05.002

[18] 李照刚. 亚硫酸钠还原浸出软锰矿的工艺研究[D]. 昆明: 昆明理工大学, 2017.

LI Z G. Study on reductive leaching of pyrolusite with sodium sulfite[D]. Kunming: Kunming University of science and technology, 2017.

[19] 魏汉可, 刘咏, 谭秀民, 等. 用SO2从软锰矿中还原浸出锰的试验研究[J]. 湿法冶金, 2015(6):458-460. WEI H K, LIU Y, TAN X M, et al. Research on reduction leaching of manganese from pyrolusite using SO2 in sulfuric acid medium[J]. Hydrometallurgy of China, 2015(6):458-460.

[20] 赵祝鹏, 罗洪涛, 陈华强, 等. 硫酸亚铁浸出软锰矿及浸出液中铁离子的处理[J]. 有色金属, 2012(2):49-51. ZHAO Z P, LUO H T, CHEN H Q, et al. Ferrous sulfate leaching pyrolusite and the treatment of iron ions in the leaching solution[J]. Nonferrous Metals, 2012(2):49-51.

[21] 高昭伟, 王海峰, 王家伟, 等. 以稻草为还原剂硫酸浸出软锰矿动力学研究[J]. 矿冶工程, 2018(4):83-86. GAO Z W, WANG H F, WANG J W, et al. Kinetics of sulfuric acid leaching of pyrolusite with straw as a reducing agent[J]. Mining and Metallurgical Engineering, 2018(4):83-86. doi: 10.3969/j.issn.0253-6099.2018.04.021

[22] 张东方, 田学达, 欧阳国强, 等. 银锰矿中锰矿物的铁屑还原浸出工艺研究[J]. 中国锰业, 2007, 25(1):24-26. ZHANG D F, TIAN X D, OUYANG G Q, et al. Reducing leaching of manganese mineral in silver-manganese ore with scrap iron as reductant[J]. China's Manganese Industry, 2007, 25(1):24-26. doi: 10.3969/j.issn.1002-4336.2007.01.007

[23] Singh V, Ghosh T K, Ramamurthy Y, et al. Beneficiation and agglomeration process to utilize low-grade ferruginous manganese ore fines[J]. International Journal of Mineral Processing, 2011, 99(1–4): 84-86.

[24] 邓益强, 乐志文. 软锰矿无煤还原制备硫酸锰新工艺研究[J]. 广西轻工业, 2007(10):38-40. DENG Y Q, YUE Z W. Study on a new process for preparation of manganese sulfate from pyrolusite by non coalreduction[J]. Light Industry Science and Technology, 2007(10):38-40. doi: 10.3969/j.issn.1003-2673.2007.10.020

[25] 卢国贤, 袁爱群, 周泽广, 等. 2种回转窑工艺还原低品位软锰矿的效果评价[J]. 中国锰业, 2014, 32(3):25-29. LU G X, YUAN A Q, ZHOU Z G, et al. Effect of products from two rotary kiln processes on reduction of low grade pyrolusite ore[J]. China's Manganese Industry, 2014, 32(3):25-29. doi: 10.3969/j.issn.1002-4336.2014.03.008

[26] 郭伟, 杨亚森, 吕慧峰, 等. 某难选贫锰铁矿的选矿试验研究[J]. 现代冶金, 2013, 41(3):22-27. GUO W, YANG Y S, LV H F, et al. Experimental study on beneficiation of a refractory low manganese iron ore[J]. Modern Metallurgy, 2013, 41(3):22-27.

[27] 刘红召, 王威, 王守敬, 等. 含锰褐铁矿焙烧——磁选工艺中锰的行为研究[J]. 矿产保护与利用, 2017(3):75-79. LIU H Z, WANG W, WANG S J, et al. Behaviors of manganese in roasting-magnetic separation process for manganese bearing limonite[J]. Conservation and Utilization of Mineral Resources, 2017(3):75-79. doi: 10.13779/j.cnki.issn1001-0076.2017.03.014

[28] 邵国强, 朱庆山, 谢朝晖. 软锰矿流态化低温还原实验研究[J]. 中国锰业, 2016, 34(2):29-33. SHAO G Q, ZHU Q S, XIE Z H. Study on the fluidizing reduction of pyrolusite at low temperature[J]. China's Manganese Industry, 2016, 34(2):29-33. doi: 10.14101/j.cnki.issn.1002-4336.2016.02.008

[29] 张汉泉, 余永富, 陆小苏, 等. 软锰矿悬浮还原焙烧试验研究[J]. 矿冶工程, 2010, 30(4):40-43. ZHANG H Q, YU Y F, LU X S, et al. Study on reducing roasting of suspending manganese oxide ore[J]. Mining and Metallurgical Engineering, 2010, 30(4):40-43. doi: 10.3969/j.issn.0253-6099.2010.04.010

[30] 封志敏, 宁顺明, 佘宗华. 磁化还原焙烧工艺处理贫锰铁矿的研究[J]. 矿冶工程, 2009, 29(3):65-68. FENG Z M, NING S M, SHE Z H. Research of magnetic reduction roasting of low grade ferromanganese ore[J]. Mining and Metallurgical Engineering, 2009, 29(3):65-68. doi: 10.3969/j.issn.0253-6099.2009.03.019

[31] 唐雪峰, 李家林. 某含锰赤铁矿石焙烧—弱磁选—强磁选试验[J]. 金属矿山, 2012, 41(8):52-55. TANG X F, LI J L. Experiment of roasting-low intensity magnetic separation-high intensity magnetic separation technology of a manganese-bearing hematite ore[J]. Metal Mine, 2012, 41(8):52-55. doi: 10.3969/j.issn.1001-1250.2012.08.014

[32] 朱宾, 陆智, 刘子帅. 广西某低品位难选锰矿选矿试验研究[J]. 矿山机械, 2015, 43(10):101-105. ZHU B, LU Z, LIU Z S. Test study on beneficiation of a low-grade refractory manganese ore from Guangxi[J]. Mining & Processing Equipment, 2015, 43(10):101-105. doi: 10.16816/j.cnki.ksjx.2015.10.024

[33] Veerendra Singh, Arijit Biswas. Physicochemical processing of low grade ferruginous manganese ores[J]. International Journal of Mineral Processing, 2017(158):35-44.

[34] Yubo GAO, Hang Goo KIM, Hong, et al. Gaseous pre-reduction for the magnetic beneficiation of ferruginous low-grade Mn ore[J]. ISIJ International, 2012, 52(5):59-763.

[35] Yubo Gao, M Olivas-Martinez, H. Y. Sohn, et al. Upgrading of low-grade manganese ore by selective reduction of iron oxide and magnetic[J]. Separation. Metallurgical and Materials Transactions B, 2012, 43B(12):1465-1475.

[36] Makhula Mpho, Bada Samson, Afolabi Ayo. Evaluation of reduction roasting and magnetic separation for upgrading Mn/Fe ratio of fine ferromanganese[J]. International Journal of Mining Science and Technology, 2003, 23(4):537-541.

[37] G V Rao, B C Acharya, B V R Murty, et al. Removal of phosphorus and enrichment of manganese from a complex ferruginous manganese ore[J]. Magnetic and Electrical Separation, 1998, 9(1):109-123.

[38] Pereira M J, Lima M M F, Lima R M F. Calcination and characterisation studies of a Brazilian manganese ore tailing[J]. International Journal of Mineral Processing, 2014, 131:26-30. doi: 10.1016/j.minpro.2014.08.003

[39] 冯雅丽, 张士元, 李浩然, 等. 生物质焦焙烧还原低品位软锰矿及其动力学[J]. 东北大学学报(自然科学版), 2015, 36(10):1482-1486. FENG Y L, ZHANG S Y, LI H R, et al. Roasting reduction and its kinetics of low-grade pyrolusite by biomass char[J]. Journal of Northeastern University (Natural Science), 2015, 36(10):1482-1486. doi: 10.3969/j.issn.1005-3026.2015.10.025

[40] N. J. Welham. Activation of the carbothermic reaction of manganese ore[J]. International Journal of Mineral Processing, 2002, 67:187-198. doi: 10.1016/S0301-7516(02)00045-5

[41] A. A. El-Geassy, M. I. Nasr, M. A. Yousef, et al. Behaviour of manganese oxides during magnetising reduction of Baharia iron ore by CO–CO2 gas mixture[J]. Ironmaking and Steelmaking, 2000, 27(2):116-122.

[42] Y. V. 斯瓦达, B. 布霍伊, S 普拉卡什, 等. 使用固体还原剂提高含铁低品位锰矿石的锰铁比[J]. 国外选矿快报, 1999(8):1-3. Y V Swada, B Bukhoi, S Prakash, et al. Using solid reducing agent to increase the ratio of Mn to Fe in low grade manganese ore containing iron[J]. Express Information of Mineral Processing Abroad, 1999(8):1-3.

[43] R H Eric, E Burucu. The mechanism and kinetics of the carbothermic reduction of mamatwan manganese ore fines[J]. Minerals Engineering, 1992, 5(7):795-815. doi: 10.1016/0892-6875(92)90247-7

[44] Yuanbo Zhang, Minghui Du, Bingbing Liu, et al. Separation and recovery of iron and manganese from high-iron manganese oxide ores by reduction roasting and magnetic separation technique[J]. Separation Science and Technology, 2017, 52(7):1321-1332. doi: 10.1080/01496395.2017.1284864

[45] Bingbing Liu, Yuanbo Zhang, Jia Wang, et al. A further investigation on the MnO2-Fe2O3 system roasted under CO-CO2 atmosphere[J]. Advanced Powder Technology, 2019(30):302-310.

[46] K S Abdel Halim, M Bahgat, M B Morsi, et al. Pre-reduction of manganese ores for ferromanganese industry[J]. Ironmaking and Steelmaking, 2011, 38(4):278-283.

[47] T Sharma. Physico-chemical processing of low grade manganese ore[J]. International Journal of Mineral Processing, 1992(35):191-203.

[48] 王海川, 周云, 吴宝国, 等. 微波辅助加热氧化锰矿还原动力学研究[J]. 中国稀土学报, 2004, 22(Album):212-215. WANG H C, ZHOU Y, WU B G, et al. Study on reduction kinetics of manganese oxide ore by microwave assisted heating[J]. Chinese Journal of rare earth, 2004, 22(Album):212-215.

-

下载:

下载: