New Analysis Method for Gold Occurrence in Carlin-type Gold Ore

-

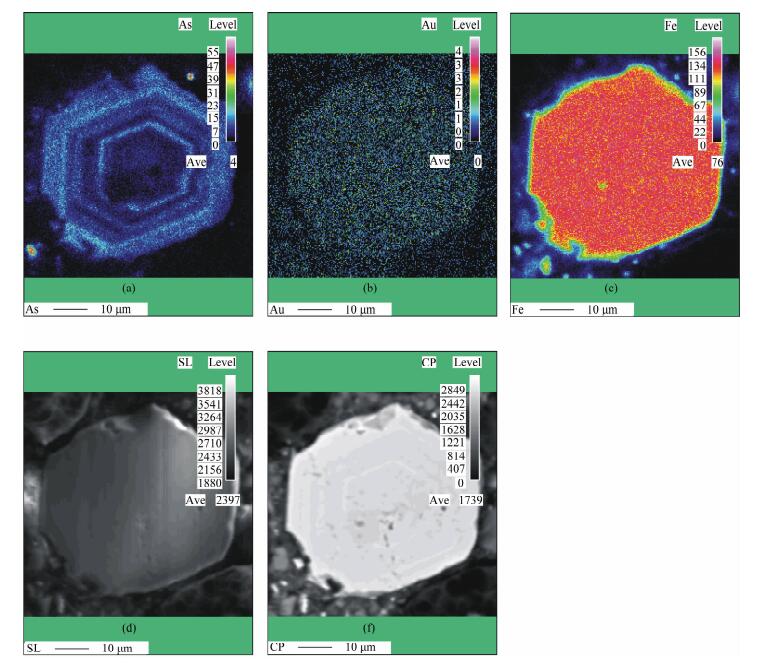

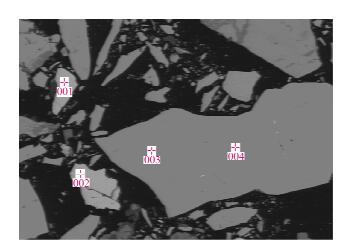

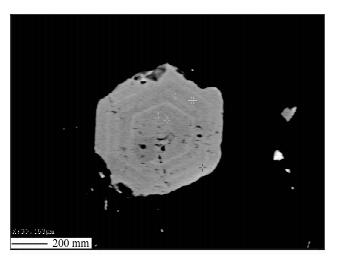

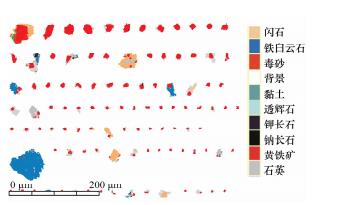

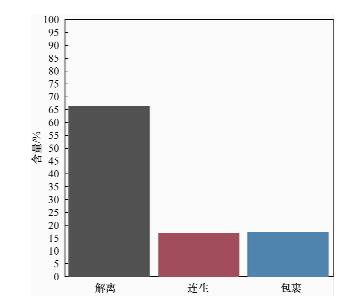

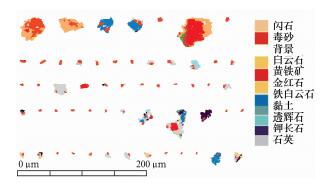

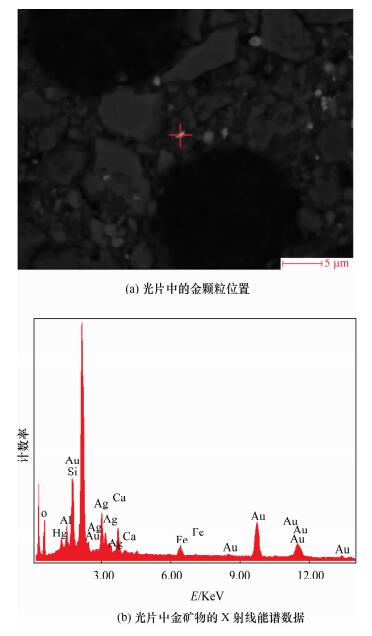

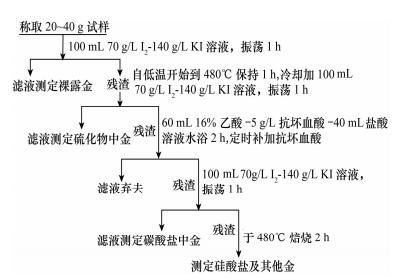

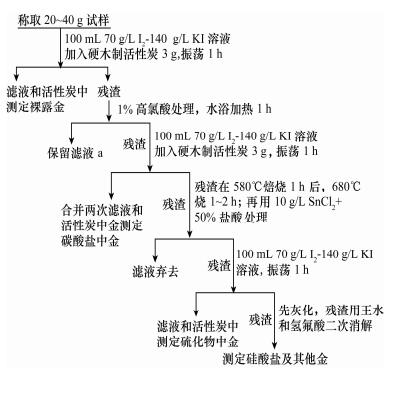

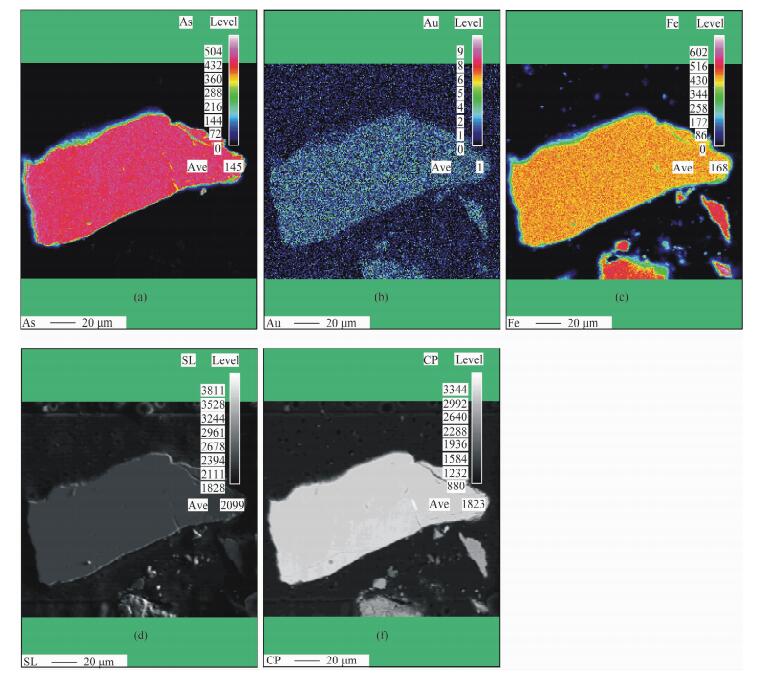

摘要: 卡林型金矿富含有机质,金主要呈显微-超显微分散状态存在,利用工艺矿物学参数自动检测分析仪(MLA)及传统化学方法只能大致判断矿石中金的赋存趋势,无法对其赋存状态准确定量。本文利用MLA仪器系统分析贵州回龙卡林型金矿,测得矿石中金主要以显微-超显微状态包裹于黄铁矿和毒砂中,少量被脉石等其他矿石包裹;黄铁矿约66%完全解离,而毒砂仅30%完全解离,载金矿物与其他矿物连生或者被包裹,将不利于硫化物包裹金的浸出。结合回龙金矿石中金的赋存特征和富含有机质的特点,对传统的物相分析流程进行改进,调整了硫化物包裹金和碳酸盐包裹金的浸出顺序,提出裸露金—碳酸盐包裹金—硫化物包裹金—硅酸盐包裹金的浸出流程,在裸露金及碳酸盐包裹金浸出时加入活性炭,利用竞争吸附抑制矿石中有机炭对金的吸附,降低有机炭对分相的影响。对比试验结果表明,采用改进的方法,有机炭含量在1%左右的金矿石分相时加入活性炭对各相测定值的影响不大;先浸出碳酸盐包裹金,再测定硫化物包裹金,各相的测定数据更加准确。改进的方法(加活性炭)用于测定回龙金矿中裸露金和碳酸盐、硫化物、硅酸盐包裹金,含量分别为1.25%、84.17%、11.46%和3.13%,与选矿试验结果相一致,表明该法适合应用于卡林型金矿中金的赋存状态分析。Abstract: Gold exists in the form of micro-super micro dispersed states in Carlin-type gold ores, which is in the form of rich organic matter. The gold occurrence state cannot be analyzed accurately or at best, can be roughly estimated by using the Mineral Liberation Analyzer (MLA) and the traditional chemistry method. In this study, carlin-type gold ore in Guizhou Huilong was analyzed systematically using MLA, and the results show that micro-super micro gold was mainly embedded in pyrite and arsenopyrite, and less was embedded in gangue minerals and other minerals. The separation degree of pyrite and arsenopyrite were 66% and 30% in minerals, respectively. As gold-bearing minerals are attached or embedded in other minerals, the separation of gold-bearing sulfides (GBS) is more difficult. The leaching orders regarding free gold (FG), gold-bearing carbonates (GBC), gold-bearing sulfides (GBS) and silicates (GBSi) were sequenced on the basis of the tradition method, gold occurrence state and high content of organic matter characteristics of Guizhou Huilong gold ore. Furthermore, according to the high content of organic matter in this deposit, the activated carbon was added in the process of leaching FG and GBC to restrain the adsorption to gold by organic carbon. The comparative studies between traditional methods (TM) and modified methods (MM) show that there is only a small effect on the detected value after adding activated carbon into the gold ores which contain about 1% of organic carbon. In MM, gold-bearing carbonates were leached prior to gold-bearing sulfides; results of every phase data were more accurate than those of TM. Along with the addition of activated carbon in MM, the contents of FG, GBS, GBC, GBSi in Guizhou Huilong gold ore were 1.25%, 84.17%, 11.46% and 3.13%, respectively, which was consistent with the results of processing experiments. This indicates that MM can be applied to analyze precisely the occurrence states of gold in carlin-type gold ores.

-

Key words:

- Carlin-type gold ore /

- iodine-potassium iodine /

- phase analysis /

- activated carbon

-

-

表 1 回龙金矿X射线荧光光谱分析数据

Table 1. Chemical composition of Huilong gold ore by XRF

组分 wB/% SiO2 42.88 TiO2 1.11 Al2O3 11.53 Fe2O3 10.08 MnO 0.30 CaO 13.44 MgO 4.28 Na2O 0.063 K2O 1.54 P2O5 0.34 SO2 4.15 As 1.26 Sr 0.050 Ba 0.044 Zr 0.017 Cr 0.012 Zn 0.011 Rb 0.0057 Y 0.0035 表 2 回龙金矿原矿多元素化学分析数据

Table 2. Analytical results of major and minor elements in Huilong gold ore

组分 wB/% Au 0.48×10-3 As 1.12 SiO2 40.84 MgO 5.38 有机炭 0.86 TCO2 24.13 Al2O3 6.15 TSO2 7.28 TFe 6.88 CaO 11.92 表 3 矿石的主要矿物组成及含量

Table 3. Analytical results of mineral constituents and mineral content in Huilong ore

矿物 wB/% 金 <0.005 黄铁矿 4.4906 毒砂 1.0363 磁黄铁矿 0.1669 黄铜矿 0.0099 方铅矿 0.0182 脉石矿物(主要为石英、

水云母、白云石、木炭碎屑)94.1542 合计 100 表 4 原矿样品中毒砂和黄铁矿的电子探针分析结果

Table 4. Analytical results of arsenopyrite and pyrite in raw ore by electron microprobe

样品编号 wB/% As S Au Fe 001(毒砂) 42.82 22.13 0.14 36.12 002(毒砂) 44.57 21.09 0.12 35.78 003(黄铁矿) 0 52.80 0.04 47.17 004(黄铁矿) 0 52.94 0.07 46.18 表 5 原矿样品中黄铁矿的电子探针分析结果

Table 5. Analytical results of pyrite in raw ore by electron microprobe

测试位置 wB/% As S Au Fe 中心 1.956 51.539 0.021 46.427 中心 2.369 51.027 0.030 45.815 中部 4.119 49.158 0 45.648 中部 2.694 50.548 0.043 45.713 中部 3.183 50.203 0.053 45.500 边缘 2.069 51.021 0 46.122 表 6 传统的碘-碘化钾物相分析流程测定的数据

Table 6. Analytical results of traditional process chart with iodine-potassium iodide

物相 金含量w(Au)/(g·t-1) 分配率/% 未加活性炭 加活性炭 未加活性炭 加活性炭 裸露金 <0.05 0.07 <1.05 1.46 碳酸盐包裹金 0.92 0.93 19.41 19.42 硫化物包裹金 3.38 3.36 71.31 70.15 硅酸盐包裹金 0.42 0.43 8.86 8.98 金各相合量 4.77 4.79 100.00 100.00 总金 4.81 4.81 - - 注:由于仪器精度问题,数据前有“<”符合表示预估值,包括仪器波动的影响;总金含量是按照国家标准方法GB/T 20899.1—2007进行分析测定。 表 7 改进的碘-碘化钾物相分析流程测定的数据

Table 7. Analytical results of improved process chart with iodine-potassium iodide

物相 金含量w(Au)/(g·t-1) 分配率/% 未加活性炭 加活性炭 未加活性炭 加活性炭 裸露金 <0.04 <0.06 <0.84 <1.25 碳酸盐包裹金 0.49 0.55 10.23 11.46 硫化物包裹金 4.11 4.04 85.80 84.17 硅酸盐包裹金 0.15 0.15 3.13 3.13 金各相合量 4.79 4.80 100.00 100.00 总金 4.81 4.81 -

[1] 岩石矿物分析编委会.岩石矿物分析(第四版 第三分册)[M].北京:地质出版社,2011: 651-655.

[2] 丁秘枣,牛洪联.金化学物相分析现状及浅析[J].内蒙古石油化工,2010(4): 19-20. http://www.cnki.com.cn/Article/CJFDTOTAL-NMSH201004007.htm

[3] 王峰,郭茂生,王凯,周红,叶青,余侃萍.金矿石化学物相分析标准物质的研制[J].岩矿测试,2006,25(3): 263-269. http://www.cnki.com.cn/Article/CJFDTOTAL-YKCS200603014.htm

[4] Coetzee L L, Theron S J, Martin G J, Merwe J D, Stanek T A. Modern gold deportments and its application to industry [J]. Minerals Engineering, 2011, 24(6): 565-575. doi: 10.1016/j.mineng.2010.09.001

[5] 陈先兵.卡林型金矿地质地球化学特征及成因综述[J].黄金地质,1996,2(2): 73-78. http://www.cnki.com.cn/Article/CJFDTOTAL-HJDZ602.014.htm

[6] Torres V M, Chaves A P, Meech J A. Process design for gold ores: A diagnostic approach [J].Minerals Engineering,1999, 12(3): 245-254. doi: 10.1016/S0892-6875(99)00002-3

[7] Gieré R, Sidenko N V, Lazareva V. The role of second-ary minerals in controlling the migration of arsenic and metals from high-sulfide wastes (Berikul gold mine, Siberia) [J].Applied Geochemistry,2003,18(9): 1347-1359. doi: 10.1016/S0883-2927(03)00055-6

[8] Goodall W R, Scales P J, Ryan C G. Applications of PIXE and diagnostic leaching in the characterisation of complex gold ores [J]. Minerals Engineering, 2005,18(10): 1010-1019. doi: 10.1016/j.mineng.2005.01.011

[9] 杨磊,杜银珠.某矿铜铅锌多金属硫化矿石中伴生金的赋存状态研究[J].矿冶,2002,7(11): 195-196. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-KYZZ200208001049.htm

[10] 郑大中,郑若峰.矿石中金的化学物相分析新方法[J].黄金,1993,14(3): 55-60. http://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ199303016.htm

[11] 徐长跃,邹海峰,田莉玉.高砷高硫金矿石中金的相态分析方法[J].世界地质,2003,22(2): 205-207. http://www.cnki.com.cn/Article/CJFDTOTAL-SJDZ200302019.htm

[12] Steger H F. Chemical phase-analysis of ores and rocks: A review of methods[J].Talanta,1976,23(2): 81-87. doi: 10.1016/0039-9140(76)80028-8

[13] Steger H F, Desjardins L E. Oxidation of sulphide minerals.Ⅲ. Determination of sulphate and thiosul-phate in oxidised sulphide minerals [J].Talanta,1977,24(11): 675-679. doi: 10.1016/0039-9140(77)80064-7

[14] 卢宜源,宾万达.贵金属冶金学[M].长沙:中南大学出版社,2011: 15-155.

[15] Saba M, Yousefi A M, Rashchi F, Moghaddam J.Diagnostic pre-treatment procedure for simultaneous cyanide leaching of gold and silver from a refractory gold/silver ore [J]. Minerals Engineering,2011,24(15): 1703-1709. doi: 10.1016/j.mineng.2011.09.013

[16] 郑大中,郑若峰.矿石中金的化学物相分析新方法[J].黄金,1993,14(3): 55-60. http://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ199303016.htm

[17] 唐肖玫,姚敬劬.化学物相分析方法研究矿石中金的赋存状态[J].岩矿测试,1992,11(1-2): 162-167. http://www.cnki.com.cn/Article/CJFDTOTAL-YKCS1992Z1024.htm

[18] Goodall W R, Scales P J, Butcher A R. The use of QEMSCAN and diagnostic leaching in the character-isation of visible gold in complex ores [J].Minerals Engineering, 2005, 18(8): 877-886. doi: 10.1016/j.mineng.2005.01.018

[19] Teaguea A J, Swaminathan C, van Deventeri J S J. The behavior of gold bearing minerals during froth flotation as determined by diagnostic leaching [J]. Minerals Engineering, 1998, 11(6): 523-533. doi: 10.1016/S0892-6875(98)00034-X

[20] 徐长跃,邹海峰,田莉玉.高砷高硫金矿石中金的相态分析方法[J].世界地质,2003,22(2): 205-207. http://www.cnki.com.cn/Article/CJFDTOTAL-SJDZ200302019.htm

[21] 赵德年.金矿样品加工讨论[J].岩矿测试,1993,12(1): 68-70. http://www.cnki.com.cn/Article/CJFDTOTAL-YKCS199301020.htm

[22] 韦鹏翔.浅析桂西卡林型金矿的成矿规律及矿石特征[J].中国科技博览,2011(31): 428.

[23] Lorenzen L. Some guidelines to the design of a diagnostic leaching experiment [J].Minerals Engineering, 1995, 8(3): 247-256. doi: 10.1016/0892-6875(94)00122-S

[24] Stegbr H F, Desjardins L E. Oxidation of sulfide minerals.Ⅴ. Galena, sphalerite and chalcogit [J].Canadian Mineralogist, 1980, 18: 365-372.

[25] 有色金属工业分析丛书编辑委员会.矿石和工业产品化学物相分析[M].北京:冶金工业出版社,1992: 55-60.

-

下载:

下载: