Influence of the Amount of Activated Gold Tailings on the Mechanical Properties and Microstructural Properties of Concrete

-

摘要:

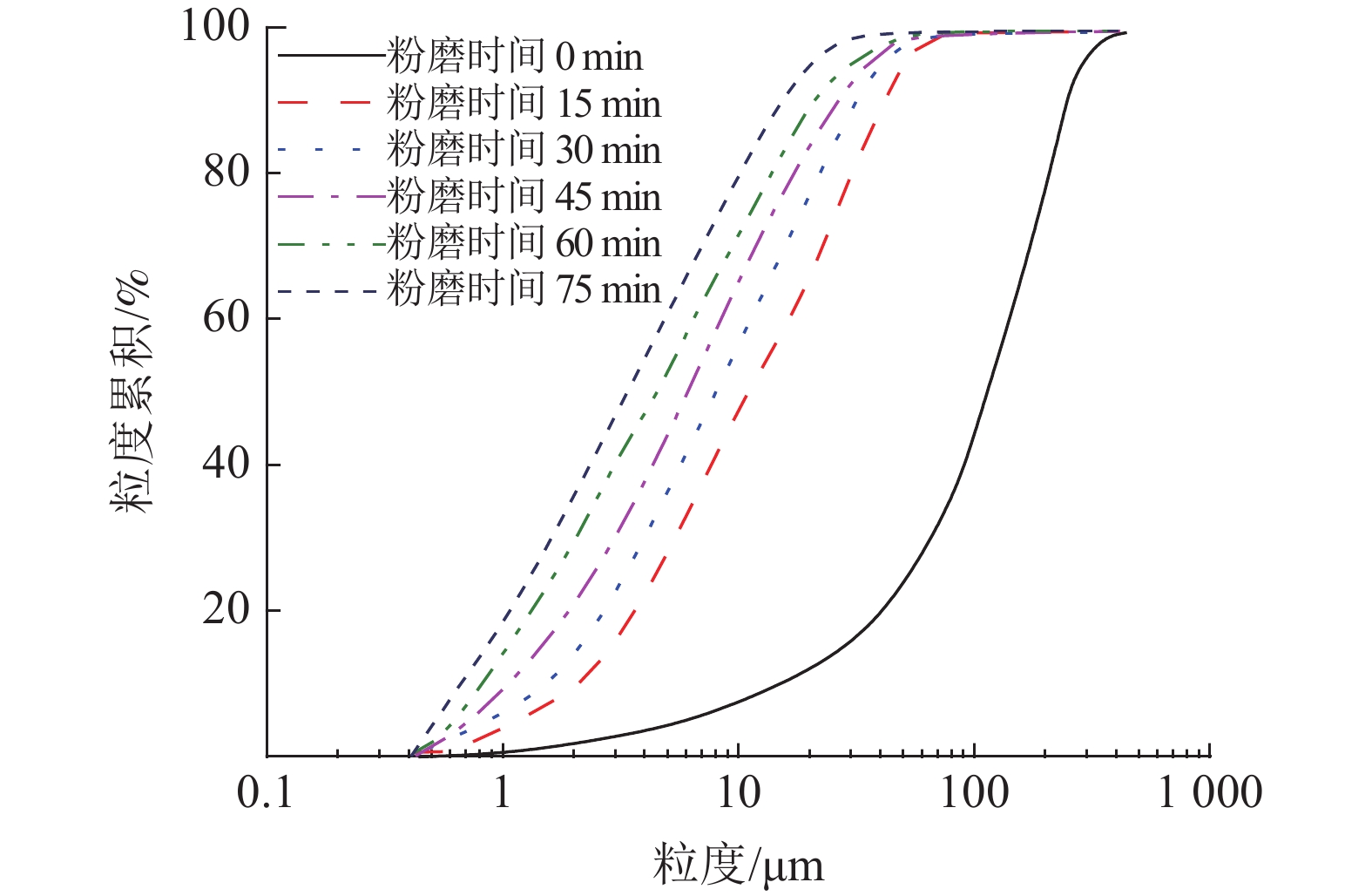

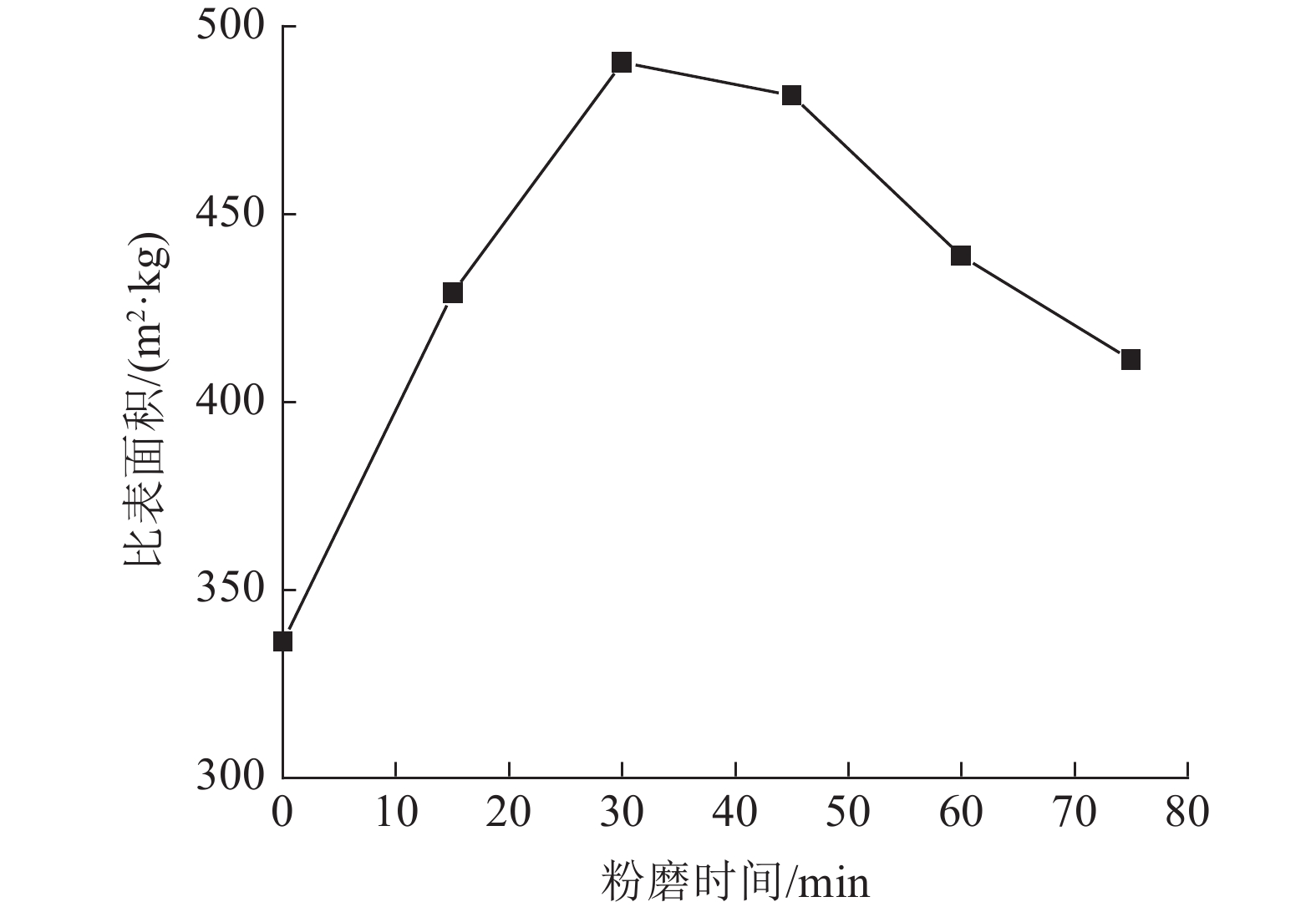

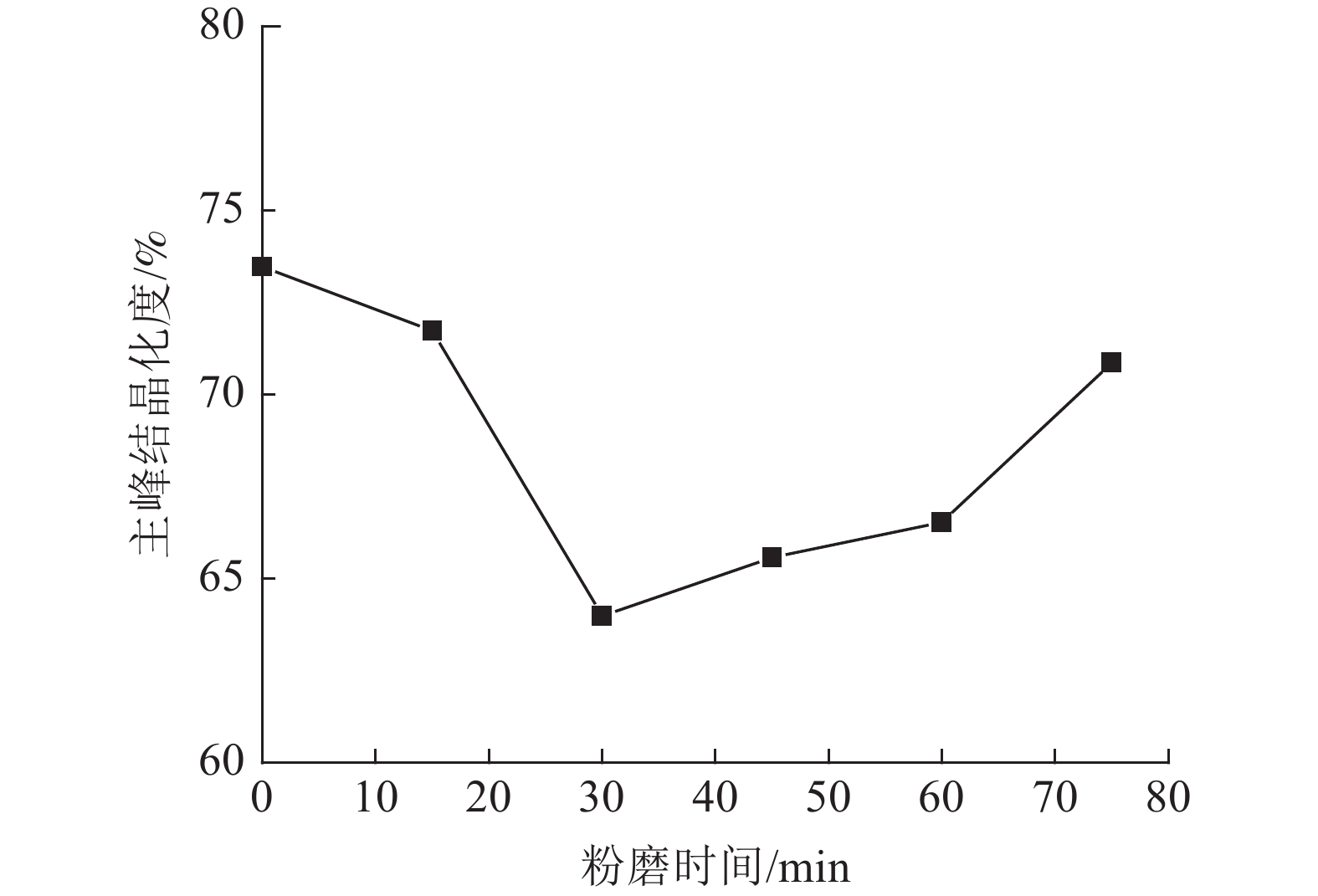

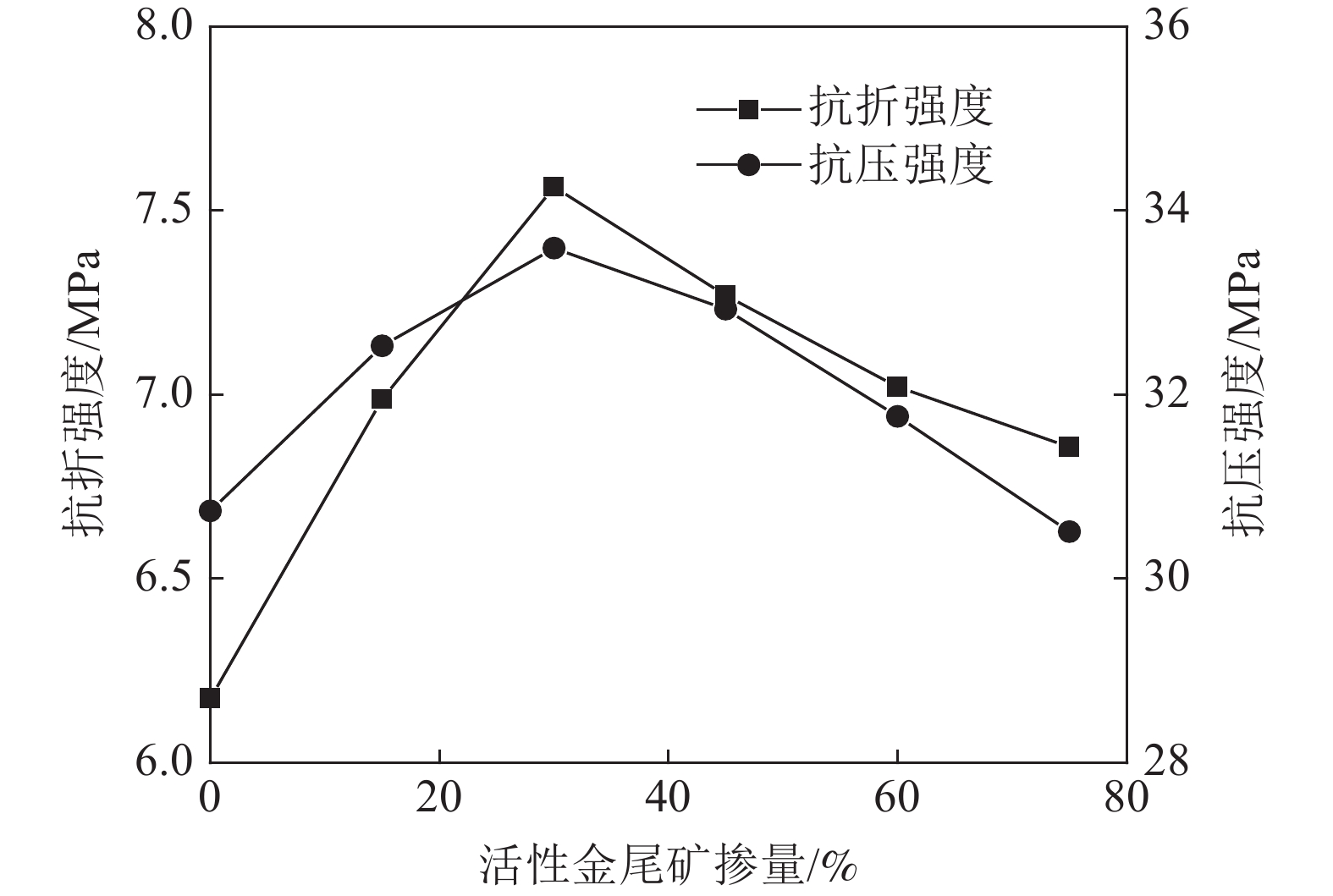

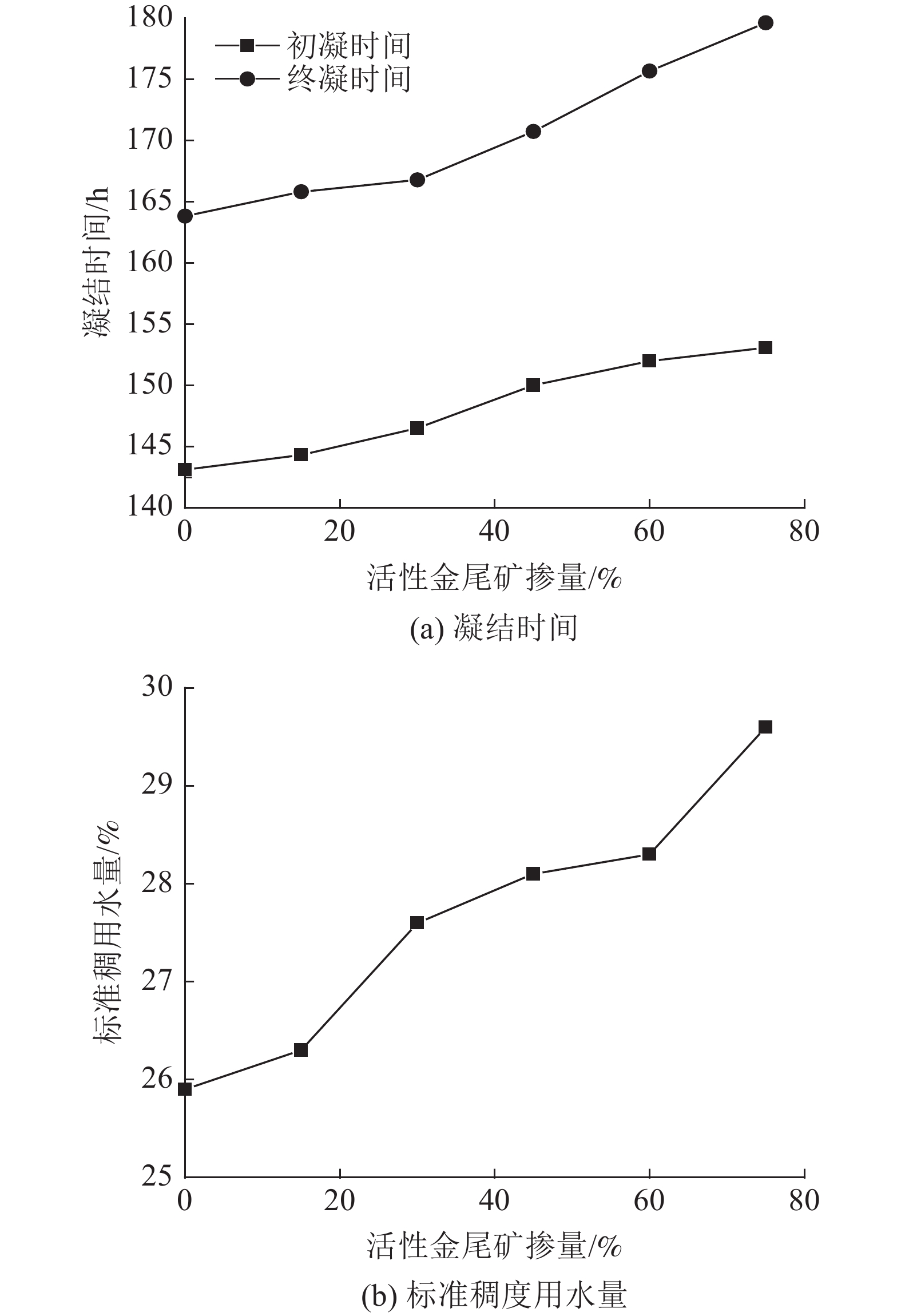

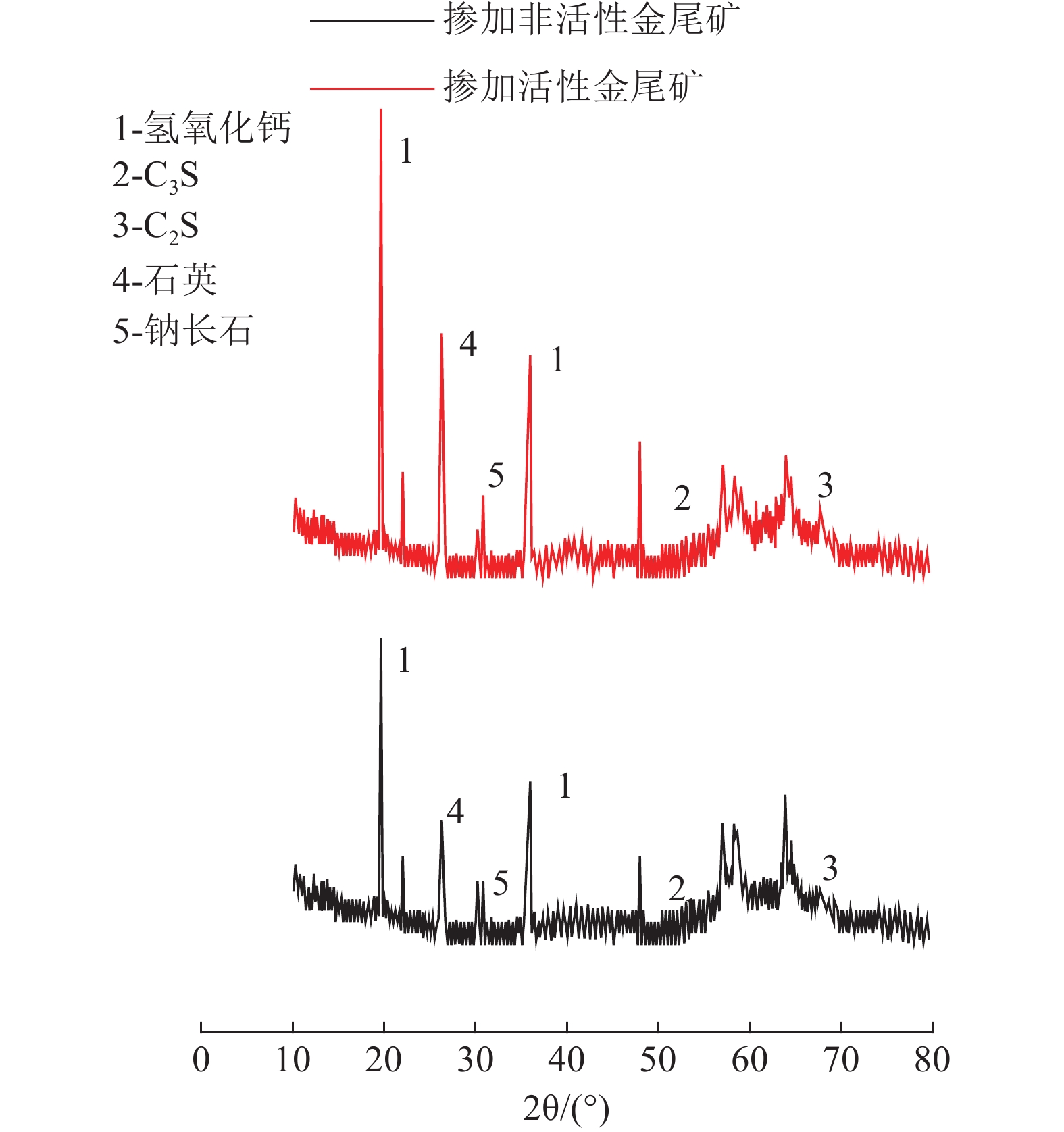

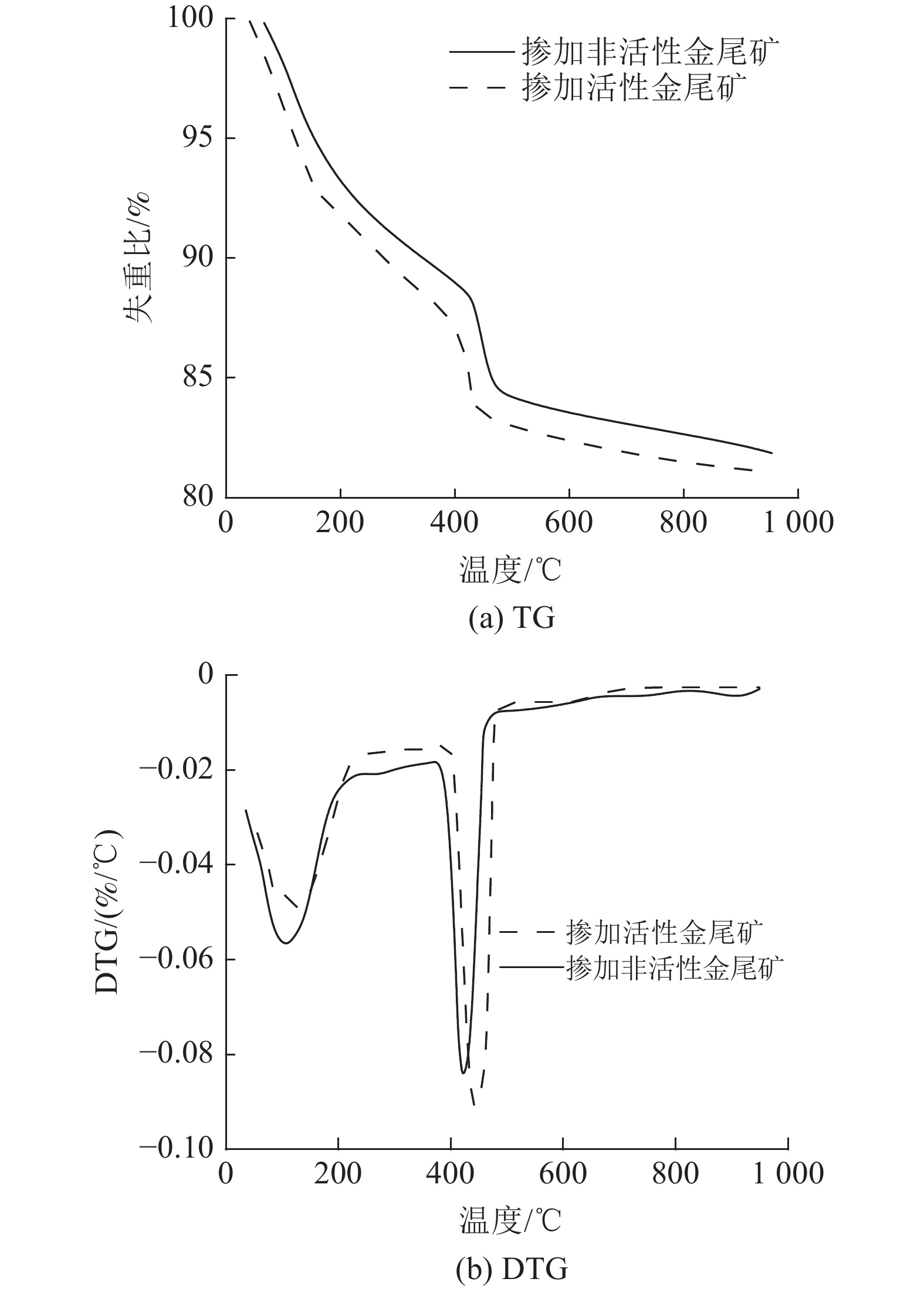

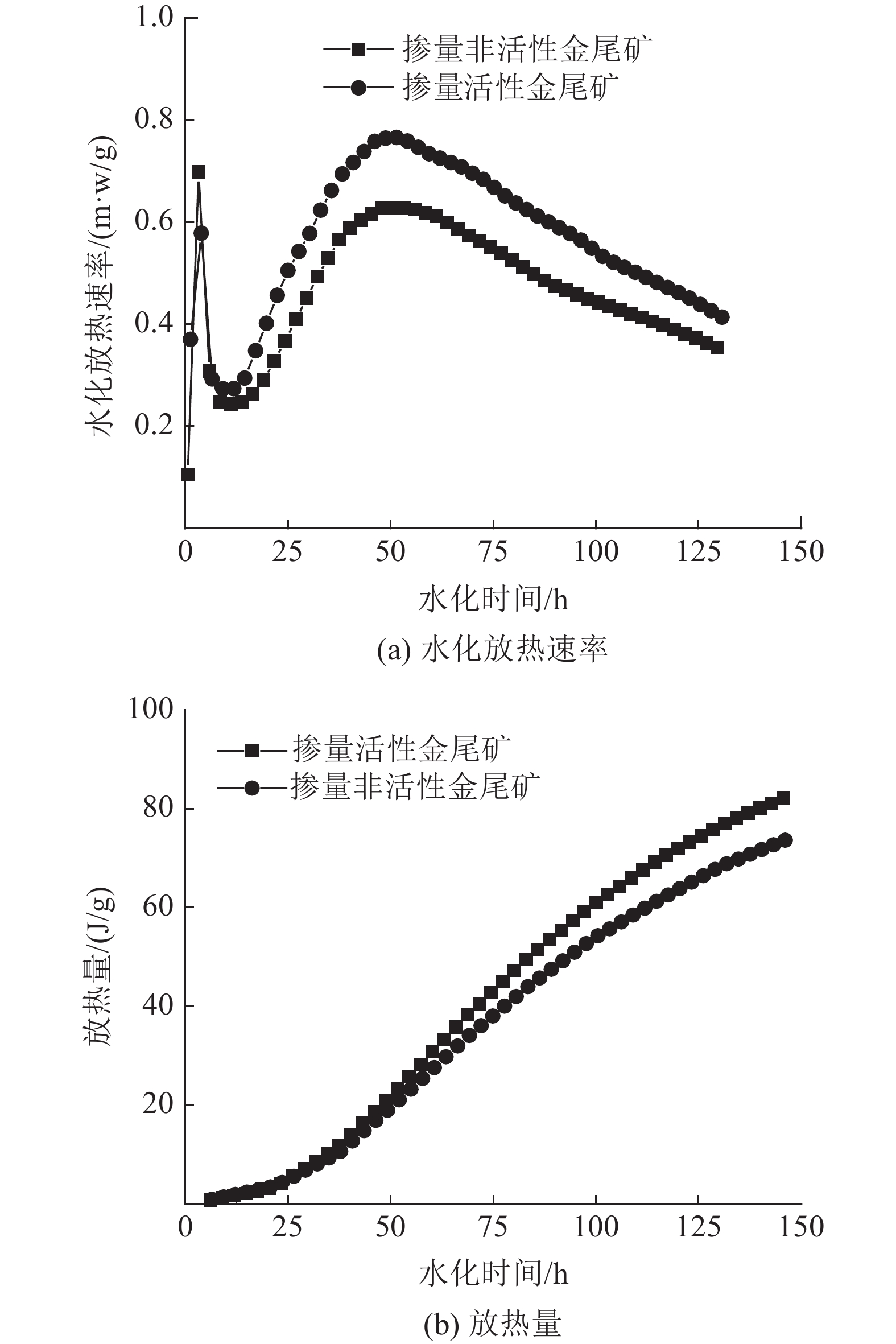

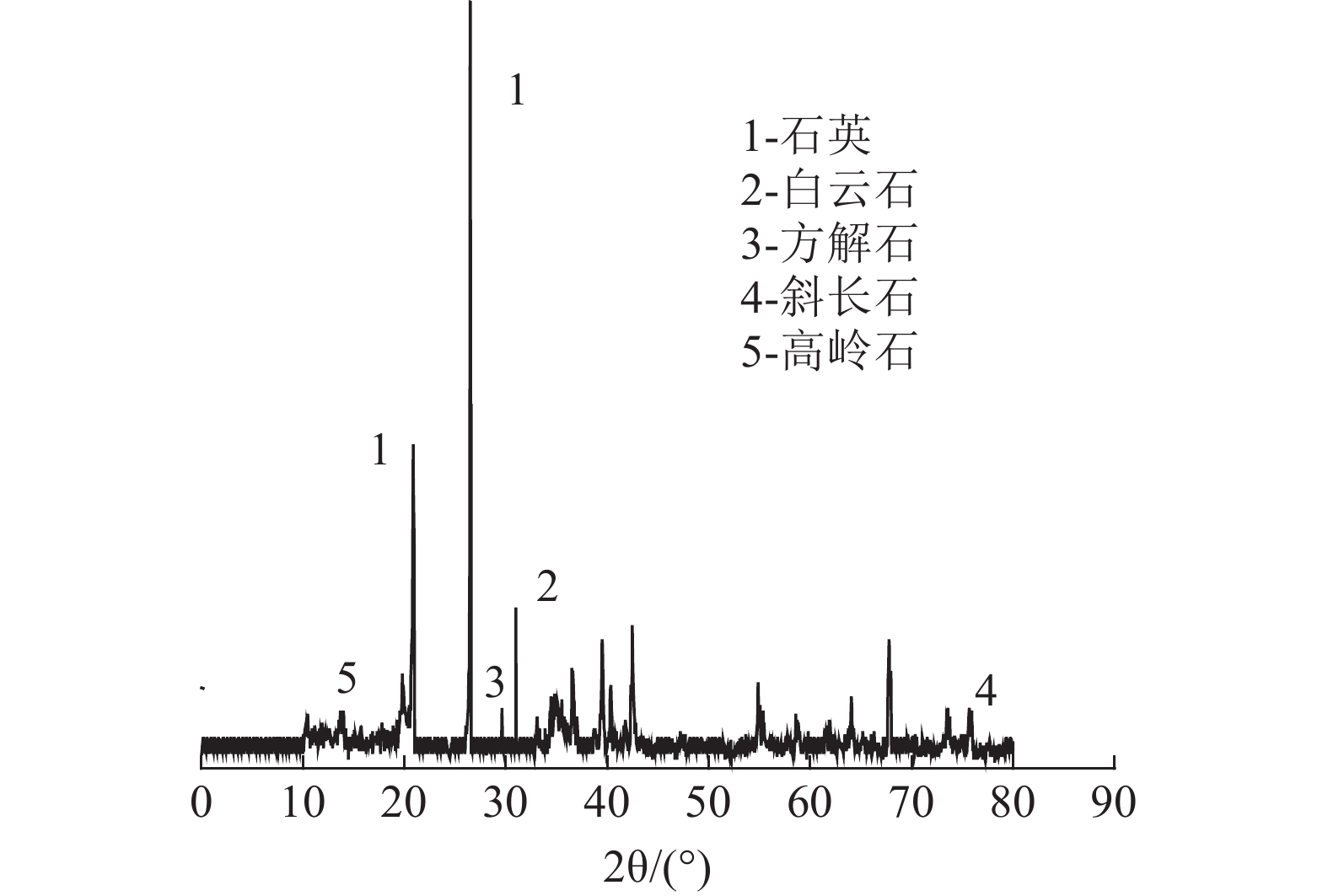

这是一篇陶瓷及复合材料领域的论文。为了研究活性金尾矿掺量对混凝土力学性能、微观结构性能和水化性能的影响,开展了不同掺量金尾矿混凝土的力学性能、XRD、TG-DTG和水化特性实验。结果表明:在粉磨时间为30 min时,金尾矿的比表面积达到了极大值以及其晶体结晶化度达到了极小值。而在金尾矿掺量为30%时,混凝土的基本力学和物理性能达到较佳状态;且掺入活性金尾矿混凝土的微观结构性能、水化放热速率和放热量均优于掺入非活性金尾矿混凝土的微观结构性能、水化放热速率和放热量。随着金尾矿粉磨时间的不断增大,金尾矿粒度累积曲线的变化规律都呈现先增大后趋于稳定的趋势,且随着粉磨时间的不断增大,金尾矿粒度累积越来越大。

Abstract:This is an essay in the field of ceramics and composites. In order to study the effect of activated gold tailings content on the mechanical properties, microstructural properties and hydration properties of concrete, the mechanical properties, XRD, TG-DTG and hydration characteristics tests of different content of gold tailings concrete were carried out. The results showed that when the grinding time was 30 min, the specific surface area of the gold tailings reached the maximum and the crystallinity reached the minimum. When the content of gold tailings was 30%, the basic mechanical and physical properties of concrete reached the best state. In addition, the microstructure performance, hydration heat release rate and heat release of concrete mixed with active gold tailings are better than those of concrete mixed with inactive gold tailings. With the continuous increase of the grinding time of gold tailings, Changing law of the cumulative curve of gold tailings particle size showed a trend of first increasing and then becoming stable. And with the continuous increase of grinding time, the accumulation of gold tailings particle size was getting larger and larger.

-

-

表 1 原料主要化学成分/%

Table 1. Main chemical composition of the materials

Al2O3 SiO2 Fe2O3 MgO Na2O CaO K2O 其他氧化物 12.36 74.18 2.98 0.41 2.57 1.21 4.63 1.66 表 2 粉煤灰的主要化学成分/%

Table 2. Main chemical composition of the fly ash

Al2O3 SiO2 Fe2O3 MgO Na2O CaO K2O S 其他氧化物 38.47 56.32 1.63 0.78 0.22 1.35 0.12 0.24 0.60 -

[1] 徐风广, 杨凤玲, 李红伟, 等. 低活性钢渣在地面用水泥基自流平砂浆中的应用研究[J]. 矿产综合利用, 2019(6):85-88. XU F G, YANG F L, LI H W, et al. Research on application of cement-based self-leveling floor mortar using low active steel slag[J]. Multipurpose Utilization of Mineral Resources, 2019(6):85-88. doi: 10.3969/j.issn.1000-6532.2019.06.019

XU F G, YANG F L, LI H W, et al. Research on application of cement-based self-leveling floor mortar using low active steel slag[J]. Multipurpose Utilization of Mineral Resources, 2019(6): 85-88. doi: 10.3969/j.issn.1000-6532.2019.06.019

[2] 庞华果, 向晓东, 江新卫, 等. 以钢渣水洗尘泥为原料制取泡沫混凝土砌块实验研究[J]. 矿产综合利用, 2018(4):87-90. PANG H G, XIANG X D, JIANG X W, et al. Experimental research on preparation of foam concrete block with steel-slag sludge as material[J]. Multipurpose Utilization of Mineral Resources, 2018(4):87-90. doi: 10.3969/j.issn.1000-6532.2018.04.020

PANG H G , XIANG X D, JIANG X W, et al. Experimental research on preparation of foam concrete block with steel-slag sludge as material[J]. Multipurpose Utilization of Mineral Resources, 2018(4): 87-90. doi: 10.3969/j.issn.1000-6532.2018.04.020

[3] 刘俊杰, 梁钰, 曾宇, 等. 利用铁尾矿制备免烧砖的研究[J]. 矿产综合利用, 2020(5):136-141. LIU J J, LIANG Y, ZENG Y, et al. Preparation of baking-free bricks by iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

LIU J J, LIANG Y, ZENG Y, et al. Preparation of baking-free bricks by iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(5): 136-141. . doi: 10.3969/j.issn.1000-6532.2020.05.021

[4] 唐加俊, 邹春霞, 薛慧君, 等. 双掺合料模袋混凝土的孔隙特征研究[J]. 硅酸盐通报, 2019, 38(7):2274-2280. TANG J J, ZOU C X, XUE H J, et al. Study on pore evolution characteristics of double-doped molded bag concrete[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7):2274-2280. doi: 10.16552/j.cnki.issn1001-1625.2019.07.046

TANG J J, ZOU C X, XUE H J, et al. Study on pore evolution characteristics of double-doped molded bag concrete[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7): 2274-2280. doi: 10.16552/j.cnki.issn1001-1625.2019.07.046

[5] 马伟丽. 纤维混凝土损伤后渗透特性试验研究[D]. 西安: 西安理工大学, 2020.

MA W L. Experimental study on permeability characteristics of fiber reinforced concrete after damage[D]. Xi’an: Xi’an University of Technology, 2020.

[6] 胡耀文, 李镜培, 谢峰. 再生混凝土抗渗性能试验研究[J]. 结构工程师, 2020, 36(3):160-166. HU Y W, LI J P, XIE F. Experimental research on impermeability of recycled concrete[J]. Structural Engineers, 2020, 36(3):160-166. doi: 10.3969/j.issn.1005-0159.2020.03.021

HU Y W, LI J P, XIE F. Experimental research on impermeability of recycled concrete[J]. Structural Engineers, 2020, 36(3): 160-166. doi: 10.3969/j.issn.1005-0159.2020.03.021

[7] 何锐, 王铜, 陈华鑫, 等. 青藏高原气候环境对混凝土强度和影响[J]. 中国公路学报, 2020, 33(7):29-41. HE R, WANG T, CHEN H X, et al. Impact of the Qinghai-Tibet Plateau’s climate and environment on the strength and influence of concrete[J]. China Journal of Highway and Transport, 2020, 33(7):29-41. doi: 10.3969/j.issn.1001-7372.2020.07.003

HE R, WANG T, CHEN H X, et al. Impact of the Qinghai-Tibet Plateau’s climate and environment on the strength and influence of concrete[J]. China Journal of Highway and Transport, 2020, 33(7): 29-41. doi: 10.3969/j.issn.1001-7372.2020.07.003

[8] 欧阳志鹏, 孙彬, 王霓, 等. 装配式结构混凝土结合面抗渗性能试验研究[J]. 建筑结构, 2020, 50(9):21-25+31. OUYANG Z P, SUN B, WANG N, et al. Experimental study on impermeability performance of concrete interface in prefabricated structures[J]. Building Structure, 2020, 50(9):21-25+31. doi: 10.19701/j.jzjg.2020.09.005

OUYANG Z P, SUN B, WANG N, et al. Experimental study on impermeability performance of concrete interface in prefabricated structures[J]. Building Structure, 2020, 50(9): 21-25+31. doi: 10.19701/j.jzjg.2020.09.005

[9] 肖莉娜. 机械-化学耦合活化对铜尾矿火山灰活性的影响[J]. 硅酸盐通报, 2020, 39(11):3595-3600. XIAO L N. Effect of mechanical-chemical coupling activation on pozzolanic activity of copper tailings[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(11):3595-3600. doi: 10.16552/j.cnki.issn1001-1625.2020.11.027

XIAO L N. Effect of mechanical-chemical coupling activation on pozzolanic activity of copper tailings[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(11): 3595-3600. doi: 10.16552/j.cnki.issn1001-1625.2020.11.027

[10] 刘海军, 赵丽丽. 钒钛磁铁矿尾矿的活化及用作水泥混合材的试验研究[J]. 钢铁钒钛, 2020, 41(4):97-102. LIU H J, ZHAO L L. Activation of vanadium-titanium magnetite tailing and its application as cement admixture[J]. Iron Steel Vanadium Titanium, 2020, 41(4):97-102. doi: 10.7513/j.issn.1004-7638.2020.04.018

LIU H J, ZHAO L L. Activation of vanadium-titanium magnetite tailing and its application as cement admixture[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 97-102. doi: 10.7513/j.issn.1004-7638.2020.04.018

[11] 刘璇, 李如燕, 崔孝炜, 等. 机械力对高硅金尾矿粒度及活性的影响[J]. 中国粉体技术, 2019, 25(2):42-46. LIU X, LI R Y, CUI X W, er al. Effect of mechanical force on particle size and activity of high silicon gold tailings[J]. China Powder Science and Technology, 2019, 25(2):42-46. doi: 10.13732/j.issn.1008-5548.2019.02.008

LIU X, LI R Y, CUI X W, er al. Effect of mechanical force on particle size and activity of high silicon gold tailings [J]. China Powder Science and Technology, 2019, 25(2): 42-46. doi: 10.13732/j.issn.1008-5548.2019.02.008

[12] 王志强, 吕宪俊, 褚会超, 等. 尾矿的火山灰活性及其在水泥混合材料中的应用[J]. 硅酸盐通报, 2017, 36(1):97-103. WANG Z Q, LYU X J, CHU H C, et al. Pozzolanic reactivity and applications of tailings in cement admixture[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(1):97-103. doi: 10.16552/j.cnki.issn1001-1625.2017.01.016

WANG Z Q, LV X J, CHU H C, et al. Pozzolanic reactivity and applications of tailings in cement admixture[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(1): 97-103. doi: 10.16552/j.cnki.issn1001-1625.2017.01.016

[13] 金珊珊, 林睿颖, 郑桂萍, 等. 低硅灰水泥砂浆孔隙结构及分形维数的演变特征[J]. 混凝土, 2021(4):109-112. JIN S S, LIN R Y, ZHENG G P, et al. Evolution of pore structure and fractal dimension of silica fume cement mortar[J]. Concrete, 2021(4):109-112.

JIN S S, LIN R Y, ZHENG G P, et al. Evolution of pore structure and fractal dimension of silica fume cement mortar[J]. Concrete, 2021(4): 109-112.

[14] 王方刚, 梁权刚, 陆加越, 等. 不同缓凝剂对水泥超长缓凝作用与水化特性的影响[J]. 硅酸盐通报, 2020, 39(7):2065-2072. WANG F G, LIANG Q G, LU J Y, et al. Effect of different retarders on the super retarding action and hydration characteristics of cement[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(7):2065-2072. doi: 10.16552/j.cnki.issn1001-1625.2020.07.006

WANG F G, LIANG Q G, LU J Y , et al. Effect of different retarders on the super retarding action and hydration characteristics of cement[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(7): 2065-2072. doi: 10.16552/j.cnki.issn1001-1625.2020.07.006

[15] 胡立志, 代飞, 李伟青, 等. 搅拌站废浆对水泥水化的影响[J]. 矿产综合利用, 2019(5):102-106. HU L Z, DAI F, LI W Q, et al. Study on effect of the slurry of concrete mmixing plant upon cement hydration[J]. Multipurpose Utilization of Mineral Resources, 2019(5):102-106. doi: 10.3969/j.issn.1000-6532.2019.05.022

HU L Z, DAI F, LI W Q, et al. Study on effect of the slurry of concrete mmixing plant upon cement hydration[J]. Multipurpose Utilization of Mineral Resources, 2019(5): 102-106. doi: 10.3969/j.issn.1000-6532.2019.05.022

[16] 王顺祥, 吴其胜, 诸华军, 等. 富硅镁镍渣粉磨细度和掺量对硅酸盐水泥水化特性的影响[J]. 材料科学与工程学报, 2018, 36(2):229-235. WANG S X, WU Q S, ZHU H J, et al. Influence of grinding fineness and content of silica-mg-ni slag on the hydration characteristics of portland cement[J]. Journal of Materials Science and Engineering, 2018, 36(2):229-235. doi: 10.14136/j.cnki.issn1673-2812.2018.02.011

WANG S X, WU Q S, ZHU H J, et al. Influence of grinding fineness and content of silica-mg-ni slag on the hydration characteristics of portland cement[J]. Journal of Materials Science and Engineering, 2018, 36(2): 229-235. doi: 10.14136/j.cnki.issn1673-2812.2018.02.011

-

下载:

下载: